Wrapped yarn based fabric for flame-retarding clothes and production method thereof

A technology of wrapping yarn and fabric, which is applied in the field of textile and garment fabrics, can solve the problems of incompatibility of flame retardancy and comfort, and achieve the effects of good flame retardancy, no reduction in flame retardancy, and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

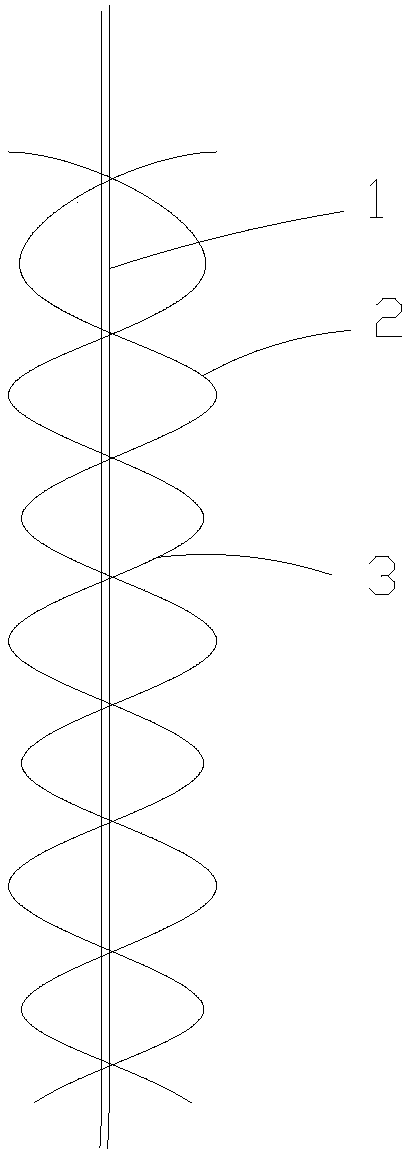

[0026] Example 1. A flame-retardant clothing fabric based on wrapping yarn, the fabric structure is jacquard, which is interwoven with weft yarn and warp yarn made of flame-retardant polyester yarn; figure 1 As shown, the weft yarn is composed of a core yarn 1, a first wrapping yarn 2 and a second wrapping yarn 3, the first wrapping yarn 2 and the second wrapping yarn 3 are spirally wrapped around the core yarn 1 in opposite directions, and the material of the core yarn 1 is Viscose fiber, the material of the first outer yarn 2 and the second outer yarn 3 is flame-retardant polyester yarn, and the linear densities of the first outer yarn 2 and the second outer yarn 3 are 83.3dtex and 166.6dtex respectively; the linear density of the warp yarn is 83.3dtex, the twist is 600T / m.

[0027] The fineness of the core yarn 1 is 20S / 2, the twist of the first wrapping yarn 2 is 1000T / m, and the twist direction is Z direction, the twist of the second wrapping yarn 3 is 800T / m, and the tw...

Embodiment 2

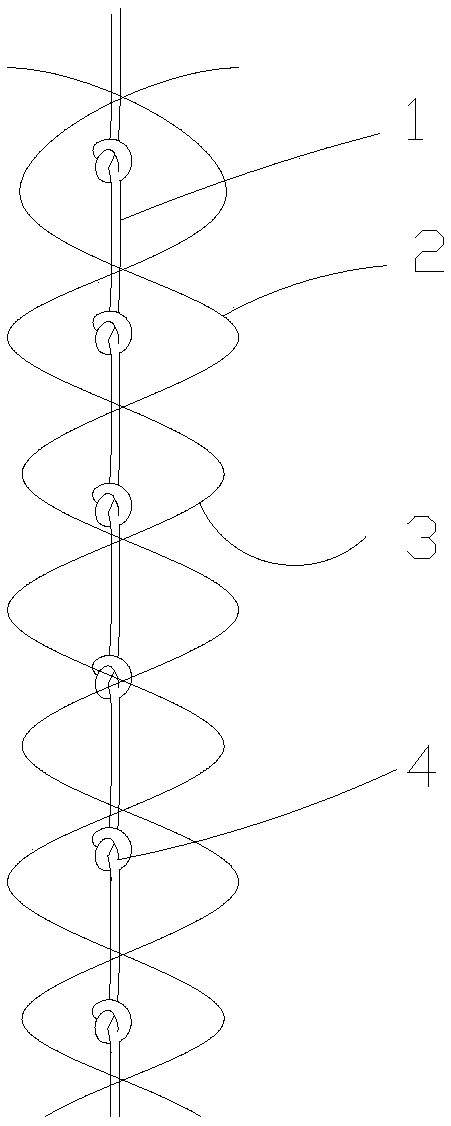

[0033] Example 2. A flame-retardant clothing fabric based on wrapping yarn, the fabric structure is jacquard, which is interwoven with weft yarn and warp yarn made of flame-retardant polyester yarn; figure 2 As shown, the weft yarn is composed of a core yarn 1, a first wrapping yarn 2 and a second wrapping yarn 3, the first wrapping yarn 2 and the second wrapping yarn 3 are spirally wrapped around the core yarn 1 in opposite directions, and the material of the core yarn 1 is Viscose fiber, the material of the first outer yarn 2 and the second outer yarn 3 is flame-retardant polyester yarn, and the linear densities of the first outer yarn 2 and the second outer yarn 3 are 83.3dtex and 166.6dtex respectively; the linear density of the warp yarn is 83.3dtex, the twist is 600T / m.

[0034] The fineness of the core yarn 1 is 40S / 2, the twist of the first wrapping yarn 2 is 1200T / m, and the twist direction is Z direction, the twist of the second wrapping yarn 3 is 1000T / m, and the ...

Embodiment 3

[0041] Example 3. A flame-retardant clothing fabric based on wrapped yarn, the fabric structure is jacquard, such as figure 1 As shown, the weft yarn and the warp yarn made of flame-retardant polyester yarn are interwoven; the weft yarn is composed of the core yarn 1, the first outer yarn 2 and the second outer yarn 3, and the first outer yarn 2 and the second outer yarn 3 are in opposite directions. Spiral wrapping outside the core yarn 1, the material of the core yarn 1 is viscose fiber, the materials of the first outer yarn 2 and the second outer yarn 3 are flame-retardant polyester yarns, and the threads of the first outer yarn 2 and the second outer yarn 3 The densities are 83.3dtex and 166.6dtex respectively; the linear density of the warp is 83.3dtex, and the twist is 600T / m.

[0042]The fineness of the core yarn 1 is 60S, the twist of the first wrapping yarn 2 is 1400T / m, and the twist is in the S direction, and the twist of the second wrapping yarn 3 is 1200T / m, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com