Environmentally-friendly acid-and alkali-resistant wire

A technology of acid and alkali resistance and wire resistance, applied in the field of electric wire, can solve the problems of easy cracking, extremely high processing equipment and production process requirements, and difficulty in producing large-section cables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

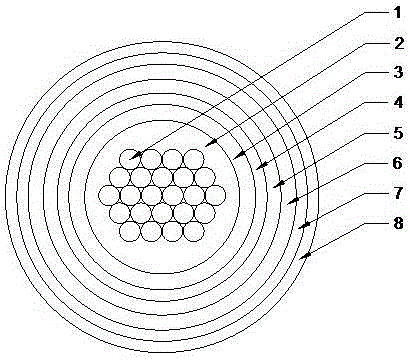

[0022] see figure 1 , in the embodiment of the present invention, a kind of environment-friendly acid-alkali-resistant electric wire, comprises seven outer protective layers and a kind of conductor, and seven outer protective layers are galvanized annealed copper tape shielding layer 2, nitrile insulating layer successively from inside to outside 3. Silver-plated copper tape armor layer 4, nickel tape shielding layer 5, aluminum tape shielding layer 6, chlorosulfonated ethylene propylene sheath layer 7 and rubber insulation layer 8, the conductor is silver-plated annealed nickel conductor 1, silver-plated annealed There are 24 nickel conductors 1, and the silver-plated annealed nickel conductors 1 are extruded and wrapped inside the galvanized annealed copper tape shielding layer 2, and a layer of nitrile insulating layer 3 is wrapped outside the galvanized annealed copper tape shielding layer 2. A layer of silver-plated copper tape armor layer 4 is wrapped outside the nitrile...

Embodiment 2

[0029] see figure 1 , in the embodiment of the present invention, a kind of environment-friendly acid-alkali-resistant electric wire, comprises seven outer protective layers and a kind of conductor, and seven outer protective layers are galvanized annealed copper tape shielding layer 2, nitrile insulating layer successively from inside to outside 3. Silver-plated copper tape armor layer 4, nickel tape shielding layer 5, aluminum tape shielding layer 6, chlorosulfonated ethylene propylene sheath layer 7 and rubber insulation layer 8, the conductor is silver-plated annealed nickel conductor 1, silver-plated annealed There are 24 nickel conductors 1, and the silver-plated annealed nickel conductors 1 are extruded and wrapped inside the galvanized annealed copper tape shielding layer 2, and a layer of nitrile insulating layer 3 is wrapped outside the galvanized annealed copper tape shielding layer 2. A layer of silver-plated copper tape armor layer 4 is wrapped outside the nitrile...

Embodiment 3

[0036] see figure 1 , in the embodiment of the present invention, a kind of environment-friendly acid-alkali-resistant electric wire, comprises seven outer protective layers and a kind of conductor, and seven outer protective layers are galvanized annealed copper tape shielding layer 2, nitrile insulating layer successively from inside to outside 3. Silver-plated copper tape armor layer 4, nickel tape shielding layer 5, aluminum tape shielding layer 6, chlorosulfonated ethylene propylene sheath layer 7 and rubber insulation layer 8, the conductor is silver-plated annealed nickel conductor 1, silver-plated annealed There are 24 nickel conductors 1, and the silver-plated annealed nickel conductors 1 are extruded and wrapped inside the galvanized annealed copper tape shielding layer 2, and a layer of nitrile insulating layer 3 is wrapped outside the galvanized annealed copper tape shielding layer 2. A layer of silver-plated copper tape armor layer 4 is wrapped outside the nitrile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com