Preparation method of safe diesel oil with flame-retardant explosion suppression function

A diesel and safe technology, applied in the direction of fuel, petroleum industry, fuel additives, etc., can solve the problems of poor storage stability, poor engine adaptability, no promotion and application, etc., and achieve clear and transparent appearance, simple and easy operation, safe and reliable efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

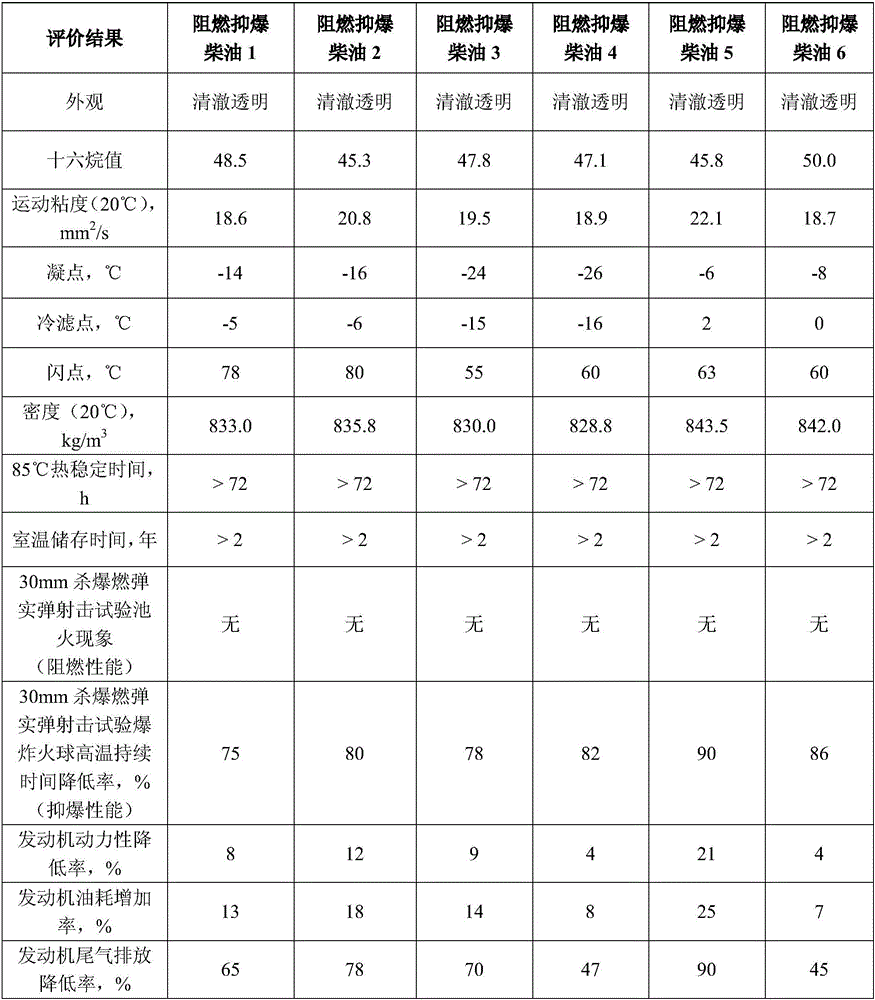

[0028]With No.-10 military diesel as base fuel, add 0.2wt% polymethyl methacrylate, 6wt% polyoxyethylene sorbitan monolaurate, 6wt% n-hexanol, 0.1wt% cetane number improver , 0.02wt% lubricity improver, 0.003wt% low temperature fluidity improver, 0.1wt% metal corrosion inhibitor, 0.05wt% rubber swelling inhibitor, 0.02wt% diesel detergent dispersant, 0.002wt% antioxidant, 0.04 Wt% flame retardant and 10wt% deionized water were blended at a blending temperature of 40°C and a stirring speed of 60r / min for 30 minutes to obtain a flame-retardant and explosion-suppressed diesel oil 1. The evaluation results are shown in Table 2.

Embodiment 2

[0030] With No.-10 military diesel as base fuel, add 0.4wt% polybutadiene, 6.5wt% oleic acid monoethanolamine soap, 6.5wt% n-hexanol, 0.1wt% cetane number improver, 0.015wt% lubricity Improver, 0.003wt% low temperature fluidity improver, 0.05wt% metal corrosion inhibitor, 0.05wt% rubber swelling inhibitor, 0.02wt% diesel detergent dispersant, 0.002wt% antioxidant, 0.04wt% flame retardant and 15wt% deionized water, at a blending temperature of 50°C and a stirring speed of 100r / min, and blending for 30 minutes, a flame-retardant and explosion-suppressed diesel oil 2 was obtained. The evaluation results are shown in Table 2.

Embodiment 3

[0032] With No.-20 automotive diesel oil as base fuel, add 3wt% polyisoprene, 10wt% cetyltrimethylammonium chloride, 5wt% n-octanol, 0.15wt% cetane number improver, 0.01wt% lubricity improver, 0.008wt% low temperature fluidity improver, 0.05wt% metal corrosion inhibitor, 0.03wt% rubber swelling inhibitor, 0.02wt% diesel detergent dispersant, 0.002wt% antioxidant, 0.06wt% % flame retardant and 10wt% deionized water, at a blending temperature of 60°C, a stirring speed of 200r / min, and blending for 60min, a flame-retardant and explosion-suppressed diesel oil 3 was obtained. The evaluation results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com