Anti-static formaldehyde-free adhesive as well as preparation method and application thereof

An aldehyde adhesive and anti-static technology, which is applied in the field of anti-static aldehyde-free adhesive and its preparation, can solve the problems of poor anti-static ability and excessive formaldehyde concentration of anti-static floor, achieve low cost and alleviate the shortage of petroleum resources , highly reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

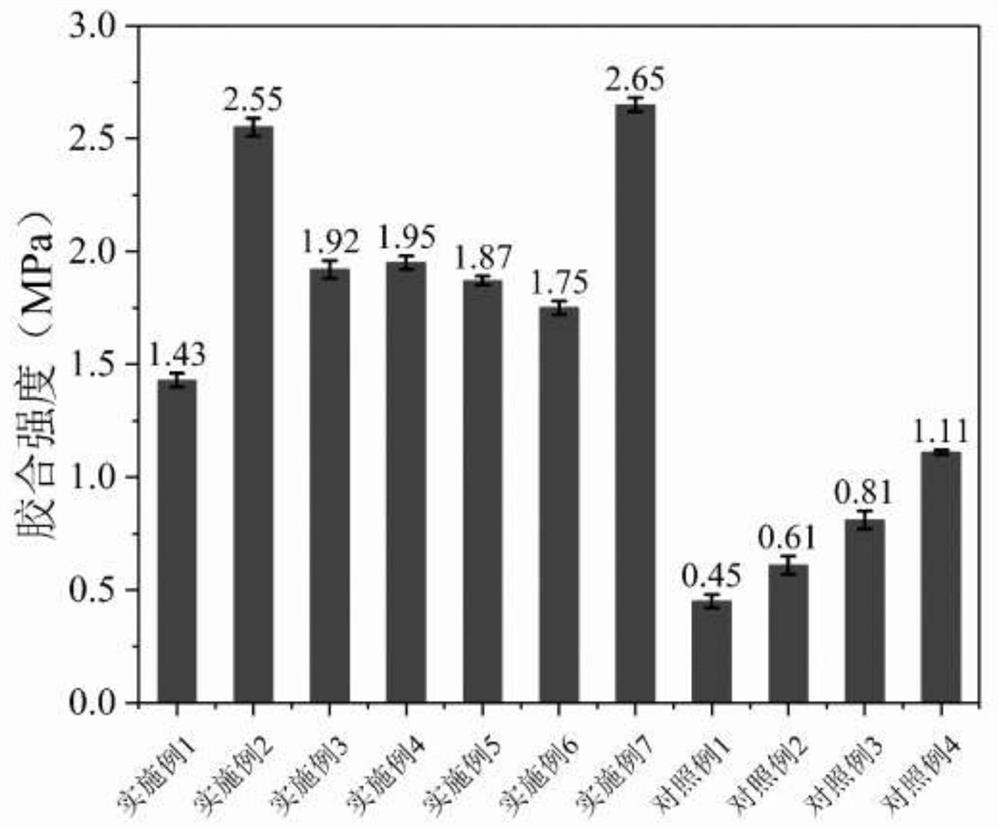

Examples

preparation example Construction

[0036] 50% barium titanate core-shell particles BaTiO 3 -The preparation method of PANI, comprises the following steps:

[0037] a Barium titanate surface modification: 10g of barium titanate nanoparticles BaTiO 3 Add to 100ml of absolute ethanol, ultrasonically disperse, add 1g of KH550 silane coupling agent, stir at 70°C, set for 0.5h, centrifuge the obtained barium titanate, wash with deionized water, and dry in an oven at 60°C for 12h , to prepare dry barium titanate nanoparticles.

[0038] b Preparation of core-shell particles: Add 100ml of HCl solution with a concentration of 1mol / L and 5g of sodium dodecylbenzenesulfonate in a three-necked flask, stir until transparent, then add the barium titanate nanoparticles prepared in step a, and Add 10g of aniline after vacuum distillation to 40g of n-hexane and mix evenly, add it into a three-necked flask, keep stirring under an ice bath at 1-5°C, after stirring evenly, add 0.5g of ammonium persulfate solution dropwise at a ra...

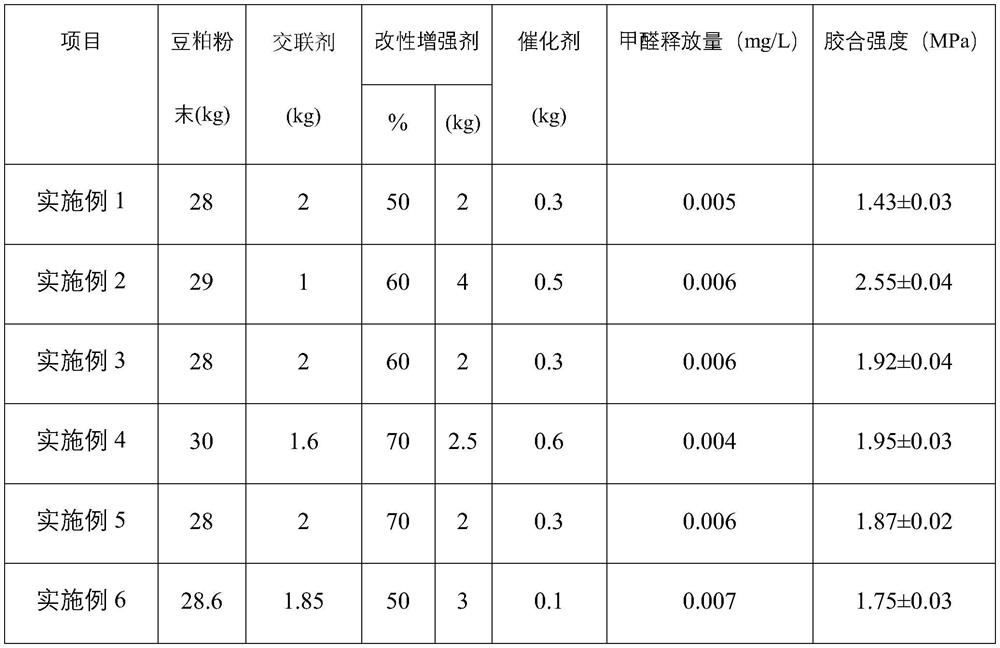

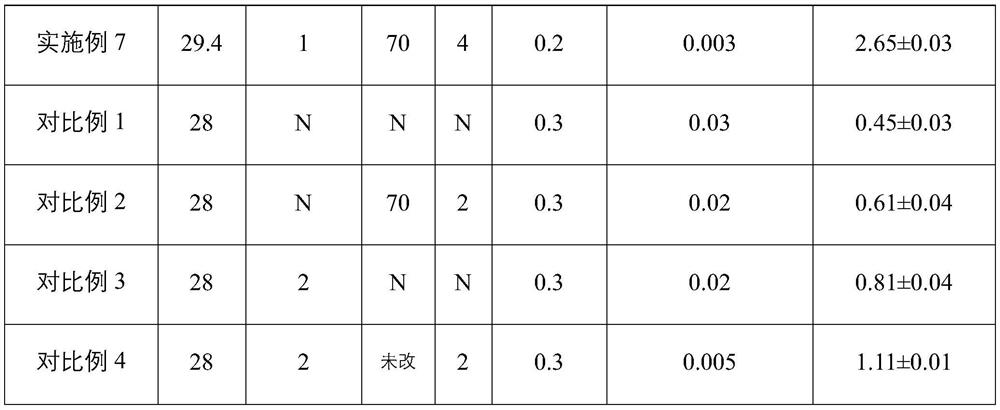

Embodiment 1

[0042] A preparation method of an antistatic formaldehyde-free adhesive, comprising the following steps:

[0043] 1) Weigh 28kg of soybean meal powder, 2kg of polyethylene glycol diglycidyl ether, and the mass percentage is 50% barium titanate core-shell particle BaTiO 3-PANI 2kg, mass percent is 0.3kg of 50% sodium hydroxide solution, dispersion medium water 70kg;

[0044] 2) The barium titanate core-shell particles BaTiO 3 -PANI was added into the dispersion medium water, and stirred for 24 hours to obtain a dispersion;

[0045] 3) Add soybean meal powder, polyethylene glycol diglycidyl ether and sodium hydroxide solution to the dispersion prepared in step 2) in sequence, stir evenly at room temperature, heat to 85°C for 30 minutes, and naturally cool down to 30°C. An antistatic and formaldehyde-free adhesive is prepared.

Embodiment 2

[0047] A preparation method of an antistatic formaldehyde-free adhesive, comprising the following steps:

[0048] 1) Weigh 29kg of soybean meal powder, 1kg of polyethylene glycol diglycidyl ether, and the mass percentage is 60% barium titanate core-shell particle BaTiO 3 -PANI 4kg, mass percent is 0.5kg of 50% sodium hydroxide solution, dispersing medium water 70kg;

[0049] 2) The barium titanate core-shell particles BaTiO 3 -PANI was added into the dispersion medium water, and stirred for 24 hours to obtain a dispersion;

[0050] 3) Add soybean meal powder, polyethylene glycol diglycidyl ether and sodium hydroxide solution to the dispersion prepared in step 2) in sequence, stir evenly at room temperature, heat to 85°C for 30 minutes, and naturally cool down to 30°C. An antistatic and formaldehyde-free adhesive is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com