Water base reaction type multifunctional metal cleaning agent and preparation method thereof

A metal cleaning agent, multi-functional technology, applied in the field of metal cleaning agents, can solve the problems such as difficult to remove heavy oil stains on the metal surface, achieve excellent cleaning and anti-rust and anti-corrosion performance, high resistance to hard water, and low cleaning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

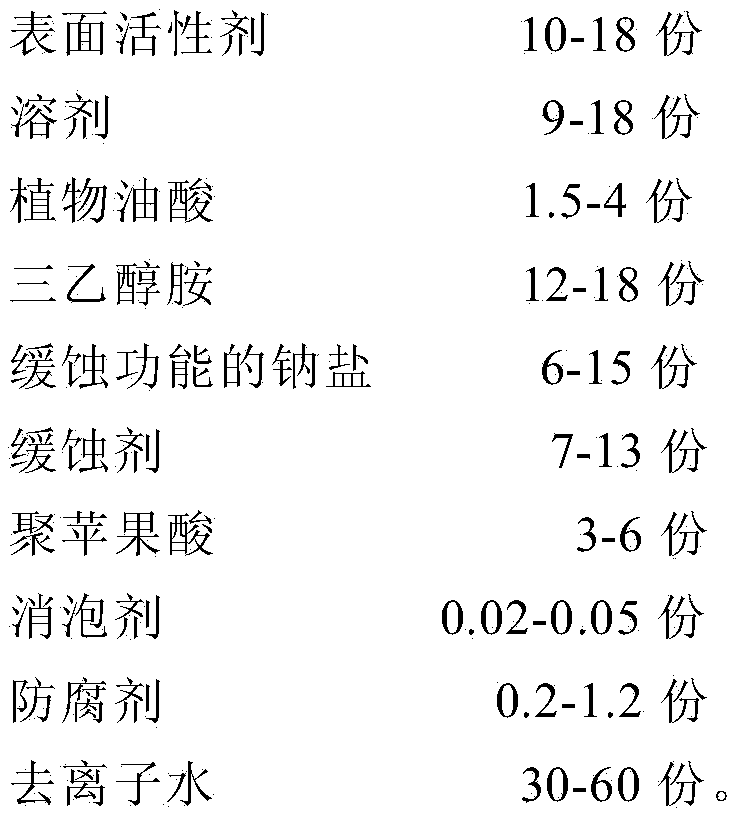

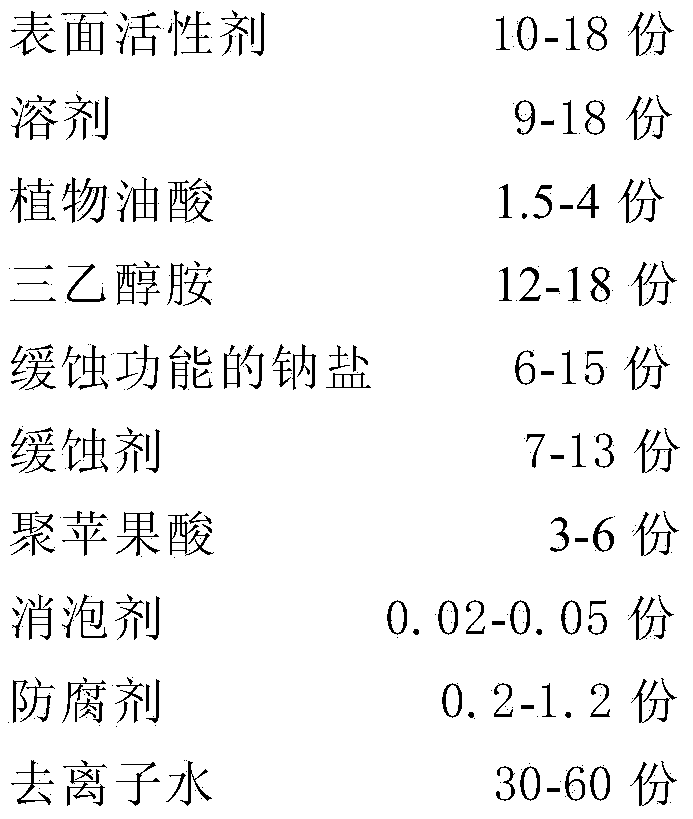

[0037] A water-based reactive multifunctional metal cleaning agent, its composition and weight (kg) are: surfactant 10 (including L644; OP-104; FMEE2); solvent 9 (including polyethylene glycol 5; propanol 2; diethylene glycol butyl ether 2); vegetable oleic acid 1.5; triethanolamine 12; corrosion inhibitor sodium salt 6 (among them sodium gluconate 2; sodium molybdate 2; sodium benzoate 2); corrosion inhibitor 7 ( Among them, borate 5; benzotriazole 2); polymalic acid 3; defoamer 5750.02; preservative 12270.2; deionized water 30.

[0038] The preparation method of this water-based reactive multifunctional metal cleaning agent, the steps of its preparation method are:

[0039] (1) Add 30 kg of deionized water to the reaction flask equipped with a reflux condenser, stirrer, thermometer and feeding funnel, raise the temperature to 65°C, add 44 kg of L6, 2 kg of OP-102 kg, and 2 kg of FMEE, heat up to 75°C, and stir for 10 Minutes to fully mix various surfactants.

[0040] (2) A...

Embodiment 2

[0046] A water-based reactive multifunctional metal cleaning agent, its composition and weight (kg) are: surfactant 18 [among them L648; OP-107; FMEE3]; solvent 18 (among them polyethylene glycol 8; propanol 5; diethylene glycol butyl ether 5); vegetable oleic acid 4; triethanolamine 18; corrosion inhibitor sodium salt 15 (among them sodium gluconate 5; sodium molybdate 5; sodium benzoate 5); corrosion inhibitor 13 ( Among them, borate 8; benzotriazole 5); sodium polymalate 6; defoamer 5750.05; preservative 12271.2; deionized water 60.

[0047] The preparation method of this water-based reactive multifunctional metal cleaning agent, the steps of its preparation method are:

[0048] (1) Add 60 kg of deionized water into the reaction flask equipped with a reflux condenser, agitator, thermometer and feeding funnel, heat up to 65°C, add 48 kg of L6, 107 kg of OP-107 kg, and 3 kg of FMEE, heat up to 75°C, and stir for 10 Minutes to fully mix various surfactants.

[0049] (2) Add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com