Patents

Literature

127 results about "Polymalic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mutant aureobasidium pullulans TKPM00006 for massively producing beta-poly(malic acid) and culture method thereof

ActiveCN101979499AHigh yieldSimplify the screening processFungiMutant preparationPullulanAureobasidium

The invention provides mutant aureobasidium pullulans TKPM00006 for massively producing beta-poly(malic acid) and a method for producing poly(malic acid) by using the mutant through fermentation. The strain is the mutant for producing beta-poly(malic acid) with high yield, which is cultured by multiple groups of composite mutagenesis technology based on beta-poly(malic acid) producing TKPM10017 screened in the soil of Wang Taibao orchard, Yinchuan, Ningxia Hui Autonomous Region, China. Under the optimization condition, the yield of beta-poly(malic acid) reaches 18.4+ / -1.3g / l.

Owner:天津慧智百川生物工程有限公司

High-yield polymalic acid-producing bacterial strain, application and method thereof

ActiveCN102827778AIncrease productionLow priceFungiMicroorganism based processesBiotechnologyPullulan

The invention discloses high-yield polymalic acid-producing bacterial strain, which specifically is aureobasidium pullulans FMT1801, wherein the preservation number is CCTCC (China Center For Type Culture Collection) NO: M2012223; industrial by-product honey can be adopted as raw material; the material cost is low, and the yield of polymalic acid is high. The invention also discloses application of the bacterial strain in production of polymalic acid and a method for producing polymalic acid. The bacterial strain has the advantages of simple process, low production cost and wide application prospect.

Owner:SOUTHWEST UNIV

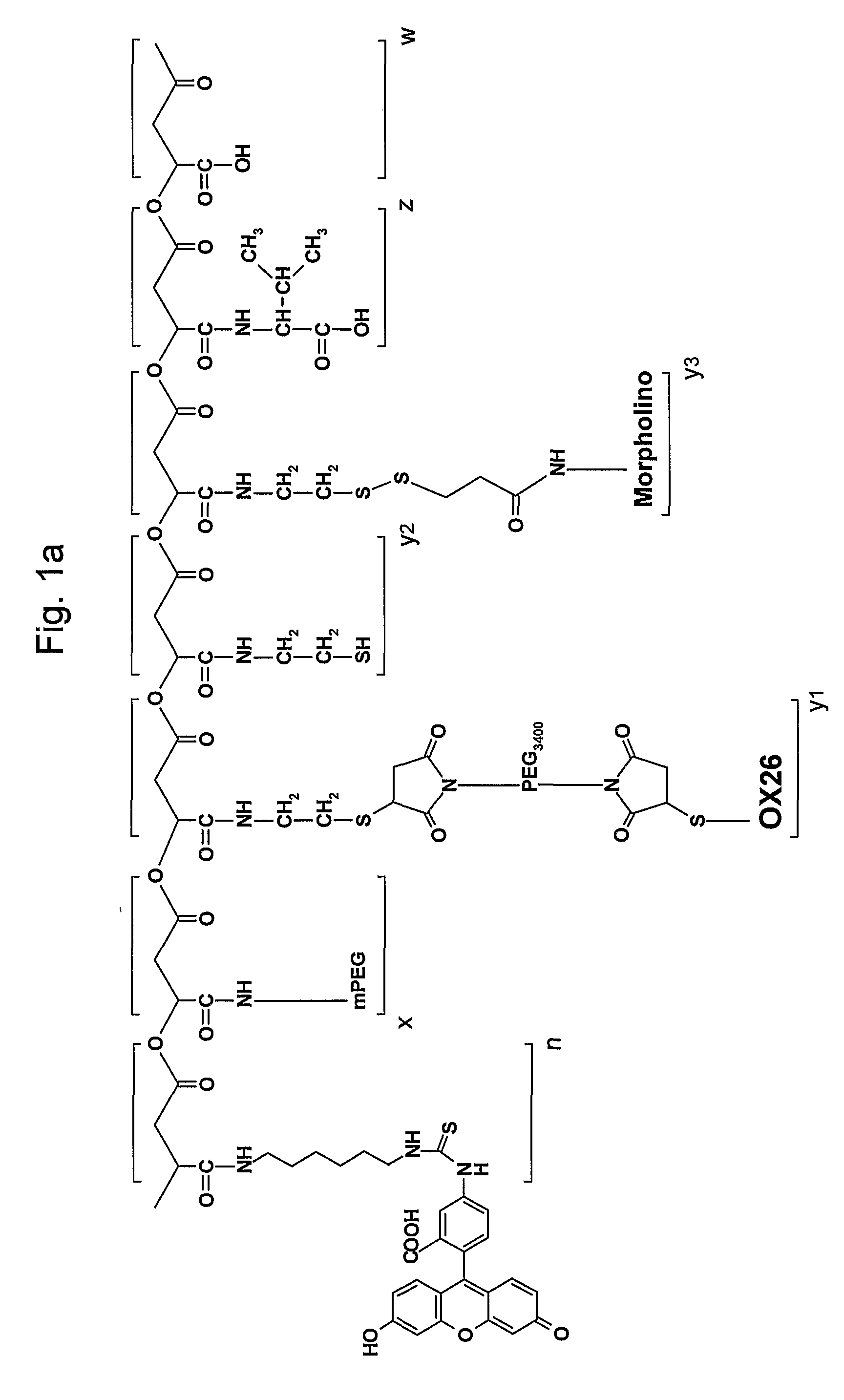

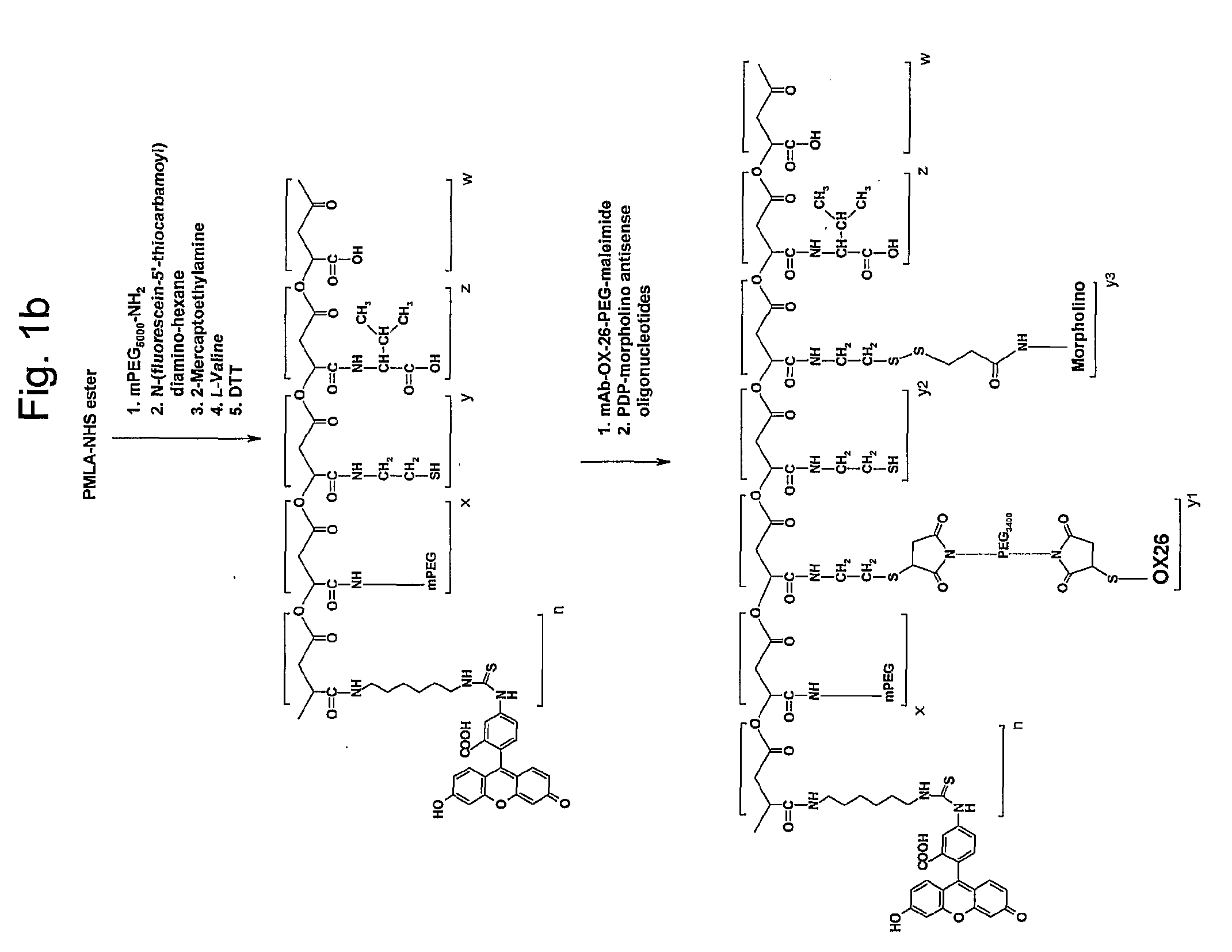

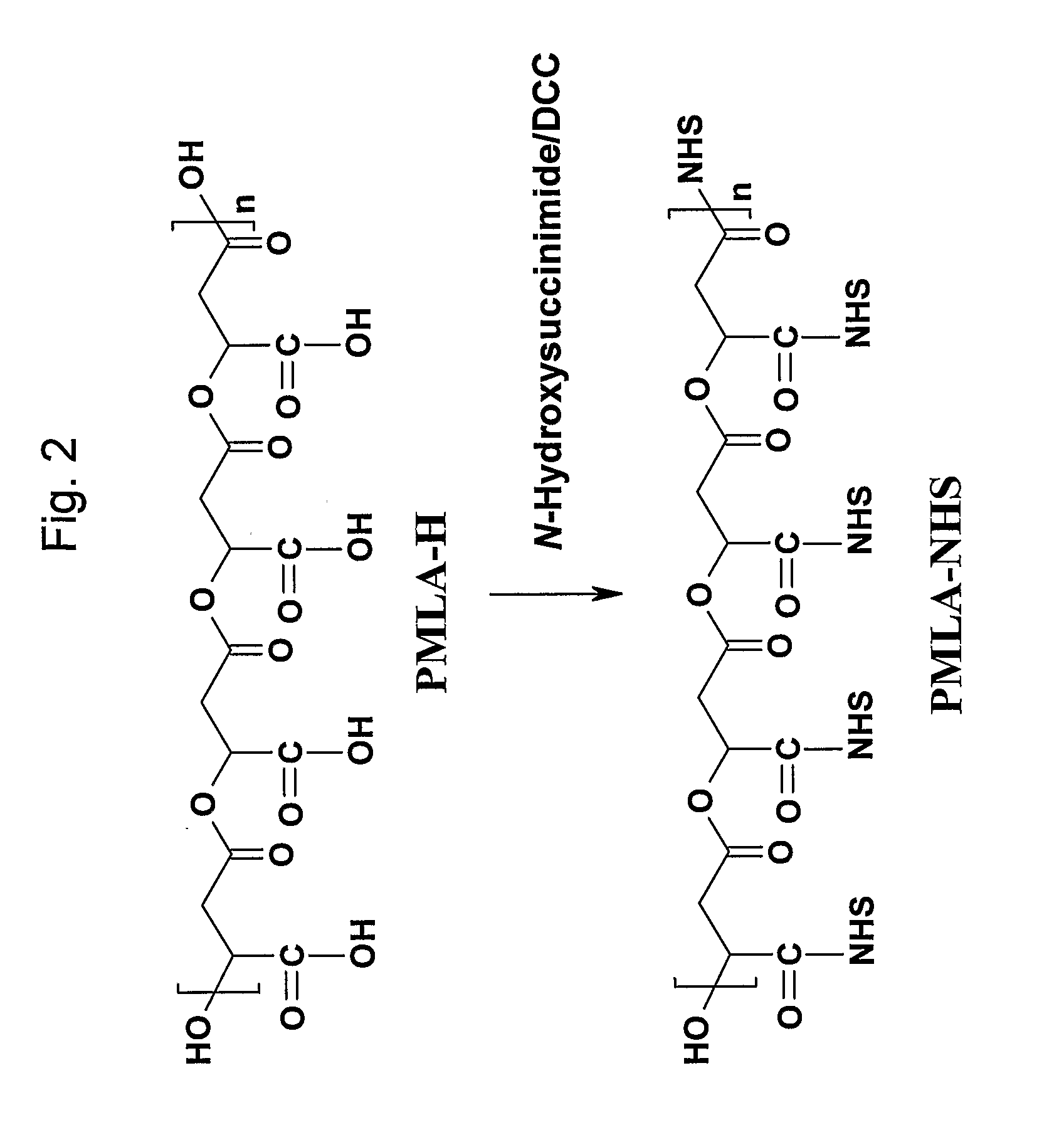

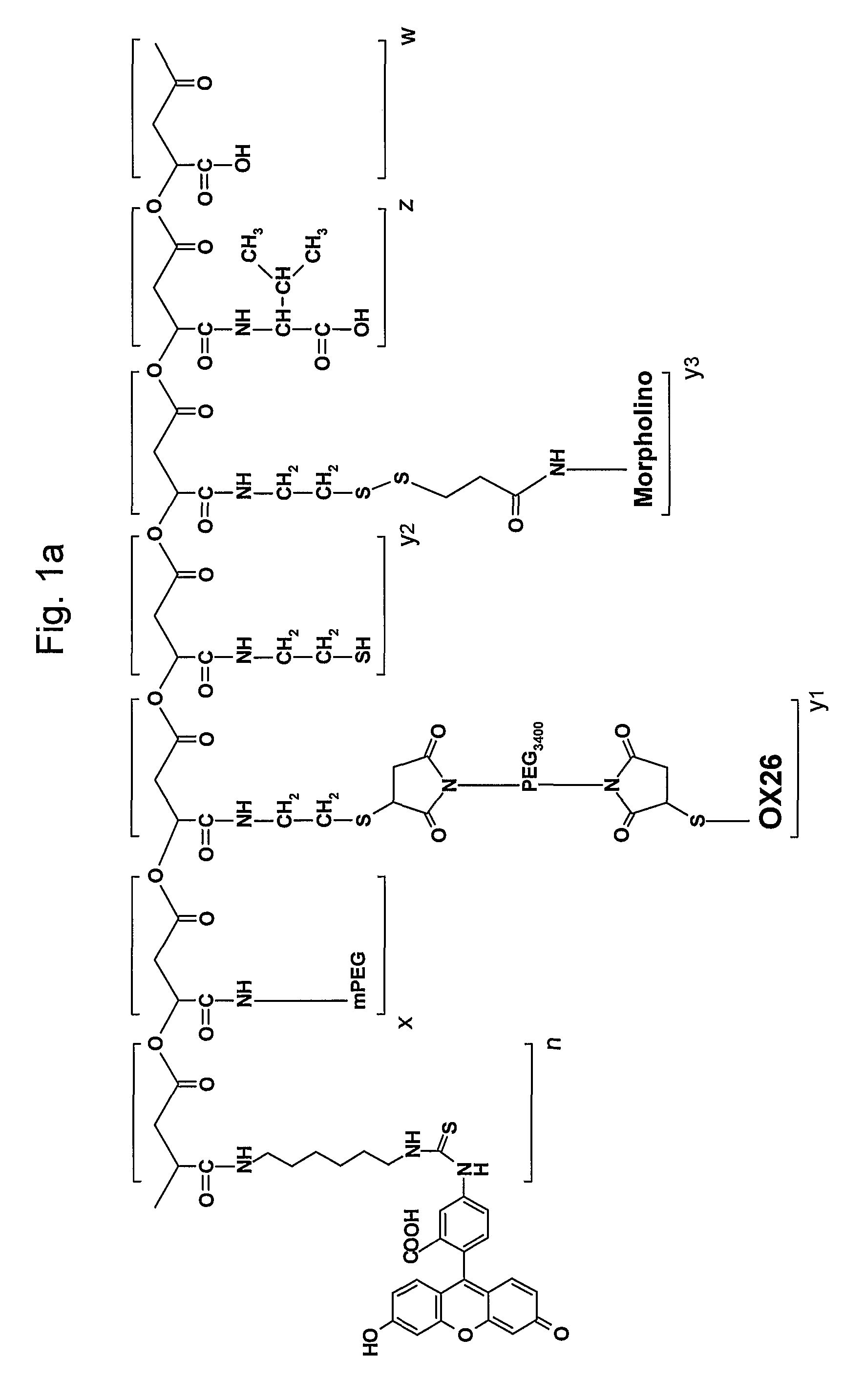

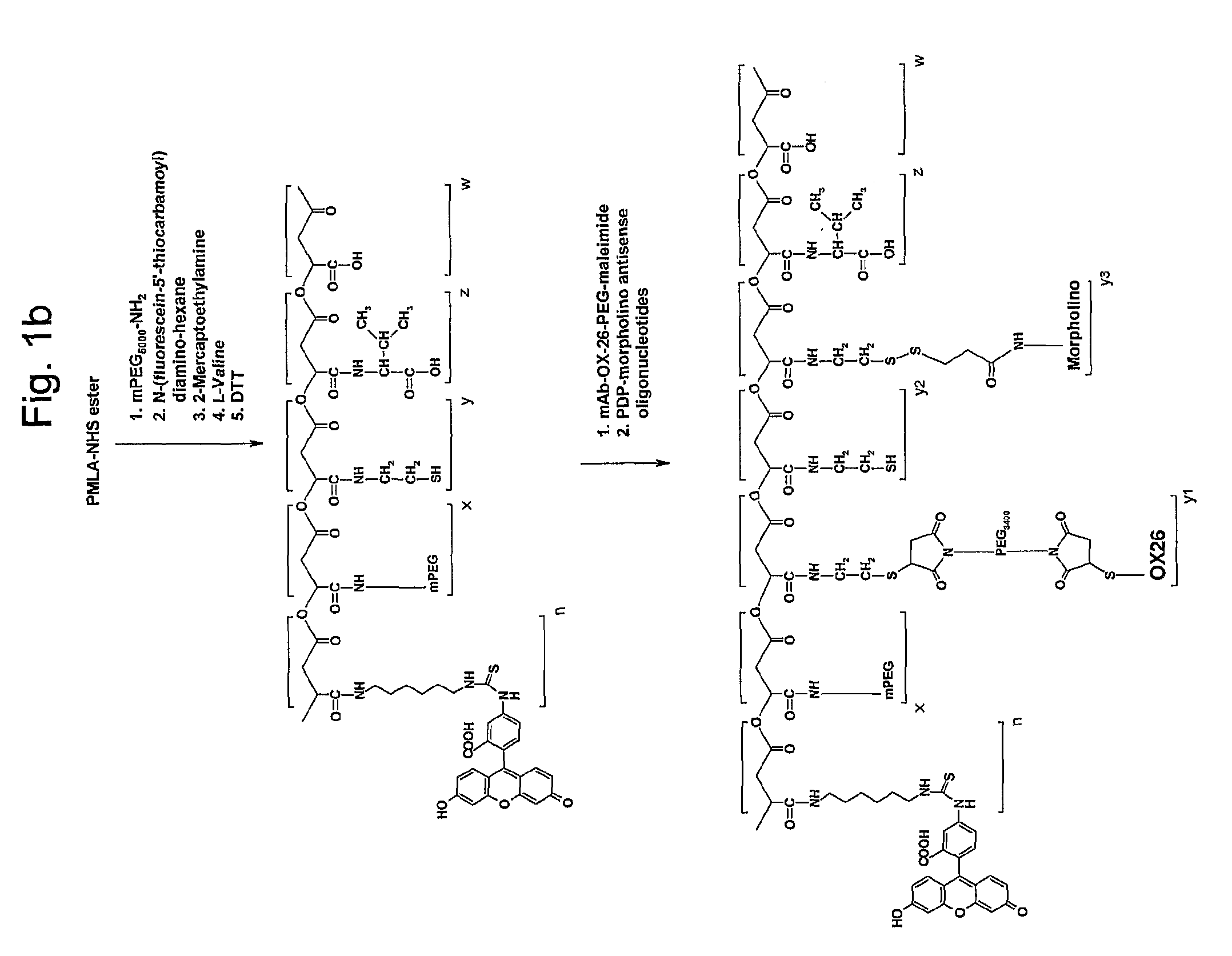

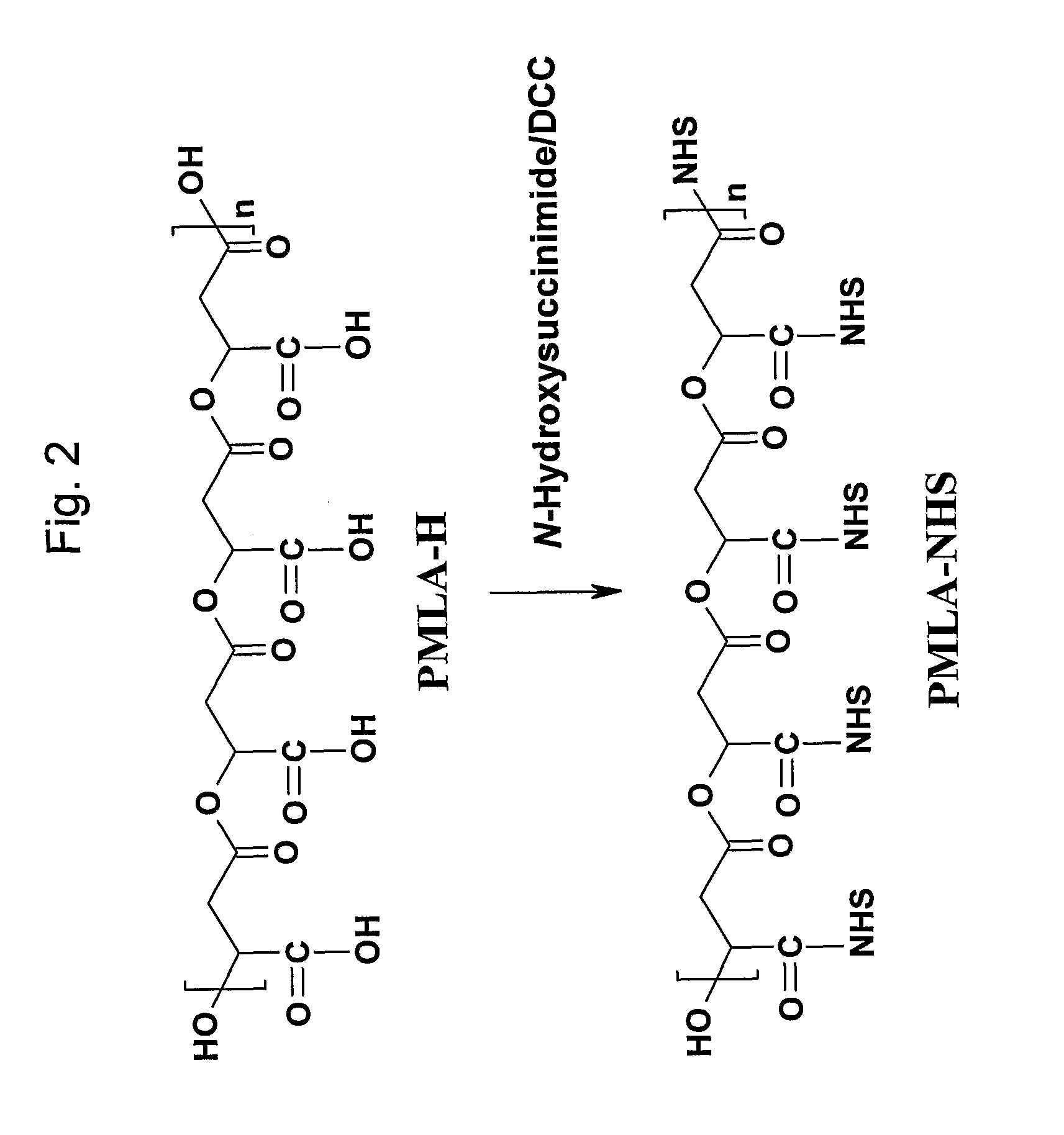

Polymalic Acid-Based Multi-Functional Drug Delivery System

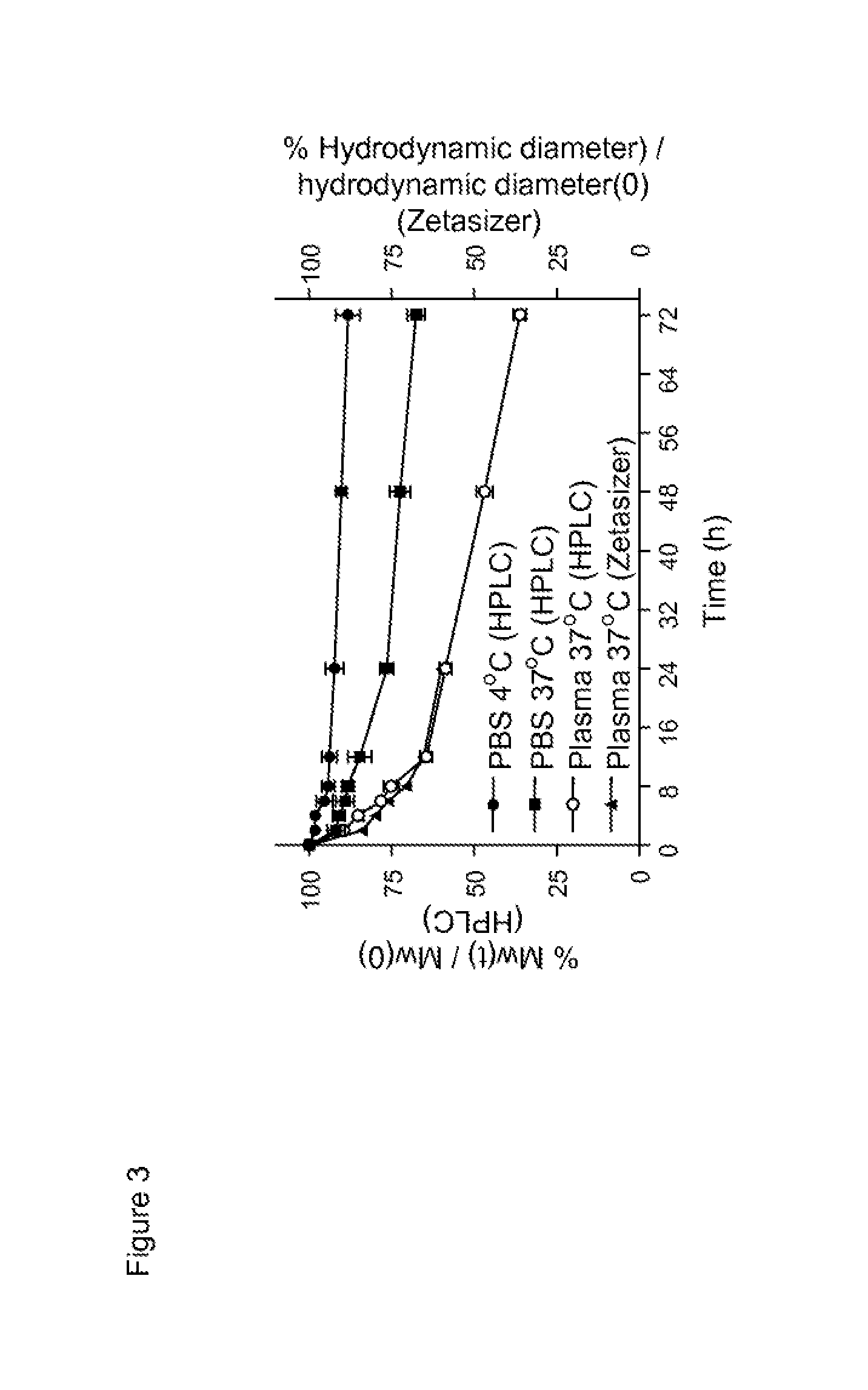

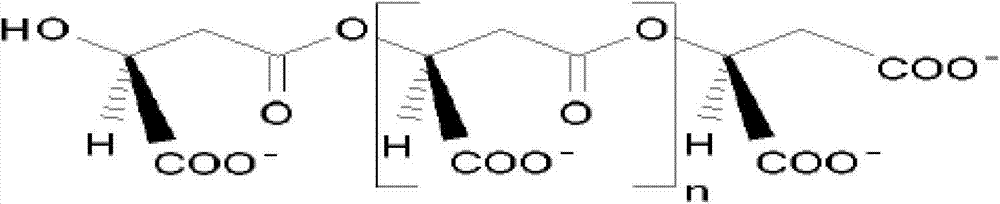

ActiveUS20070259008A1Low toxicityReadily availableOrganic active ingredientsPharmaceutical delivery mechanismNatural sourceFluorescence

A structured drug system that is useful for delivering a drug payload to a specific tissue or cell type is disclosed. The system is based on purified polymalic acid. This polymer isolated from natural sources is biocompatible, biodegradable and of very low toxicity. The polymer is extremely water soluble and contains a large number of free carboxyl groups which can used to attach a number of different active molecules. In the examples disclosed N-hydroxysuccinimide esters of the carboxyl groups are used to attach such molecules. The active molecules include monoclonal antibodies to promote specific cellular uptake and specific pro-drugs such as antisense nucleic acids designed to modify the cellular metabolism of a target cell. The pro-drugs are advantageously linked by a somewhat labile bond so that they will be released under specific conditions. In addition, the system contains amide-linked valine to encourage membrane disruption under lysosomal conditions. Polyethylene glycol groups are attached to extend the drug system's circulation half-life. In addition, fluorescent reported groups can be readily included to aid in visualizing and confirming drug system targeting. The drug system can deliver treatments for a wide range of diseases and is specially advantageous for treatment of neoplasms.

Owner:CEDARS SINAI MEDICAL CENT

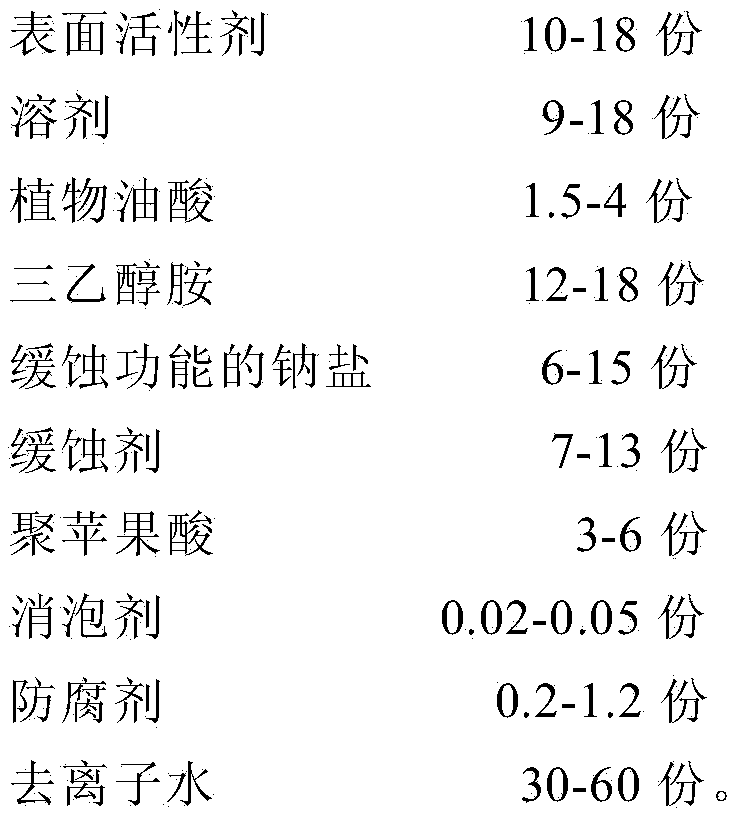

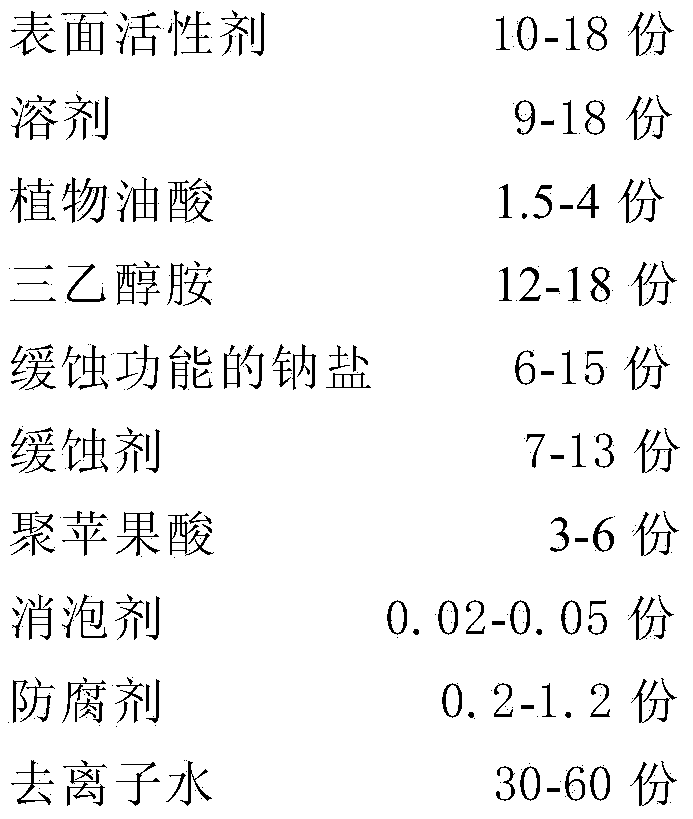

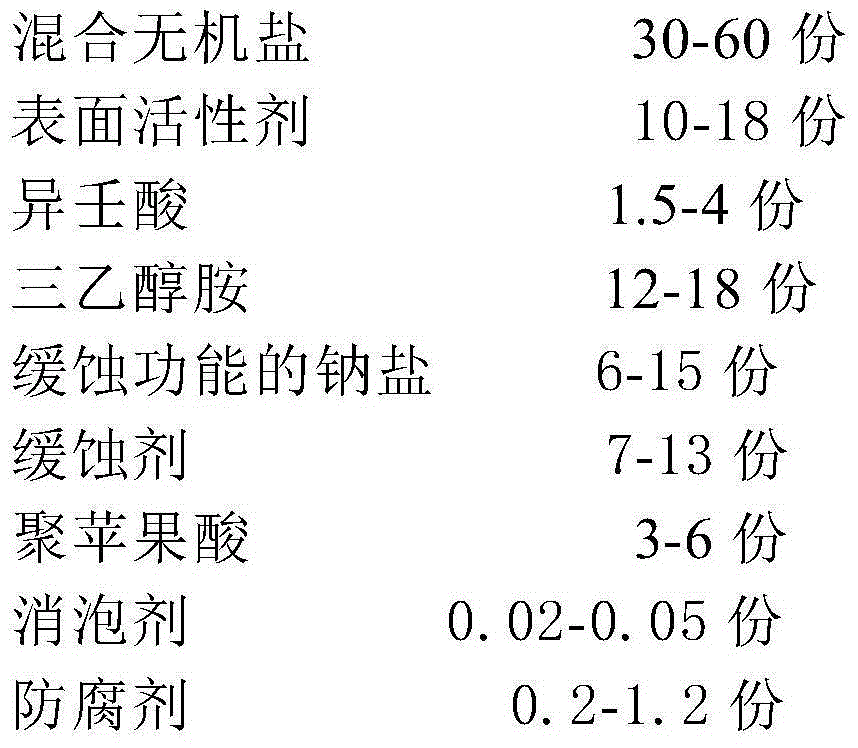

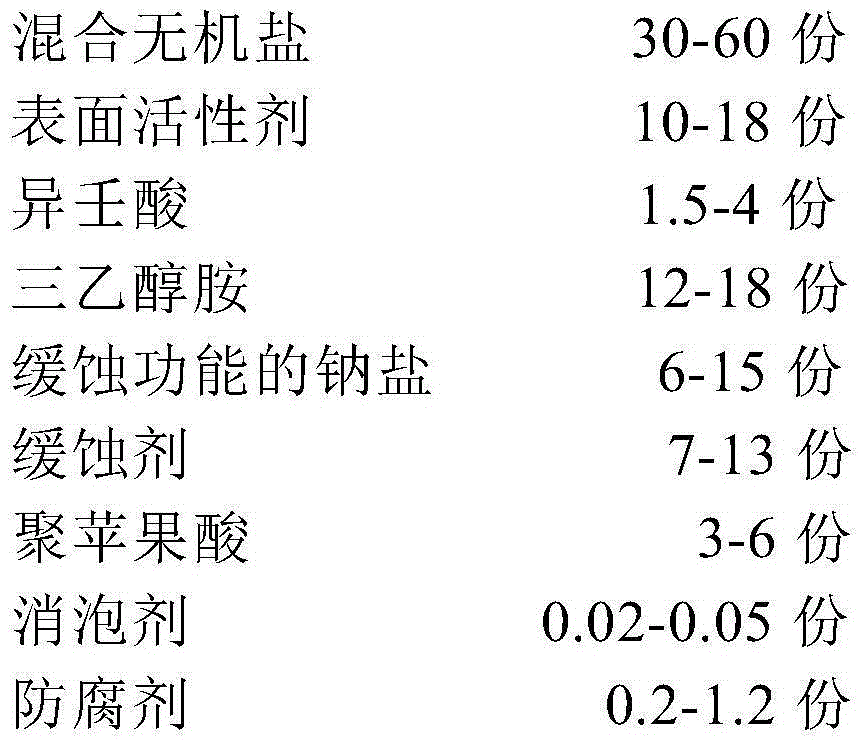

Water base reaction type multifunctional metal cleaning agent and preparation method thereof

The invention relates to a water base reaction type multifunctional metal cleaning agent which consists of a surfactant, a solvent, vegetable oil acid, triethanolamine, sodium salt with a corrosion inhibition function, a corrosion inhibitor, polymalic acid, an antifoaming agent 575, a preservative 1227, deionized water and the like. The metal cleaning agent is non-toxic, harmless, pollution-free, harmless to human body and corrosion-free to the metal surface, avoids peculiar smell and deterioration after long-time use, has excellent cleaning and anti-rust functions, particularly realizes thorough removal of the thick and hard carbon deposit and stubborn stains, does not corrode various types of metals such as cast iron, carbon steel, copper, aluminum and zinc, and is suitable for the cleaning of an ultrasonic machine, cleaning of a spray machine, manual soaking and rinsing and the like; and the natural anti-rust time of the cleaned workpiece exceeds 45 days.

Owner:天津市澳路浦润滑科技股份有限公司

Resin Composition, Molded Product From Resin Composition and Method for Preparing Resin Composition

InactiveUS20070270527A1Eliminate the problemImprove flame retardant performanceConductive materialOrganic conductorsCellulosePolybutylene

Disclosed is a biodegradable resin composition containing at least one biodegradable organic high molecular compound, a flame retardant additive containing a phosphorus-containing compound, and a hydrolysis suppressing agent suppressing the hydrolysis of the at least one biodegradable organic high molecular compound. An aliphatic polyester resin is polylactic acid, polycaprolactone, polyhydroxy lactic acid, polyhydroxy valeric acid, polyethylene succinate, polybutylene succinate, polybutylene adipate, polymalic acid, polyesters synthesized by fermentation, or a copolymer containing at least one of them. A polysaccharide is cellulose, starch, chitin, chitosan, dextrane, a derivative of at least one of them, or a copolymer containing at least one of them.

Owner:LERNER DAVID LITTENBERG KRUMHOLZ & MENTLIK LLP

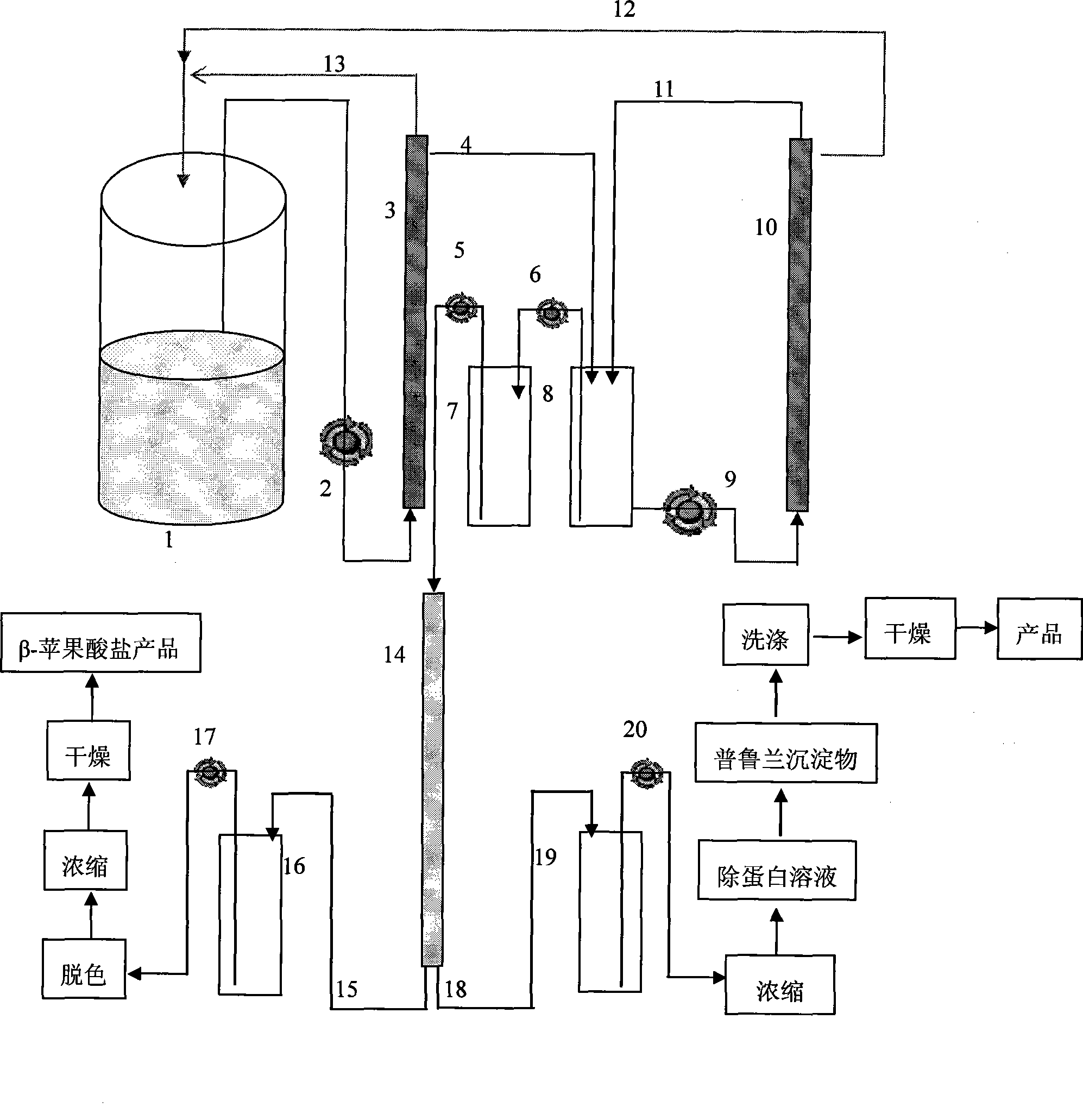

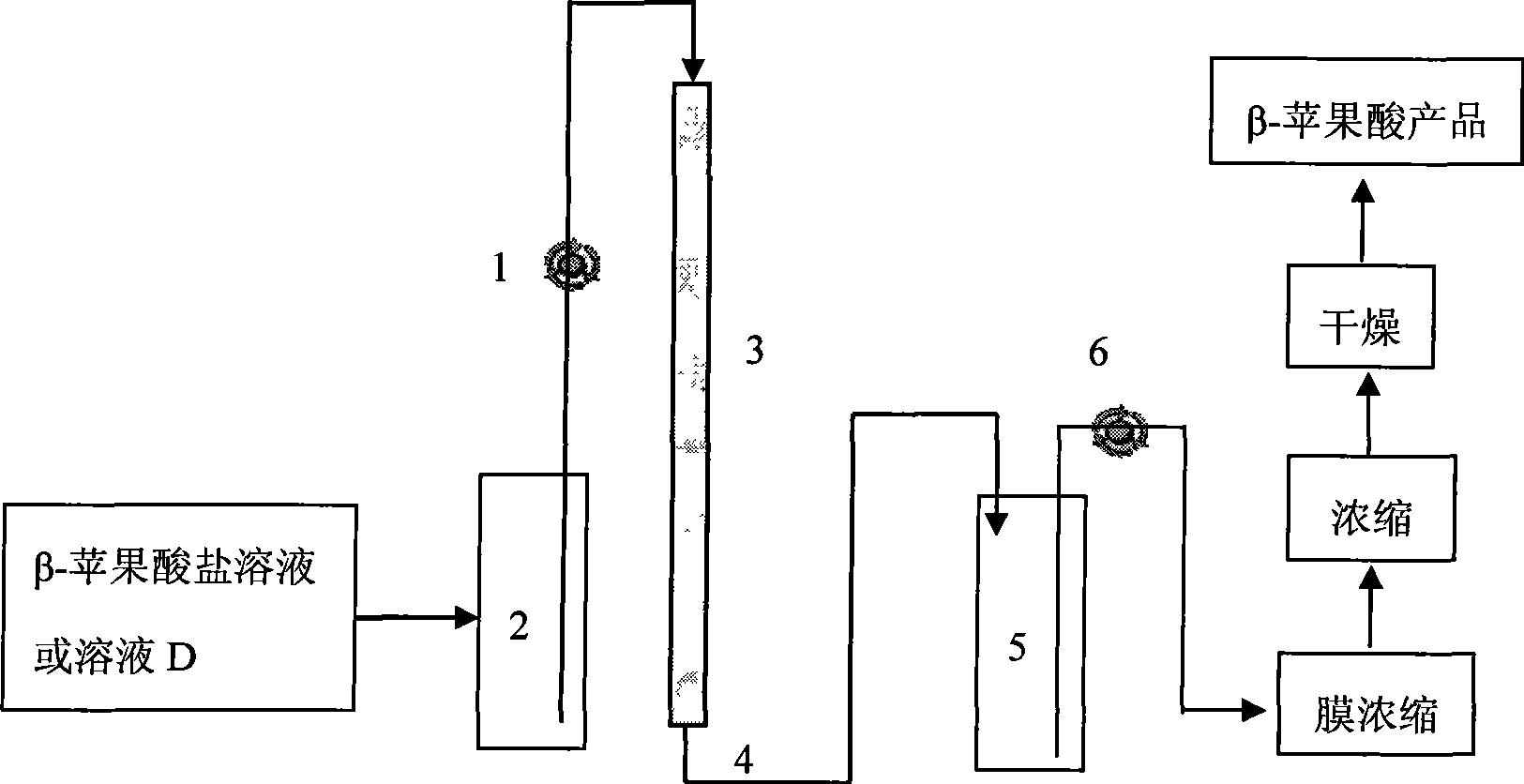

Preparation f beta-poly malic acid and salt thereof

ActiveCN101487034AHigh yieldReduce feedback inhibitionMicroorganism based processesFermentationPullulanStrong acids

The invention discloses a method for preparing Beta-poly malic acid and a salt thereof and simultaneously obtaining a byproduct pullulan. The method is realized by adopting the following technical proposal: return thalli and interception are implemented by a membrane technique in a fermentation process, high molecular weight Beta-poly malic acid is concentrated, and low molecular weight Beta-polymalic acid, pullulan and other components are recycled in a fermentation system; a weakly basic anion exchange resin is adopted to absorb the Beta-poly malic acid and lead pullulan solution to penetrate, alkaline solution is adopted to elute the Beta-poly malic acid that is adsorbed on the resin, and eluting solution is purified and dried, thus obtaining the salt product of the Beta-poly malic acid; a penetrating fluid is concentrated, chloroform and butanone mixture solution is adopted to remove protein, and the pullulan is precipitated by ethanol alcohol precipitation, orderly washed by acetone and ethyl ether, and dried by P2O5, thus obtaining a powder pullulan product; a strong acid cation exchange resin is adopted to absorb salt ions in salt solution of the Beta-poly malic acid, a membrane is used for removing extra acid in the desalted solution, and the obtained solution is concentrated and dried, thus obtaining the Beta-poly malic acid product.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

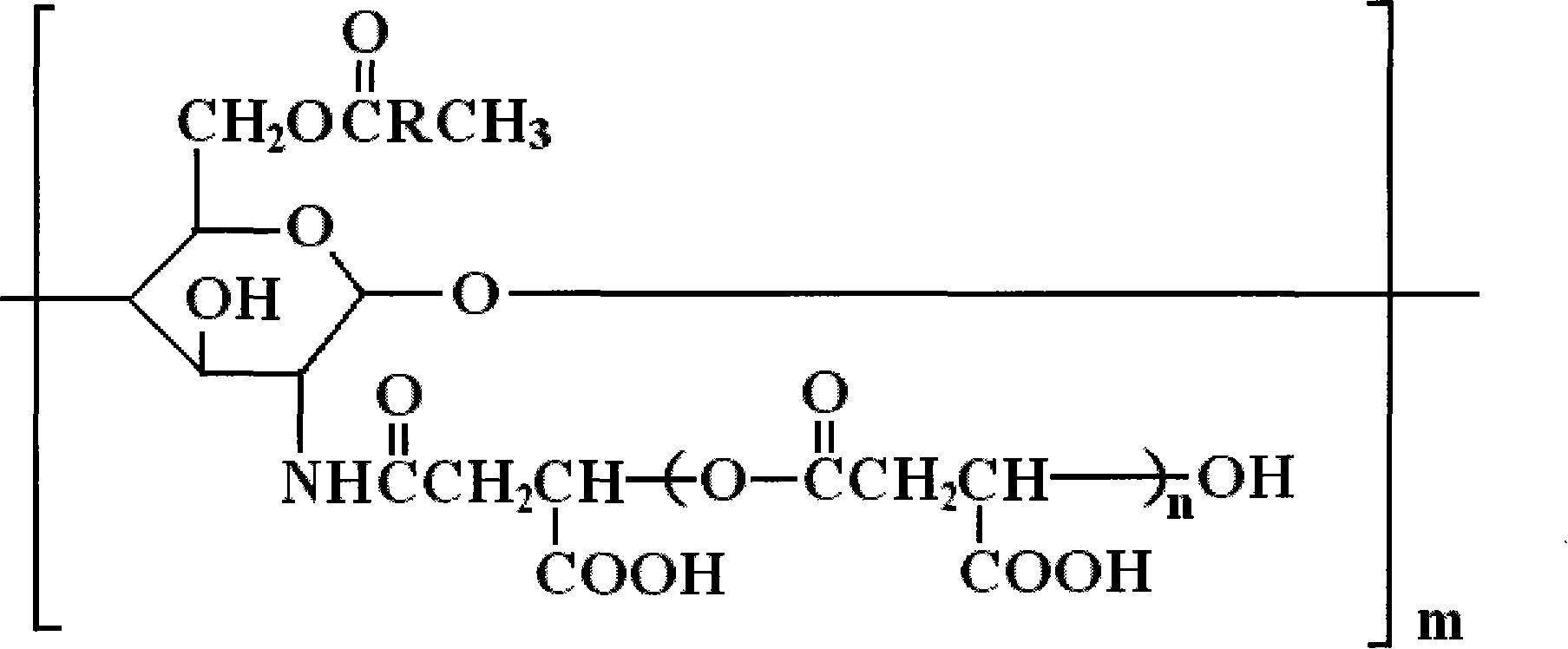

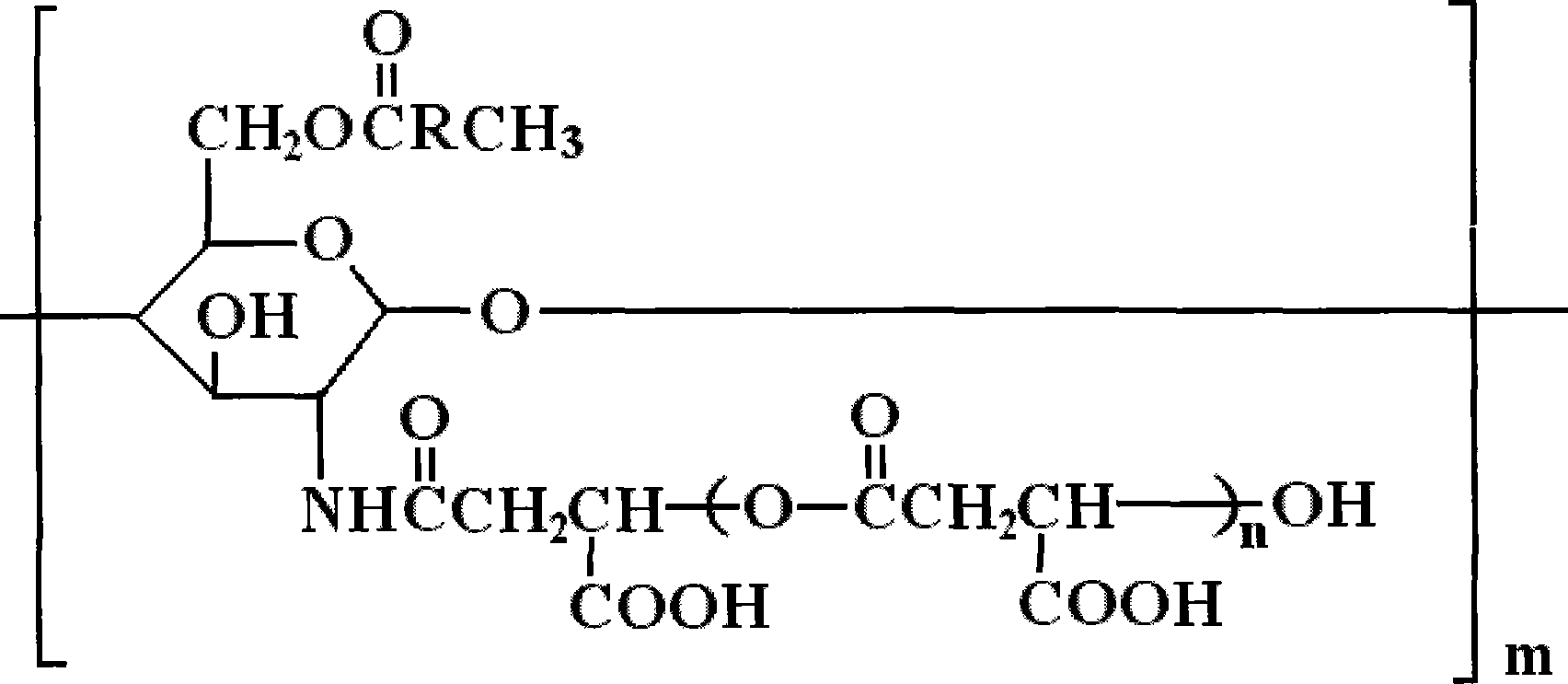

Derivative of amphoteric chitosan, preparation method, and application in pharmacy

InactiveCN101050243ANo toxicityGood biocompatibilityPharmaceutical non-active ingredientsBiocompatibility TestingAmphiphilic chitosan

This invention discloses a method for preparing amphiphilic chitosan derivative and its pharmaceutical application. The method comprises: connecting acylchlorinated long-chain fatty acid and chitosan by esterification, connecting end-activated poly (benzyl malate) and O-long-chain alkyl chitosan via amido bond, and performing catalytic hydrogenation to remove protective groups and obtain amphiphilic chitosan derivative. The amphiphilic chitosan derivative can form nanoparticles of 100-300 nm in aqueous solution, and has such advantages as high biodegradability, high biocompatibility and easy modification.

Owner:FUDAN UNIV

Method for producing beta-polymalic acid by inert support adsorption solid-state fermentation

InactiveCN101696430AReduce dosageHigh yieldMicroorganism based processesFermentationMicroorganismPullulan

The invention provides a novel method for producing beta-polymalic acid by the solid-state fermentation of microorganisms, and relates to a novel process of producing the beta-polymalic acid by using an inert adsorption composite material to the solid-state fermentation of aureobacidium pullulans(at present, the strain is stored in the general microorganism center of China Committee for Culture Collection of Microorganisms, and the CGMCC No. is 3337.). The method comprises the following steps of: selecting a nontoxic inert support which is good in physical water absorption and stable in nature and has a porous structure, evenly mixing the inert support and a liquid culture medium inoculated with the aureobacidium pullulans in a certain ratio, sending the mixture to a solid-state reactor for fermentation, extracting a substrate after the solid-state fermentation with water, and inspecting the content of the polymalic acid. By the method, the fermentation efficiency of the polymalic acid is improved, and the transfer efficiency of oxygen in the fermentation process is enhanced; at the same time, because the inert support can be recycled, the discharge of the solid wastes is greatly reduced; the utilization ratio of the fermentation equipment is high, the fermentation period is short, the products are easy to be separated and extracted, and the yield and purity of the polymalic acid are improved; and the operating cost is low, the economic benefits are obvious, and the industrialized production is facilitated.

Owner:天津北洋百川生物技术有限公司

Polymalic acid-based multi-functional drug delivery system

ActiveUS7935677B2Readily availableHigh in numberGenetic material ingredientsPharmaceutical delivery mechanismDiseaseNatural source

A structured drug system that is useful for delivering a drug payload to a specific tissue or cell type is disclosed. The system is based on purified polymalic acid. This polymer isolated from natural sources is biocompatible, biodegradable and of very low toxicity. The polymer is extremely water soluble and contains a large number of free carboxyl groups which can used to attach a number of different active molecules. In the examples disclosed N-hydroxysuccinimide esters of the carboxyl groups are used to attach such molecules. The active molecules include monoclonal antibodies to promote specific cellular uptake and specific pro-drugs such as antisense nucleic acids designed to modify the cellular metabolism of a target cell. The pro-drugs are advantageously linked by a somewhat labile bond so that they will be released under specific conditions. In addition, the system contains amide-linked valine to encourage membrane disruption under lysosomal conditions. Polyethylene glycol groups are attached to extend the drug system's circulation half-life. In addition, fluorescent reported groups can be readily included to aid in visualizing and confirming drug system targeting. The drug system can deliver treatments for a wide range of diseases and is specially advantageous for treatment of neoplasms.

Owner:CEDARS SINAI MEDICAL CENT

Method for preparing beta-polymalic acid and simultaneously coproducing byproduct prussian blue

InactiveCN101100687AReduce manufacturing costHigh purityMicroorganism based processesFermentationUltrafiltrationEthanol precipitation

Beta-polyoxysuccinic acid and Prussian blue as by-product are prepared by: inoculating activated fungus in fermenting medium for 8-14 days at 24-30 deg.C and 120rpm, separating solid from liquid to remove mycelia, adding alcohol with equal volume to separate Prussian blue deposit and melanochrome, concentrating supernatant and centrifuging with double-volume alcohol to separate Prussian blue, re-concentrating, adding four volume alcohol to deposit beta-polyoxysuccinic acid, and dissolving into water, removing residual melanochrome and micro-molecular materials, and frozen drying to obtain beta-polyoxysuccinic acid, dissolving separated Prussian blue in mixed alcohol-butanone to remove melanochrome, and dialyzing and frozen drying to obtain Prussian blue. It can remove melanochrome effectively to quality purity and reduce pollution by discharged Prussian blue and melanochrome.

Owner:NANKAI UNIV

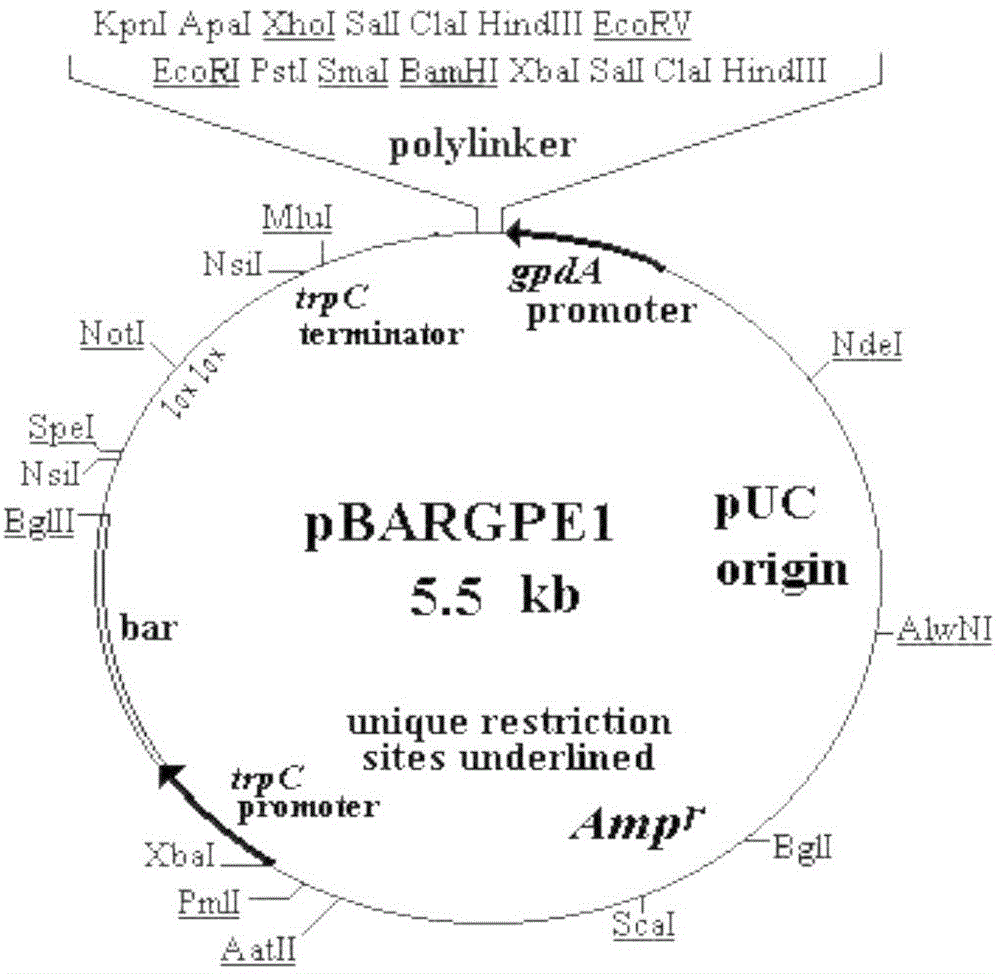

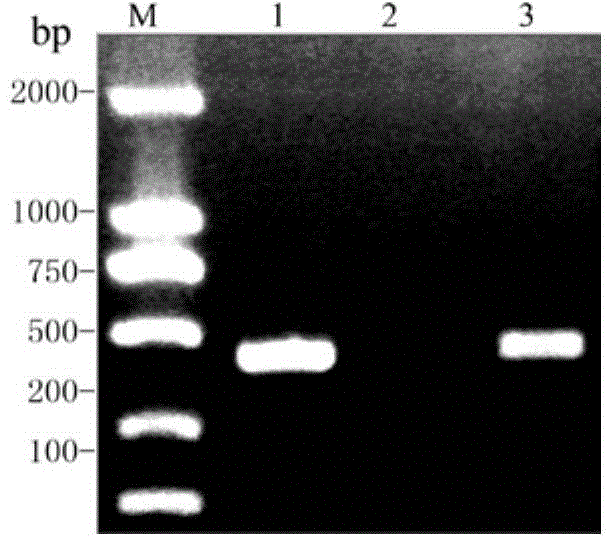

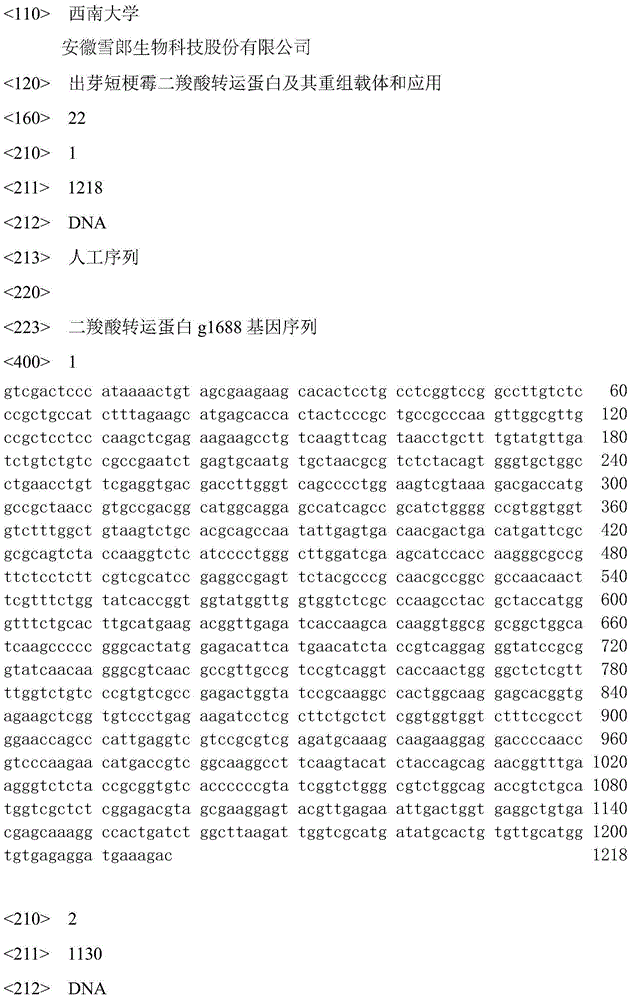

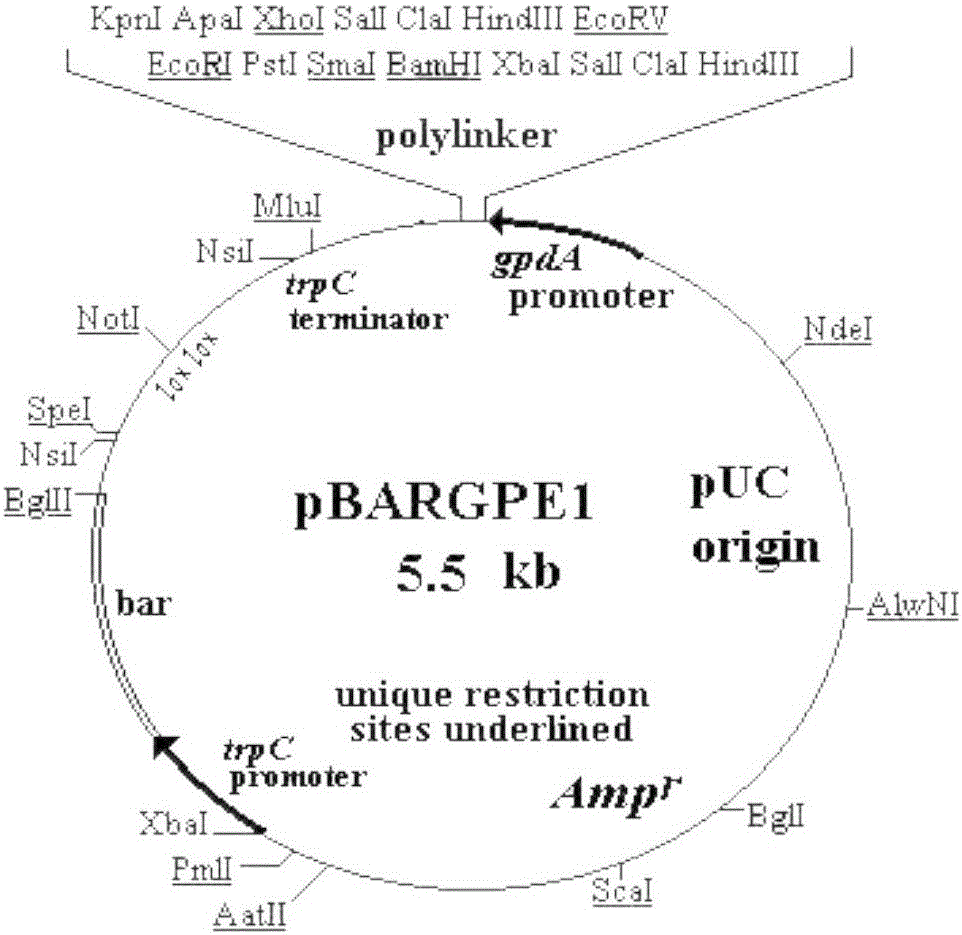

Aureobasidium pullulans dicarboxylic acid transport protein and recombinant vector and application thereof

The invention discloses aureobasidium pullulans dicarboxylic acid transport protein and a recombinant vector and application thereof. Amino acid sequence of the aureobasidium pullulans dicarboxylic acid transport protein is shown as SEQ ID NO.7, SEQ ID NO.8, SEQ ID NO.9 or SEQ ID NO.10 while nucleotide sequence of the same is shown as SEQ ID NO.1, SEQ ID NO.2, SEQ ID NO.3, SEQ ID NO.4 and SEQ ID NO.5. Overexpression of dicarboxylic acid transport protein in aureobasidium pullulans can increase yield of polymalic acid, and no free malic acid is detected in fermentation liquor, so that dicarboxylic acid transport protein gene is related to synthetic transport of the polymalic acid, and a foundation is laid for increasing yield of the polymalic acid.

Owner:SOUTHWEST UNIVERSITY +1

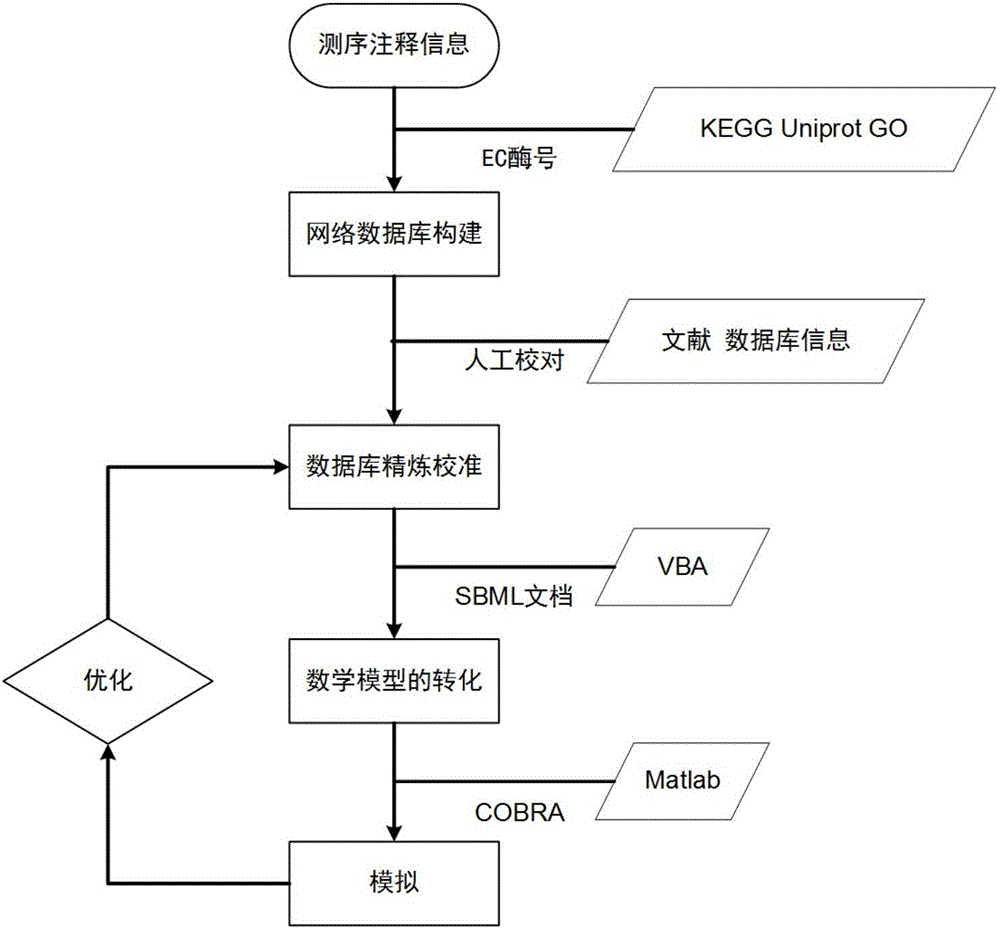

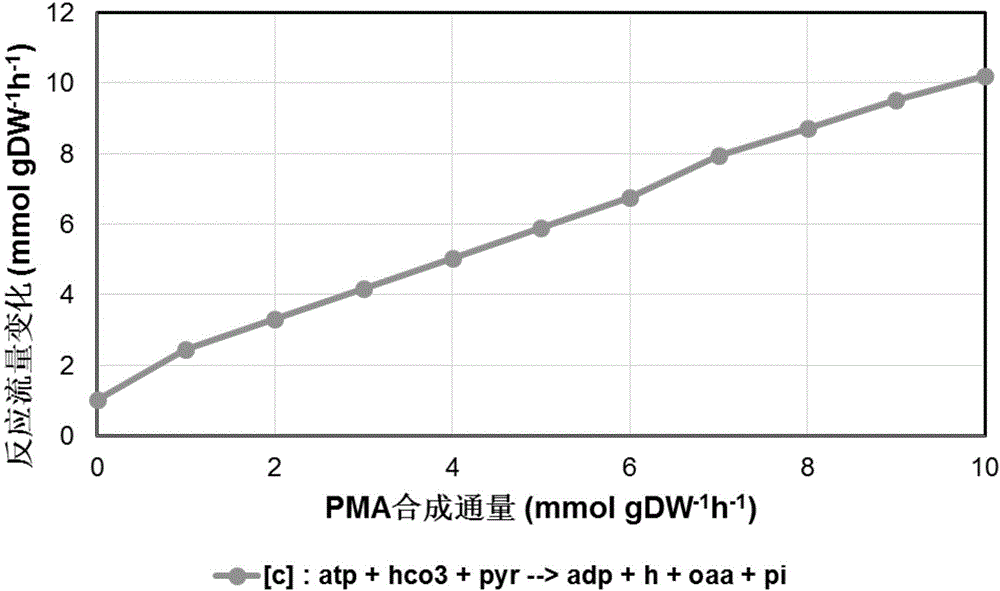

Aureobasidium pullulans genome scale metabolism network model and application thereof

The invention discloses an aureobasidium pullulans genome scale metabolism network model and application thereof. Construction of the aureobasidium pullulans genome scale metabolism network model comprises four steps of building of a network database, refining and calibrating of the database, building of a mathematical model and validation and analysis of the model. According to the constructed aureobasidium pullulans genome scale metabolism network model, a gene target for potentially improving polymalic acid can be predicted, a guiding platform is provided for research and comprehensive analysis of aureobasidium pullulans, and the aureobasidium pullulans genome scale metabolism network model has great significance on transformation of the aureobasidium pullulans to obtain high-yield metabolic products of the polymalic acid and pullulan.

Owner:SOUTHWEST UNIVERSITY +1

Beta-poly malic acid/chitosan nano drug sustained-release microcapsule and preparation method thereof

InactiveCN102961362AGood biocompatibilityPromote degradationPharmaceutical delivery mechanismPharmaceutical non-active ingredientsPolyelectrolyteChitosan malate

The invention discloses a beta-poly malic acid / chitosan nano drug sustained-release microcapsule and a preparation method thereof. The beta-poly malic acid / chitosan nano drug sustained-release microcapsule comprises a core material and a wall material, wherein the core material is a medicine, and the raw material of the wall material consists of beta-poly malic acid and chitosan; and the mass ratio of beta-poly malic acid to chitosan to the medicine in the beta-poly malic acid / chitosan nano drug sustained-release microcapsule is 10:2.5:(3-5). The preparation method comprises the step of preparing the beta-poly malic acid / chitosan nano drug sustained-release microcapsule from beta-poly malic acid, chitosan and the medicine by utilizing a polyelectrolyte self-assembly principle. The beta-poly malic acid / chitosan nano drug sustained-release microcapsule prepared by the preparation method disclosed by the invention has the advantages of homogeneous granularity, good stability, good sustained release effect and no damage to a human body; and the preparation method disclosed by the invention is simple, mild in conditions and suitable for industrial production.

Owner:SHANGHAI INST OF TECH

Medium capable of improving polymalic acid yield, use of the medium and method for producing polymalic acid by the medium

InactiveCN102899365AIncrease productionIncrease ATPMicroorganism based processesFermentationBiotechnologyPullulan

The invention discloses a medium capable of improving a polymalic acid yield. The medium contains 1 to 20g / L of citric acid or citrate. The medium can provide external power donors to aureobasidium pullulans in fermentation, and can improve a cellular ATP supply level thereby improving a polymalic acid yield maximally by 57.1%. The medium can be used for producing polymalic acid by aureobasidium pullulan fermentation and has good economic benefits.

Owner:SOUTHWEST UNIVERSITY

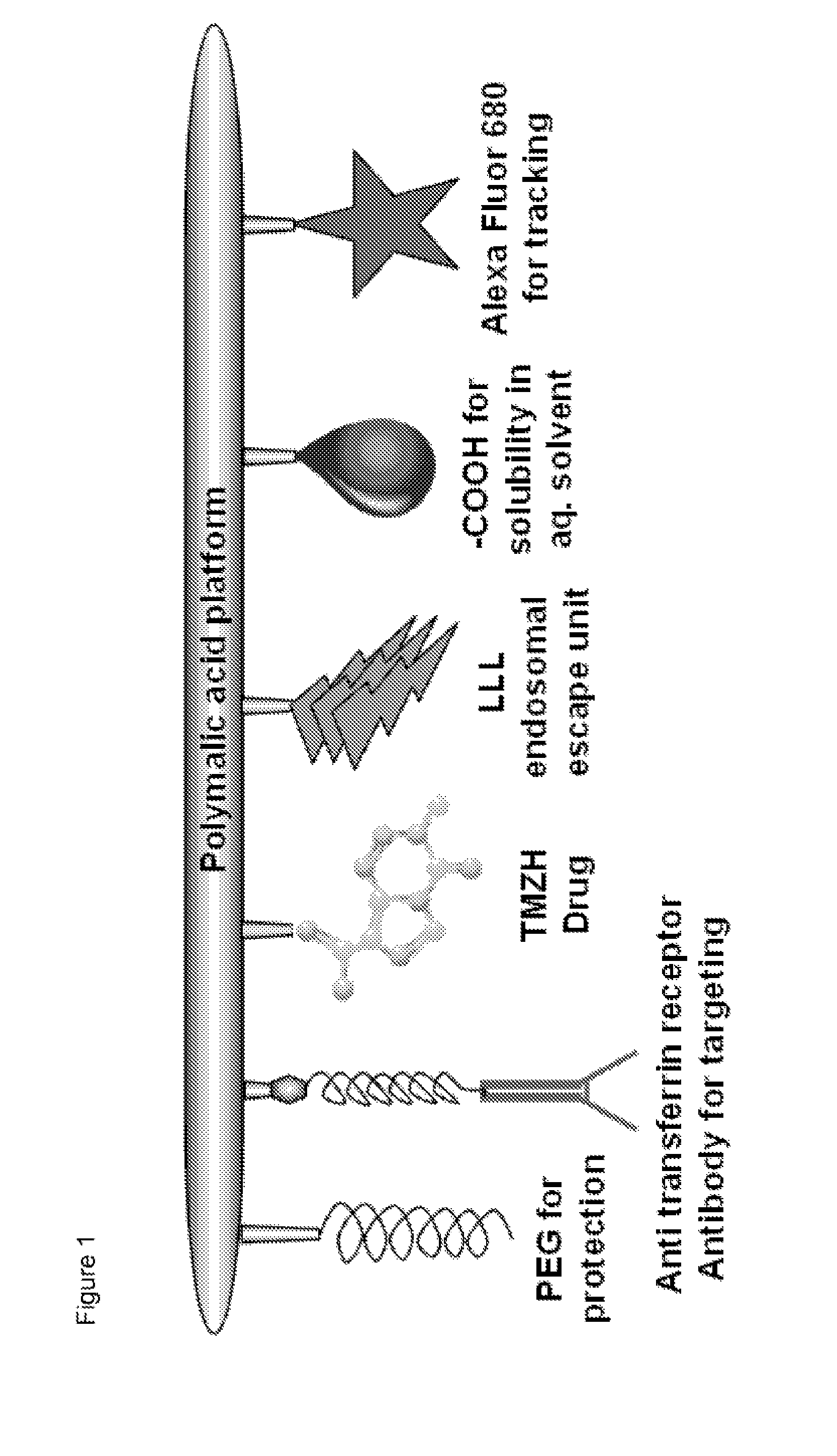

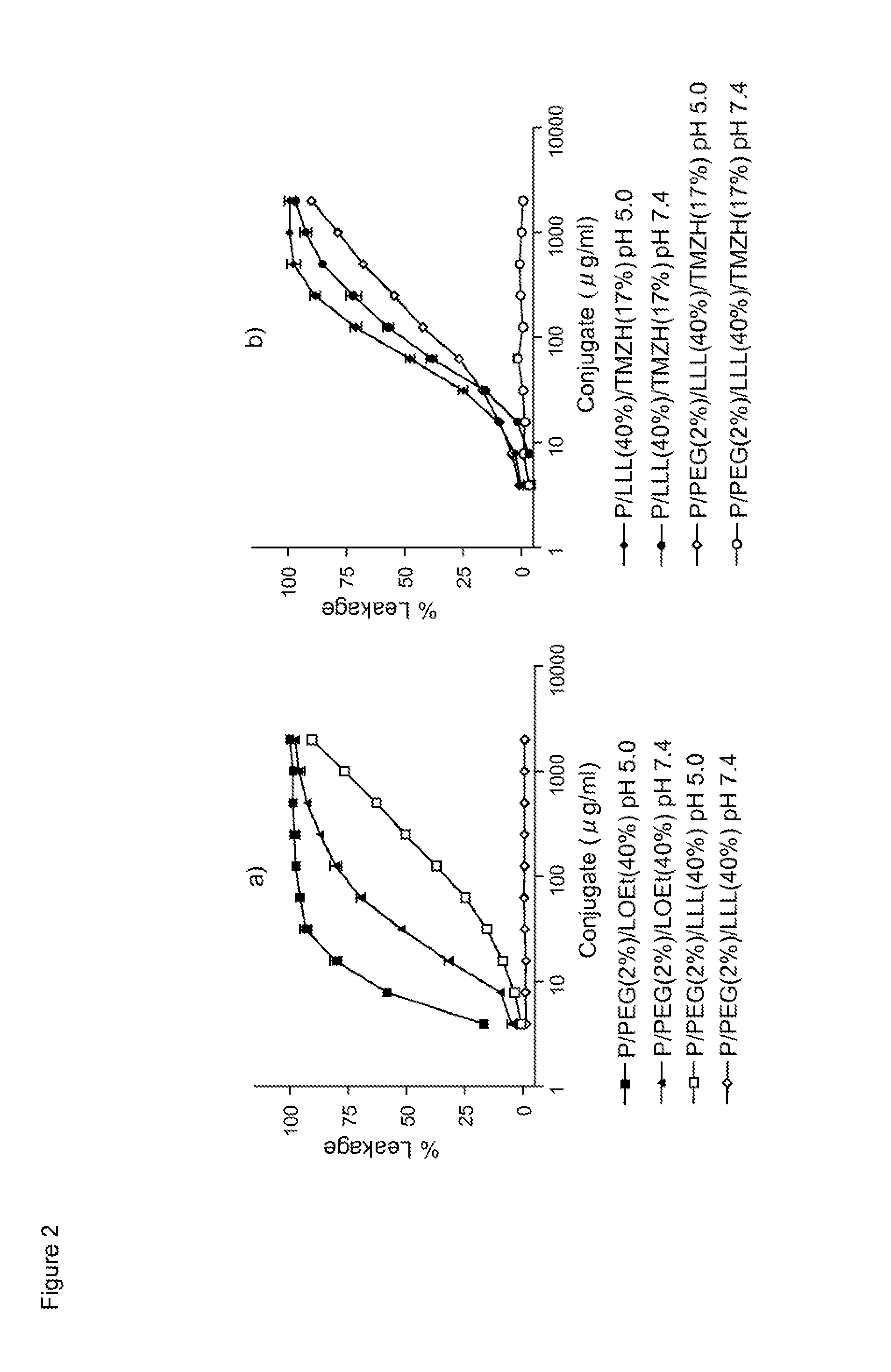

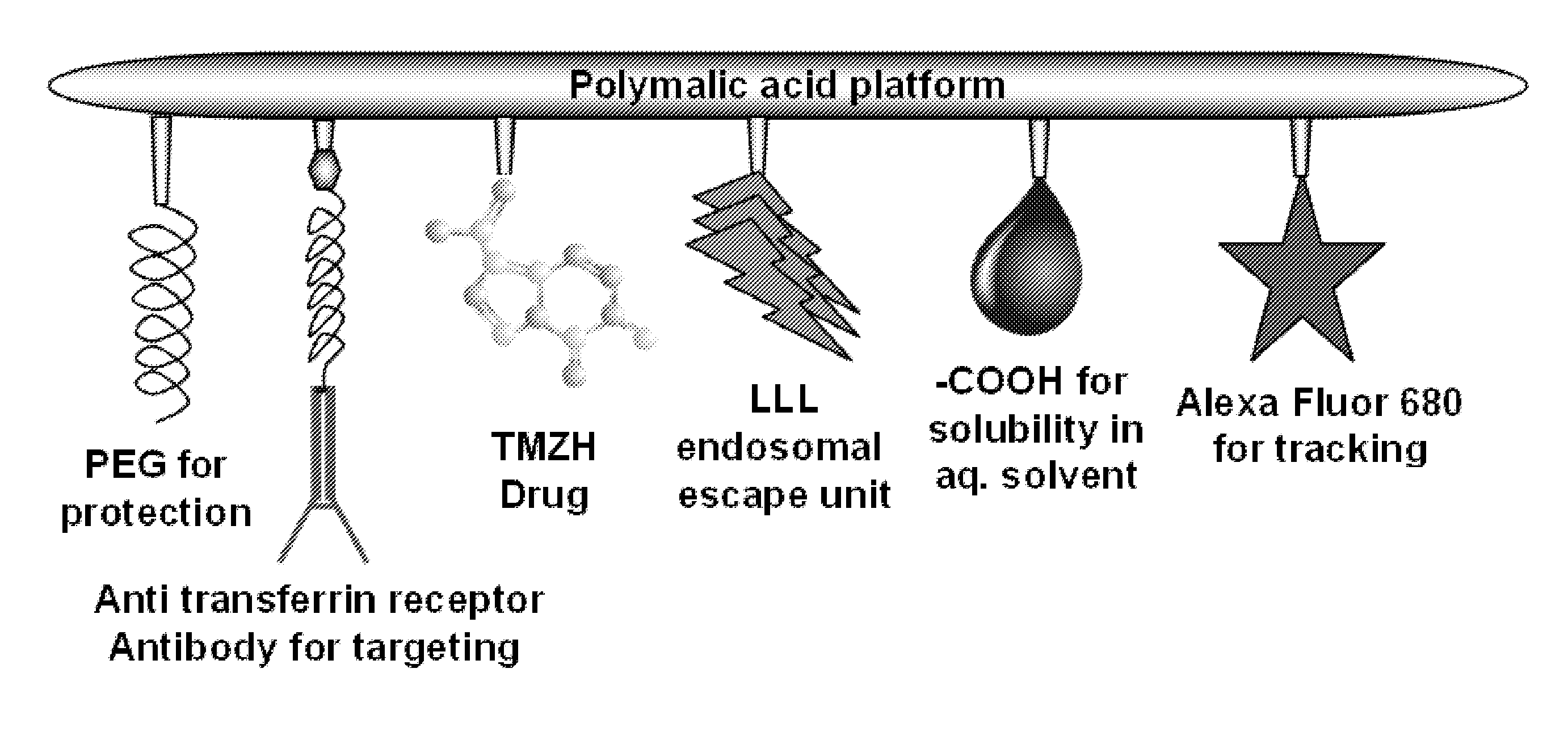

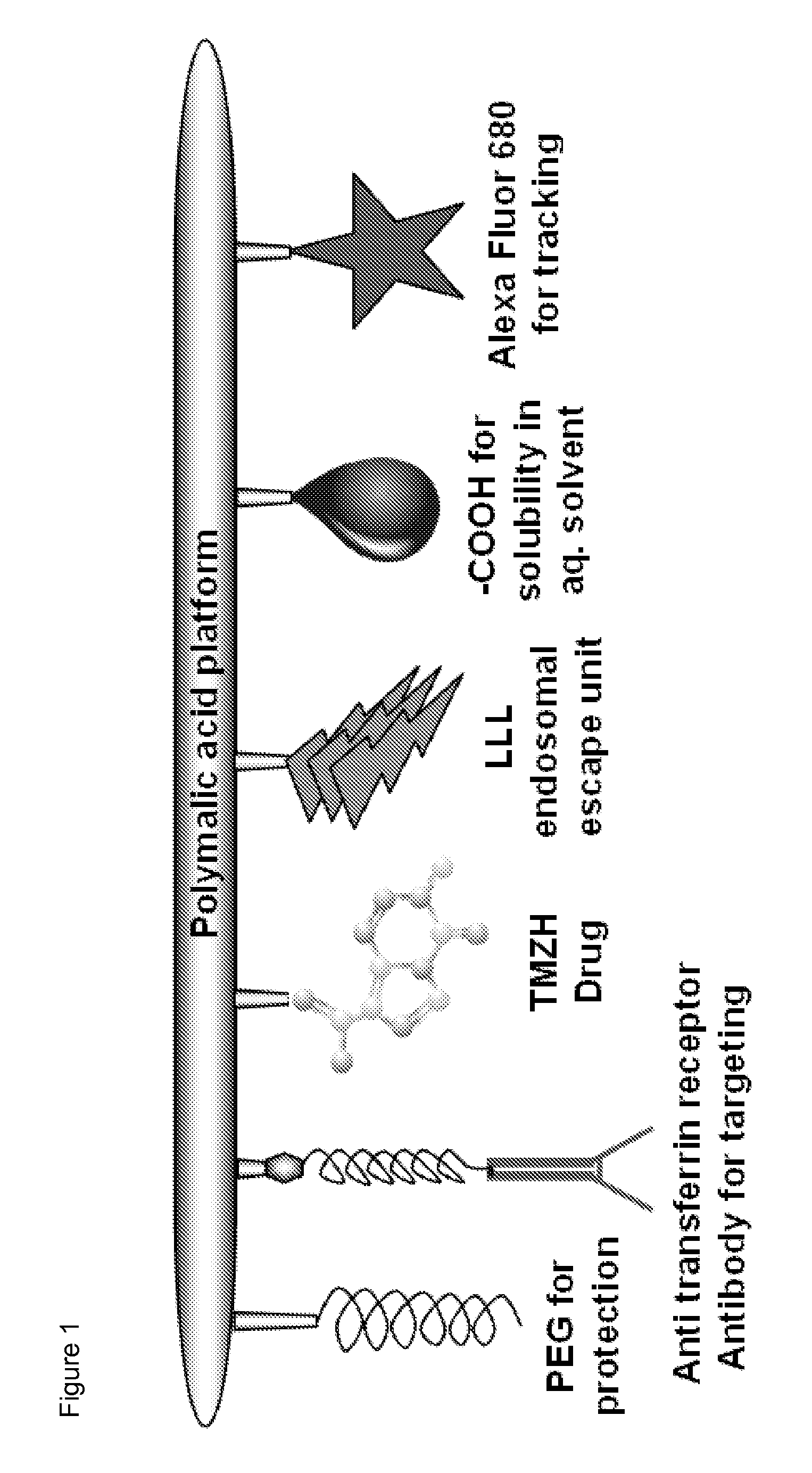

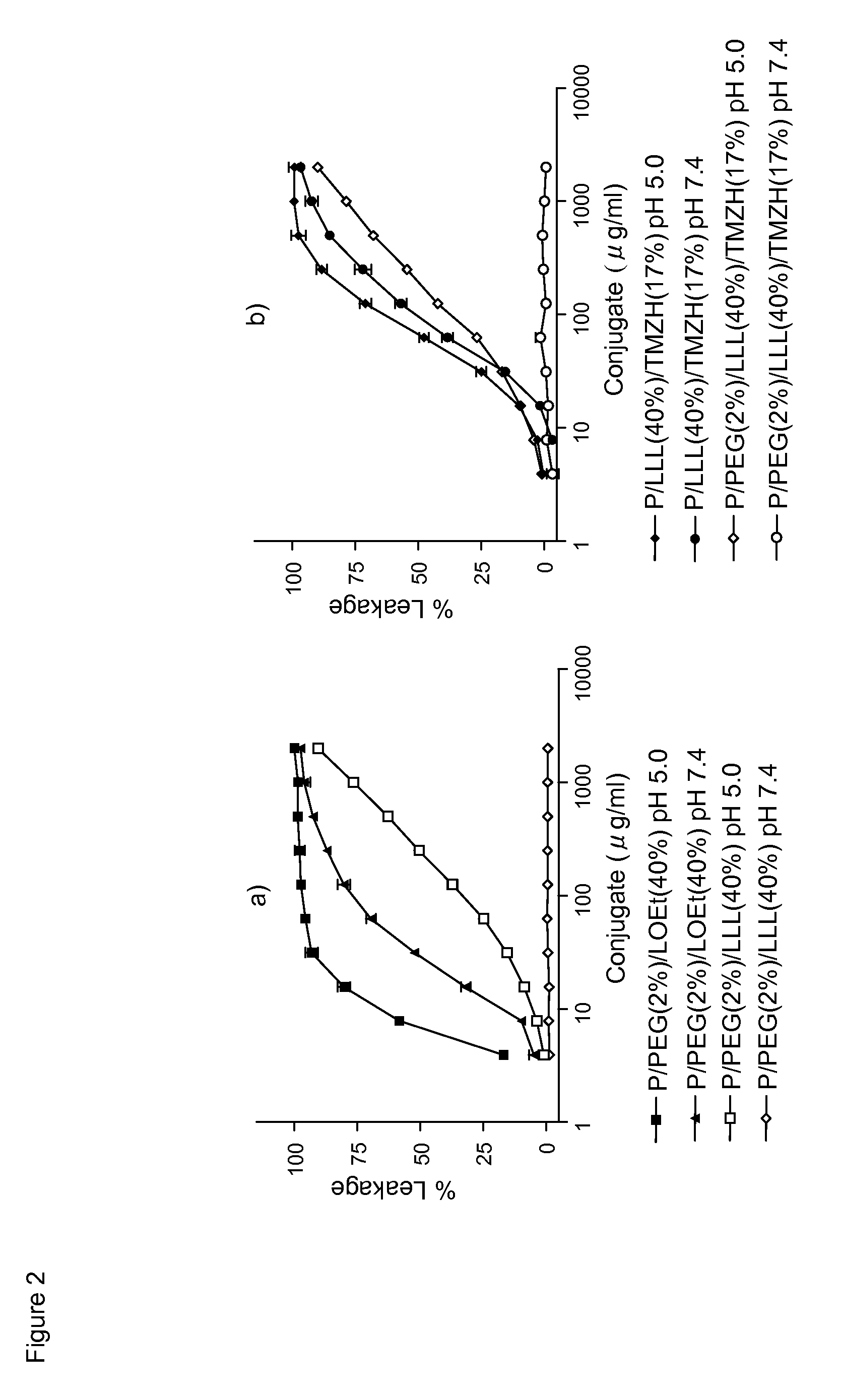

Drug delivery of temozolomide for systemic based treatment of cancer

The present invention relates to methods of drug delivery for the treatment of a condition or disease, such as cancer. In one embodiment, the invention provides a method of preparing a multifunctional nanoconjugate of temozolomide (TMZ) by conjugating TMZ in its hydrazide form to a polymalic acid platform. In another embodiment, the polymalic acid platform is conjugated to a monoclonal antibody to transferrin receptor, a trileucine (LLL) moiety, and / or a polyethylene glycol (PEG) moiety. The present invention relates to methods of drug delivery for the treatment of a condition or disease, such as cancer. In one embodiment, the invention provides a method of preparing a multifunctional nanoconjugate of temozolomide (TMZ) by conjugating TMZ in its hydrazide form to a polymalic acid platform. In another embodiment, the polymalic acid platform is conjugated to a monoclonal antibody to transferrin receptor, a trileucine (LLL) moiety, and / or a polyethylene glycol (PEG) moiety.

Owner:CEDARS SINAI MEDICAL CENT

Fermentation medium for improving output and purity of beta-polymalic acid produced by zymotechnics

The invention discloses a fermentation medium for improving output and purity of beta-polymalic acid produced by zymotechnics, and belongs to the field of biofermentation engineering. The fermentation medium is compounded by the following components: cane sugar, sodium nitrate, monopotassium phosphate, potassium chloride, manganese sulfate, bitter salt, calcium carbonate, ammonium nitrate, aminosuccinic acid, amidocaproic acid, threonine, amino-isovalerianic acid, histidine, cytosine, adenine and bilineurine. Through the optimized compound of the amino acid, the bilineurine, purine pyrimidine growth factor, peptone in the conventional semi-synthetic culture medium is substituted, a fire-new compound fermentation medium is obtained, difficulty in fading during extracting can be lowered, the content of beta-polymalic acid in zymotic fluid reaches 33-40 g / L, the purity can reach 80-90 percent, and meanwhile a solid practice basis is established for latter metabolomics research.

Owner:天津北洋百川生物技术有限公司

New process for fermenting Beta-polymalic acid

InactiveCN101696434AIncrease production capacityMicroorganism based processesFermentationInorganic saltsMicroorganism

The invention discloses a new process for fermenting a Beta-polymalic acid by using a microorganism fermentation process, which is realized in such a way: culturing Aureobasidium pullulans ipe-1 in a culture medium containing carbon sources, nitrogen sources, inorganic salts sand trace elements under the condition of controlling the pH value and dissolved oxygen; controlling the fermentation pH value by aqueous alkali; and adjusting the ventilation quantity, the tank pressure and the stirring speed to control the concentration of the dissolved oxygen. The pH value is 5.5-7.0, an organic carbon source and an inorganic source are matched for use, the concentration of the dissolved oxygen is controlled to be larger than 70 percent within 16h before fermentation, and the concentration of the dissolved oxygen is controlled to be 10-80 percent after fermentation, thereby being suitable for accumulating Beta-polymalic acid in a large quantity.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Process for producing beta-polymalic acid by feed-batch fermentation

InactiveCN102154389ALow costImprove fermentation yieldMicroorganism based processesFermentationSucroseBatch fermentation

The invention discloses a feed-batch fermentation process improving the yield of beta-polymalic acid, which is implemented by the following scheme: culturing a strain aureobasidium pullulans ipe-1 in a culture medium containing a carbon source, a nitrogen source, inorganic salt and trace elements while controlling the pH value and dissolved oxygen; and based on a batch fermentation production process, adopting glucose as the initial sugar, and 36-48 hours later, starting to continuously add the feed-batch solution of which the carbon source is glucose, sucrose, a mixed solution of glucose and fructose or a mixed solution of glucose and sucrose, and the inorganic salt contains sodium nitrate, calcium chloride and zinc sulfate. The yield of beta-polymalic acid is improved by 20-50% in comparison with the batch fermentation process. Through the invention, the original production method is changed, the yield of the beta-polymalic acid is obviously improved, the cost is lowered, and the process disclosed by the invention can be used for industrial large-scale fermentation production of beta-polymalic acid.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Water-based heavy-duty multifunction metal cleaning agent and preparation method thereof

The present invention relates to a water-based heavy-duty multifunction metal cleaning agent, wherein the components in the formula comprise a mixed inorganic salt, a surfactant, isononanoic acid, triethanolamine, a sodium salt having corrosion inhibition function, a corrosion inhibitor, polymalic acid, a defoamer 585, a preservative 1227 and the like. According to the present invention, the metal cleaning agent has characteristics of no toxicity, no harm, no pollution, no damage on human body, no corrosion on metal surface, no odor after long term use, no deterioration, extremely excellent cleaning function and extremely excellent rust resistance, especially and completely cleans thick and hard deposited carbon and stubborn stains, does not corrode various types of cast irons, carbon steels, copper, aluminum, zinc and other metals, and is suitable for ultrasonic machine cleaning, spraying machine cleaning, manual soaking rinsing and the like, wherein the natural anti-rust time of the cleaned work-piece achieves more than or equal to 50 days.

Owner:天津市澳路浦润滑科技股份有限公司

Soil conditioner capable of improving soil fertility and preparation method thereof

InactiveCN105418248AIncrease the granular structureImprove water holding capacitySuperphosphatesCalcareous fertilisersPhosphoric acidFerric-edta

The invention discloses a soil conditioner capable of improving the soil fertility. The soil conditioner is characterized by being prepared from the following raw materials in parts by weight: 6 to 8 parts of ferric sodium edelate, 10 to 15 parts of disodium hydrogen phosphate, 20 to 30 parts of limestone powder, 12 to 25 parts of bamboo powder, 5 to 15 parts of sodium octaborate tetrahydrate, 10 to 20 parts of sugar alcohols magnesium, 10 to 13 parts of crop straw powder, 11 to 14 parts of excrements of livestocks, 5 to 10 parts of potassium chloride, 4 to 8 parts of calcium powder, 1 to 2 parts of alkaloid, 5 to 10 parts of calcium superphosphate and 5 to 7 parts of polymalic acid ester. When the soil conditioner disclosed by the invention is used for planting plants, the usage of a bactericide can be reduced; the pH value of soil can be improved quickly; the organic content in the soil can be increased, and meanwhile, the bamboo powder change into humic acid under the action of ferric sodium edelate and sugar alcohols magnesium, and the granular structure of the soil can be continuously improved; the growth of garden plants can be promoted, and absorption of toxic metal to garden plants in the soil is improved.

Owner:江苏艺轩园林景观工程有限公司

Resin composition, molded product from resin composition and method for preparing resin composition

InactiveUS7645823B2Improve flame retardant performanceConductive materialOrganic conductorsCellulosePolybutylene

Owner:LERNER DAVID LITTENBERG KRUMHOLZ & MENTLIK LLP

Textile oxygen bleaching stabilizer

InactiveCN103696225APrevent deposits from stickingRough and hardFibre treatmentBleaching apparatusFiberPolymer science

The invention relates to a textile oxygen bleaching stabilizer, and belongs to the technical field of textile auxiliaries. The stabilizer comprises the following components by weight: 8-10 parts of tartaric acid, 2-5 parts of polymalic acid, 6-8 parts of polyacrylamide, 20-40 parts of a chelating agent, 2-5 parts of a surfactant and 60-80 parts of water. The textile oxygen bleaching stabilizer provided by the invention has strong pigment adsorption effect and good bleaching effect, and can effectively prevent deposition and adhesion of silicon scale on the fabric surface, and the bleached textile does not gain rough or hard hand feel; at the same time, the stabilizer can effectively control the decomposition rate of hydrogen peroxide, and effectively avoid local holes on fiber and damage to the fiber.

Owner:JIANGSU ZHONGXIN RESOURCES GRP

Application of polymalic acid or/and salt to preparation of fertilizer, product prepared from polymalic acid or/and salt and preparation method

The invention discloses application of polymalic acid or / and salt to preparation of fertilizer, a product prepared from polymalic acid or / and salt and a preparation method. Application ranges of the polymalic acid and salt are broadened by using the polymalic acid and salt to prepare fertilizer, and polymalic acid and salt can be absorbed by crops, cause no secondary contamination to soil, have higher affinity for numerous nutrient elements in fertilizer, can accelerate the formation of root systems of crops, reduce the application quantity of fertilizer, improve the utilization rate of fertilizer and the yield and property of crops, and have a broad application prospect.

Owner:SOUTHWEST UNIVERSITY

Method for preparing beta-polymalic acid of high purity

InactiveCN103103225AHigh puritySimple methodMicroorganism based processesFermentationPurification methodsFreeze-drying

The invention discloses a method for preparing beta-polymalic acid of high purity, belonging to the field of the preparation of high-molecular polymer. The method for preparing beta-polymalic acid of high purity comprises the main steps of activation of strains, cultivation of seeds, fermentation culture and separation and purification, and is characterized in that the separation and purification method comprises the following steps of removing of pulan polysaccharide, extraction of rough polymalic acid, removing of polysaccharide difficult to separate in a sample, centrifugal collection of precipitate, and freeze drying. Compared with the existing invention, the method has the beneficial effects that firstly a sample of high purity can be obtained through a simpler method, fewer devices are invested, and the production cost is lower; and secondly the obtained sample has high purity and can lay a certain foundation for subsequent application.

Owner:天津北洋百川生物技术有限公司

Method for increasing yield of aureobasidium pullulans synthesized polymalic acid

InactiveCN105624218AIncrease productionImprove permeabilityMicroorganism based processesFermentationTemperature controlPullulan

The invention discloses a method for increasing the yield of aureobasidium pullulans synthesized polymalic acid. The method comprises the following steps: culturing seeds, and performing fermental cultivation, namely, adding an active agent consisting of CTTE and DMSO in the fermentation process in different stages, controlling the temperature of the fermentation process by using a stage temperature control method, setting the cultivation temperature to 25-35 DEG C for 0-40 hours, adjusting the temperature to 20-30 DEG C after 40 hours, flowing 0.1-0.14% of CTTE at a logarithmic growth stage in the fermentation process, and flowing 0.06-0.1% of DMSO at the middle fermentation stage. By the adoption of the method, the yield of polymalic acid is increased by improving permeability of cell membranes, the fermentation period is also shortened, the yield of polymalic acid is generally increased by 40%, the production cost is reduced, and the production efficiency is improved.

Owner:天津北洋百川生物技术有限公司

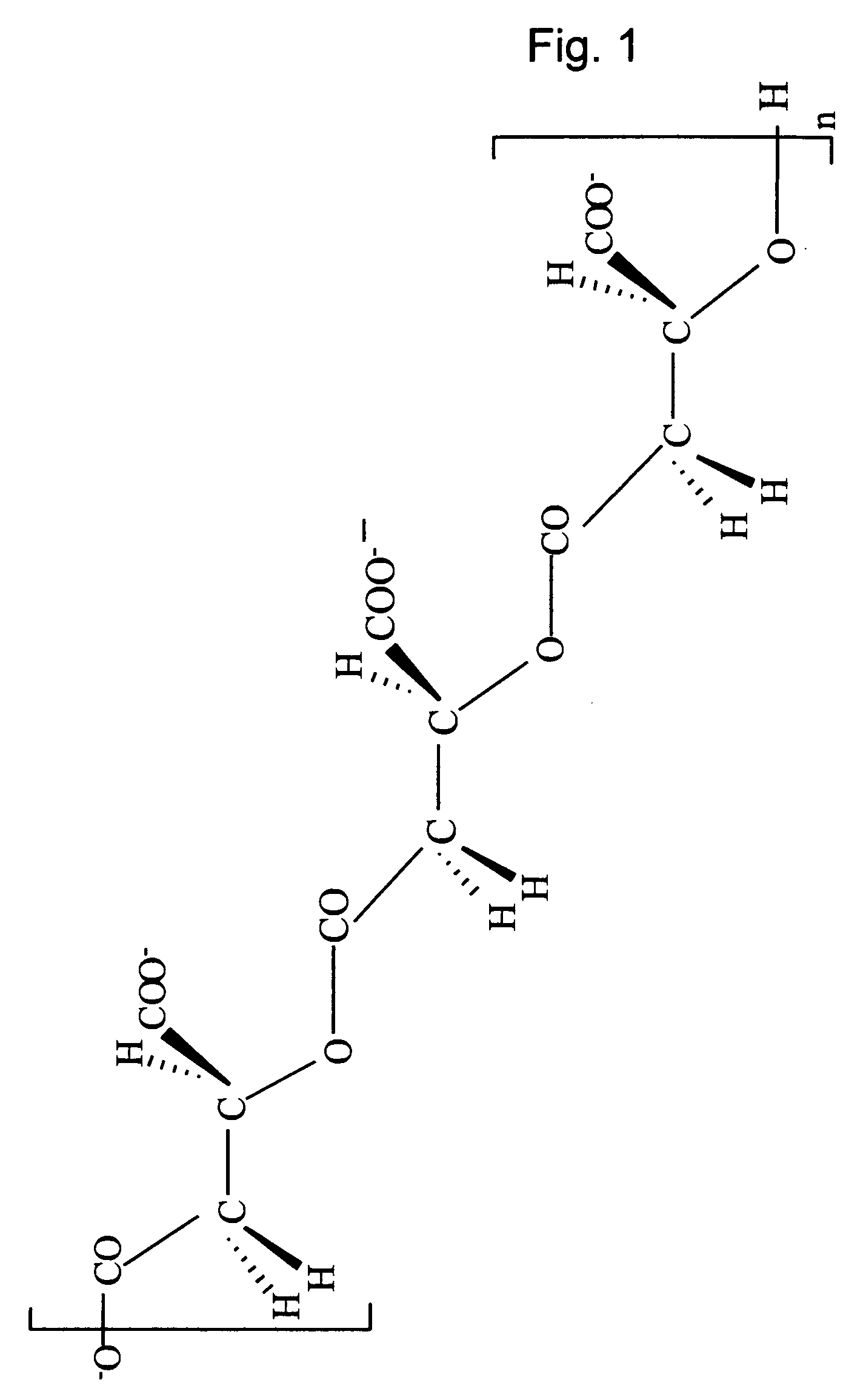

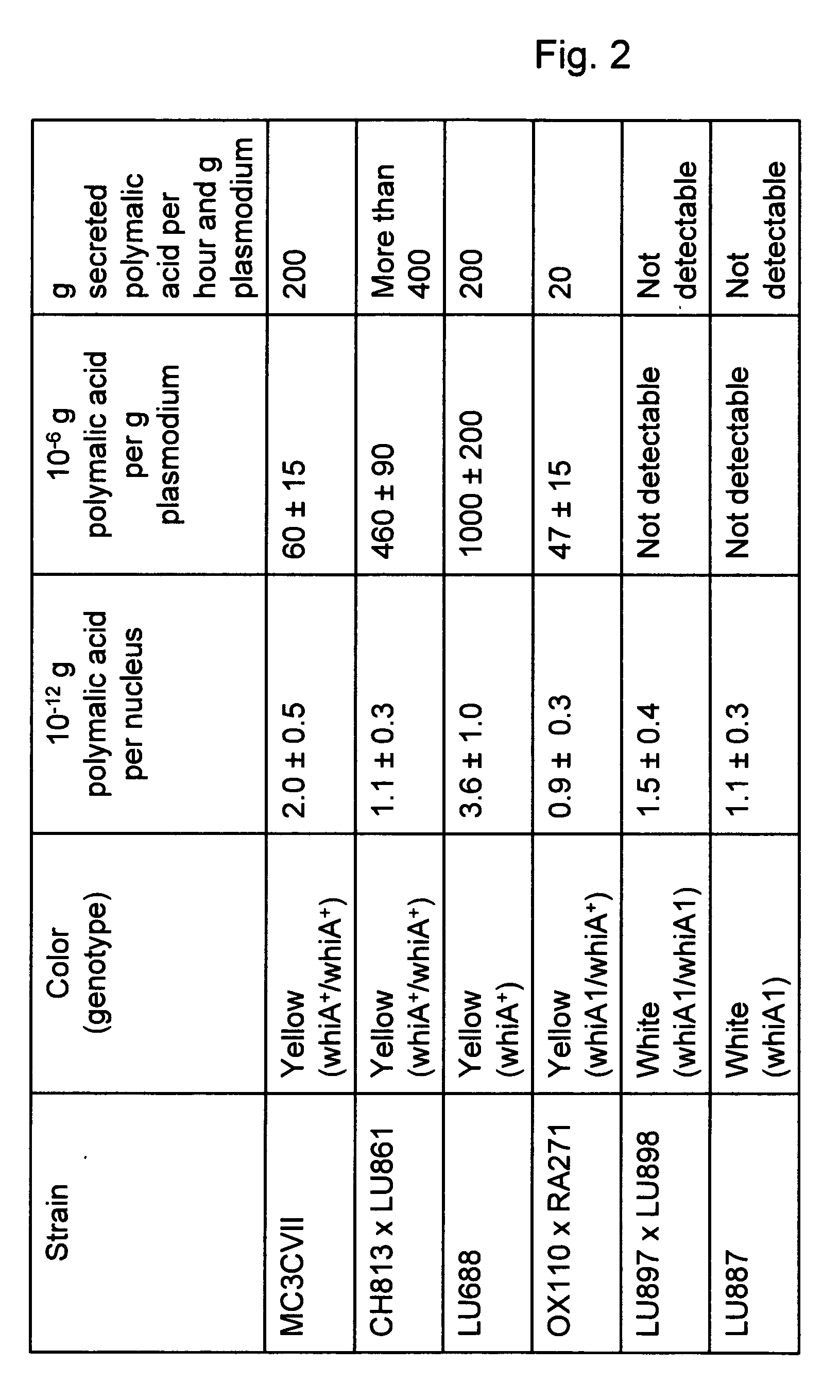

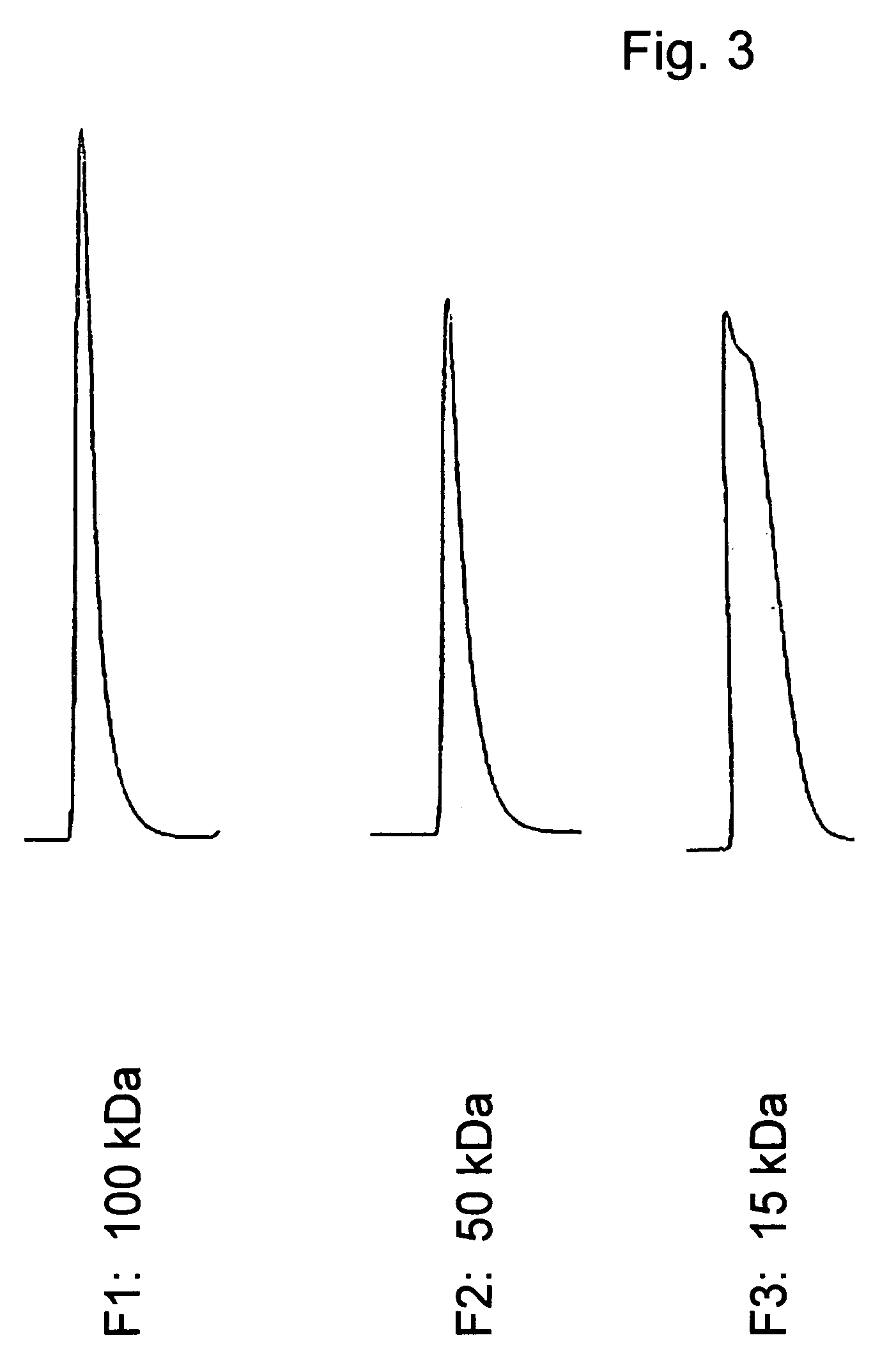

Production of long chain unbranched beta-poly(L-malic acid) by large scale Physarum cultivation and high-grade purification of the same

ActiveUS20100216199A1Increase production capacitySuppress foamFermentationChemical synthesisPolyester

The invention is a large-scale production and purification of beta-poly(L-malic acid), biodegradable natural polyester of L-malic acid of molecular weight 30,000 to 300,000 from plasmodia of the Physarum family, especially Physarum polycephalum. This will replace previous laborious and uncontrolled production by bioreactor methods of high productivity and quality, especially to obtain pure polymer of high molecular weight. The described 20-liter bioreactor method can be scaled up for industrial purpose at optimal production and minimum growth time to prevent degradation The invention includes the method of isolation of polymalic acid of 100,000 Mn (number-averaged molecular weight) from the culture broth optimized towards high yields of extremely pure polymalic acid. The non-hygroscopic, water and organic solvent-soluble polymer is endotoxin and agglutinin free and ready to use in chemical syntheses. Because of its high molecular weight and purity it offers a wide spectrum of applications in pharmacy and medicine.

Owner:HOLLER EGGEHARD

Resin composition, molded product, and method for producing the resin composition

A biodegradable resin composition comprising at least one biodegradable organic polymeric compound, a flame retardant additive containing a phosphorous compound, and a hydrolysis inhibitor capable of inhibiting the hydrolysis of at least one organic polymeric compound. As an aliphatic polyester resin, use is made of polylactic acid, polycaprolactone, polyhydroxybutyric acid, polyhydroxyvaleric acid, polyethylene succinate, polybutylene succinate, polybutylene adipate, polymalic acid, microbially synthesized polyester or a copolymer containing at least one of these. As a polysaccharide, use is made of cellulose, starch, chitin, chitosan, dextran, a derivative of any of these or a copolymer containing at least one of these.

Owner:SONY CORP

Method for producing polymalic acid through repeated fermentation that can be made into resting cells

InactiveCN102286555AReduce usageShorten seed production timeMicroorganism based processesFermentationContinuous fermentationConcentrations glucose

The invention relates to a method for producing polymalic acid through continuous fermentation which can be made into resting cells. The implementation steps are as follows: (1) preparation of slant strains; (2) preparation of seed liquid; (3) the above seed liquid is used for inoculation into Fermentation in a 5L aseptic fermenter; (4) Do not control the pH in the early stage of fermentation, and then continuously add NaOH to control the pH of the fermentation broth to 5.0-5.5 after the emergence of mycelium balls; (5) After 55-60 hours of fermentation, the When the glucose concentration is 8-10g / L, stop the fermentation, add fresh medium again, and repeat the fermentation; (6) Resting cell preparation; (7) Use the same fermentation method for resting cell fermentation; (8) Fermentation The solution was filtered with a hollow fiber membrane with a molecular weight cut-off of 6000Da, added an equal volume of absolute ethanol to precipitate, dried and weighed; the yield of polymalic acid was 50-57g / L. The method can effectively reduce the non-optimal economic stage in the fermentation process, and achieve the purposes of shortening the fermentation time, improving the utilization rate of equipment, and reducing the production cost of products.

Owner:天津实发中科百奥工业生物技术有限公司

Drug delivery of temozolomide for systemic based treatment of cancer

The present invention relates to methods of drug delivery for the treatment of a condition or disease, such as cancer. In one embodiment, the invention provides a method of preparing a multifunctional nanoconjugate of temozolomide (TMZ) by conjugating TMZ in its hydrazide form to a polymalic acid platform. In another embodiment, the polymalic acid platform is conjugated to a monoclonal antibody to transferrin receptor, a trileucine (LLL) moiety, and / or a polyethylene glycol (PEG) moiety. The present invention relates to methods of drug delivery for the treatment of a condition or disease, such as cancer. In one embodiment, the invention provides a method of preparing a multifunctional nanoconjugate of temozolomide (TMZ) by conjugating TMZ in its hydrazide form to a polymalic acid platform. In another embodiment, the polymalic acid platform is conjugated to a monoclonal antibody to transferrin receptor, a trileucine (LLL) moiety, and / or a polyethylene glycol (PEG) moiety.

Owner:CEDARS SINAI MEDICAL CENT

Preparation method of cigarette paper additive

The invention relates to a preparation method of cigarette paper additive, which belongs to the field of paper chemicals and comprises the following steps that: dispersing polymalic acid into water by 0.5 to 20mg / ml; dripping KOH solution into the water solution of the polymalic acid, and stirring the mixture; adding the water solution of metal salt into transparent solution and stirring, increasing the temperature to 40 to 60DEG C, maintaining the temperature for 1 to 2h, reducing the temperature of reaction solution to 20DEG C, slowly dripping the reaction solution into acetone while stirring, precipitating, filtering, and washing and drying a filter cake sequentially with acetone and ether; the ratio of the materials of the steps is respectively as follows: polymalic acid: KOH=100:4 to 40, m / m; KOH:metal salt=100:6 to 70, m / m; and the metal salts is one or more types of zinc acetate, zinc lactate, iron lactate, ferric citrate, germanium manganese acetate and tartaric acid. The preparation method of the cigarette paper additive has simple method and mild reaction conditions, and the prepared cigarette paper additive can be quickly dissolved in water.

Owner:MUDANJIANG HENGFENG PAPER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com