Dome-screen simulation cabin structure and preparation method thereof

A technology for simulating cabins and domes, which is applied in simulators, simulating devices for space navigation conditions, space navigation equipment, etc., can solve the problems of small number of projection equipment, high cost, poor fixation effect, etc., and achieves short development cycle, Low-cost, easy-to-fix effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

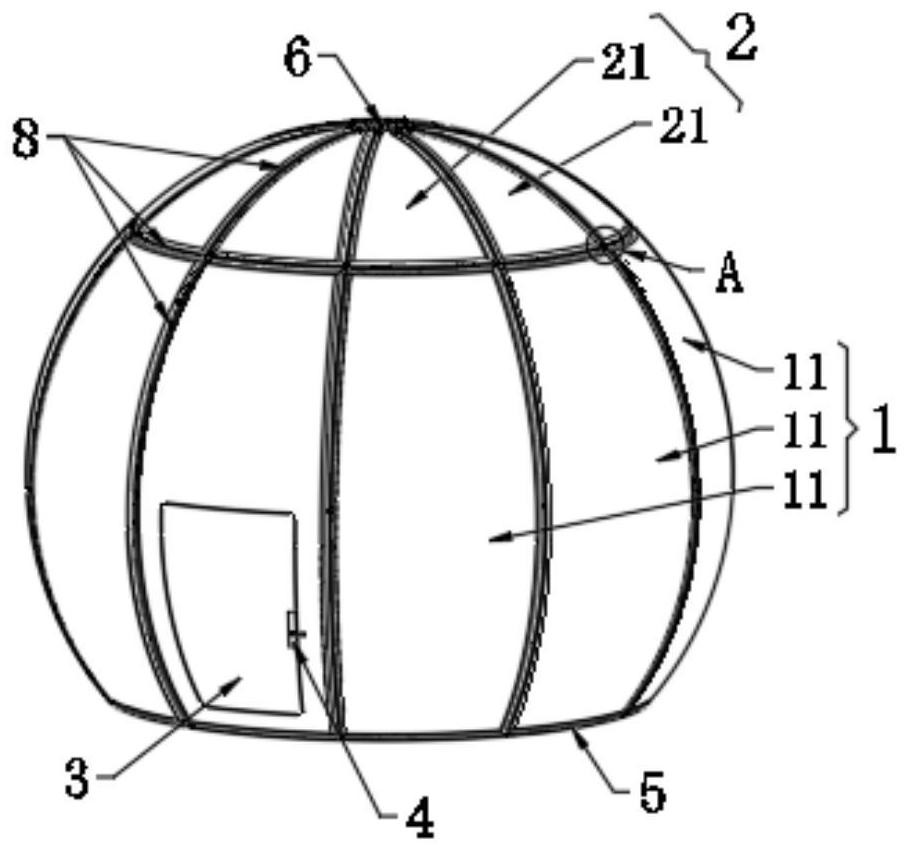

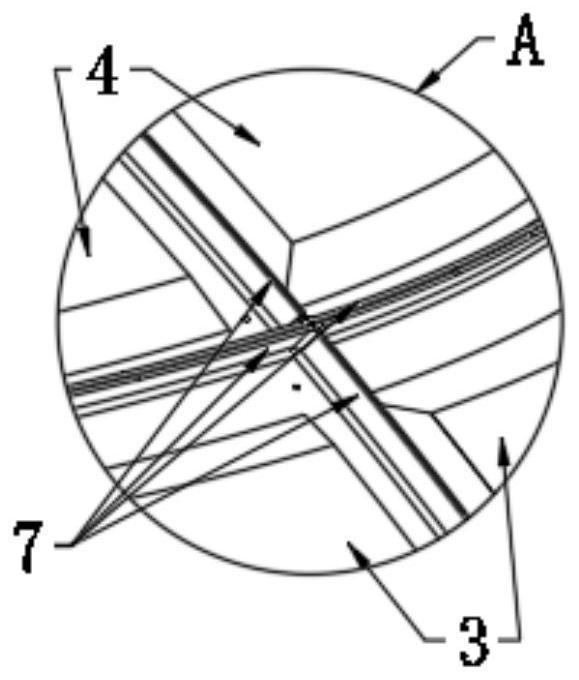

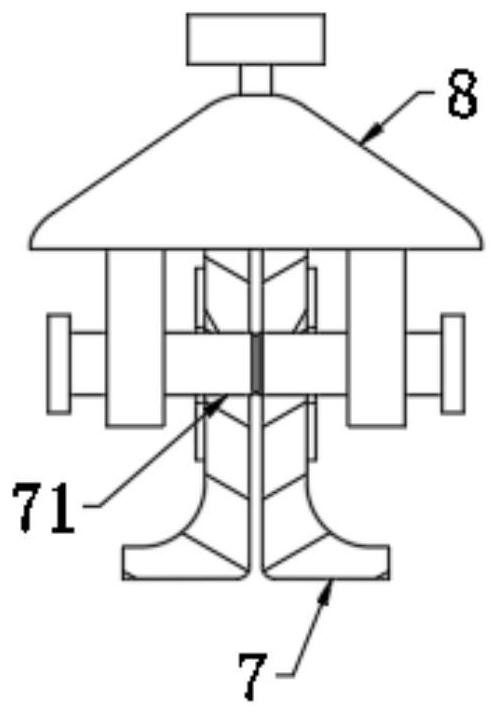

[0031] refer to Figure 1-6 In this embodiment, a dome simulation cabin structure is proposed, including a belly compartment 1 and a top compartment 2. The belly compartment 1 includes a plurality of webs 11 distributed in a circle, and the top compartment 2 includes a plurality of webs 11 distributed in a circle. The top plate 21, the two sides and the top of the web 11 and the periphery of the top plate 21 are fixed with flanged plates 7, and the two adjacent webs 11, the two adjacent top plates 21, the top plate 21 and the web 11 are close to each other One side of each side is connected together by corresponding two flanged plates 7, and two assembly holes 71 are opened on the flanged plates 7, and two fastening mechanisms are provided on the two flanged plates 7 that are fitted together. 8. The fastening mechanism 8 includes a trapezoidal box 81. Two rectangular blocks 84 are slidably installed in the trapezoidal box 81. Round rods 85 are arranged on the two rectangular b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com