Preparation f beta-poly malic acid and salt thereof

A technology of polymalic acid and malate, which is applied in the field of fermentation engineering, can solve the problems of no large-scale application of β-polymalic acid, high production cost, and long fermentation cycle, so as to shorten the fermentation cycle, increase yield, Reduces the effect of feedback inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

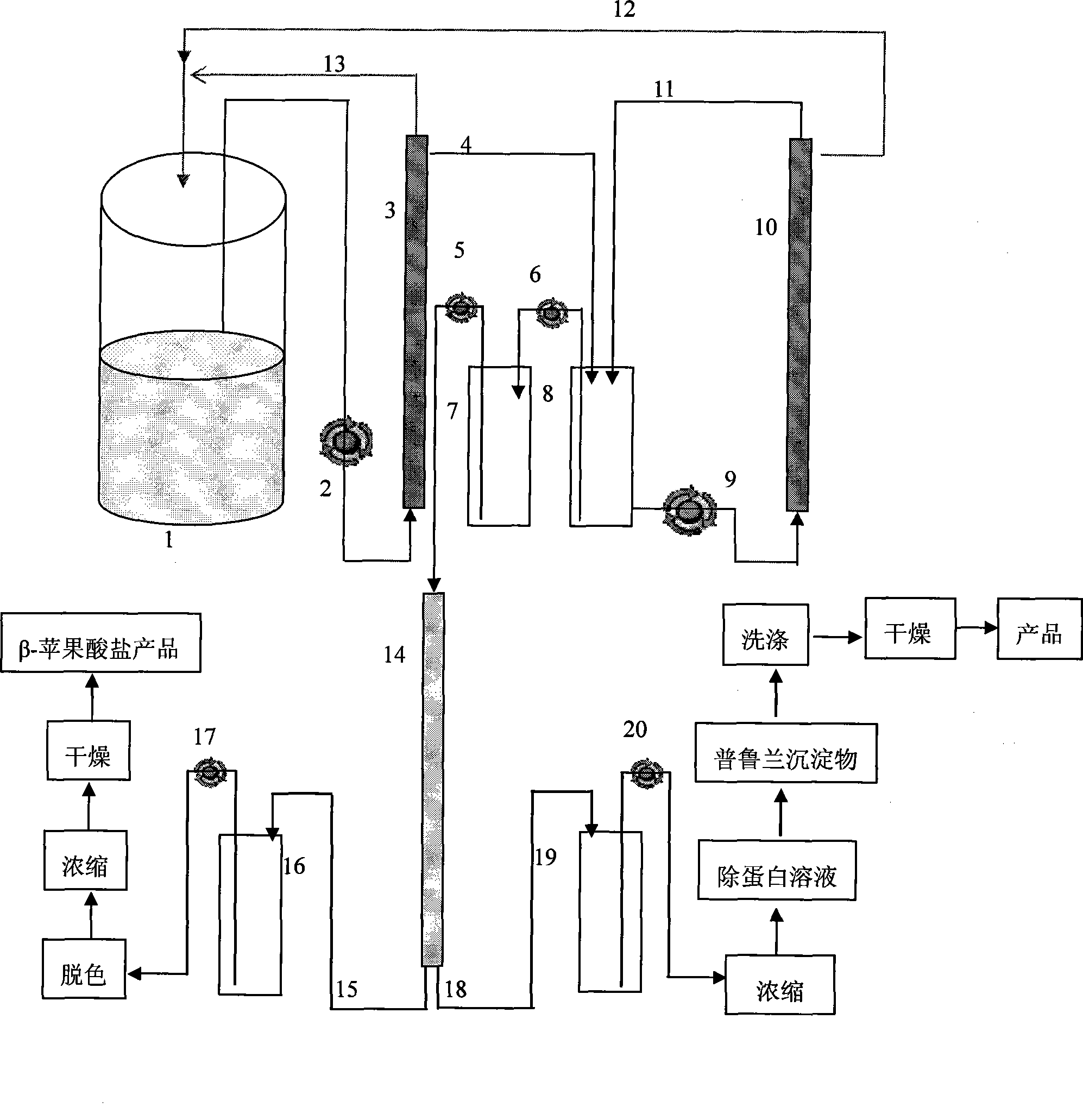

[0048] Prepare β-polymalic acid, β-polymalate and pullulan as follows:

[0049] The first step, culture medium preparation

[0050] ①Activation medium: potato dextrose medium, sterilized at 121°C for 15 minutes;

[0051] ② Preparation of fermentation medium (w / v): 10% glucose, 0.2% NaNO 3 , 0.01% KH 2 PO 4 , 0.02% MgSO 4 ·7H 2 O, 0.05% KCl, pH 4.0-4.5, sterilized at 121°C for 15 minutes.

[0052] The second step, the activation of bacteria

[0053] The strain of Aureobasidium pullulans ipe-1 stored at 4°C was transferred to the slant of the activation medium, and the activation culture was carried out at 25°C for 48 hours.

[0054] The third step, seed cultivation

[0055] Inoculate the activated seed culture on the slant into a 500ml Erlenmeyer flask containing 100ml of fermentation medium, and culture it with shaking at 25°C and 200r / min for 48 hours.

[0056] The fourth step, inoculation and fermentation

[0057] The culture obtained in the third step was inoculat...

Embodiment 2

[0063] Prepare β-polymalic acid, β-polymalate and pullulan as follows:

[0064] The first step, culture medium preparation

[0065] Same as Example 1

[0066] The second step, the activation of bacteria

[0067] Same as Example 1

[0068] The third step, seed cultivation

[0069] Same as Example 1

[0070] The fourth step, inoculation and fermentation

[0071] Inoculate the culture obtained in the third step into a 7L fermenter with 4L of fermentation medium at an inoculum size of 10%, with an initial pH of 4.0-4.5, a temperature of 25°C, an aeration rate of 0.5-2.5vvm, and a rotation speed of 600-700r / min, cultivated for 7 days, at this time, the bacteria were partially autolyzed, and the sugar consumption rate decreased. Finally, the content of β-polymalic acid in the fermented liquid was 8.7g / L, and the molecular weight was in a wide range of 5KDa-1000kDa.

[0072] Step 5 Preparation of β-polymalic acid and by-product pullulan

[0073] ① Centrifuge the β-polymalic ...

Embodiment 3

[0077] Prepare β-polymalic acid, β-polymalate and pullulan as follows:

[0078] The first step, culture medium preparation

[0079] Same as Example 1

[0080] The second step, the activation of bacteria

[0081] Same as Example 1

[0082] The third step, seed cultivation

[0083] Same as Example 1

[0084] The fourth step, inoculation and fermentation

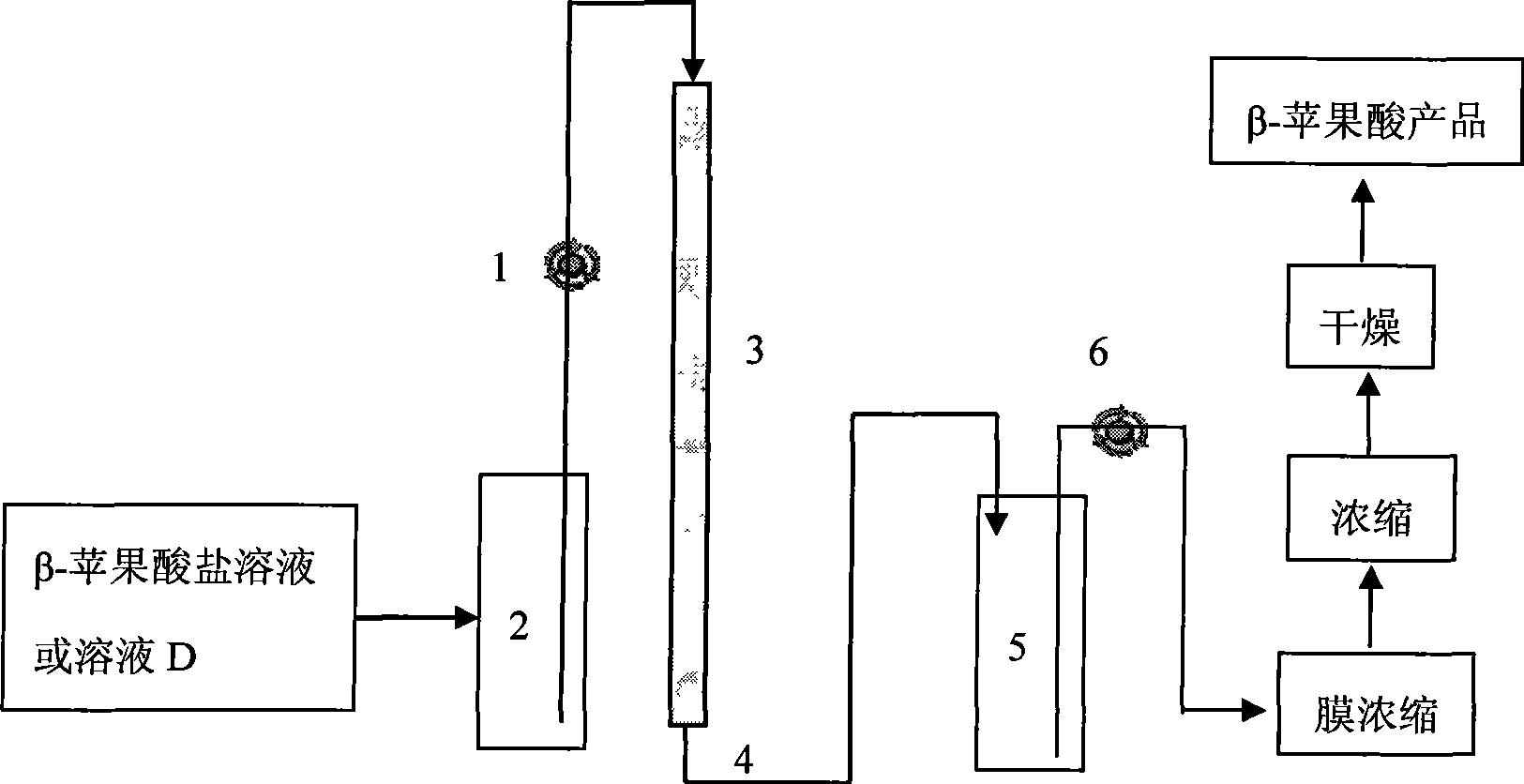

[0085]Inoculate the culture obtained in the third step into the fermentation medium, pH 4.0-4.5, temperature 25°C, air flow 0.5-2.5vvm, rotation speed 600-700r / min, cultivate for 72h, start pump 1 to make the cells pass through Membrane module A (see attached picture, membrane pore size 0.8μm) is backflowed into the fermenter, the pressure difference is 0.05-0.1mpa, the permeate 1 is concentrated by membrane module B (see attached picture, molecular weight cut-off 100KDa), and the concentrated solution is returned to the storage tank 1. The permeate 2 is returned to the fermenter. Control the content of β-polymalic acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com