Patents

Literature

94results about "Cell temperature regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

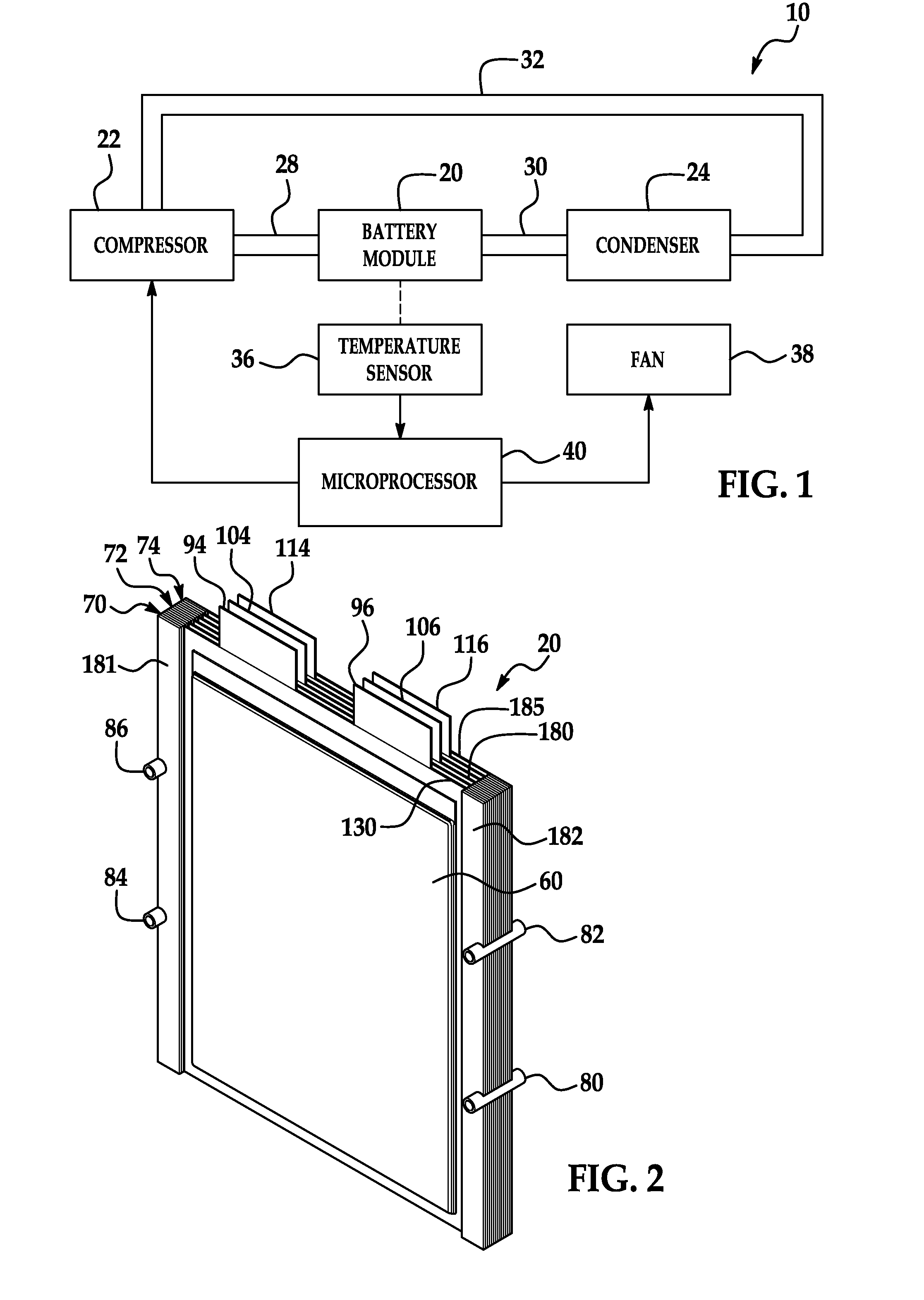

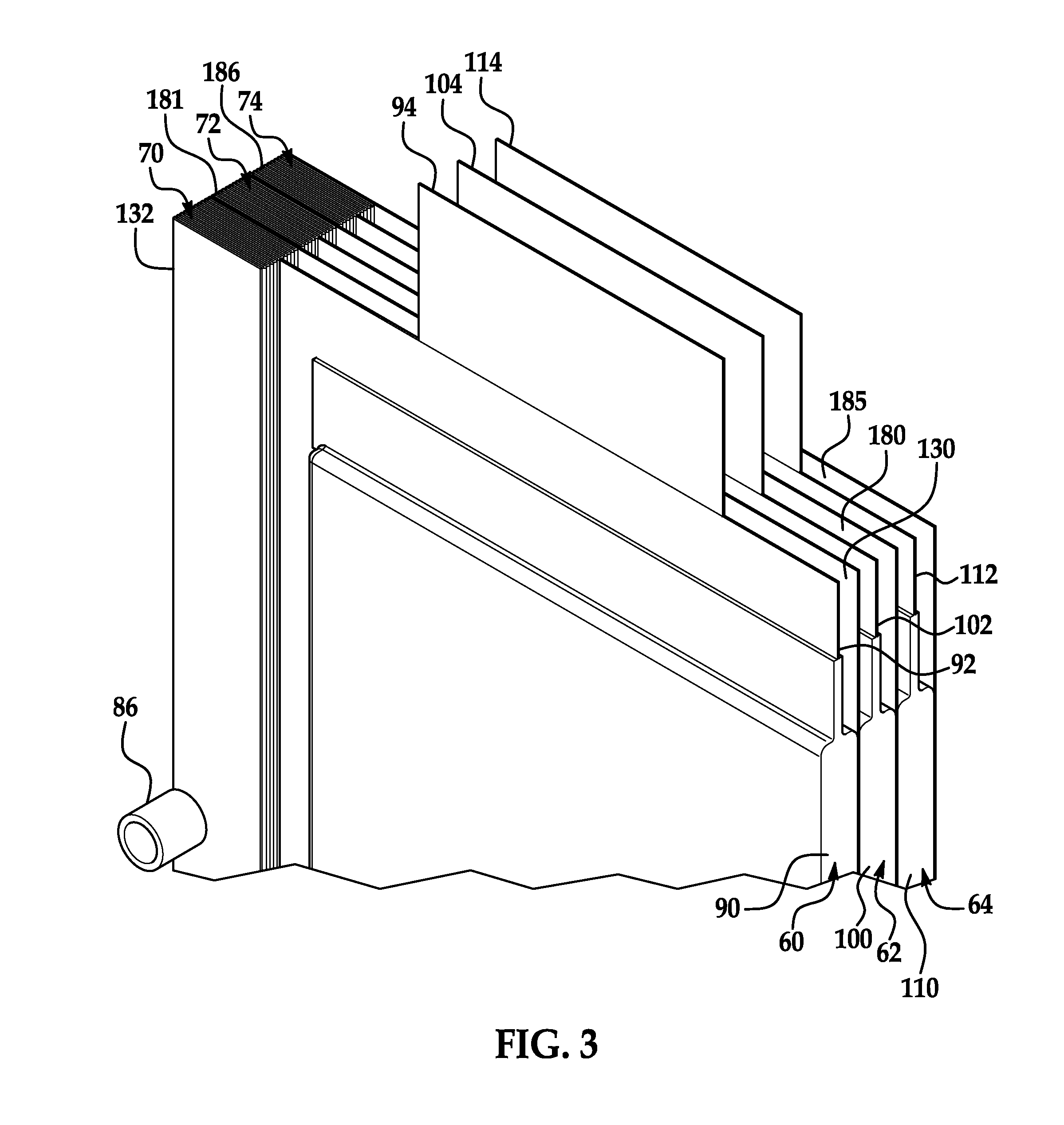

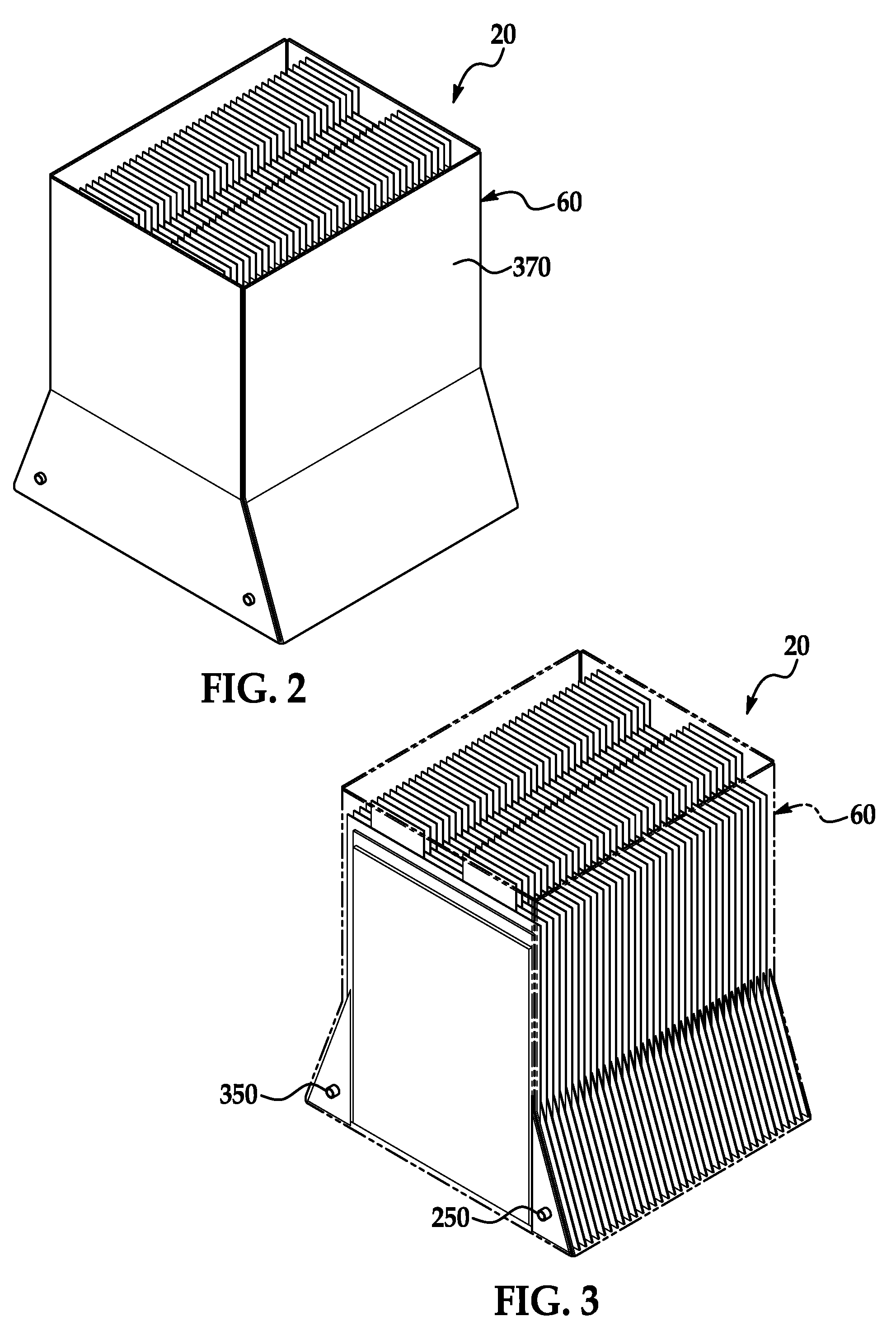

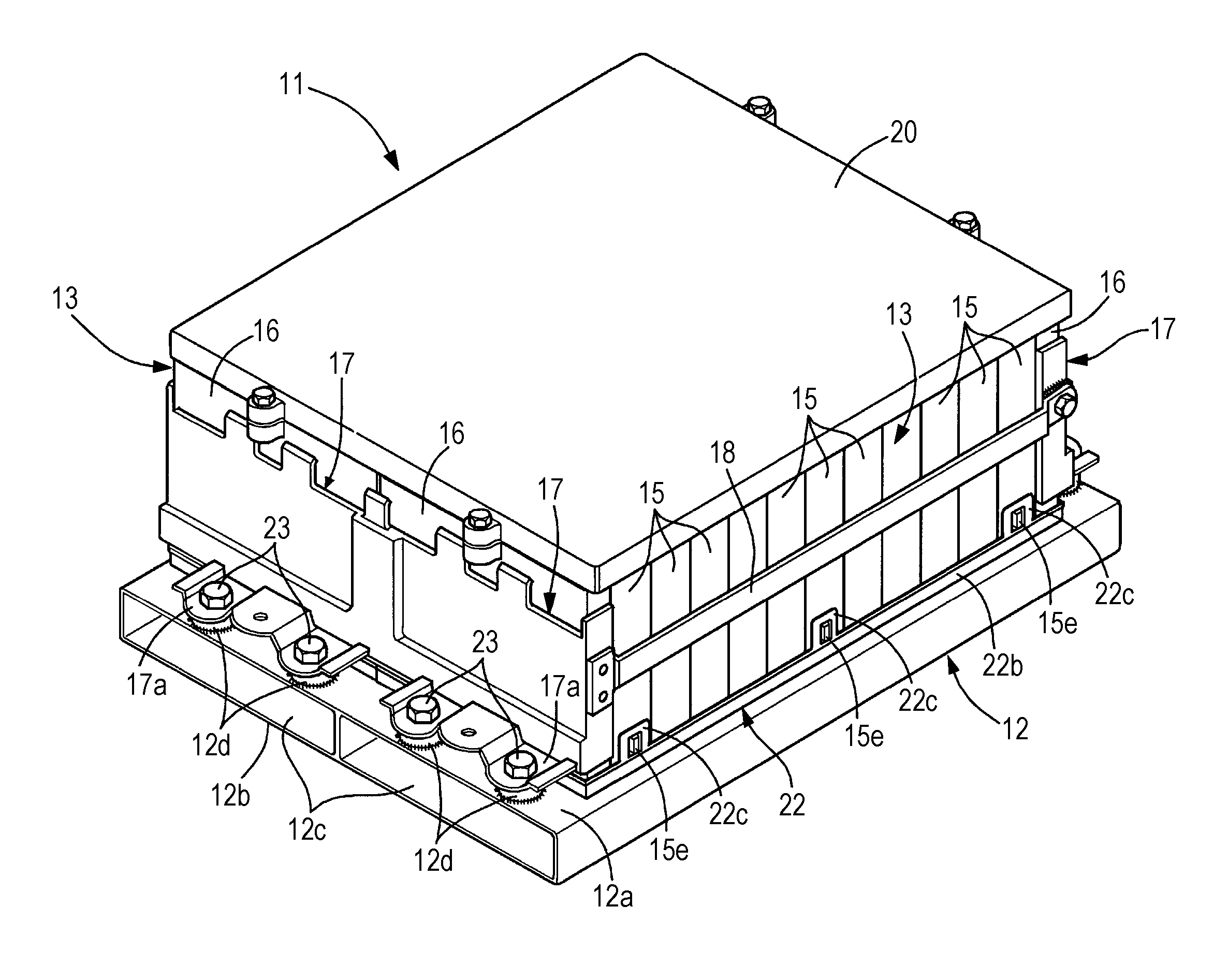

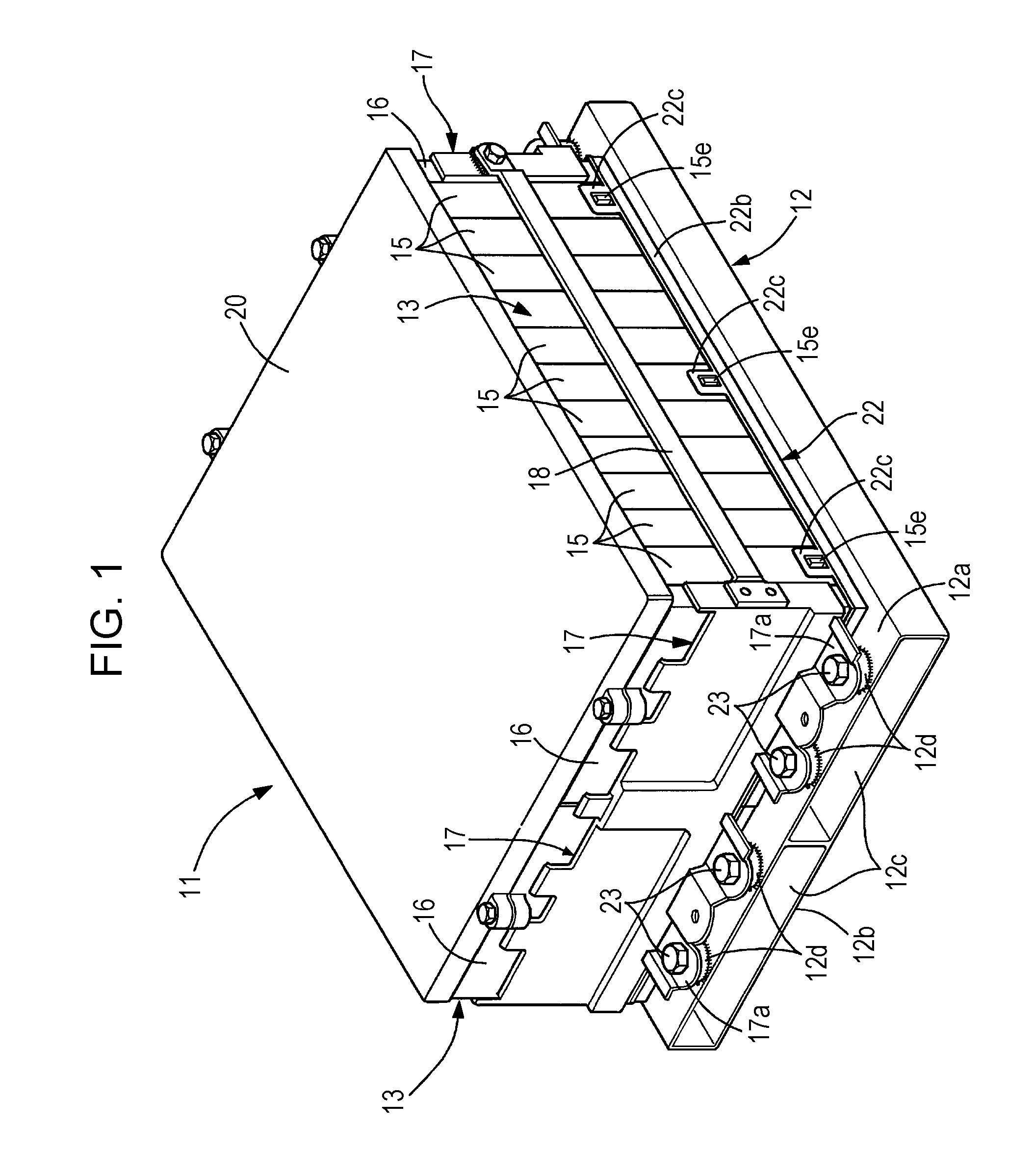

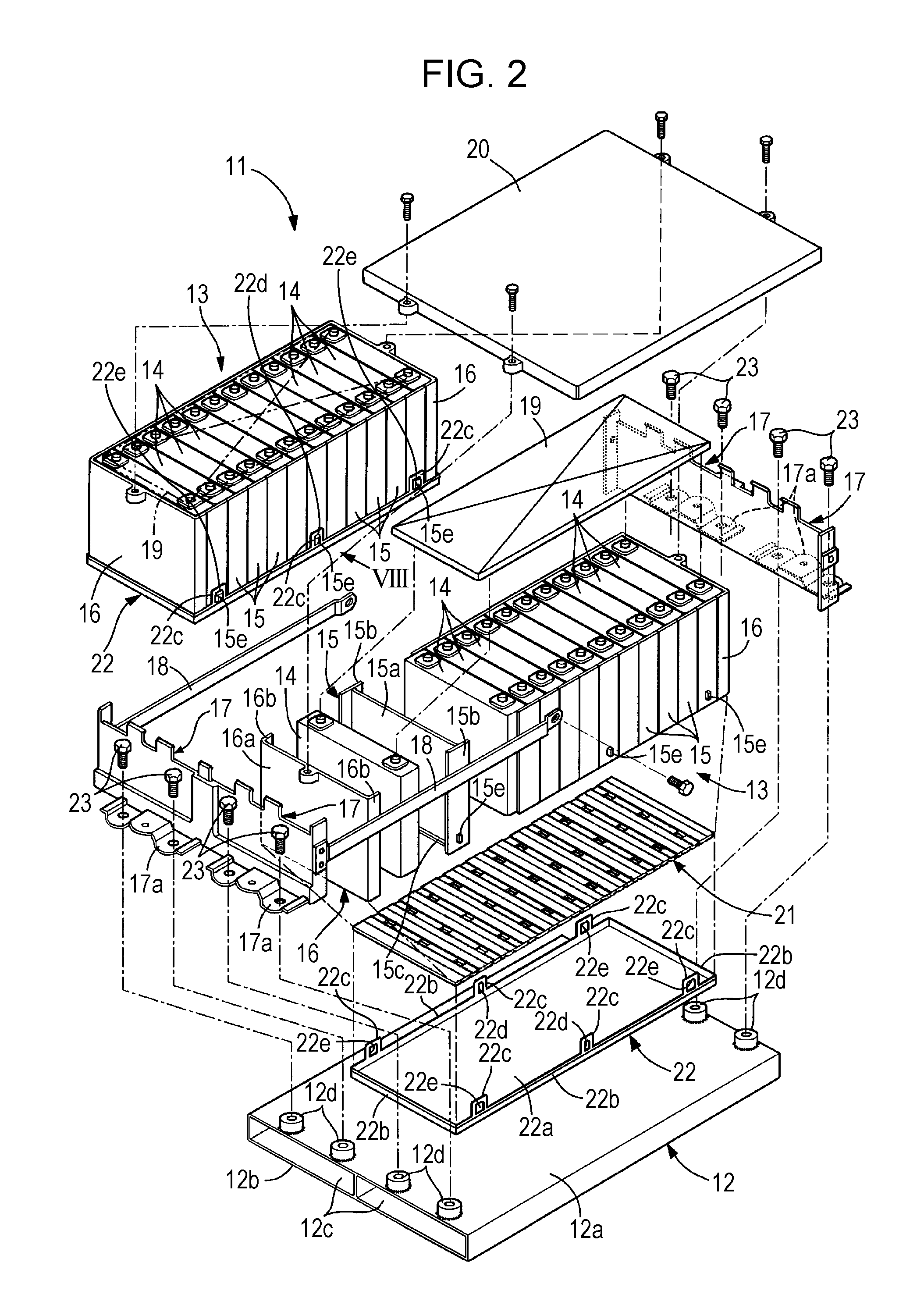

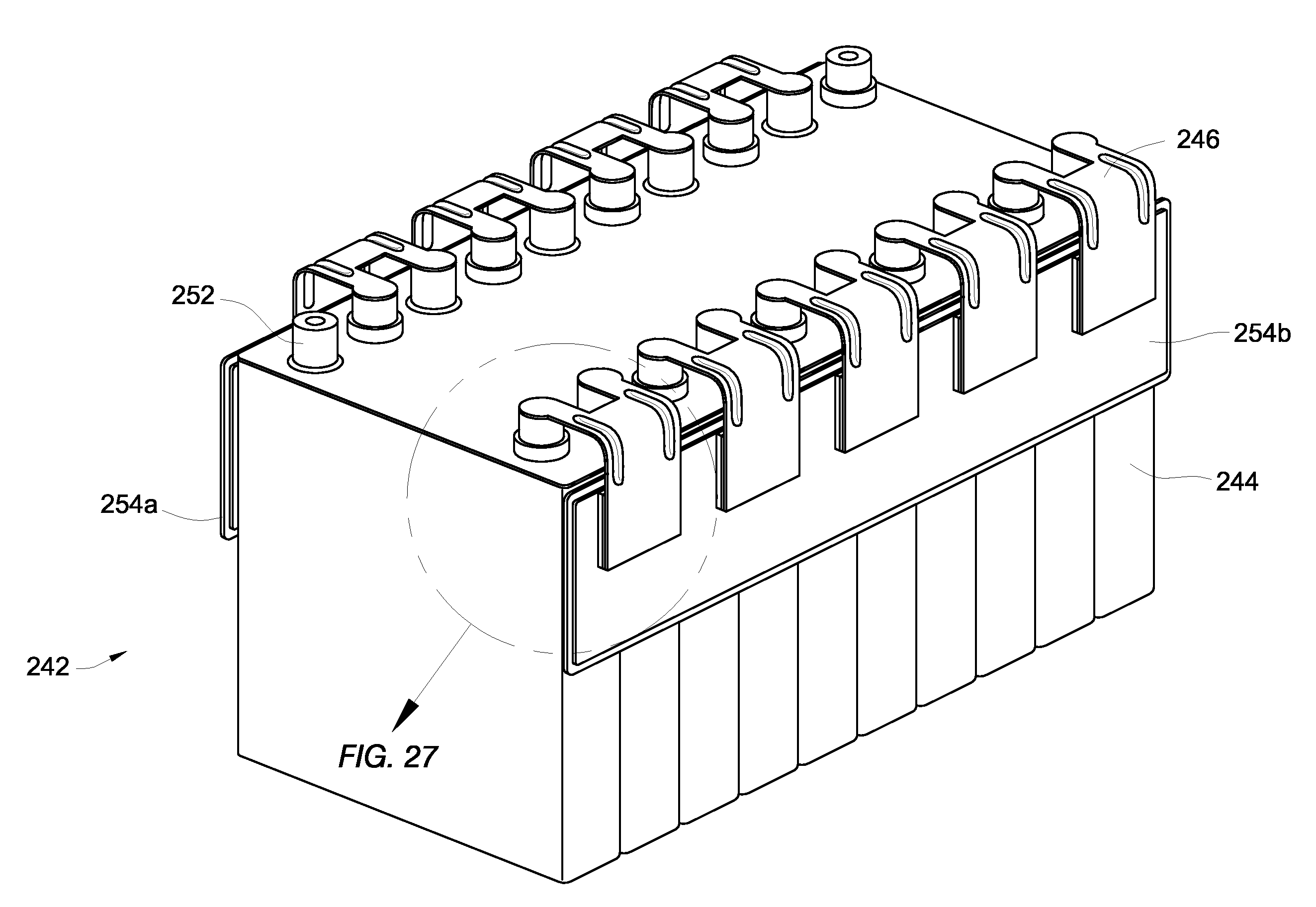

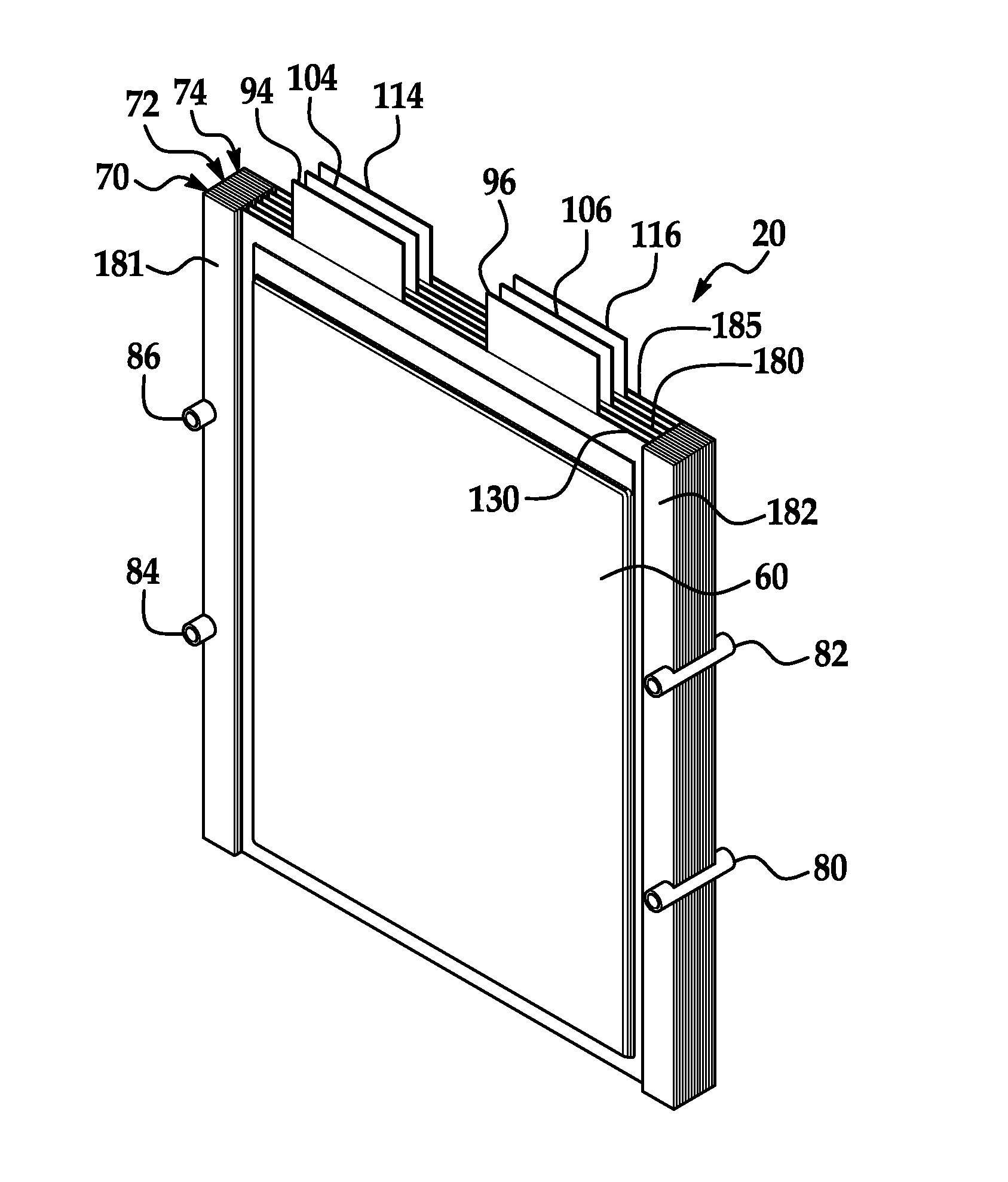

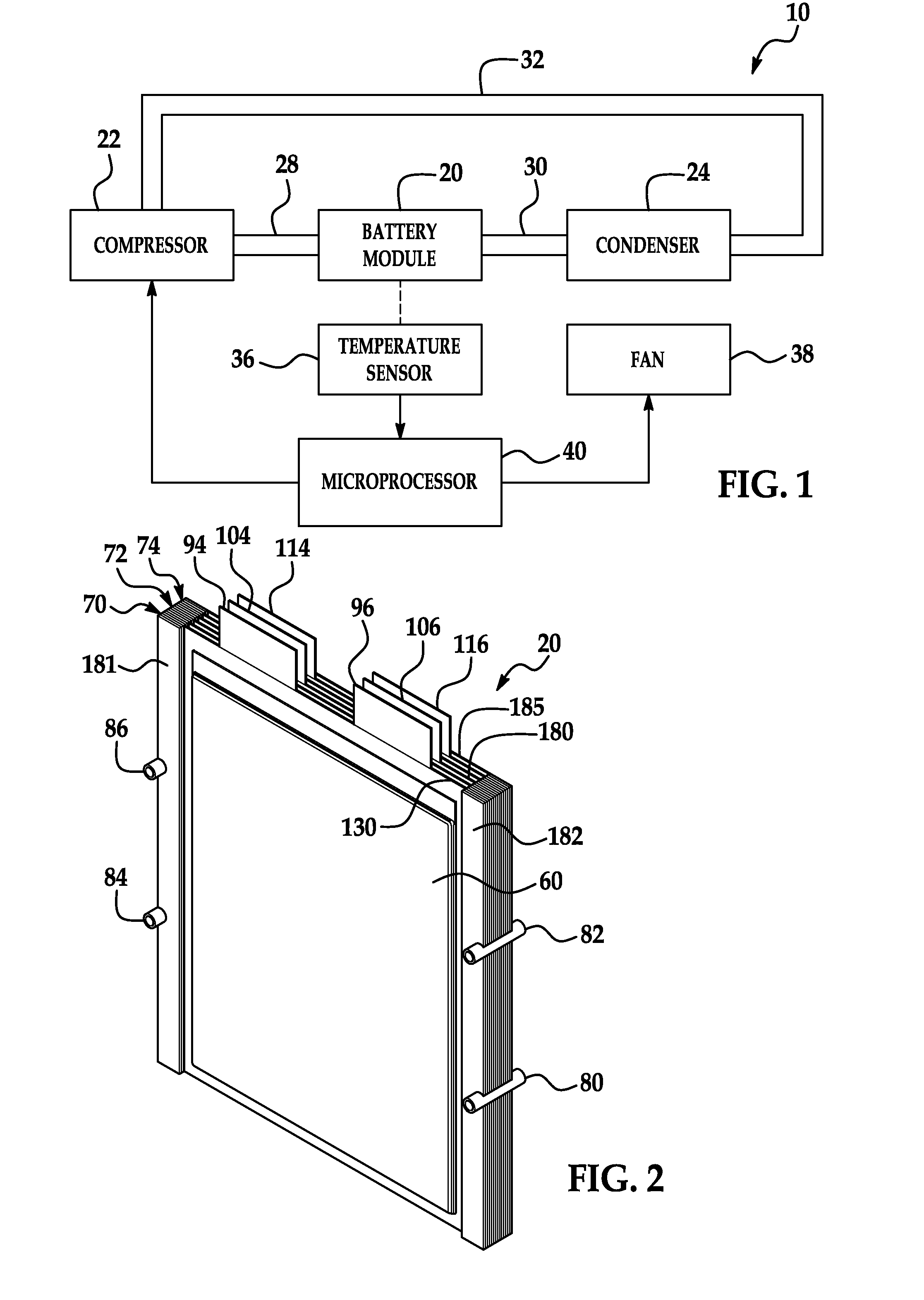

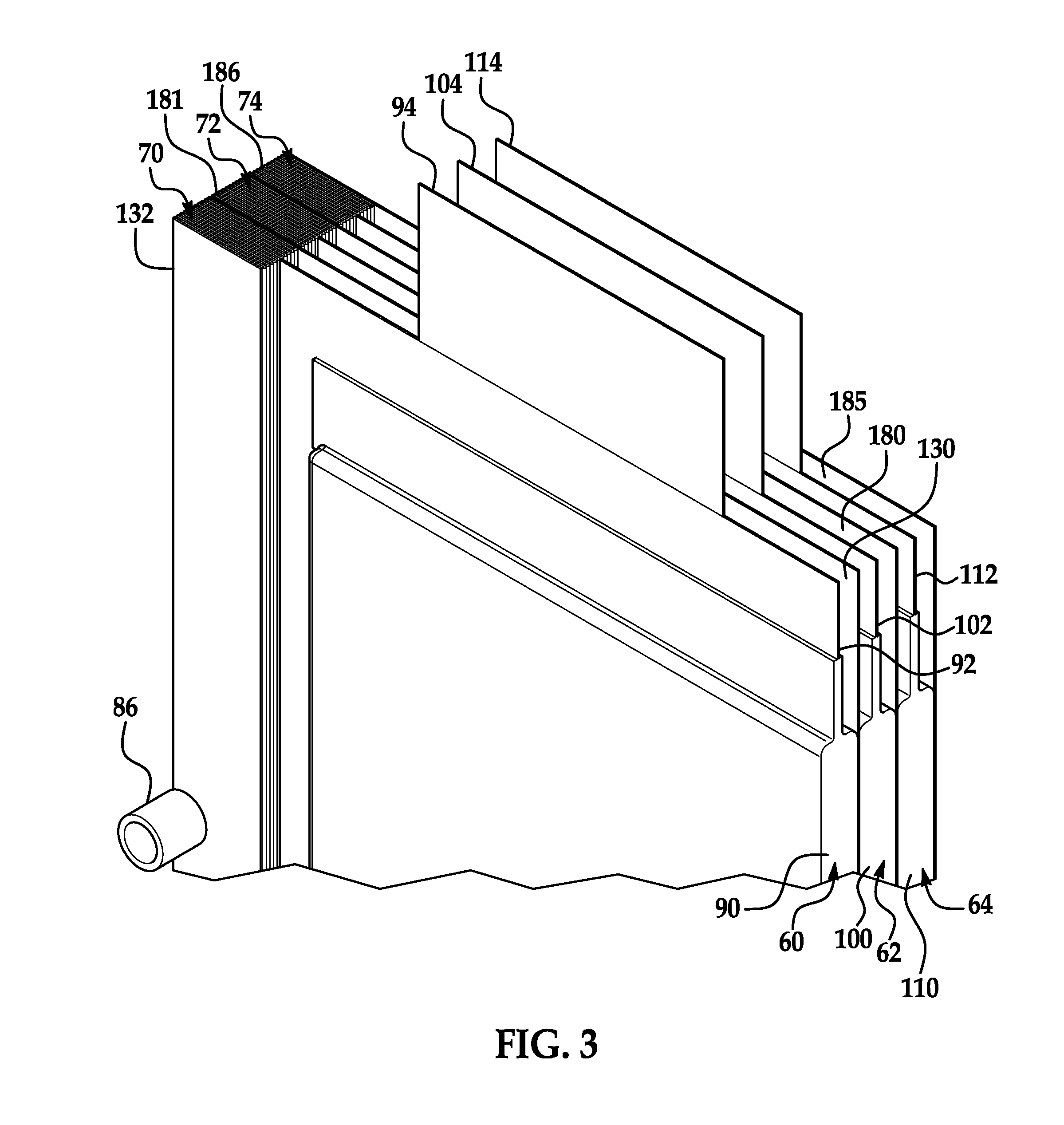

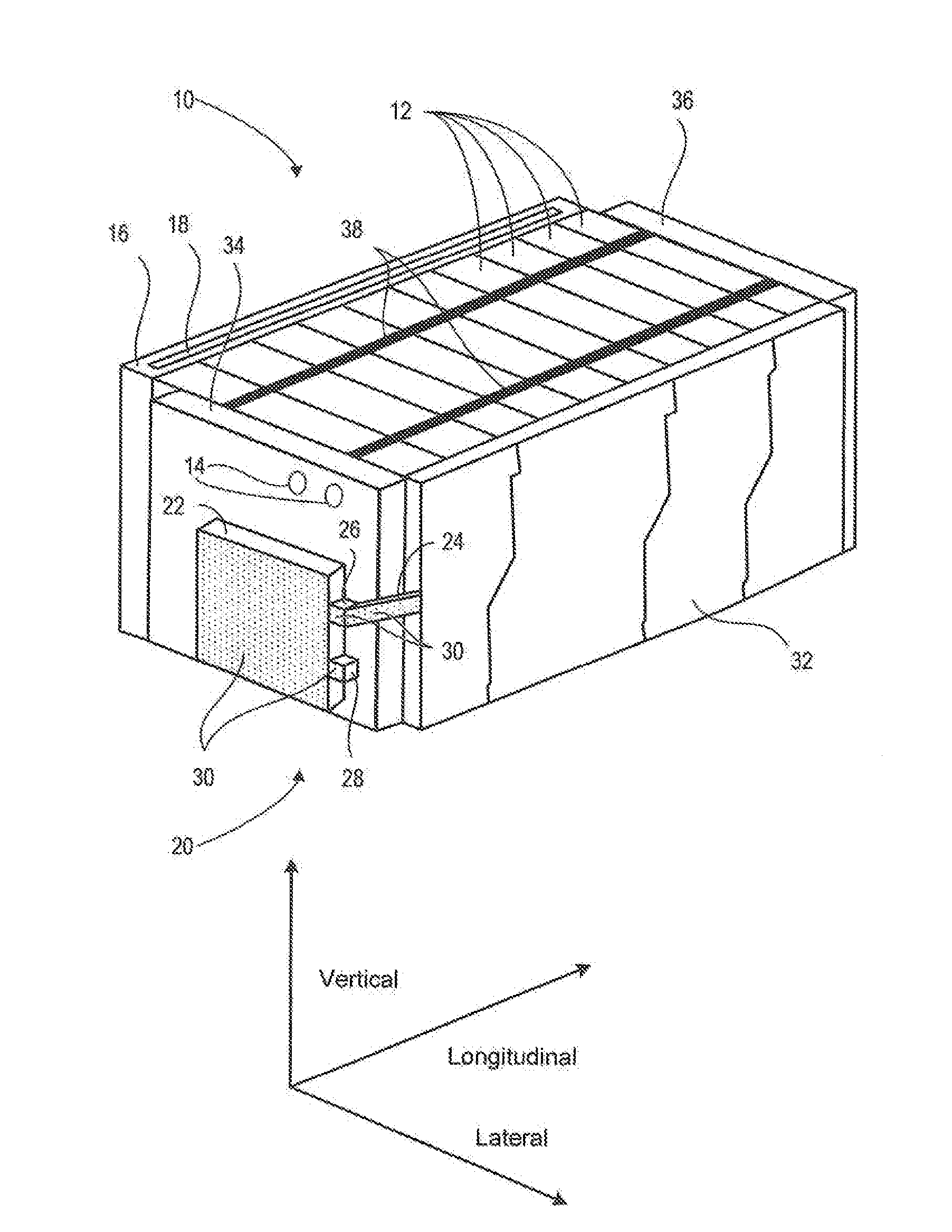

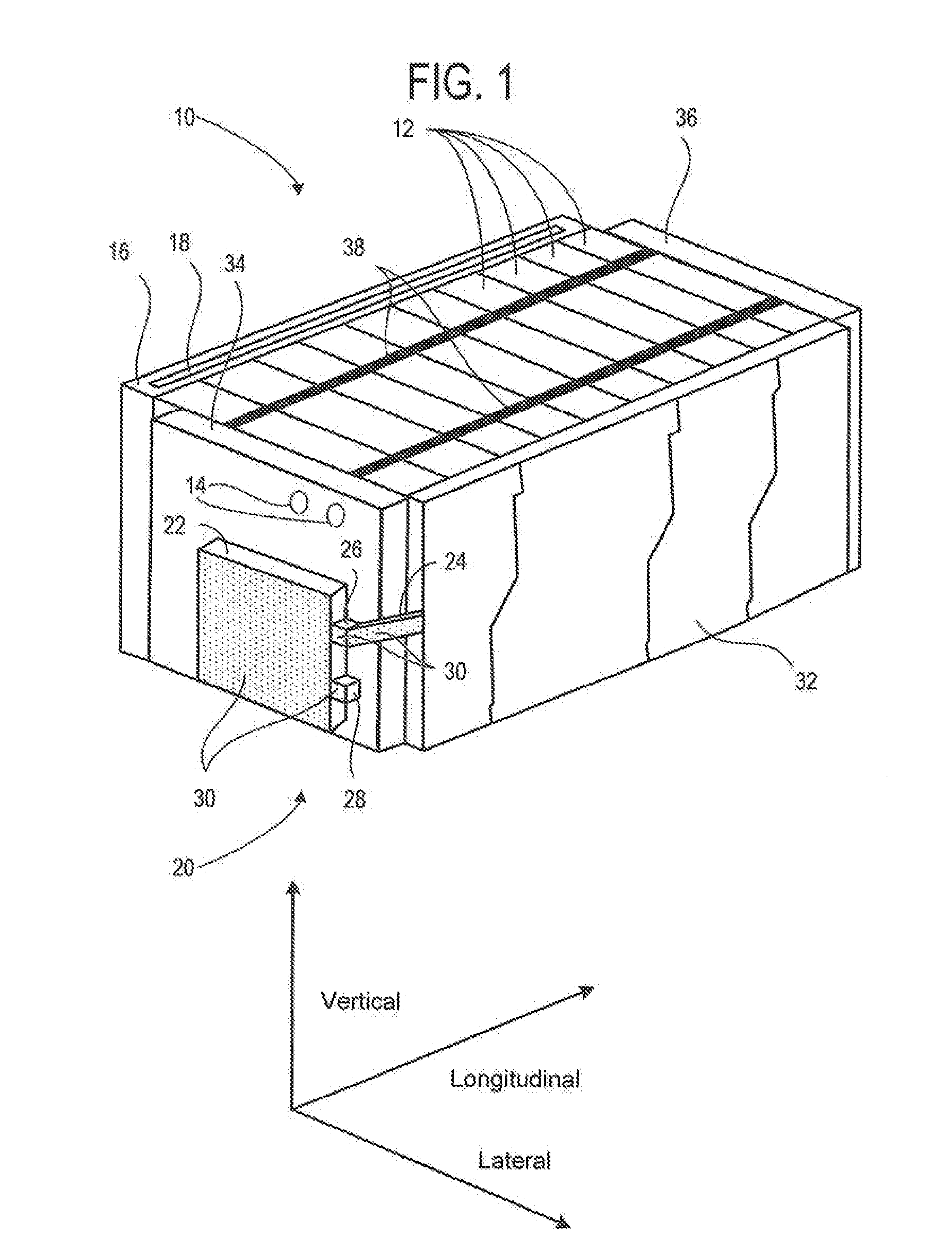

Battery systems, battery modules, and method for cooling a battery module

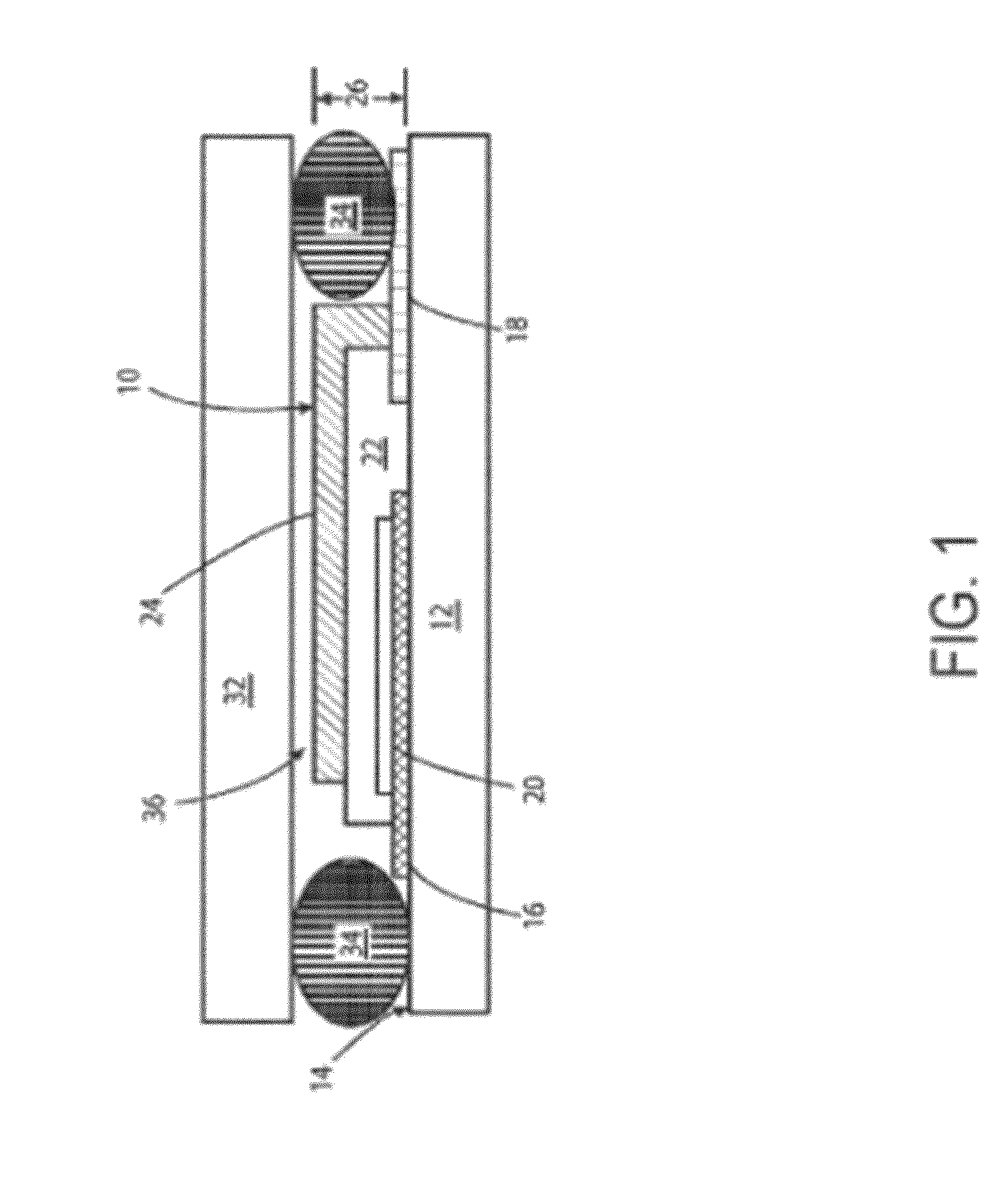

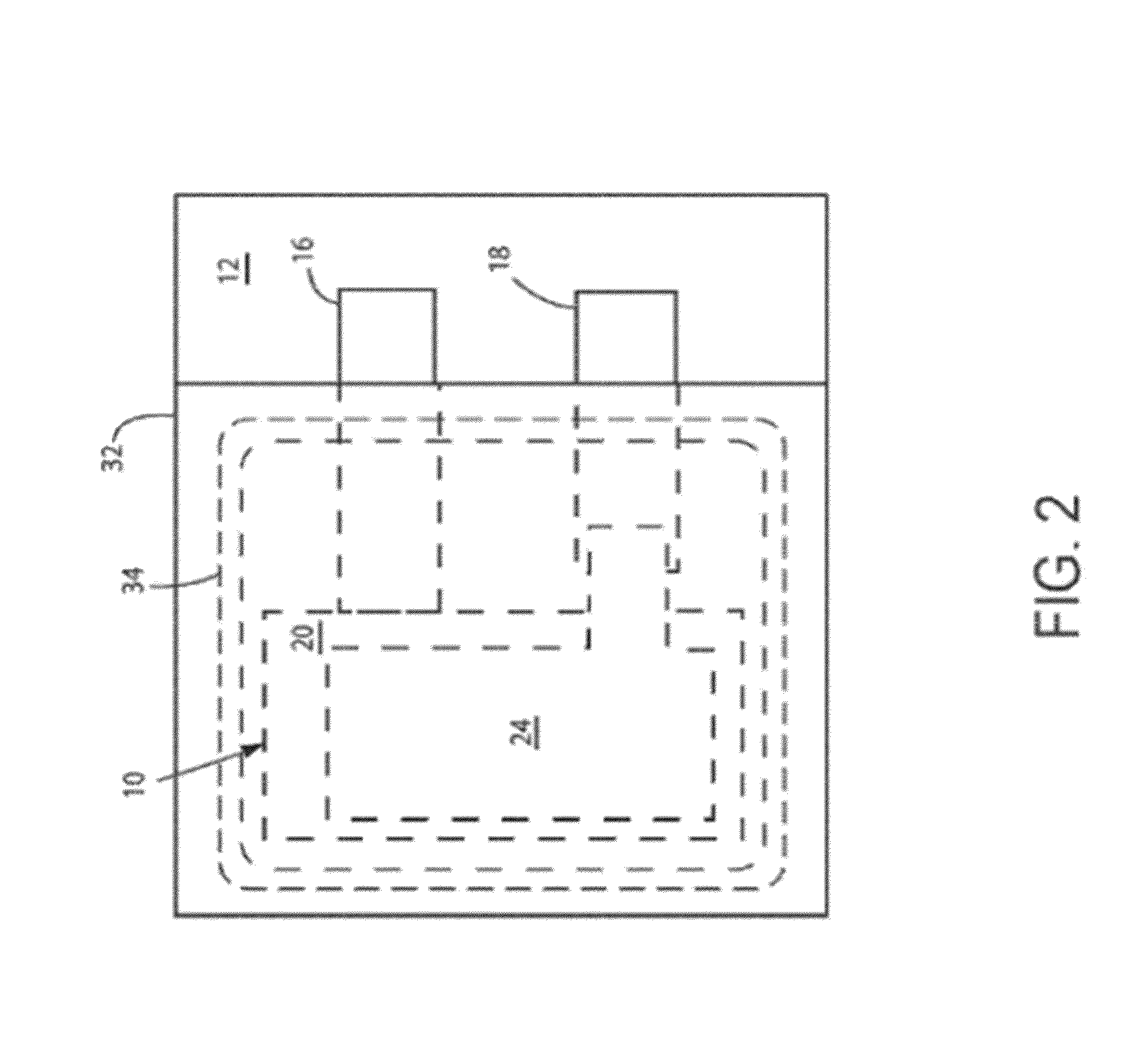

Battery systems, battery modules, and a method for cooling a battery module are provided. The battery module includes a first battery cell, and a first cooling fin having a first panel portion and first and second rail portions that are disposed on first and second ends, respectively, of the first panel portion. The first battery cell is disposed adjacent to a first side of the first panel portion. The first and second rail portions have a thickness greater than the first panel portion. The first cooling fin conducts heat energy from the first battery cell into the first cooling fin to cool the first battery cell. The battery module further includes first and second conduits extending through the first and second rail portions, respectively, that receive a fluid that flows through the first and second conduits to conduct heat energy from the first cooling fin into the fluid.

Owner:LG ENERGY SOLUTION LTD

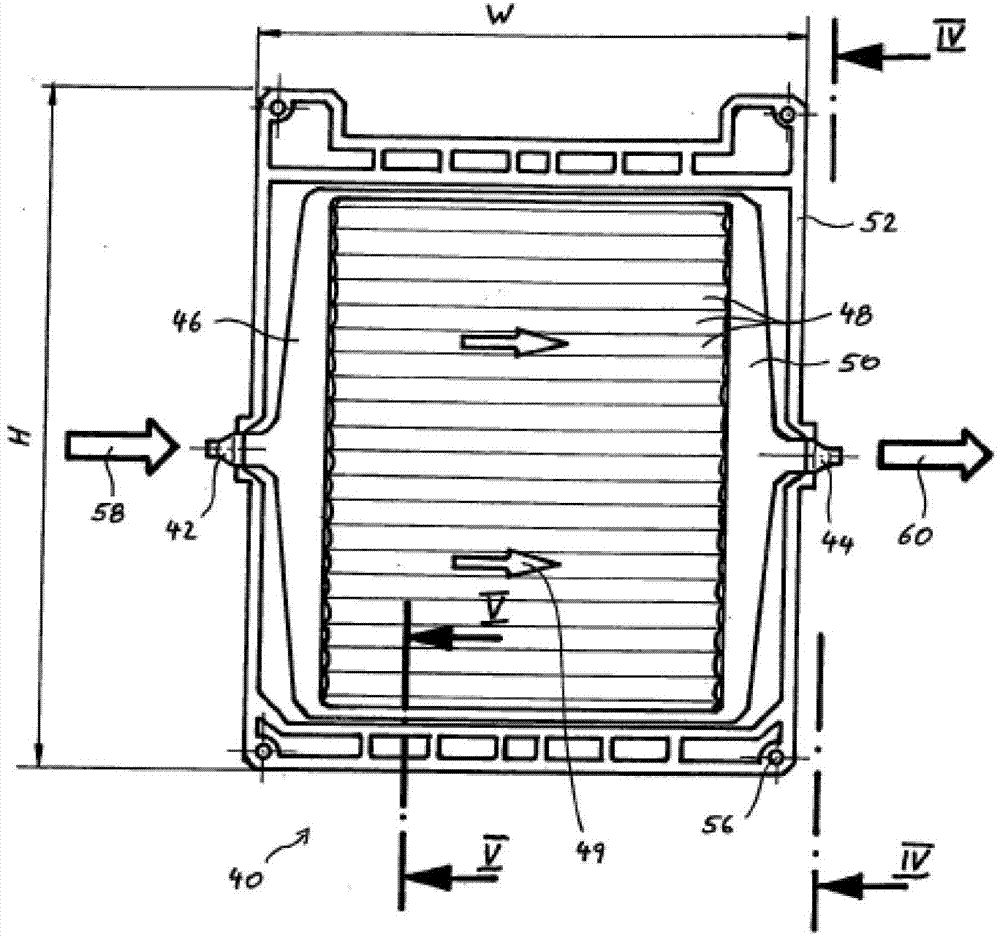

Cooling Structure For Batteries and Electrical Units

InactiveUS20080251246A1Use minimizedSuppression temperature differenceTemperatue controlSemiconductor/solid-state device detailsElectrical batteryEngineering

Owner:HONDA MOTOR CO LTD

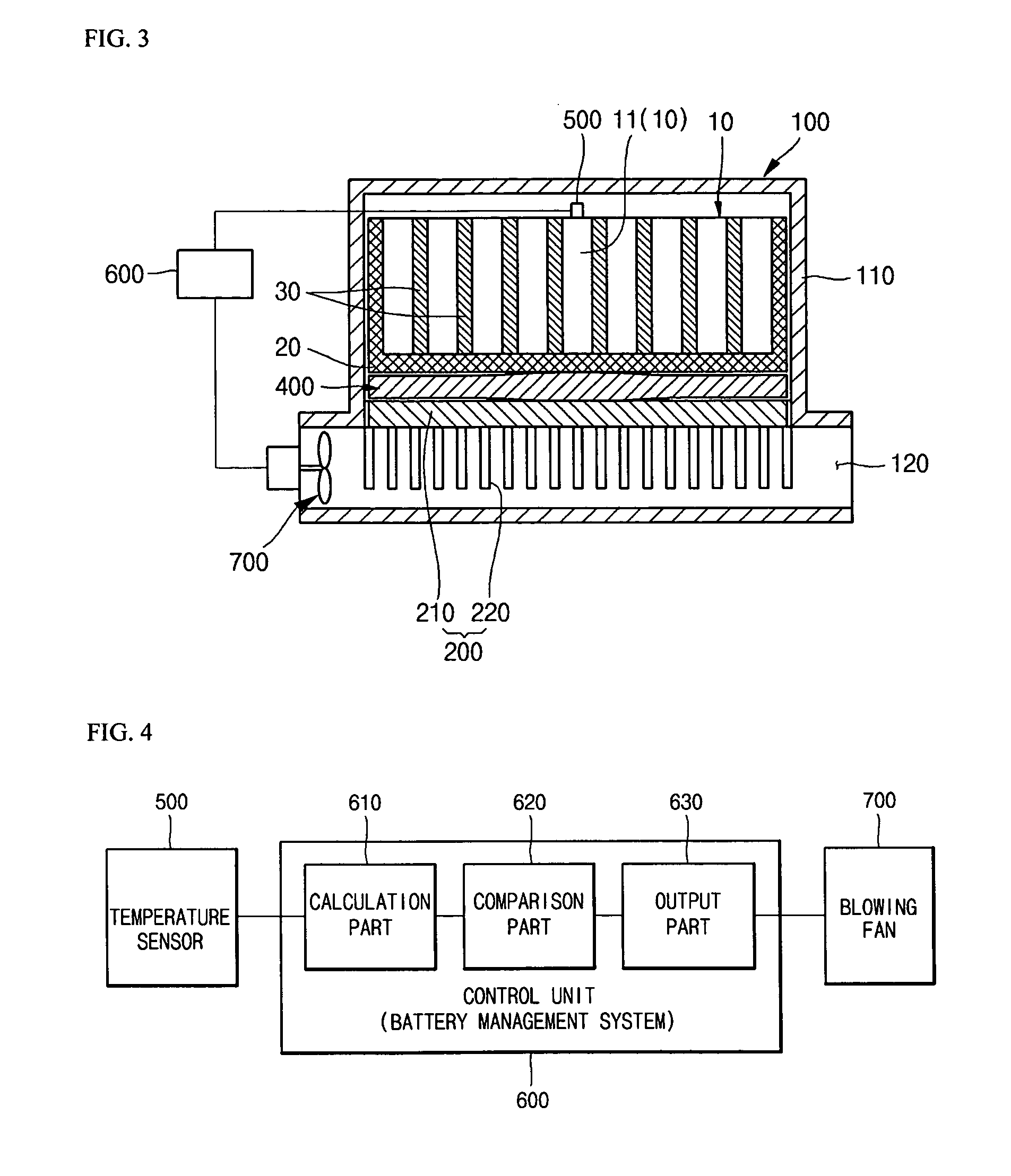

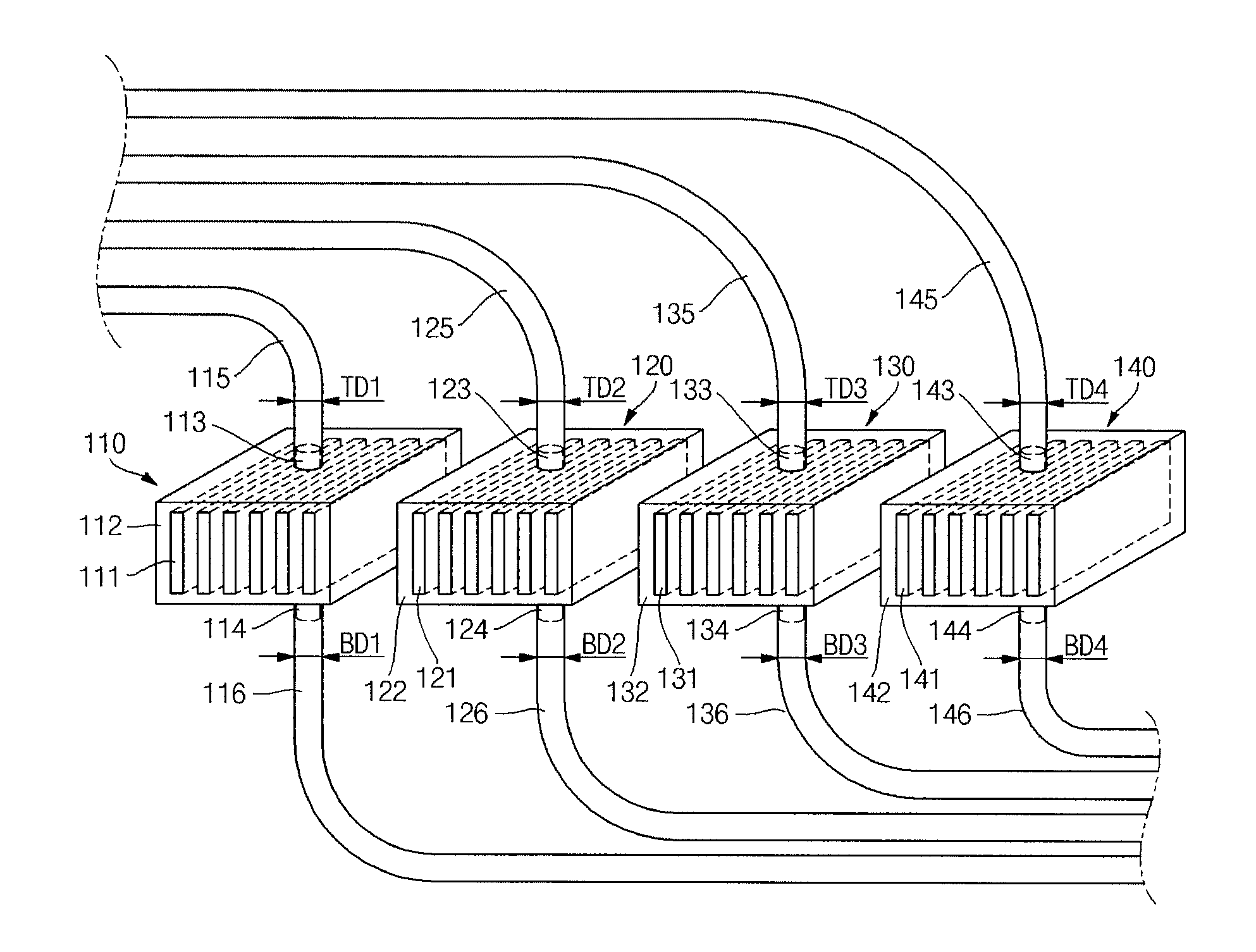

Cooling apparatus of a battery module

ActiveUS20110189523A1Minimize temperature deviationCell temperature controlCell temperature regulationElectrical batteryComputer module

Disclosed is a cooling apparatus of a battery module, which can minimize temperature deviation between a plurality of secondary batteries constituting the battery module. The cooling apparatus of a battery module includes a housing including an accommodation part accommodating the battery module, and an air passage through which outside air passes, a first heat transfer member fixed to the housing and having a surface exposed to the air passage, and a second heat transfer member disposed between the battery module and the first heat transfer member. The second heat transfer member may contact a portion in the battery module having relatively high temperature.

Owner:ROBERT BOSCH GMBH +1

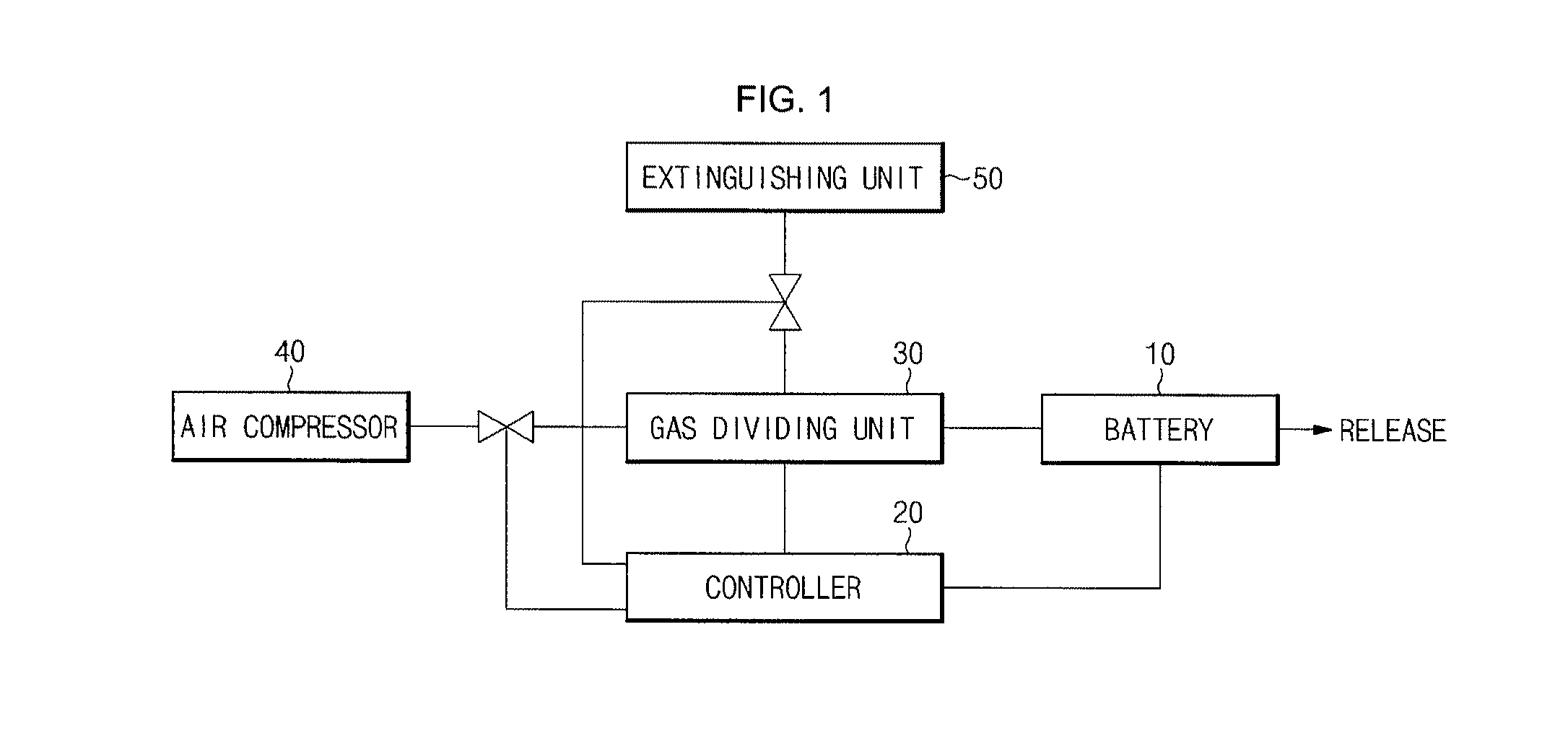

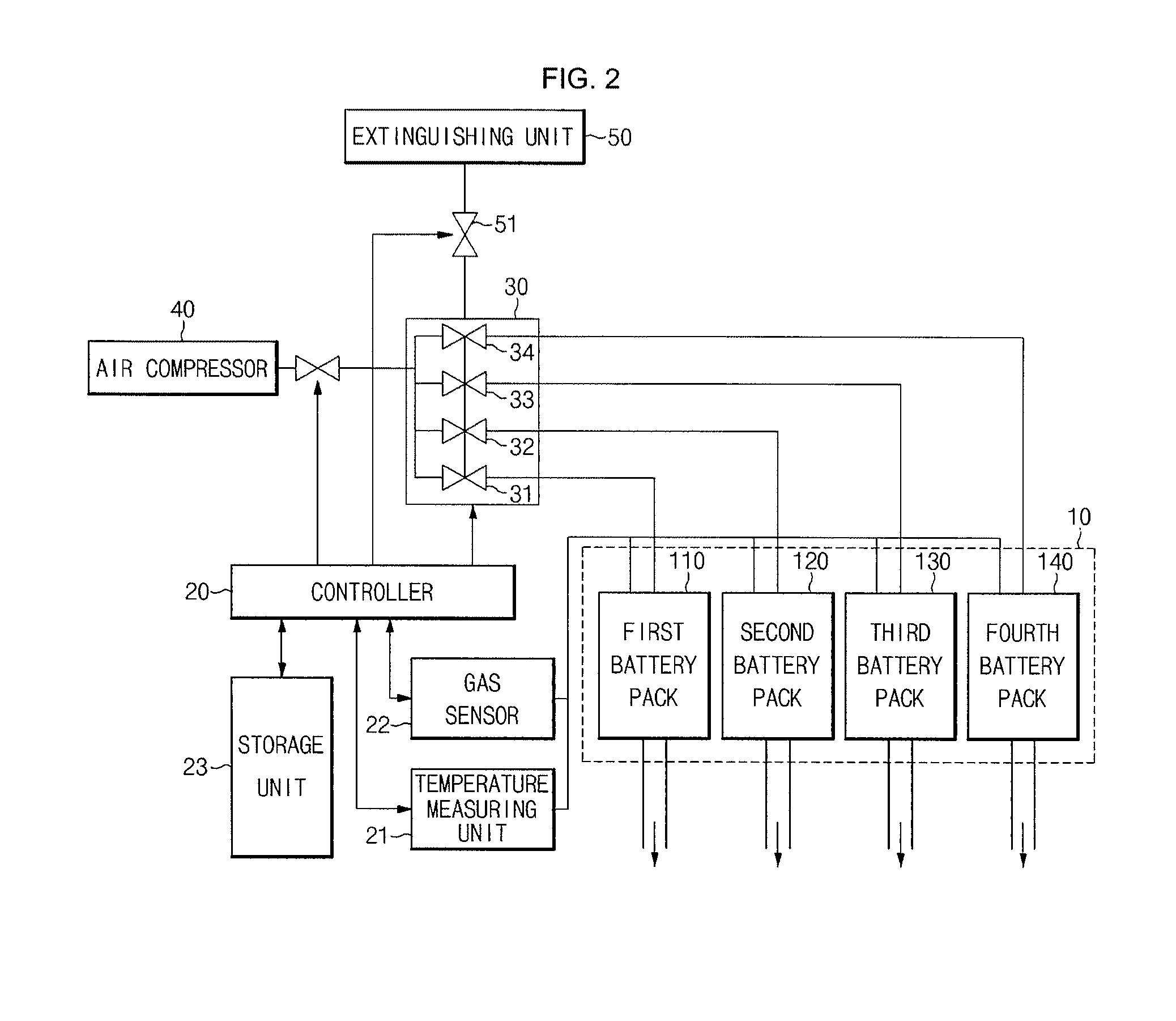

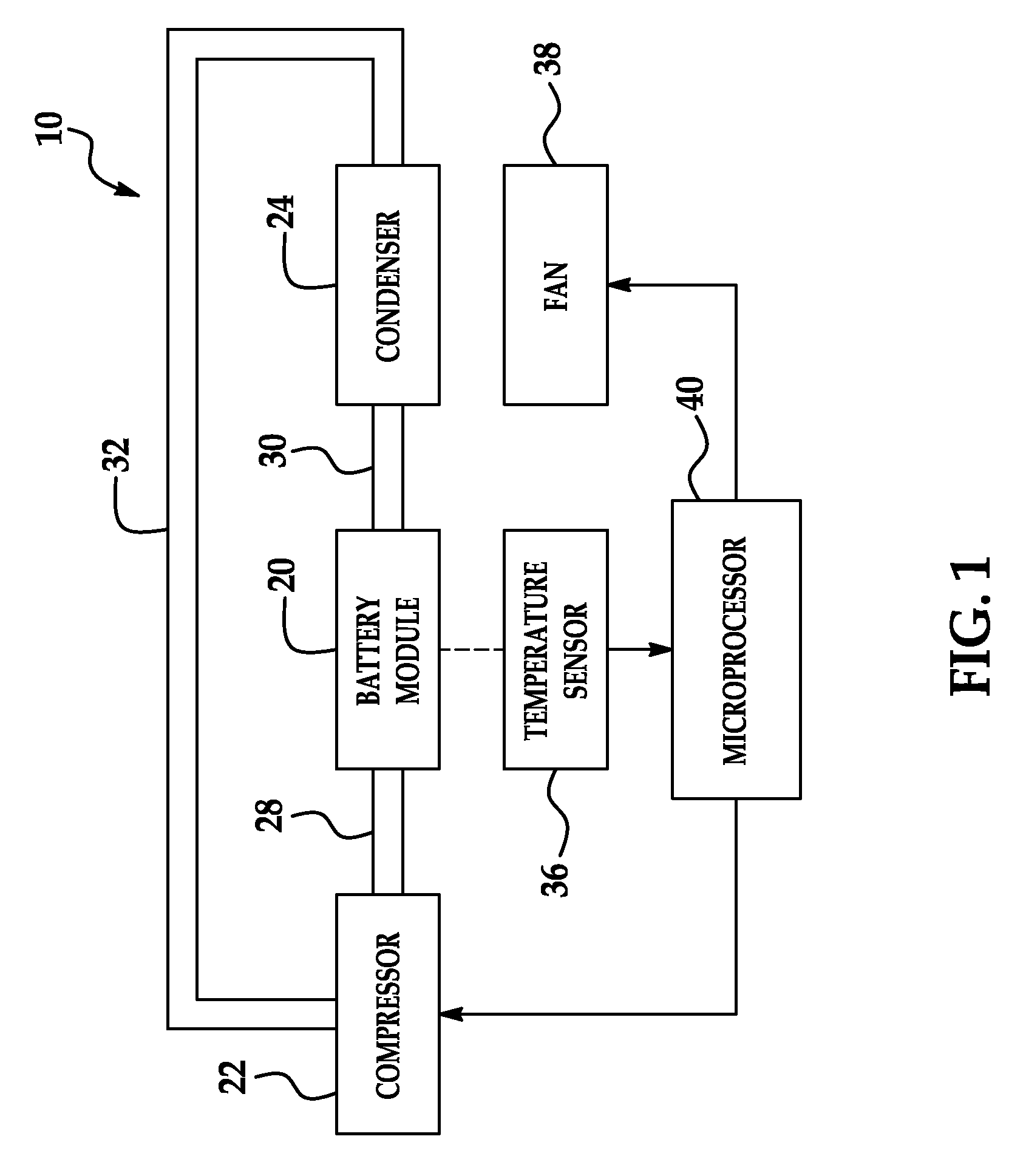

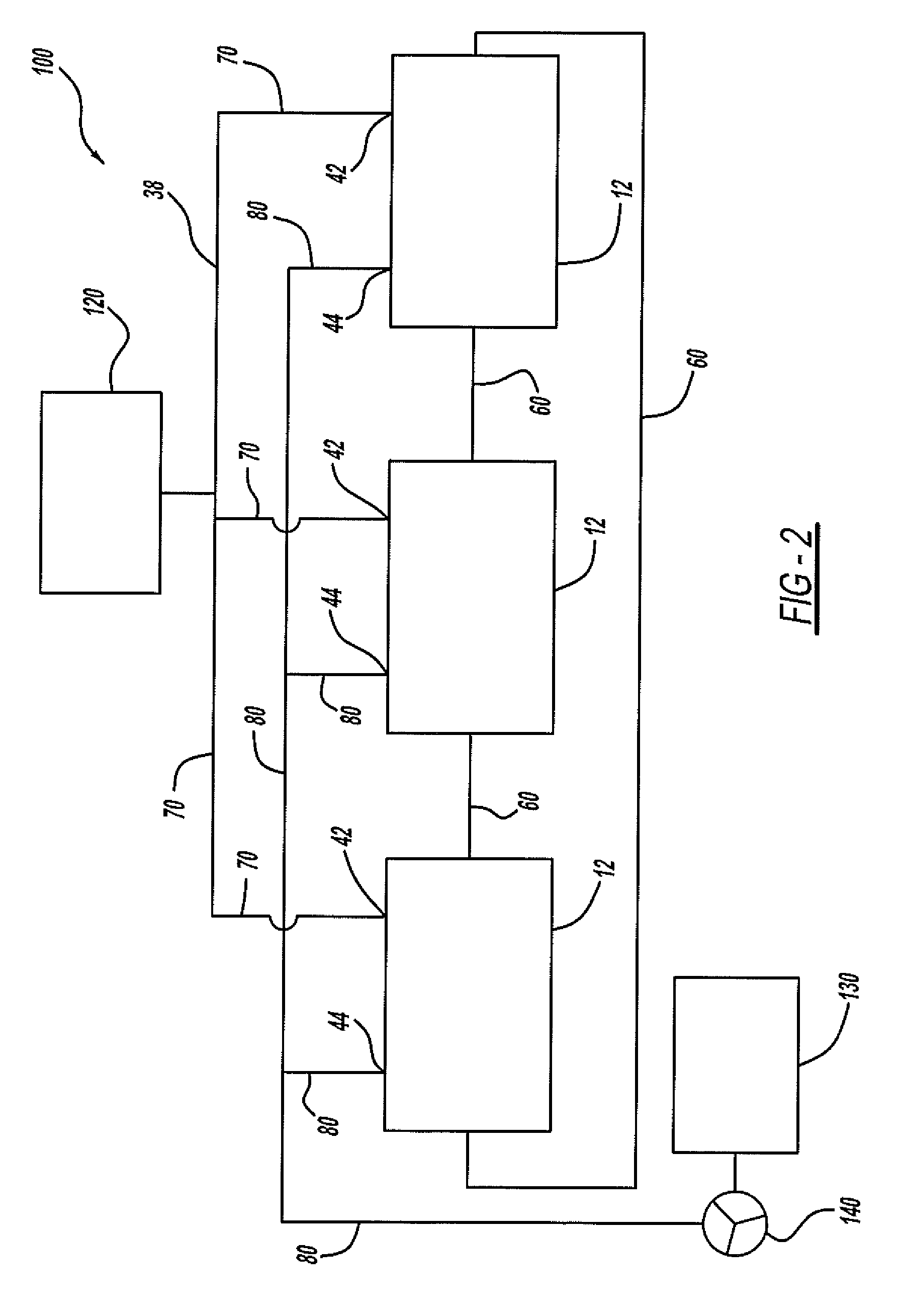

Battery system and driving method thereof

ActiveUS20110189511A1Improve battery performanceCell/batteries leak testingCell temperature controlElectrical batteryEngineering

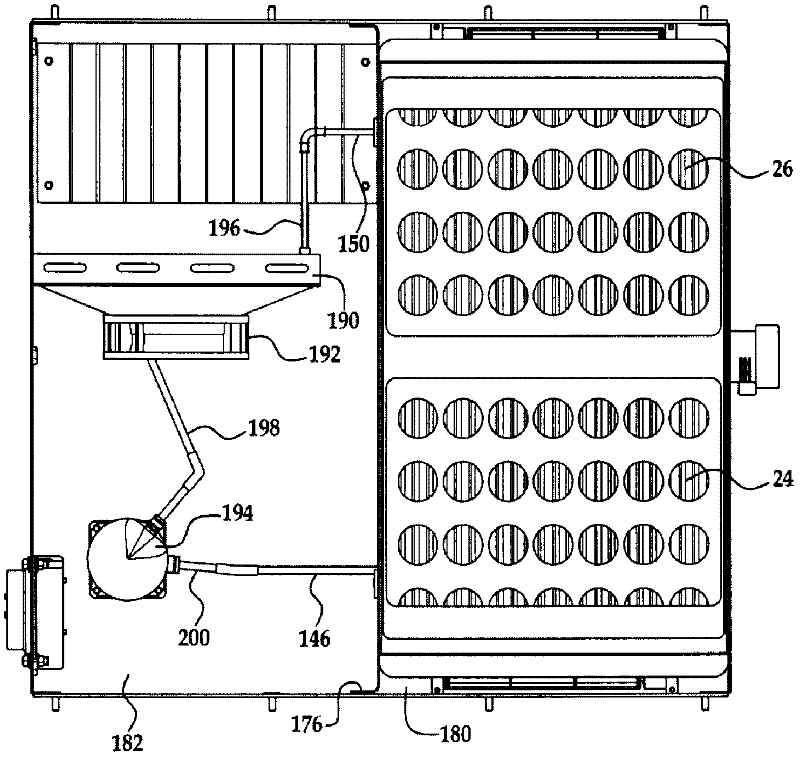

A battery system capable of cooling overheated battery packs among a plurality battery packs each mounted in a battery case by measuring temperatures of the battery packs is disclosed, and a driving method thereof is provided. In one embodiment, the battery system includes a plurality of battery packs, an air compressor for supplying a compressed cooling air to the plurality of battery packs, a gas dividing unit coupled between the plurality of battery packs and the air compressor and including a plurality of valves, and a controller for controlling opening and closing of each of the plurality of valves according to temperatures of the plurality of battery packs.

Owner:SAMSUNG SDI CO LTD +1

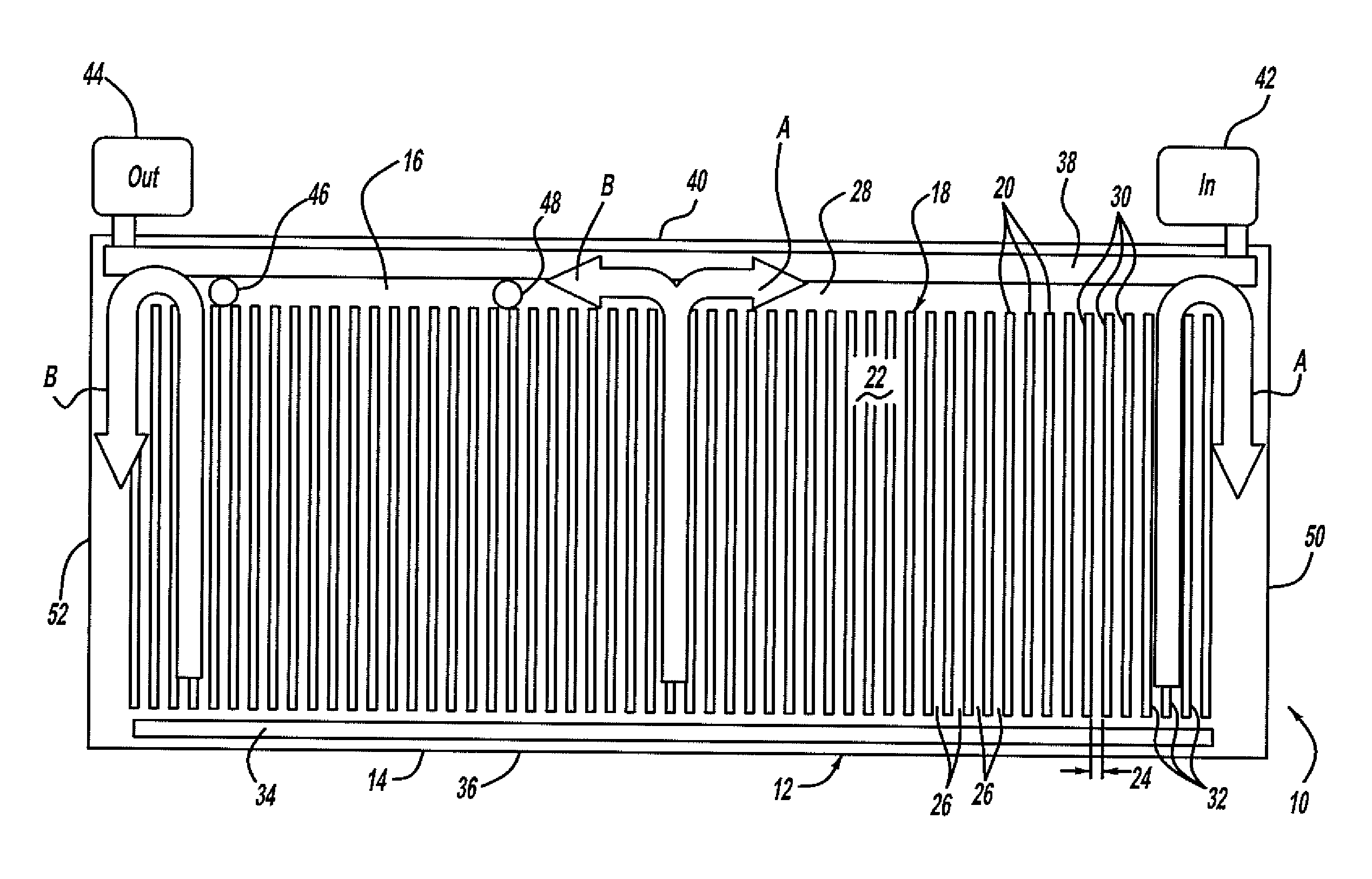

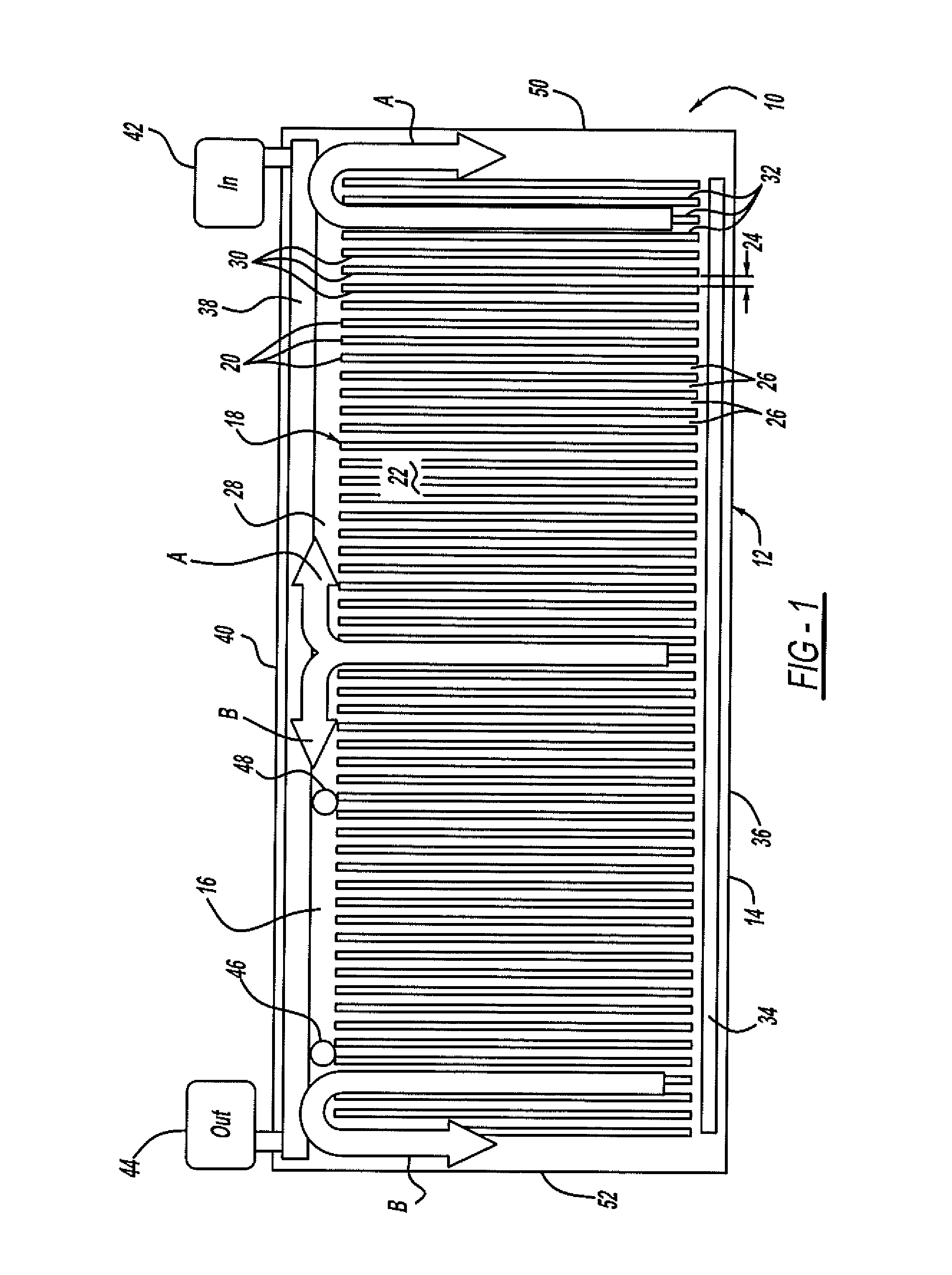

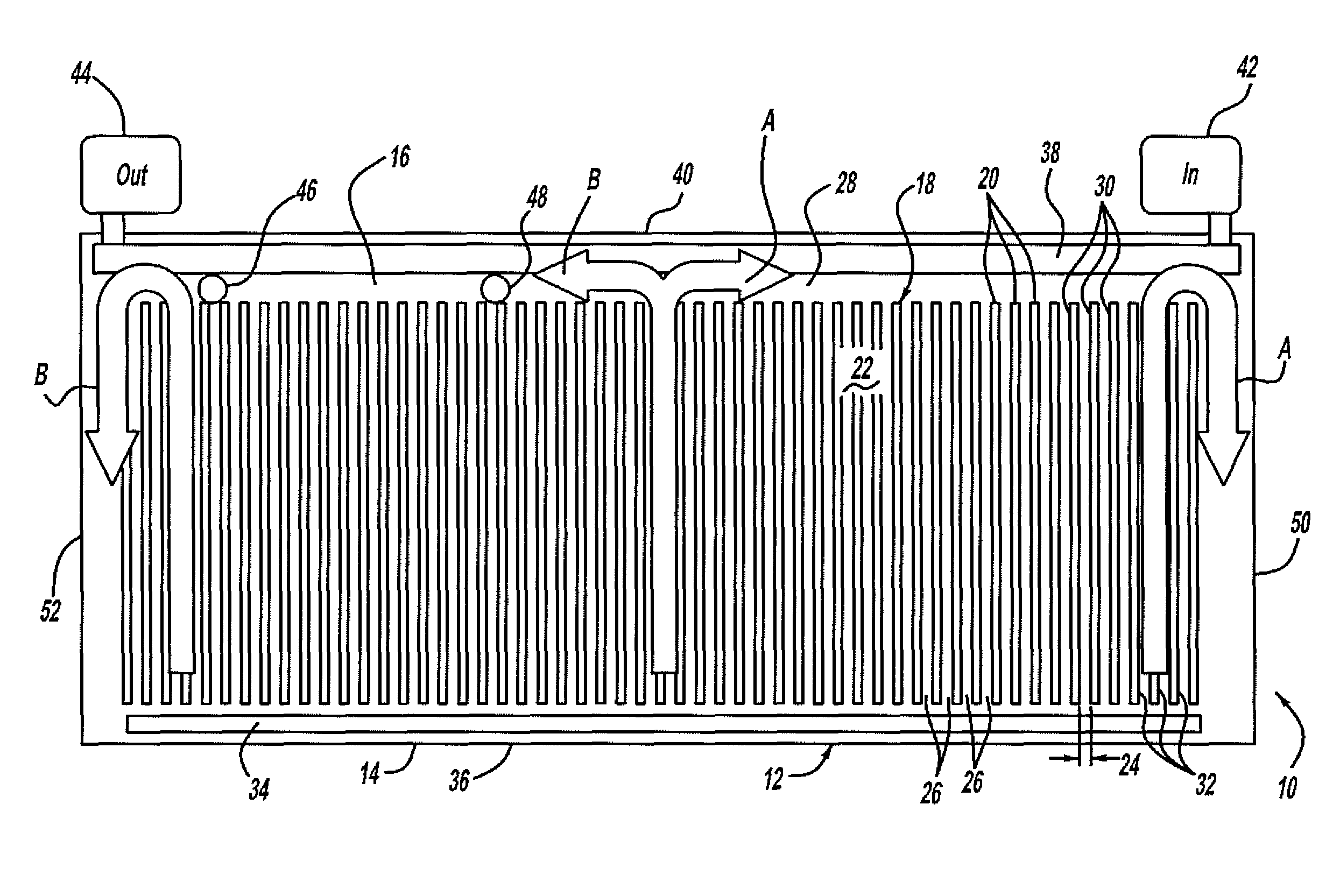

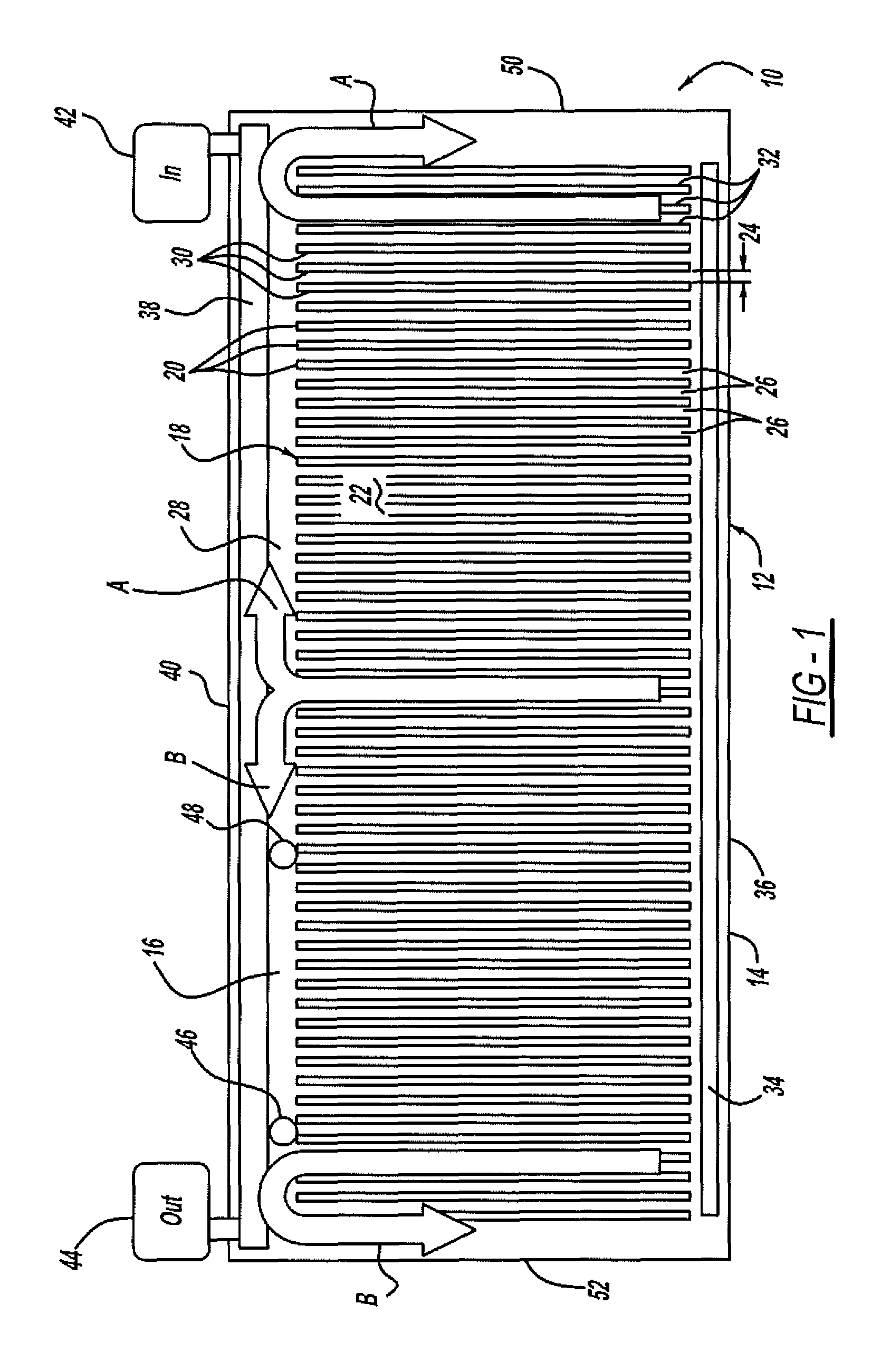

Lithium ion battery cooling system

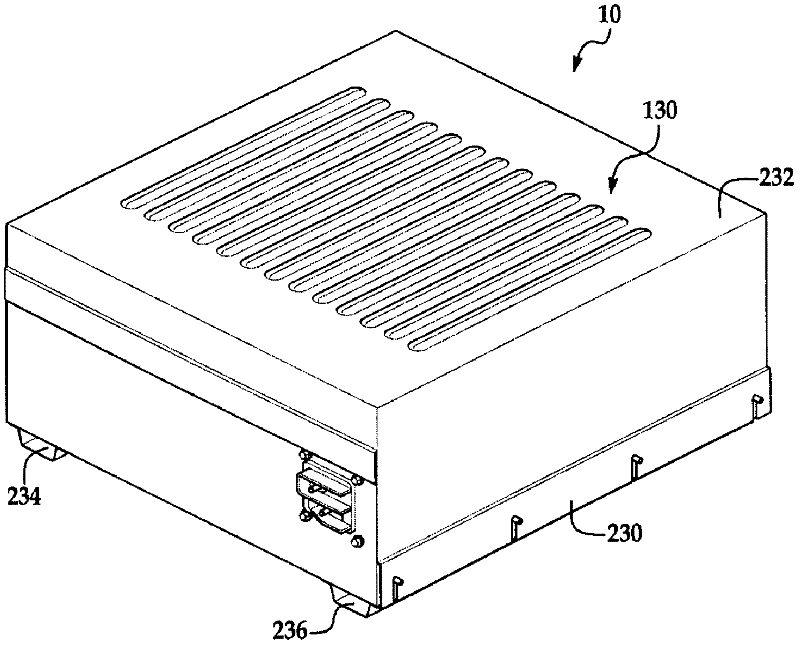

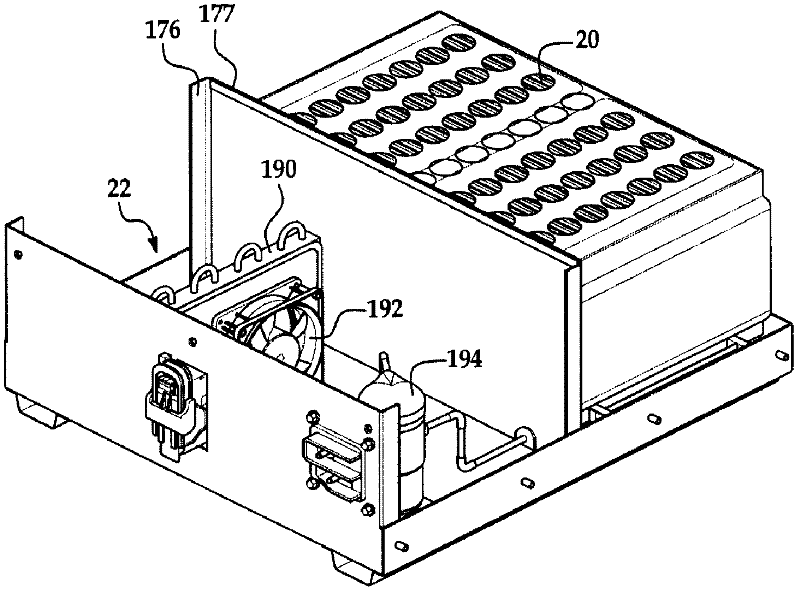

ActiveUS20130122331A1Readily apparentUniform surface temperatureFinal product manufactureCell temperature controlDielectricInterior space

A Lithium Ion battery cooling system for use in a hybrid vehicle comprises a plurality of self-contained liquid cooling modules, each cooling module including a closed and sealed container having an interior space. Each cooling module includes a battery assembly disposed within the interior space of the container and a plurality of battery cells having at least one fluid channel formed therebetween for receiving a fluid therein. A dielectric fluid is disposed within the at least one fluid channel. The dielectric fluid substantially immerses and is in contact with the battery assembly to heat and cool the battery assembly. A heating element is disposed within the interior space and heats the dielectric fluid. A cooling element is disposed within the interior space and cools the dielectric fluid.

Owner:GM GLOBAL TECH OPERATIONS LLC

Battery module and method for cooling the battery module

A battery module and a method for cooling the battery module are provided. The battery module includes a housing having an electrically non-conductive oil disposed therein, and a battery cell disposed in the housing that contacts the electrically non-conductive oil. The battery module further includes first and second heat conductive fins disposed in the housing that contacts the electrically non-conductive oil. The first and second heat conductive fins extract heat energy from the electrically non-conductive oil. The battery module further includes first and second conduits extending through the first and second heat conductive fins, respectively. The first and second conduits receive first and second portions of a fluid, respectively, therethrough and conduct heat energy from the first and second heat conductive fins, respectively, into the fluid to cool the battery cell.

Owner:LG ENERGY SOLUTION LTD

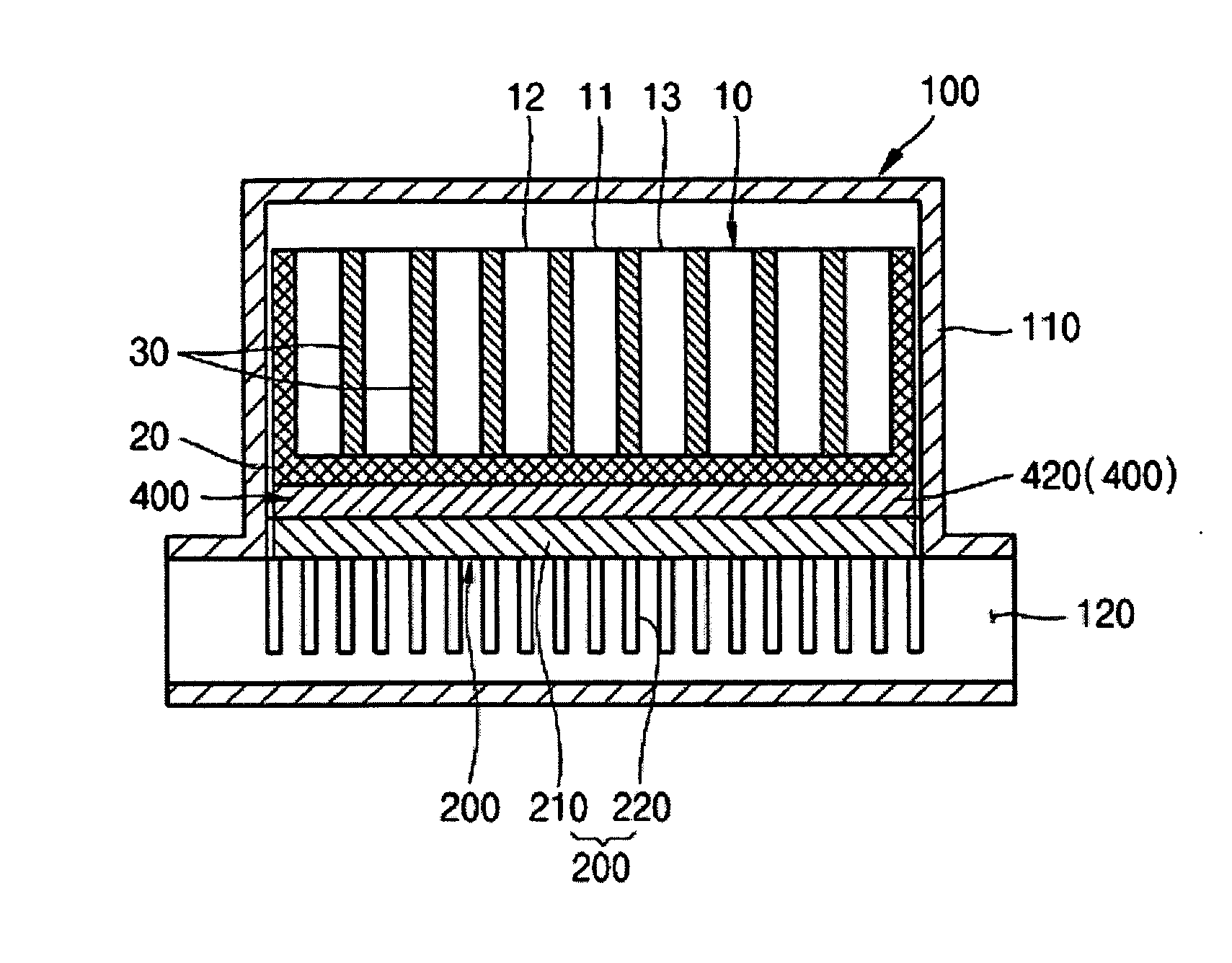

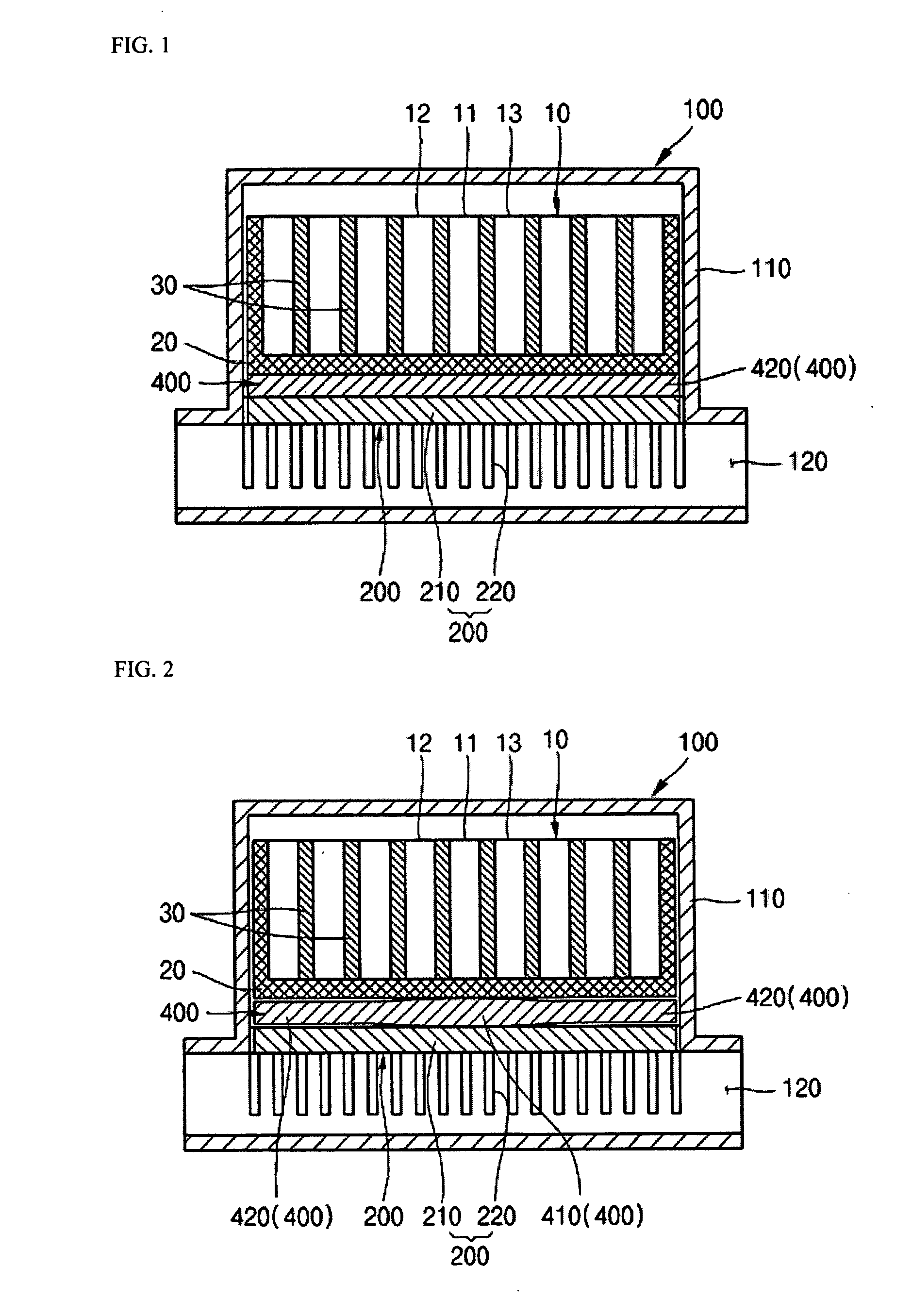

Battery cooling structure

ActiveUS20130149582A1Cell temperature controlCell temperature regulationBattery cellElectrical and Electronics engineering

A battery cooling structure includes a cooling plate and an electrically insulative sheet. The cooling plate is to support a cooling surface of a battery module to cool the battery module including a plurality of battery cells arranged side by side. The electrically insulative sheet has an electrical non-conductivity and is disposed between the cooling surface of the battery module and the cooling plate to transfer heat from the cooling surface to the cooling plate.

Owner:HONDA MOTOR CO LTD

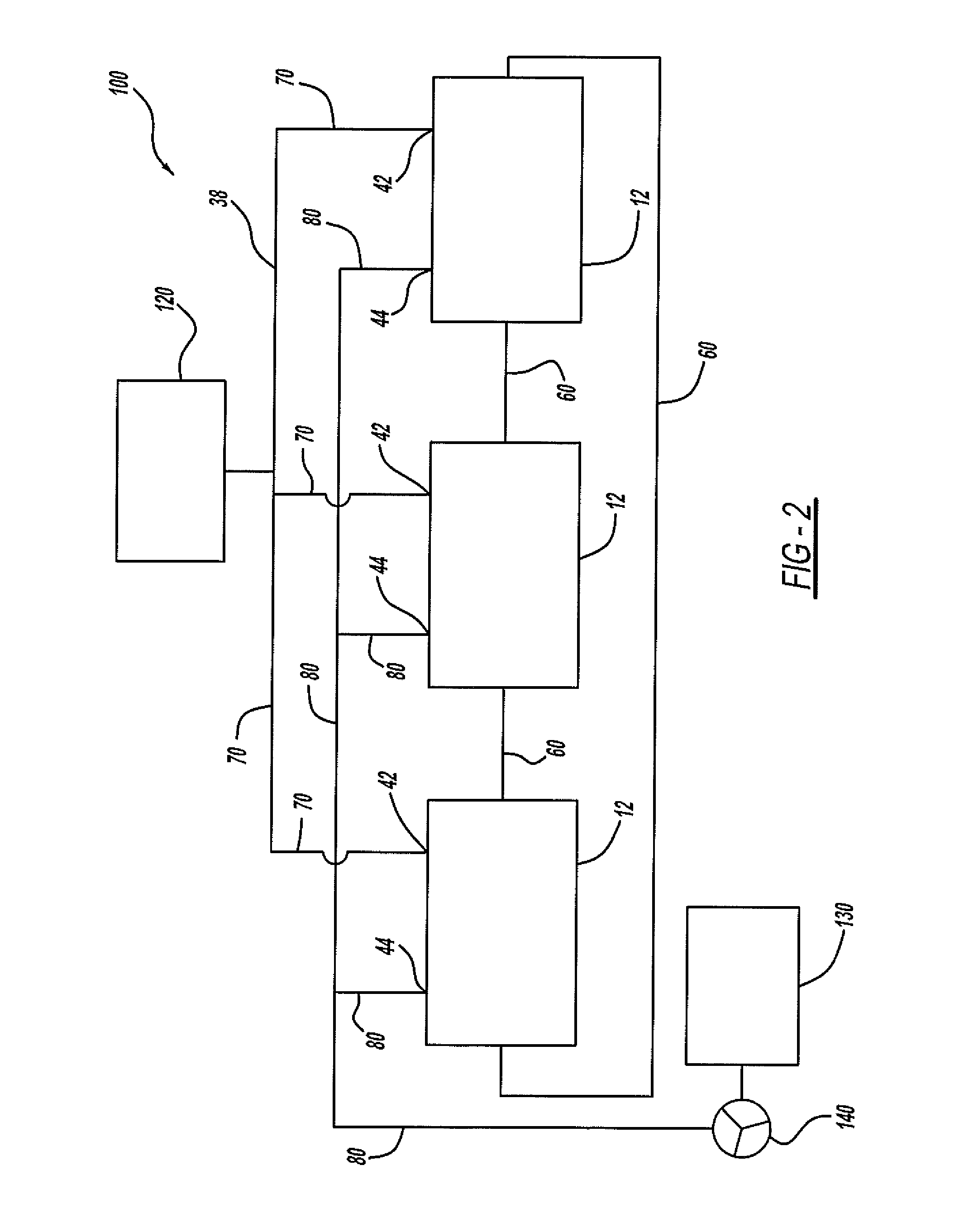

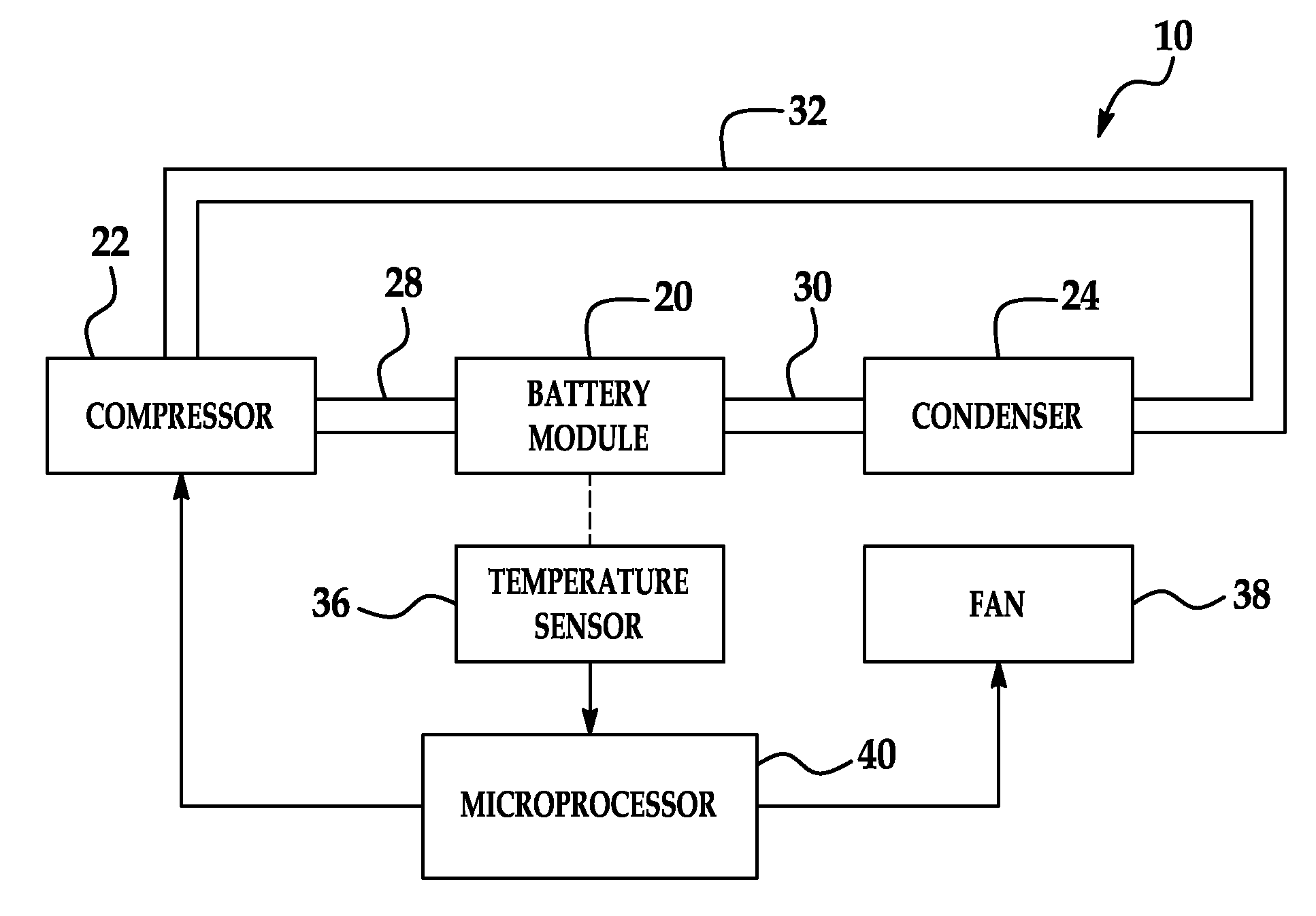

Lithium ion battery cooling system comprising dielectric fluid

ActiveUS8852772B2Uniform surface temperatureFinal product manufactureCell temperature controlInterior spaceDielectric

A Lithium Ion battery cooling system for use in a hybrid vehicle comprises a plurality of self-contained liquid cooling modules, each cooling module including a closed and sealed container having an interior space. Each cooling module includes a battery assembly disposed within the interior space of the container and a plurality of battery cells having at least one fluid channel formed therebetween for receiving a fluid therein. A dielectric fluid is disposed within the at least one fluid channel. The dielectric fluid substantially immerses and is in contact with the battery assembly to heat and cool the battery assembly. A heating element is disposed within the interior space and heats the dielectric fluid. A cooling element is disposed within the interior space and cools the dielectric fluid.

Owner:GM GLOBAL TECH OPERATIONS LLC

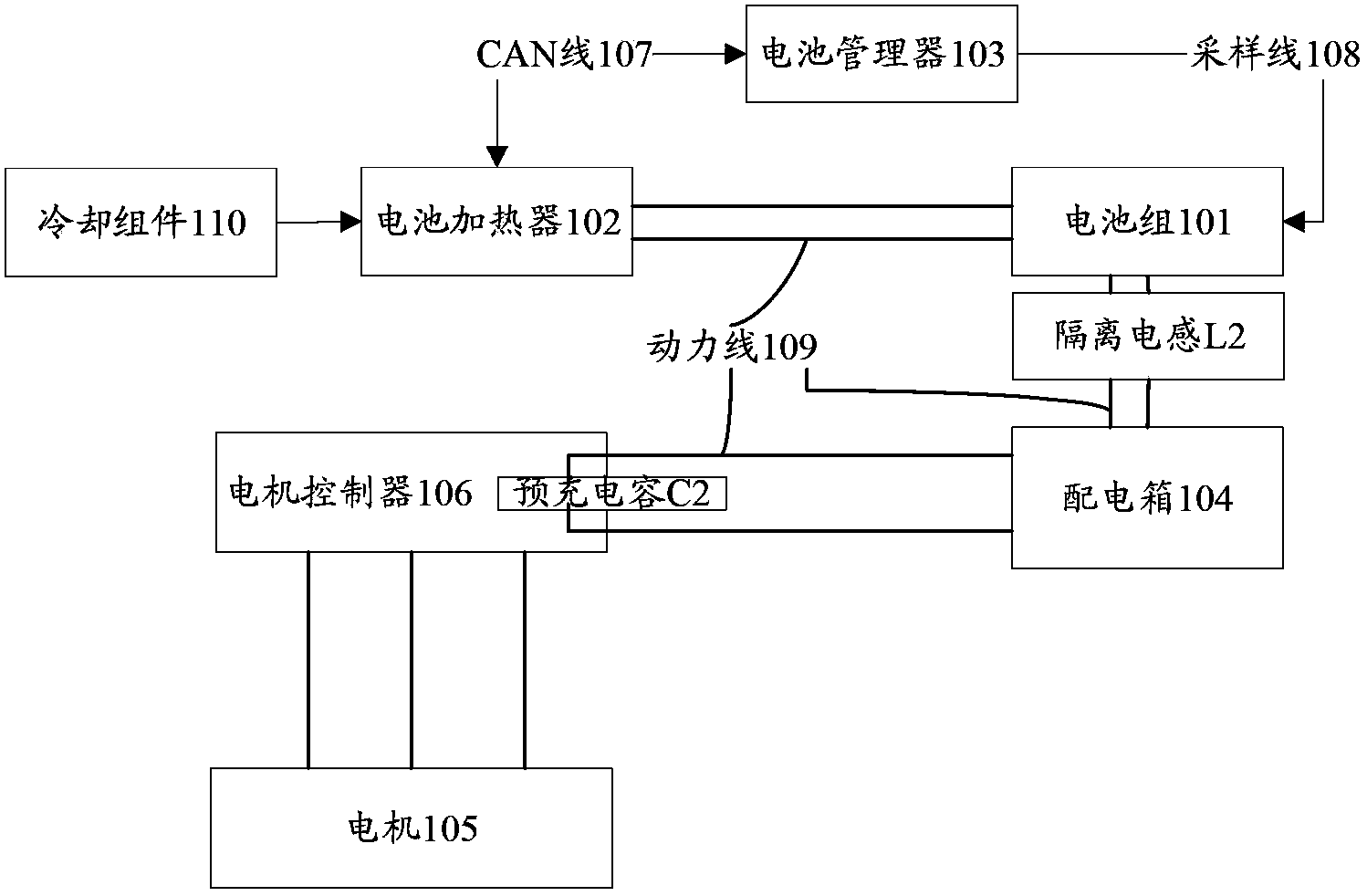

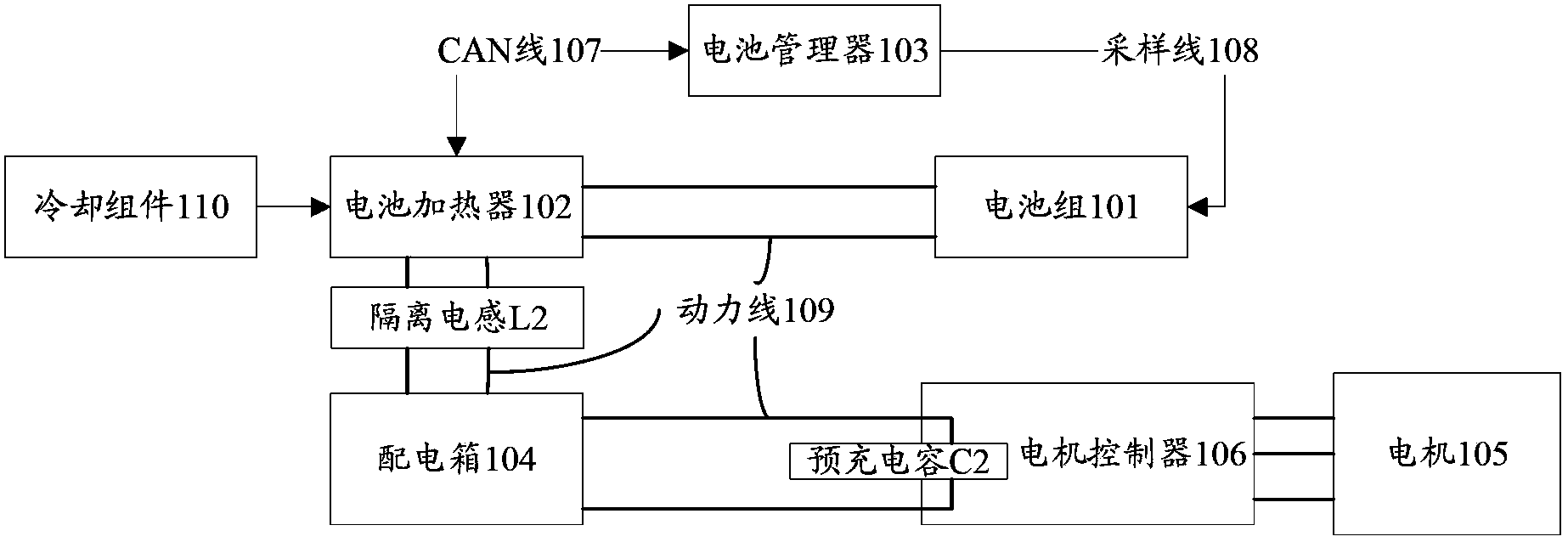

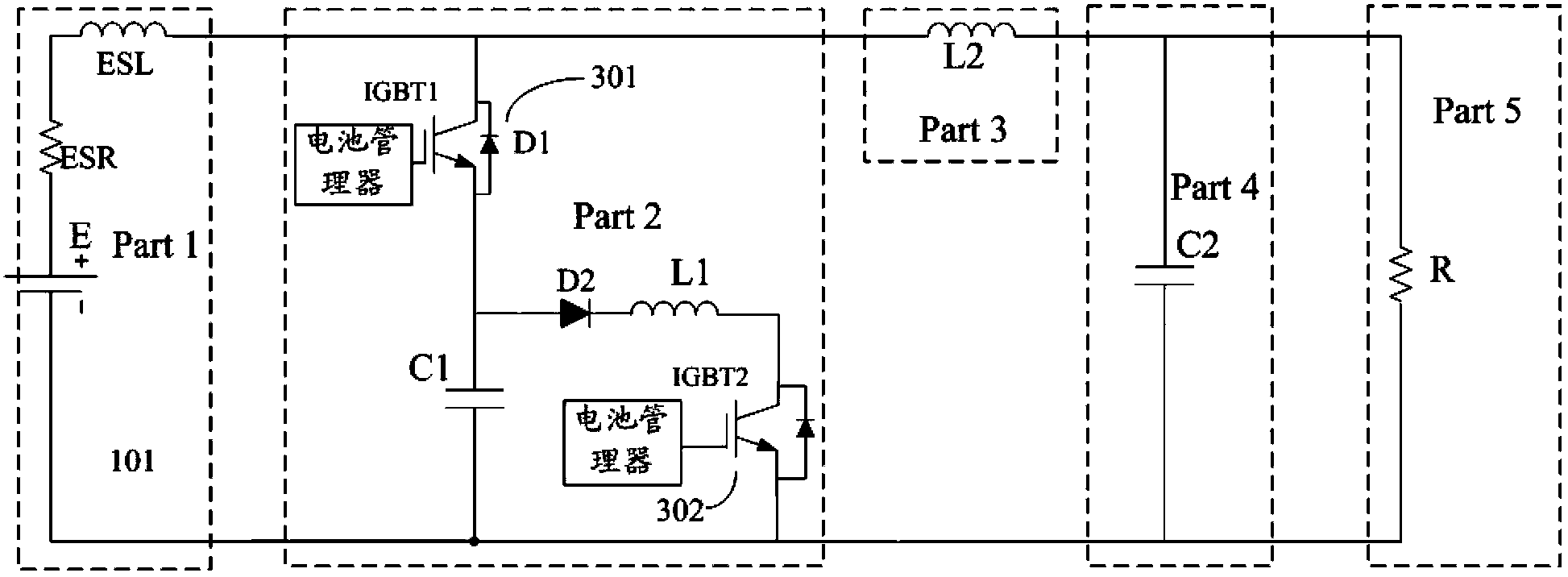

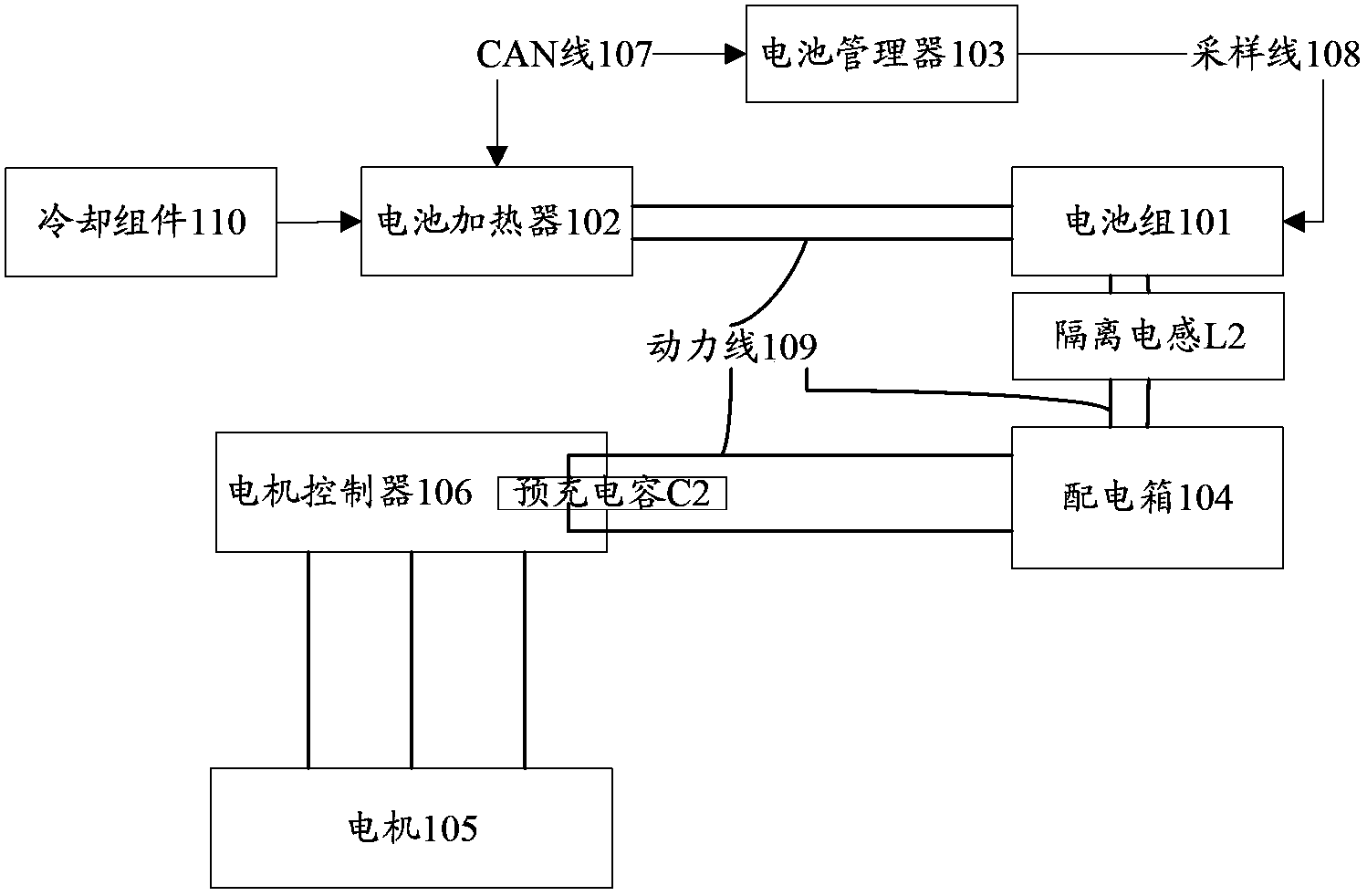

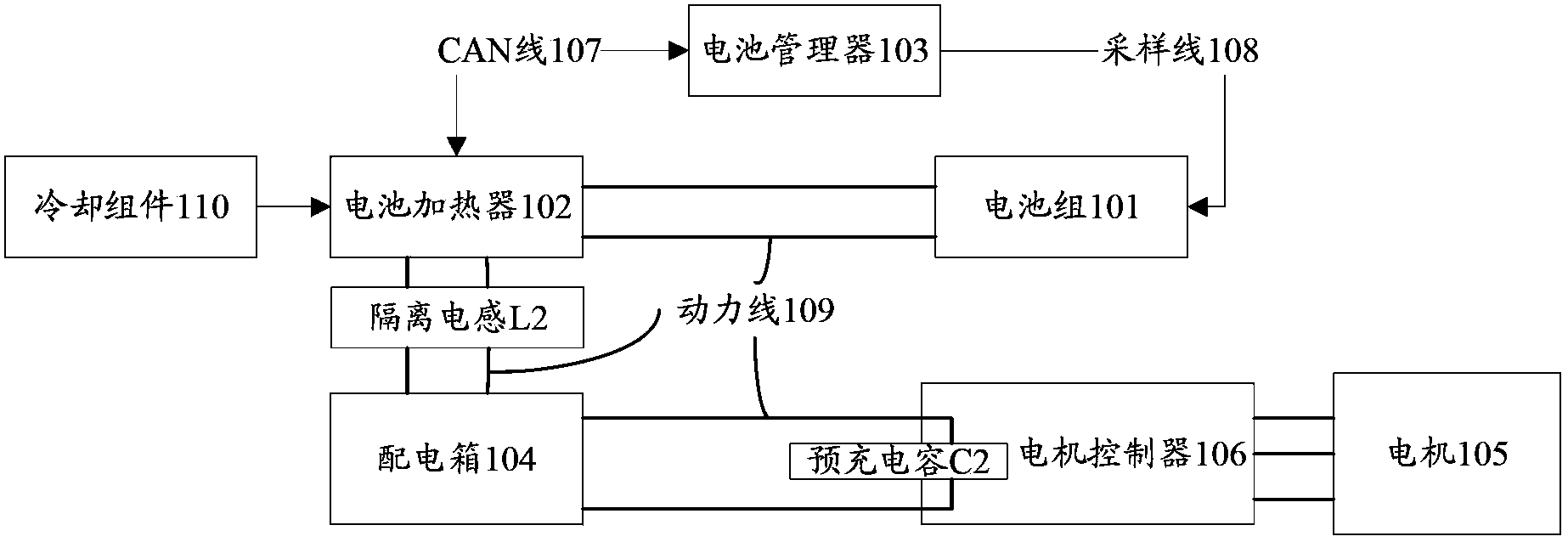

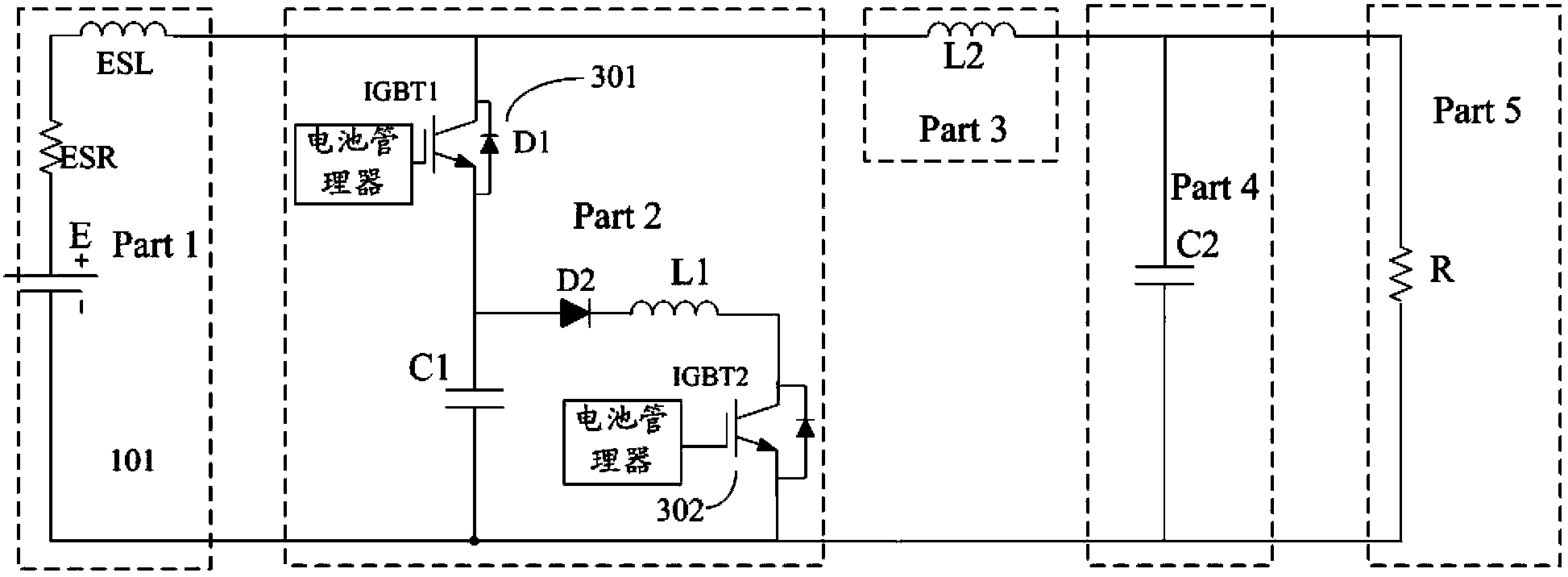

Electric car and electric car power system and battery heating method

ActiveCN103419666AGuaranteed powerExtended service lifeCell temperature controlCell temperature regulationCapacitanceElectrical battery

The invention provides an electric car power system which comprises a battery pack, a battery heater, a battery manager, a distribution box, a motor, a motor controller and an isolation inductor. The battery heater is connected with the battery pack. The battery manager is respectively connected with the battery pack and the battery heater and used for alternately controlling the battery heater to heat the battery pack according to accelerator depth change velocity of an electric car when the temperature of the battery pack is lower than a first heating temperature threshold and the residual electric quantity is higher than a shutdown electric quantity threshold. The distribution box is used for distributing voltage output by the battery pack. The motor controller is connected with the motor and the distribution box and provided with a first input end, a second input end and a pre-charging capacitor. The pre-charging capacitor is connected between the first input end and the second input end and matched with the isolation inductor. The power system is capable of realizing heating and greatly lowering use limitation in a low-temperature environment, high in heating efficiency, low in cost, and highly practical. The invention further provides an electric car battery heating method and an electric car.

Owner:BYD CO LTD

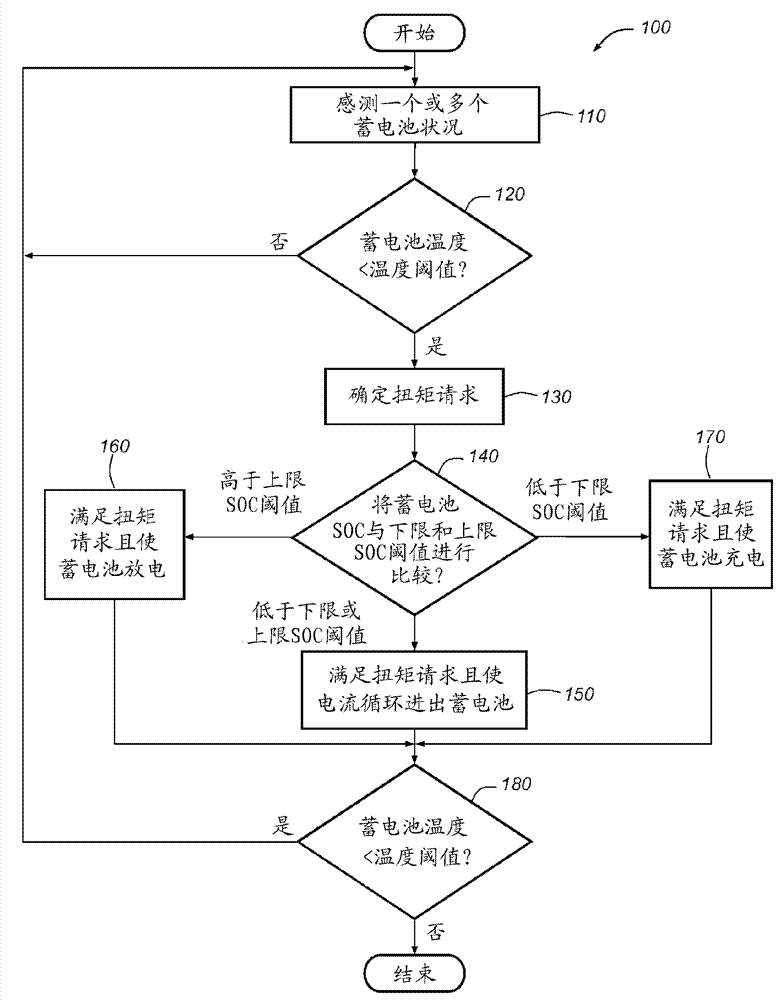

Method and system for heating a vehicle battery

ActiveCN102738537ACell temperature regulationPropulsion by batteries/cellsElectrical resistance and conductanceInternal resistance

A method and system for heating a vehicle battery, such as the type used for vehicle propulsion in a hybrid electric vehicle (HEV). Depending on the battery chemistry involved, such batteries may not perform well in extremely cold environments. For instance, a lithium-ion battery can exhibit a high internal resistance when the battery is extremely cold, which in turn can negatively affect the available power or other capabilities of the battery. According to an exemplary embodiment, the method and system take advantage of the high internal resistance in a cold vehicle battery by purposely cycling electrical current in and / or out of the battery so that heat is created. This heat warms up the vehicle battery and thereby improves its overall performance and capabilities.

Owner:GM GLOBAL TECH OPERATIONS LLC

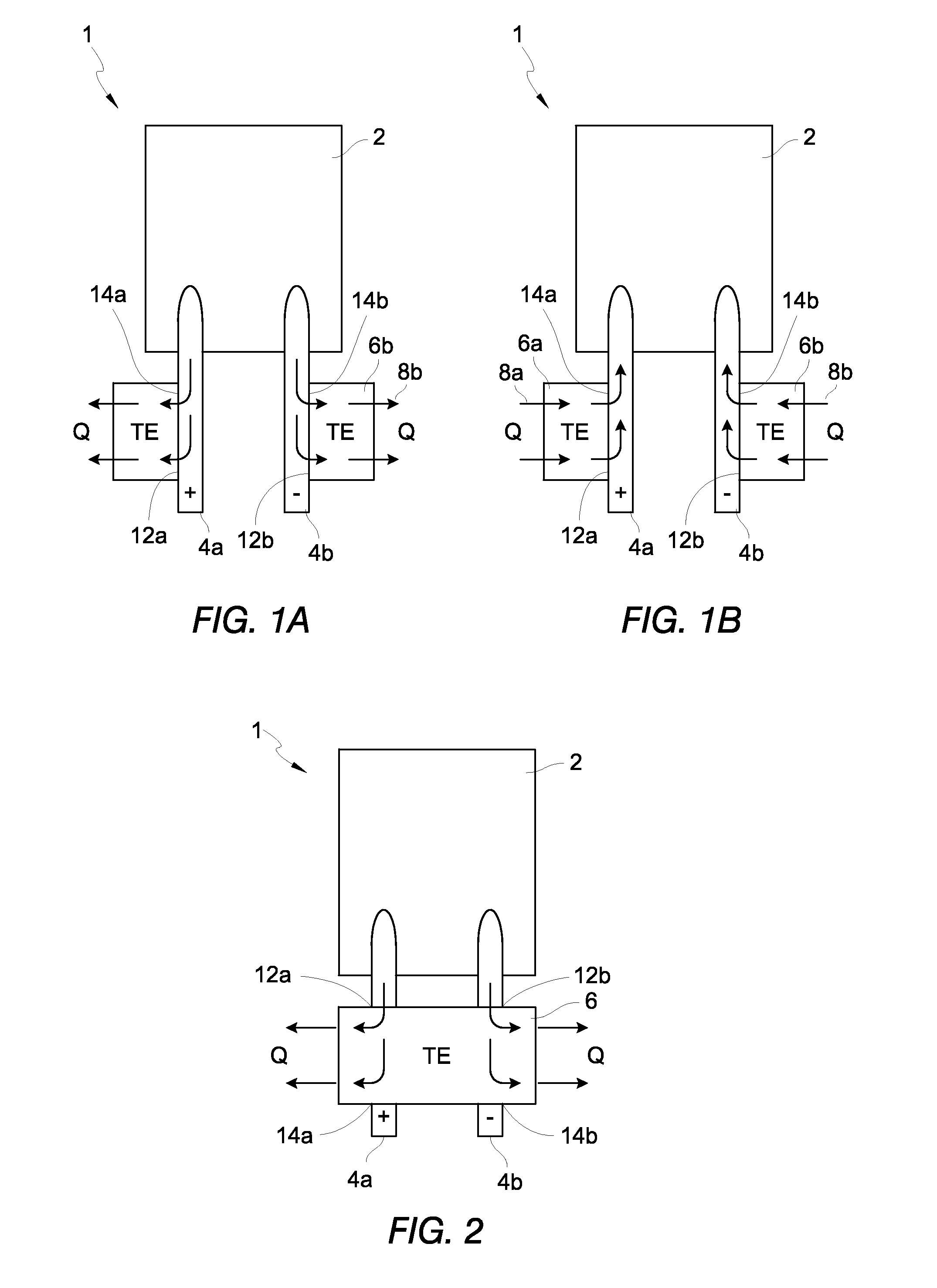

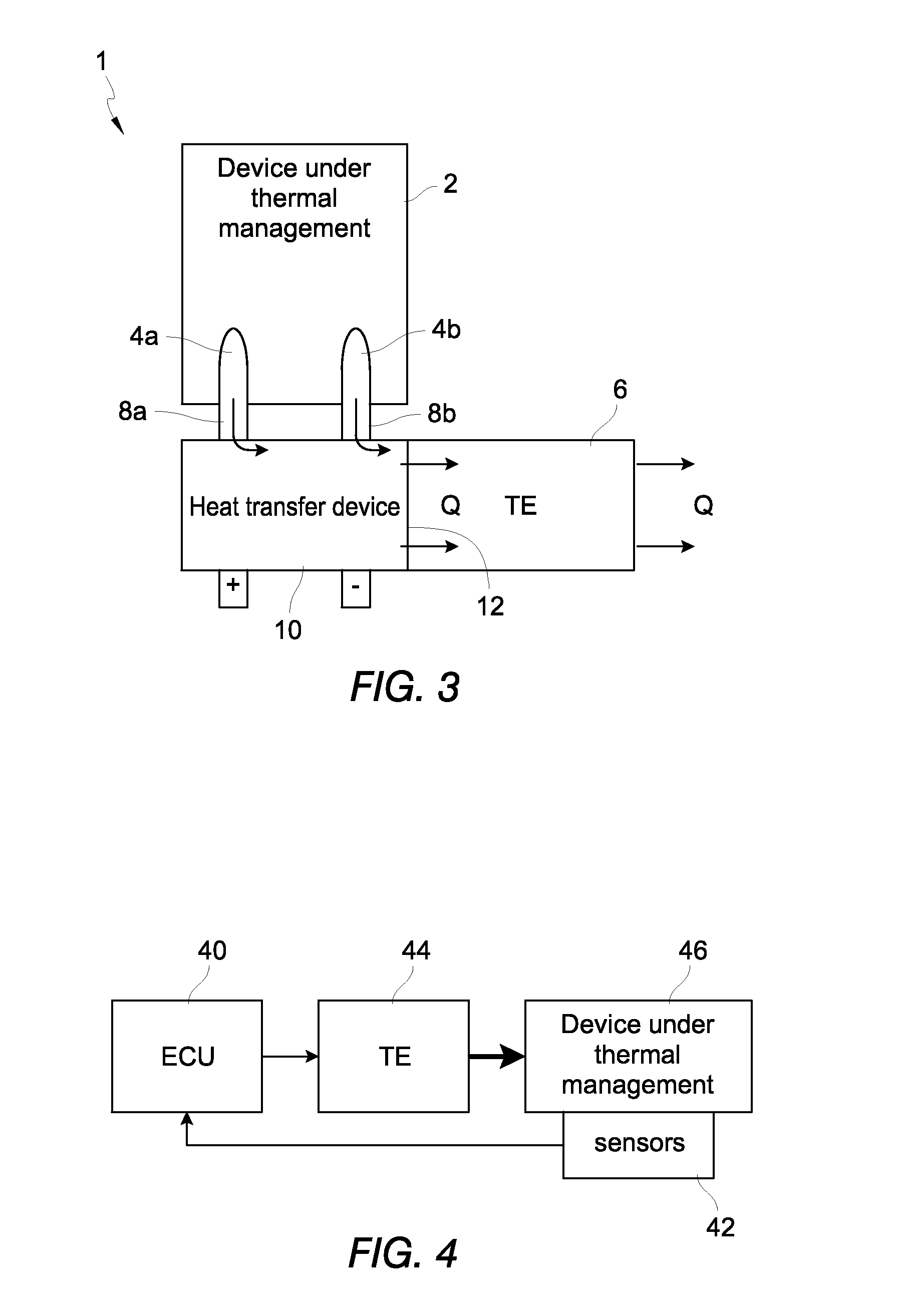

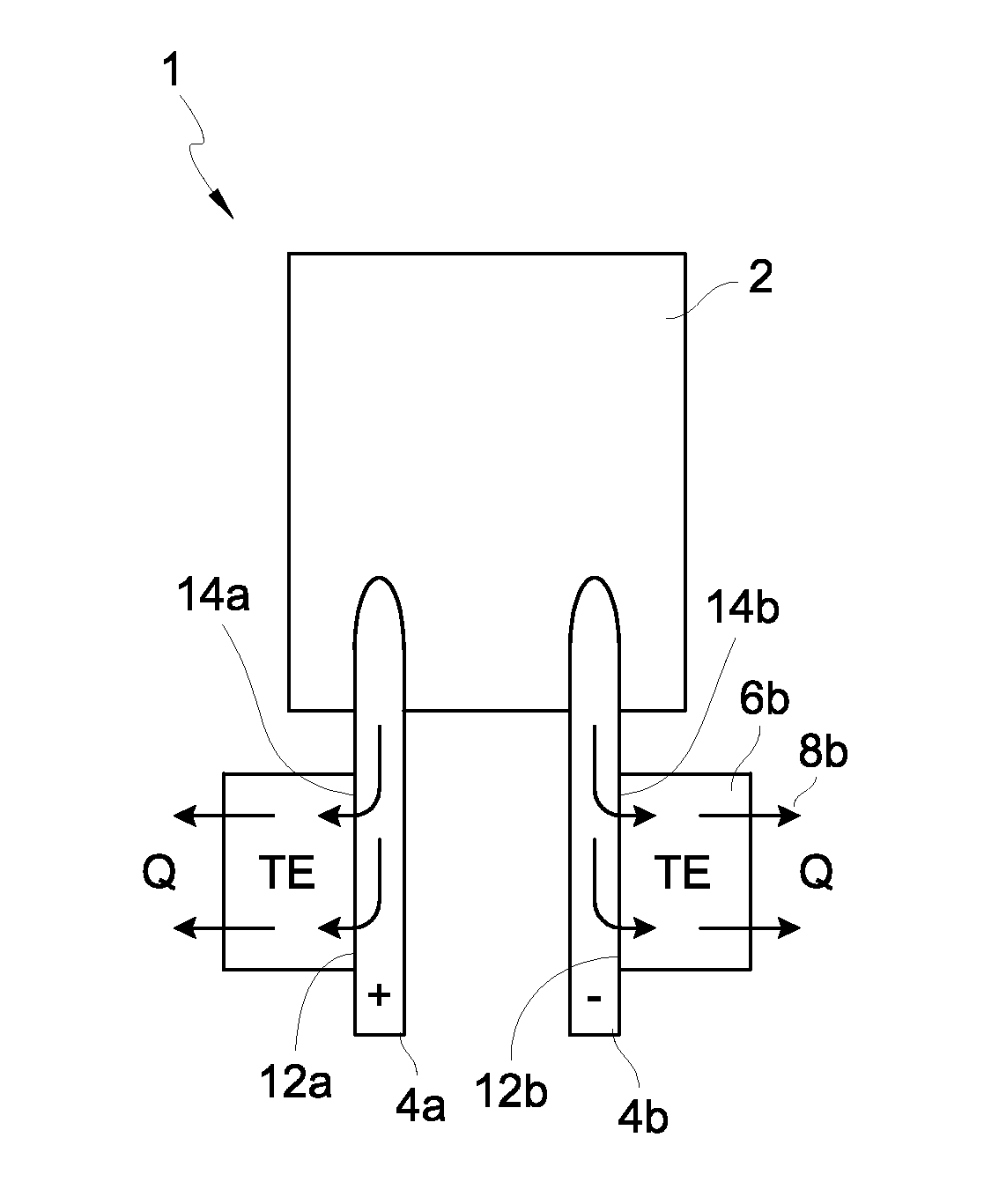

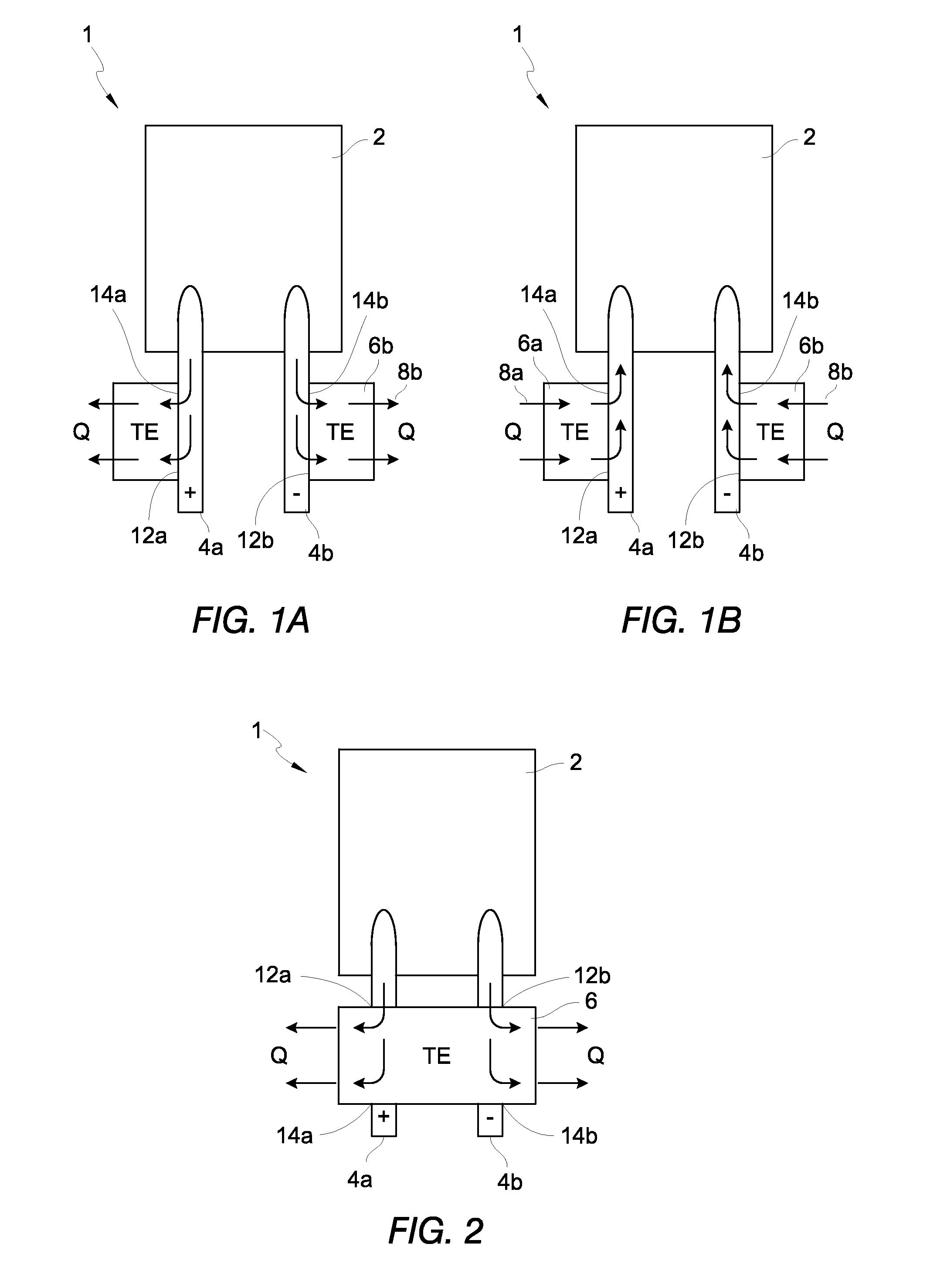

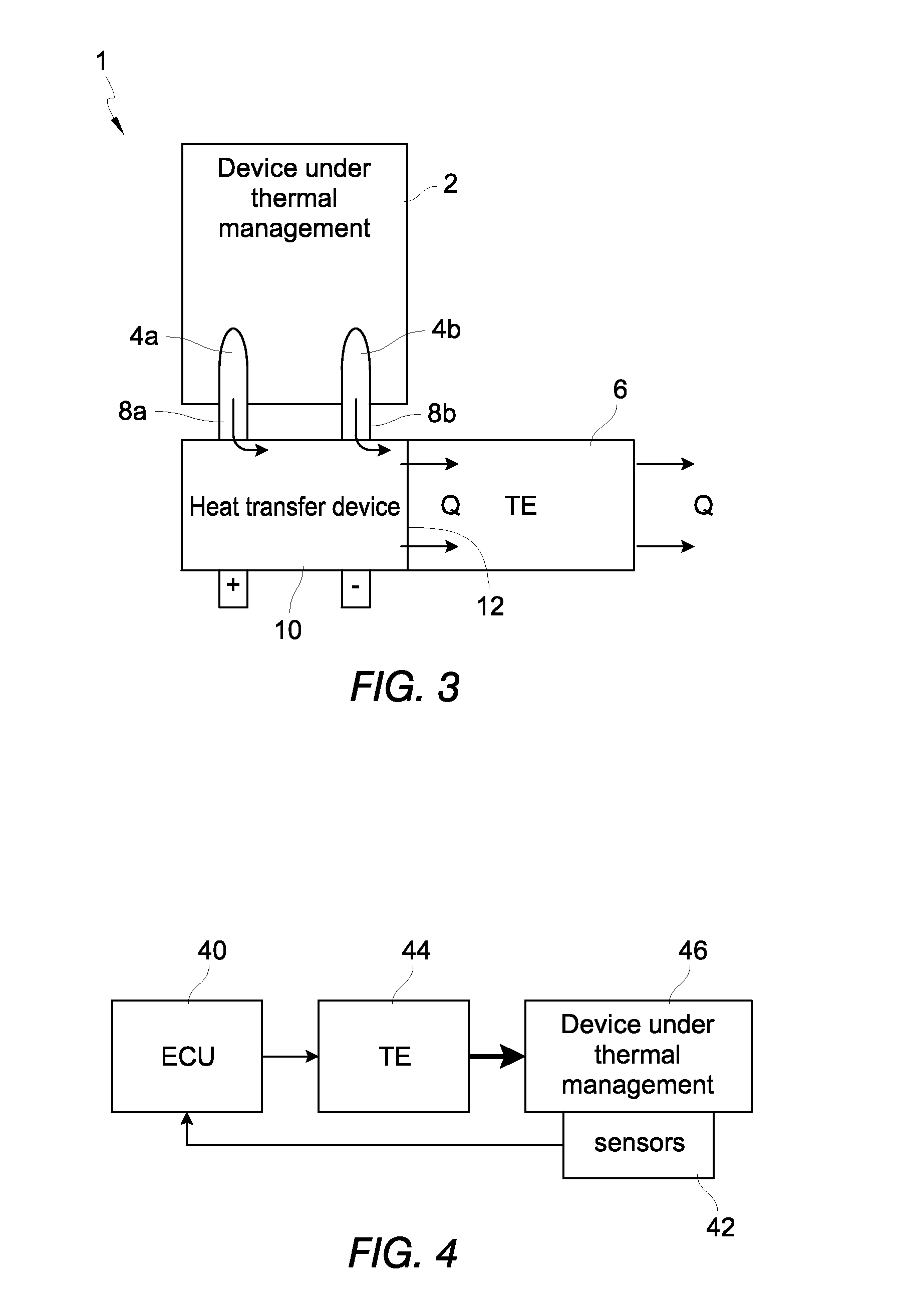

Thermoelectric-based thermal management of electrical devices

InactiveUS20130059190A1Reduce morbidityImprove power efficiencyCell temperature controlCell temperature regulationElectricityElectrical conductor

Disclosed embodiments include thermoelectric-based thermal management systems and methods configured to heat and / or cool an electrical device. Thermal management systems can include at least one electrical conductor in electrical and thermal communication with a temperature-sensitive region of the electrical device and at least one thermoelectric device in thermal communication with the at least one electrical conductor. Electric power can be directed to the thermoelectric device by the same electrical conductor or an external power supply, causing the thermoelectric device to provide controlled heating and / or cooling to the electrical device via the at least one electrical conductor.

Owner:GENTHERM INC

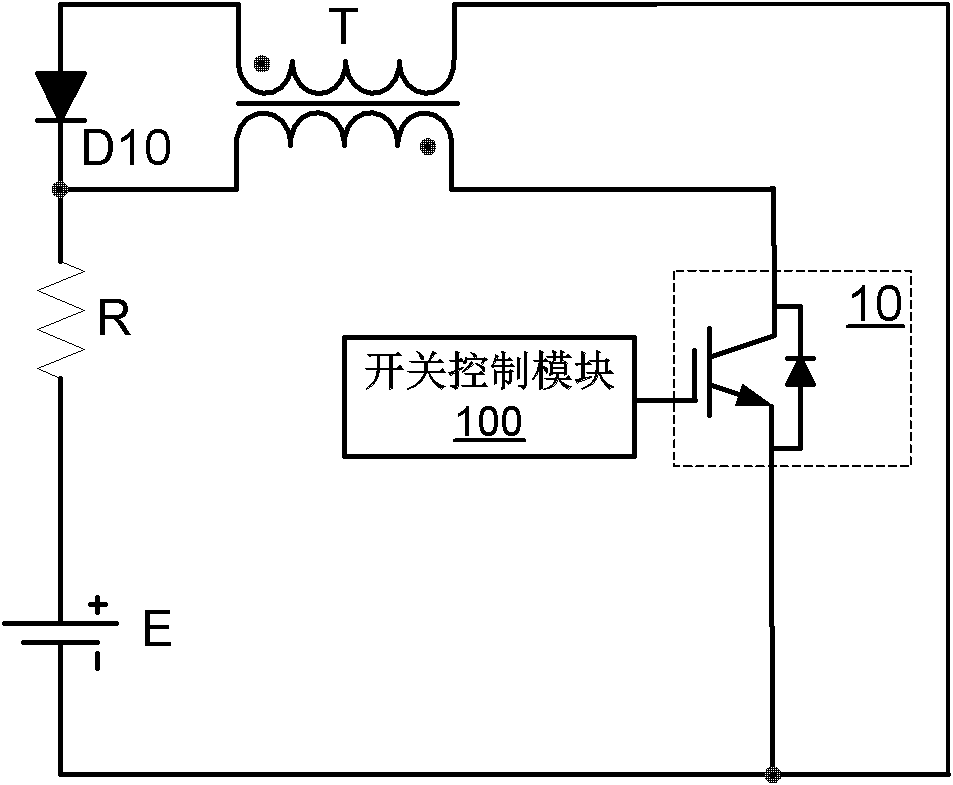

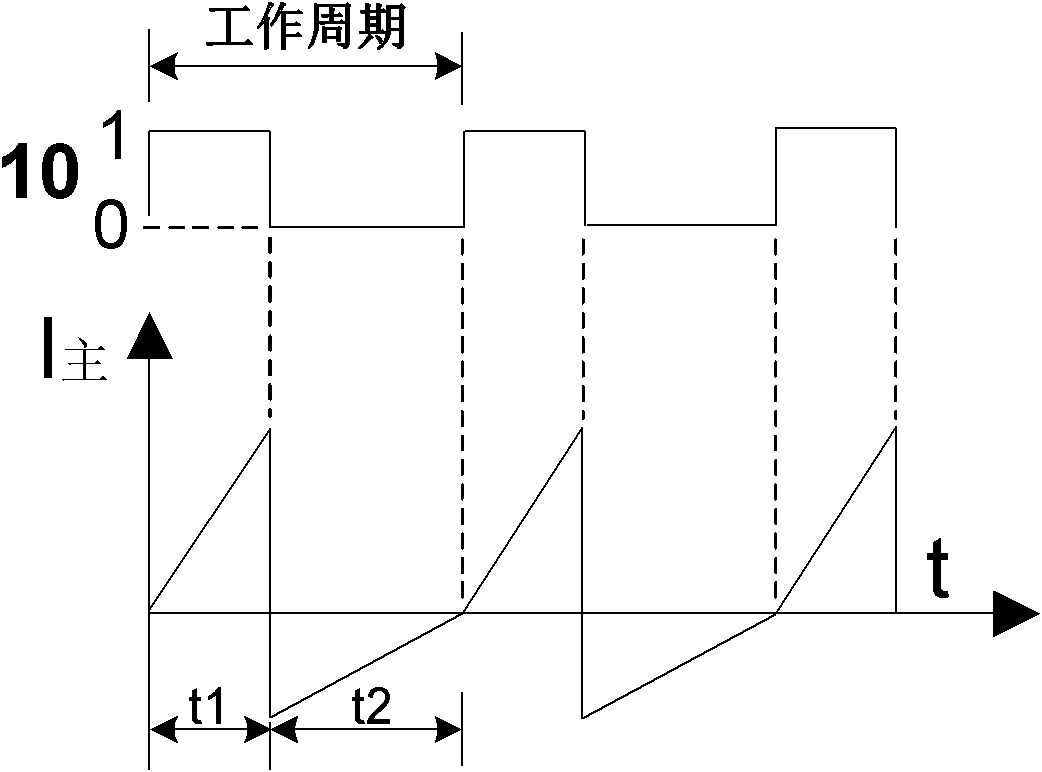

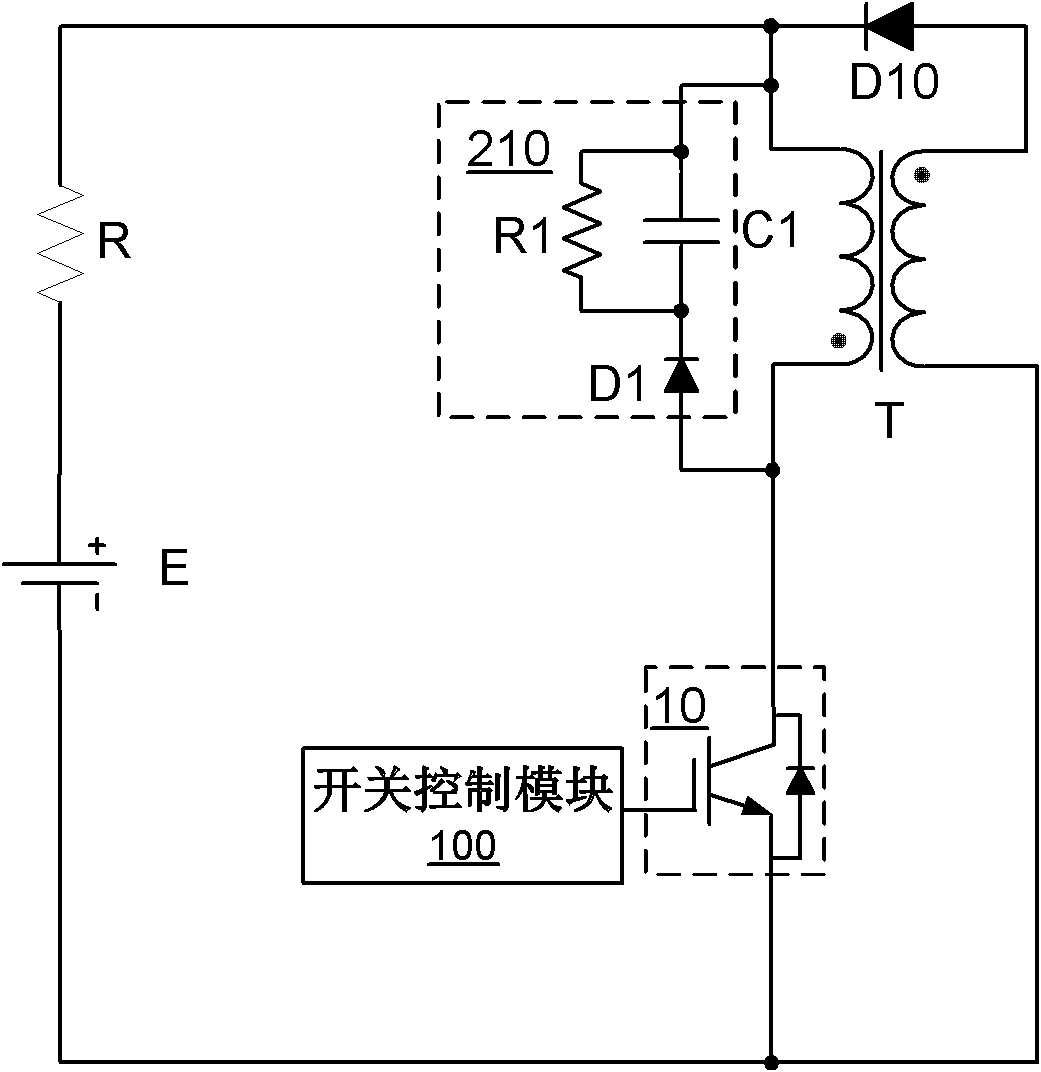

Heating circuit of battery

ActiveCN102074752AReduce lossSolid-state devicesCell temperature regulationBattery chargeTransformer

The invention provides a heating circuit of a battery. The heating circuit comprises a switching device (10), a switching control module (100), a unidirectional semiconductor element D10, a damping element R and a transformer (T), wherein the switching control module (100) is electrically connected with the switching device (10); the battery, the damping element R, the first coil of the transformer (T) and the switching device (10) are mutually connected in series to form a battery discharging circuit; and the battery, the damping element R, the second coil of the transformer (T) and the unidirectional semiconductor element D10 are mutually connected in series to form a battery charging circuit. Current limit and energy storage are realized by using the transformer (T), the current in the charging and discharging circuits can be reduced to avoid damaging the battery, and the energy consumption of the whole heating process is reduced.

Owner:BYD SEMICON CO LTD

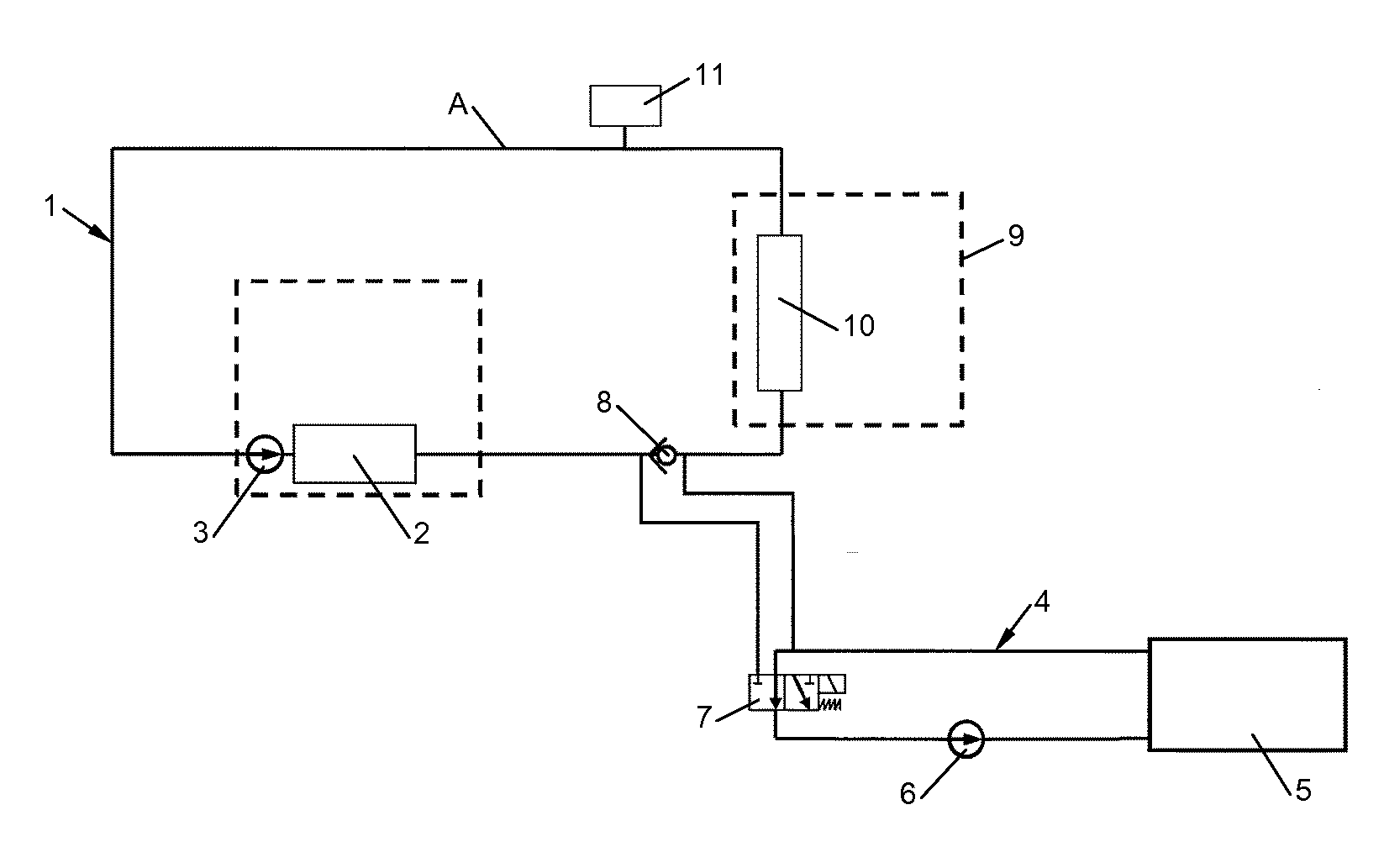

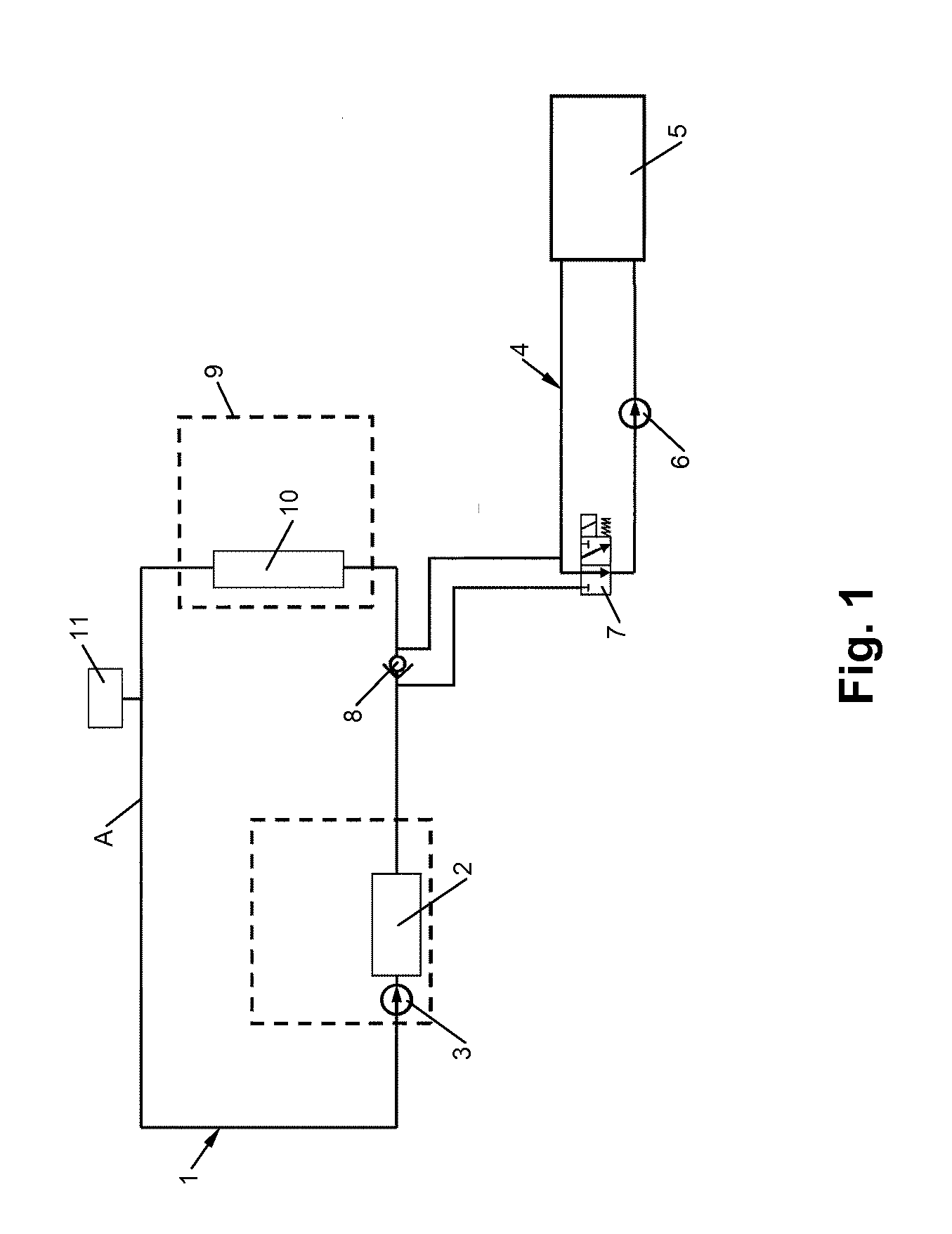

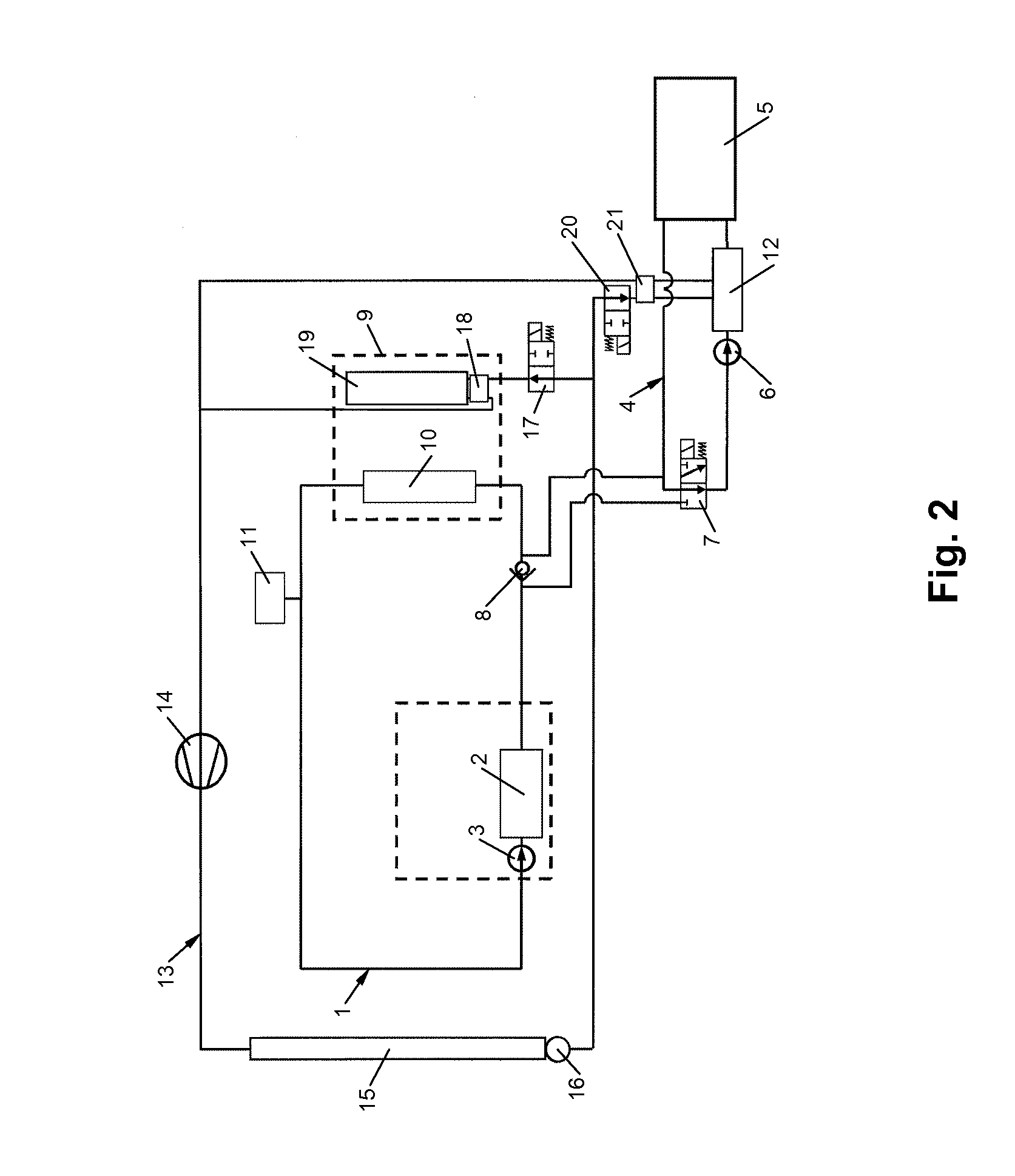

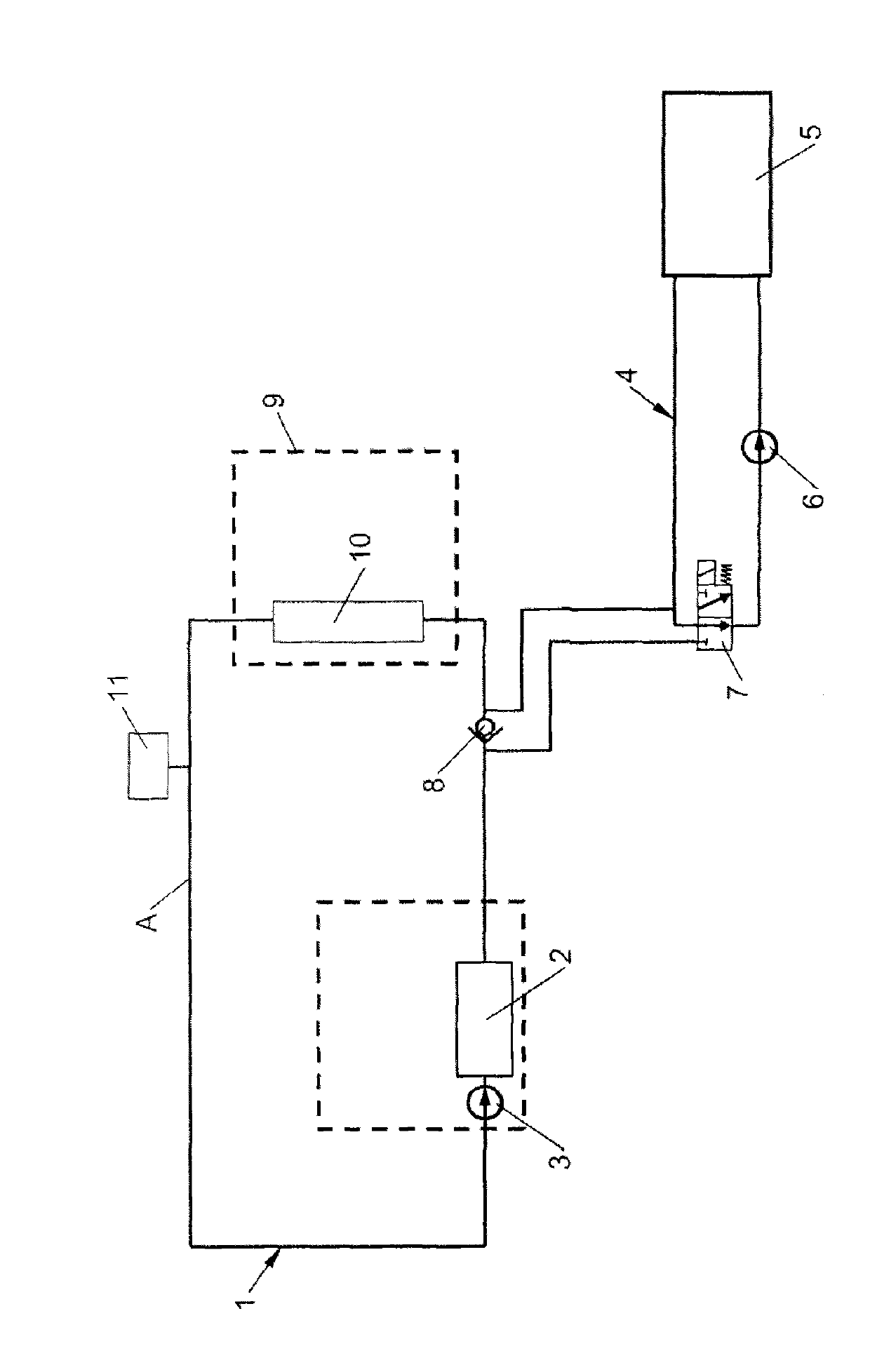

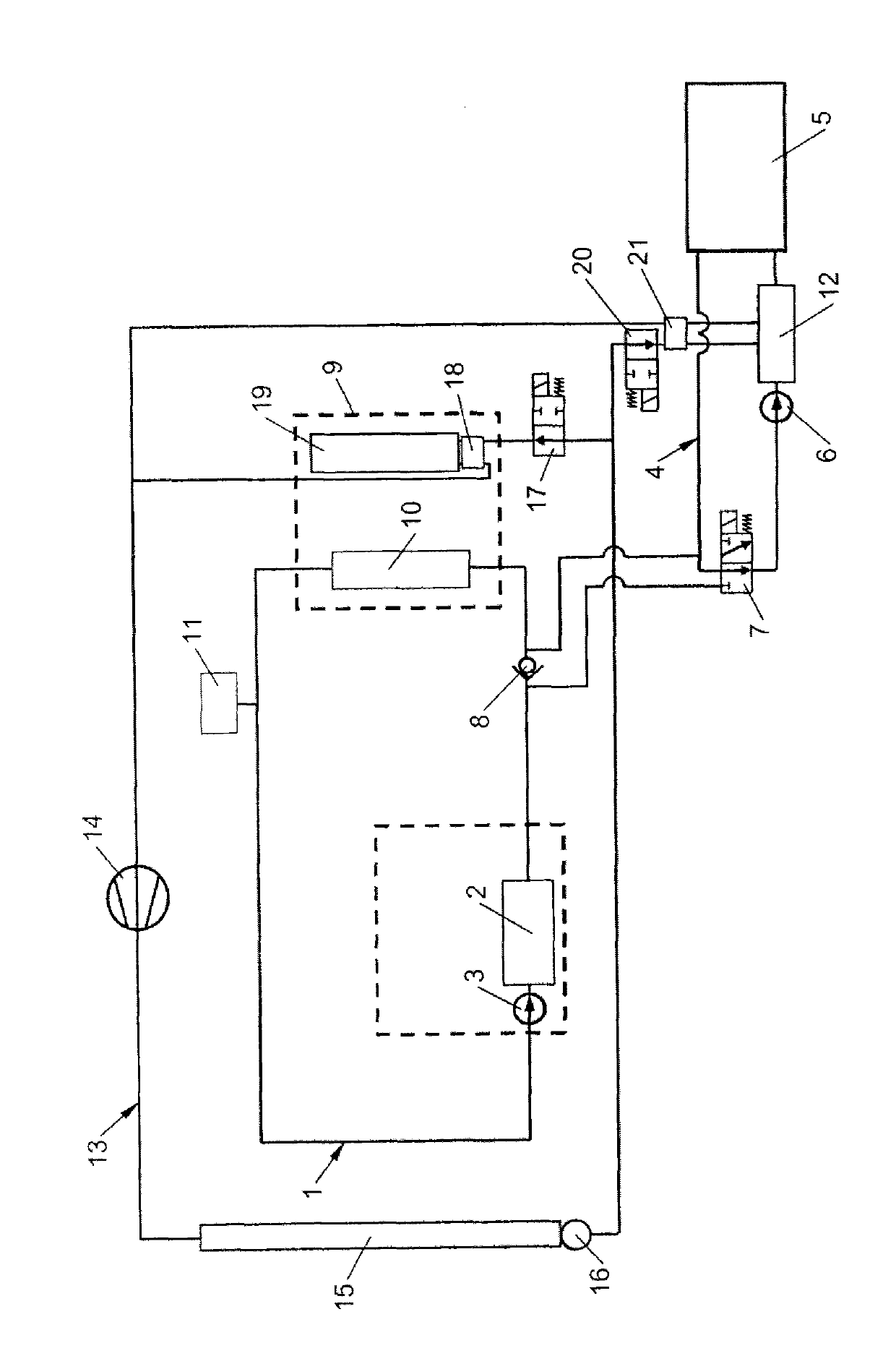

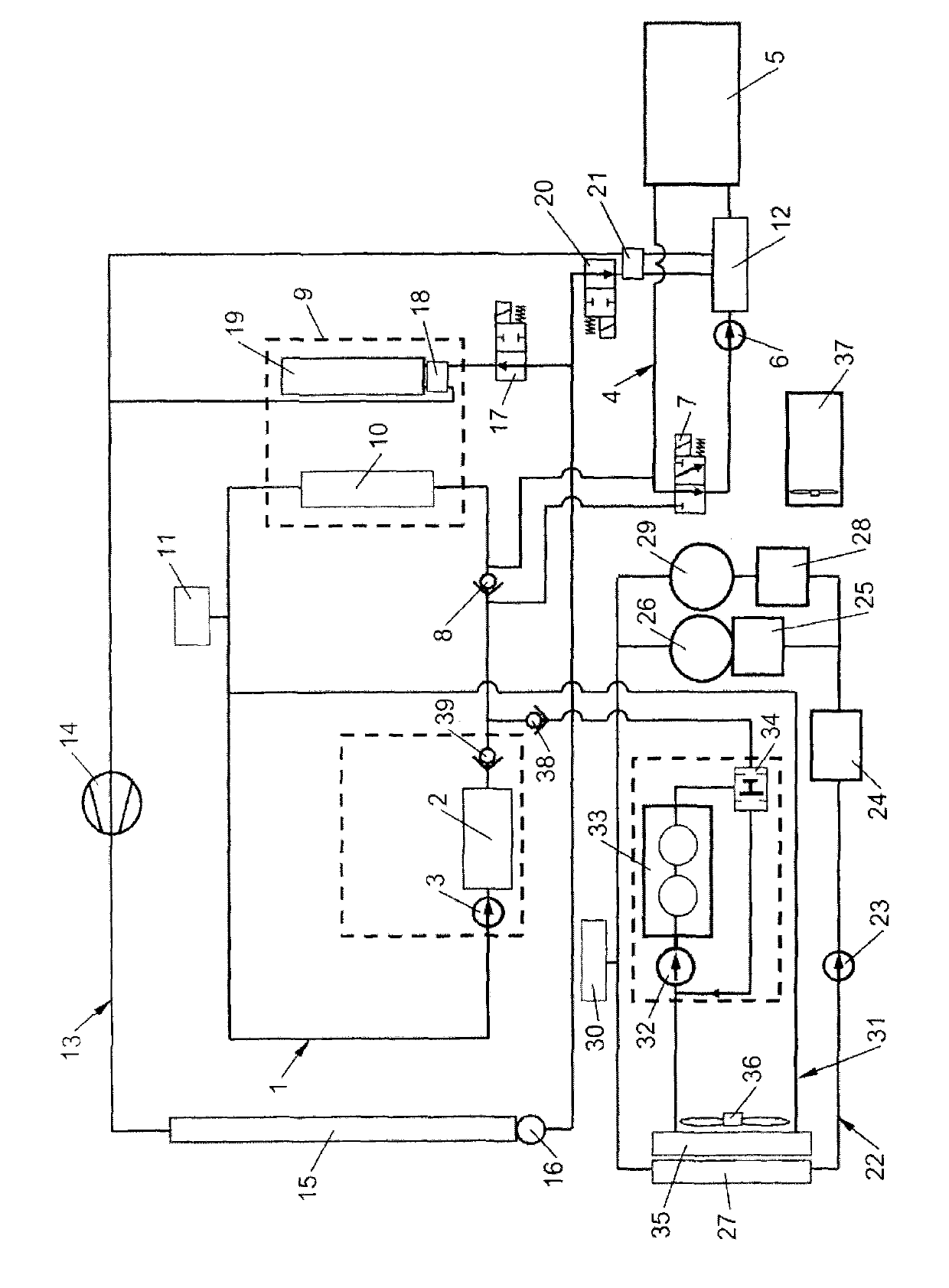

Heating/cooling system for a battery of a motor vehicle, and operating method for the same

InactiveUS20130140001A1Add operation methodCell temperature regulationVehicle heating/cooling devicesMobile vehicleHeat carrier

A motor vehicle and a method for operating the same. The motor vehicle includes a first heating / cooling circuit with a heat source / sink arranged therein and a first pump, and a second heating / cooling circuit with a battery to be heated / cooled arranged therein and a second pump. The heating / cooling circuits can be selectively operatively and / or fluidically connected by way of at least one valve such that the same liquid heat carrier flows through both heating / cooling circuits.

Owner:MAGNA STEYR FAHRZEUGTECHN

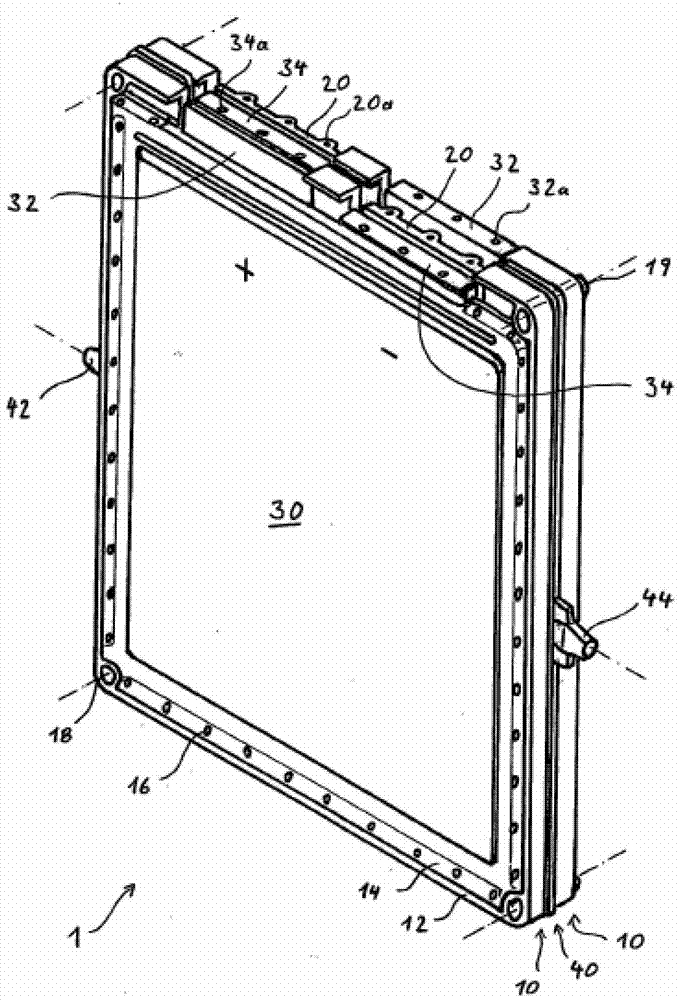

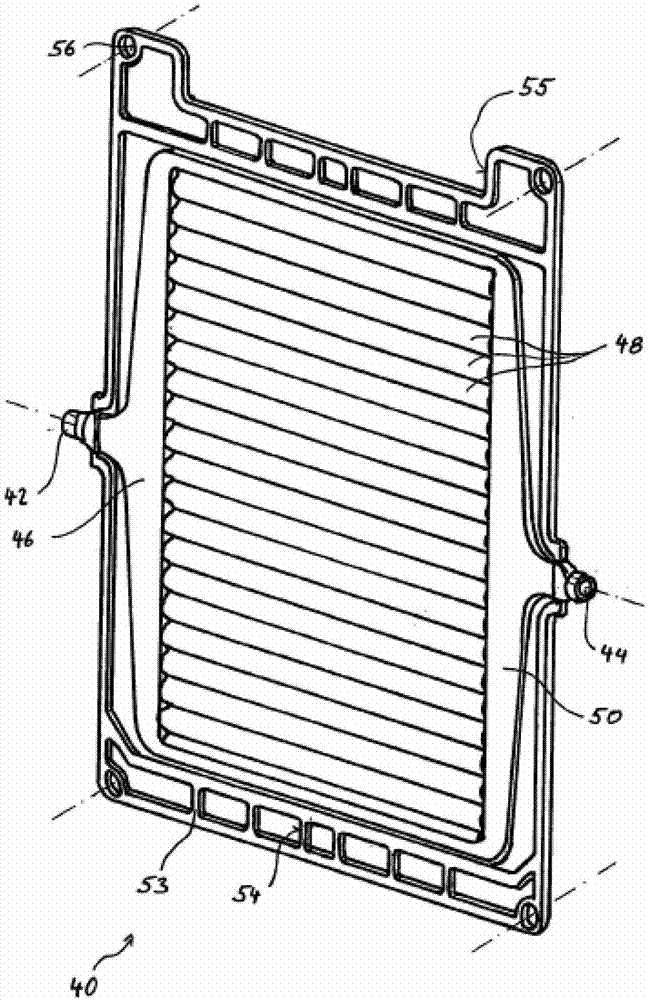

Cooling element, method for producing same, and electrochemical energy storage device comprising cooling element

InactiveCN102906933ASmall-sized cells cases/jacketsCell temperature controlEngineeringElectrochemical energy storage

The invention relates to a cooling element, which is designed and equipped in particular to be disposed between electrochemical energy storage cells, comprising a heat exchanger structure through which a heat transfer medium can flow and which is formed at least substantially of two film layers or film layer structures, the opposing surfaces of which are placed against one another and which are connected at junctures within the surfaces, wherein the junctures define cavities between the surfaces, wherein the heat transfer medium can be conducted through said cavities.

Owner:LI TEC BATTERY

Hybrid car and power system and battery heating method thereof

The invention provides a power system and a battery heating method of a hybrid car. The system comprises a battery pack, a battery heater, a battery manager, a distribution box, a motor controller, an engine, a motor and a shielded inductor. The battery heater is connected with the battery pack; the battery manager is used for controlling the battery heater to heat the battery pack at first power or second power under a condition that the hybrid car is in an electric mode or hybrid mode when the temperature of the battery pack is lower than a first heating temperature threshold and residual electric quantity is higher than a driving electric quantity threshold. The motor controller is connected with the motor and the distribution box, provided with a first input end, a second input end and a pre-charging capacitor connected between the first input end and the second input end, and used for supplying power to the motor according to a control command and voltage distributed by the distribution box. The shielded inductor matches with the pre-charging capacitor of the motor controller. The power system can realize heating, and is high in heating efficiency, low in cost and high in practicality. The invention further provides the hybrid car.

Owner:BYD CO LTD

Thermoelectric-based thermal management of electrical devices

InactiveUS8722222B2Reduce morbidityHigh currentCell temperature controlCell temperature regulationElectricityElectrical conductor

Disclosed embodiments include thermoelectric-based thermal management systems and methods configured to heat and / or cool an electrical device. Thermal management systems can include at least one electrical conductor in electrical and thermal communication with a temperature-sensitive region of the electrical device and at least one thermoelectric device in thermal communication with the at least one electrical conductor. Electric power can be directed to the thermoelectric device by the same electrical conductor or an external power supply, causing the thermoelectric device to provide controlled heating and / or cooling to the electrical device via the at least one electrical conductor.

Owner:GENTHERM INC

Heating/cooling system for a vehicle battery and operation method for the same

InactiveCN103213472ALow costVersatileAir-treating devicesCell temperature regulationHeat carrierElectrical and Electronics engineering

The invention relates to a motor vehicle. The motor vehicle includes a first heating / cooling circuit (1) with a heat source / sink (2) arranged therein and a first pump (3), and a second heating / cooling circuit with a battery (5) to be heated / cooled arranged therein and a second pump (6). The heating / cooling circuits can be selectively operatively and / or fluidically connected by way of at least one valve such that the same liquid heat carrier flows through both heating / cooling circuits. In particular, also in the second heating / cooling circuit (4) between the valve (7) and the battery (5) is provided with a heat exchanger (12) and / or a fluid reservoir and / or a cyclone and / or a long circuit. Furthermore, the invention also relates to a method of operating the motor vehicle.

Owner:MAGNA STEYR FAHRZEUGTECHN

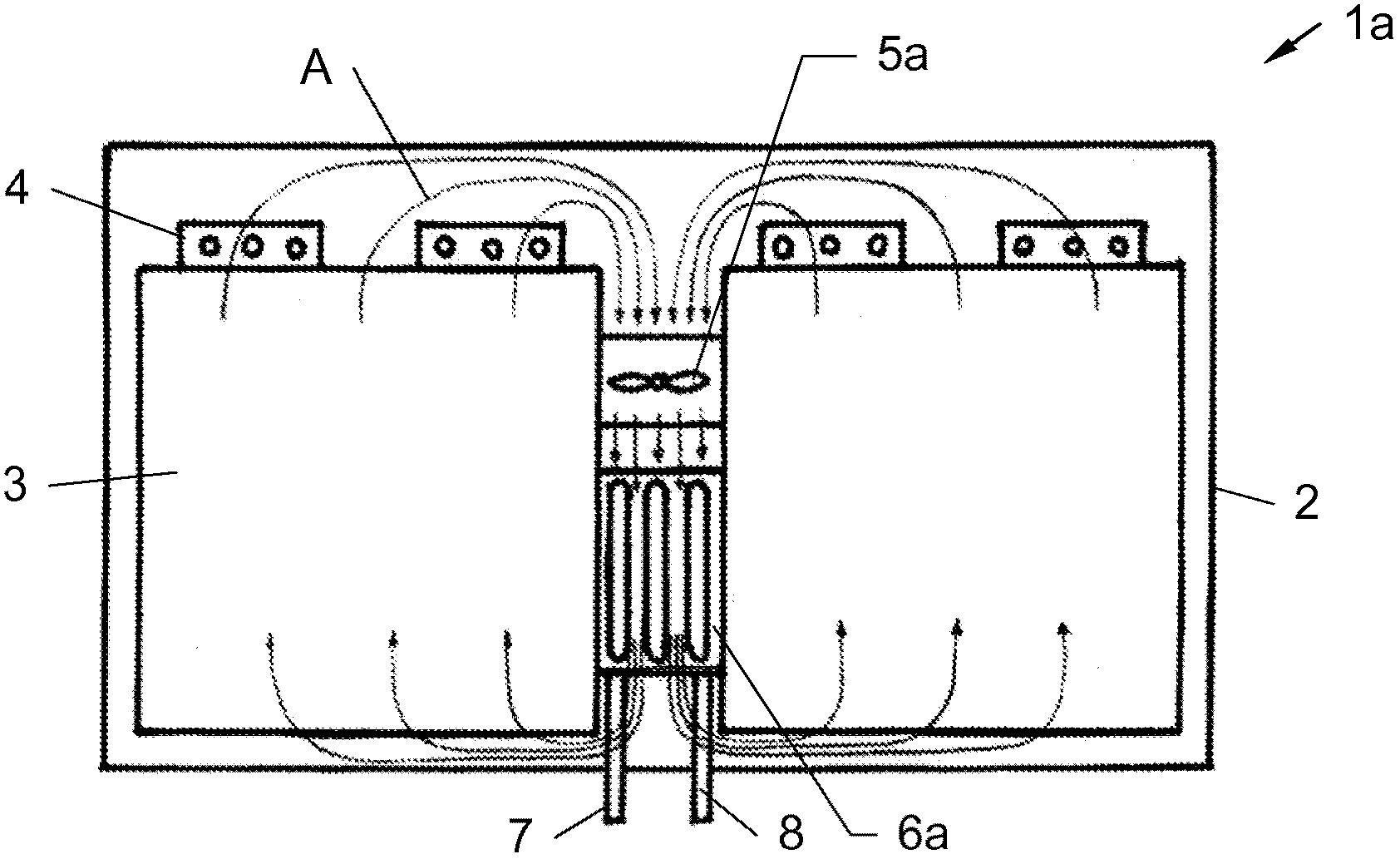

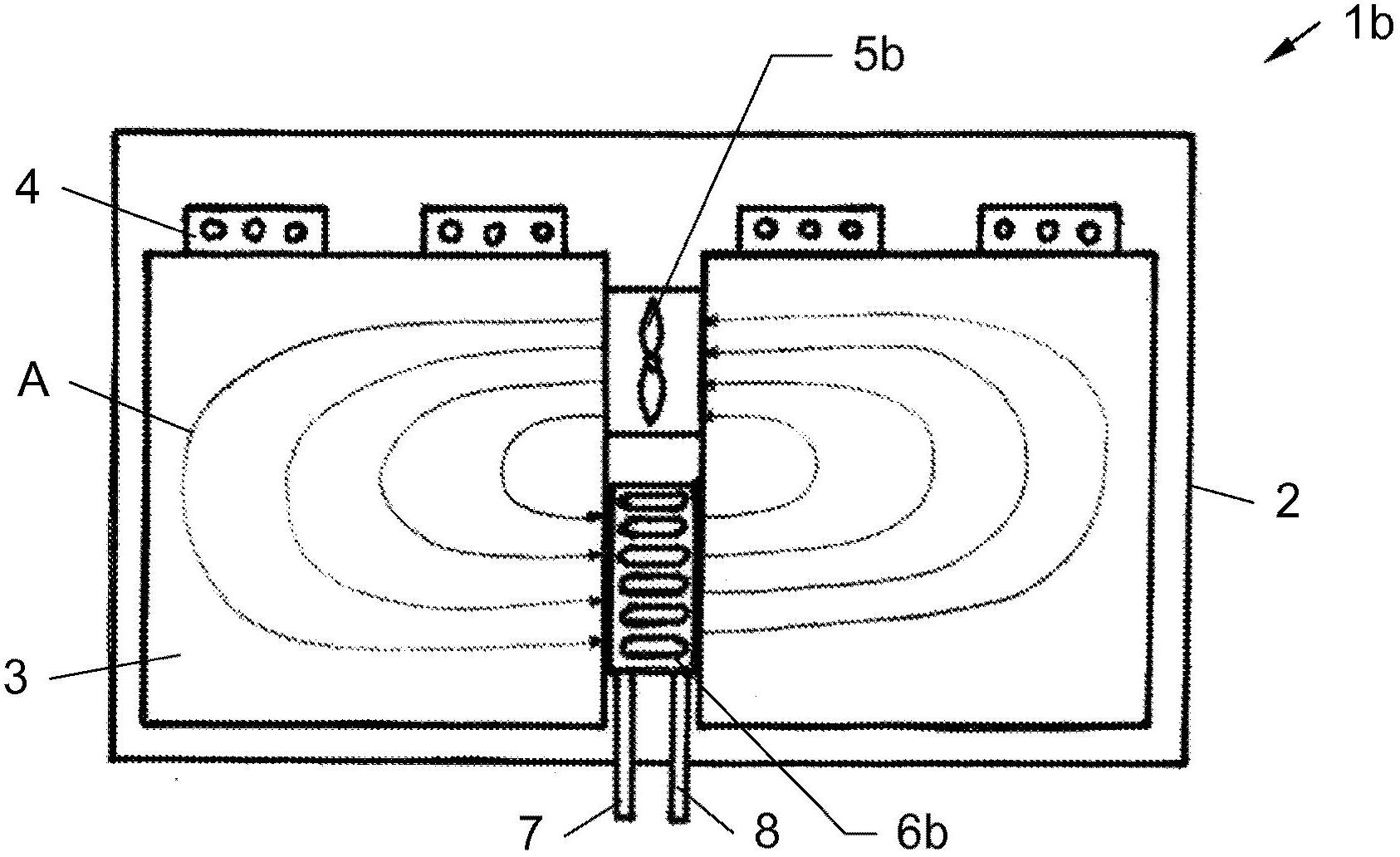

Battery having temperature regulation

InactiveCN102696130ANo risk of damageEliminate local overheatingAir-treating devicesSmall-sized cells cases/jacketsGalvanic cellHeat exchanger

A battery (Ia.. Ie) having a housing (2) and a plurality of galvanic cells (3) arranged in the housing (2) is provided. In addition, a fan (5a..5c) is arranged in the housing (2) to create a fluid flow circulating inside the housing (2). According to the invention, a heat exchanger (6a..6e) having a forward flow (7) and a return flow (8) for a heat transfer medium, which lead out of the housing (2) is arranged in the flow path (A) of the fluid flow.

Owner:BRUSA ELECTRONICS AG

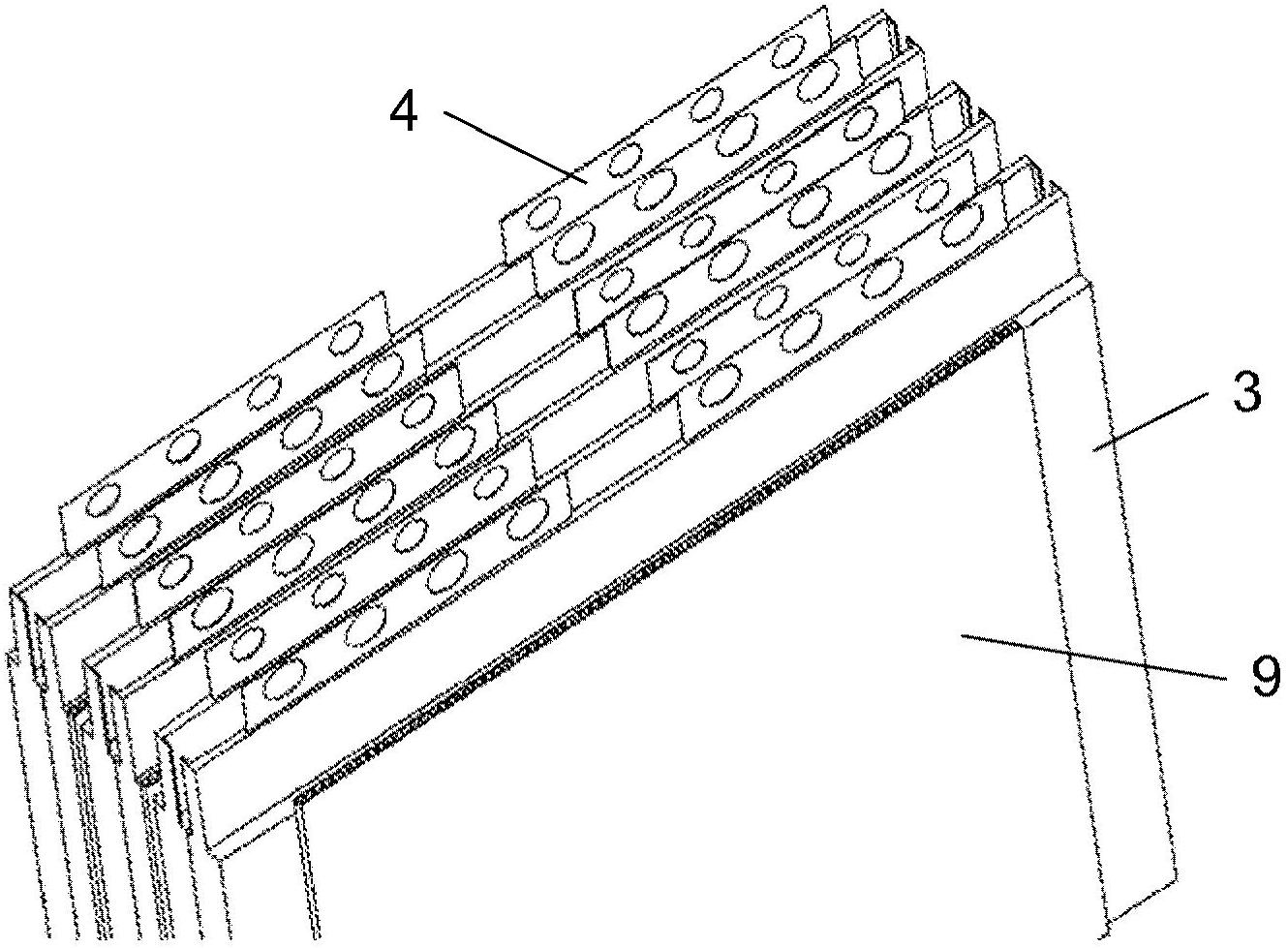

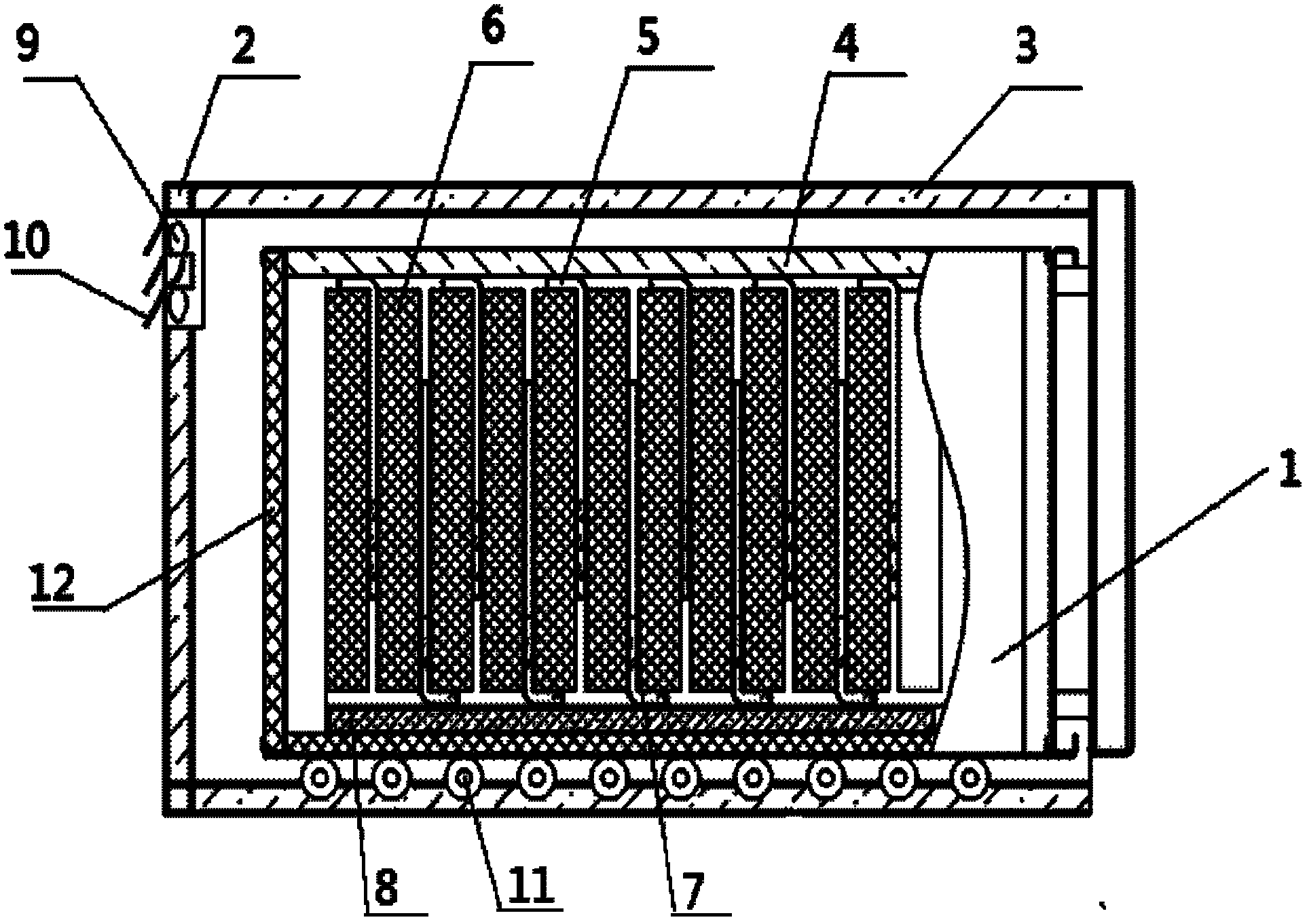

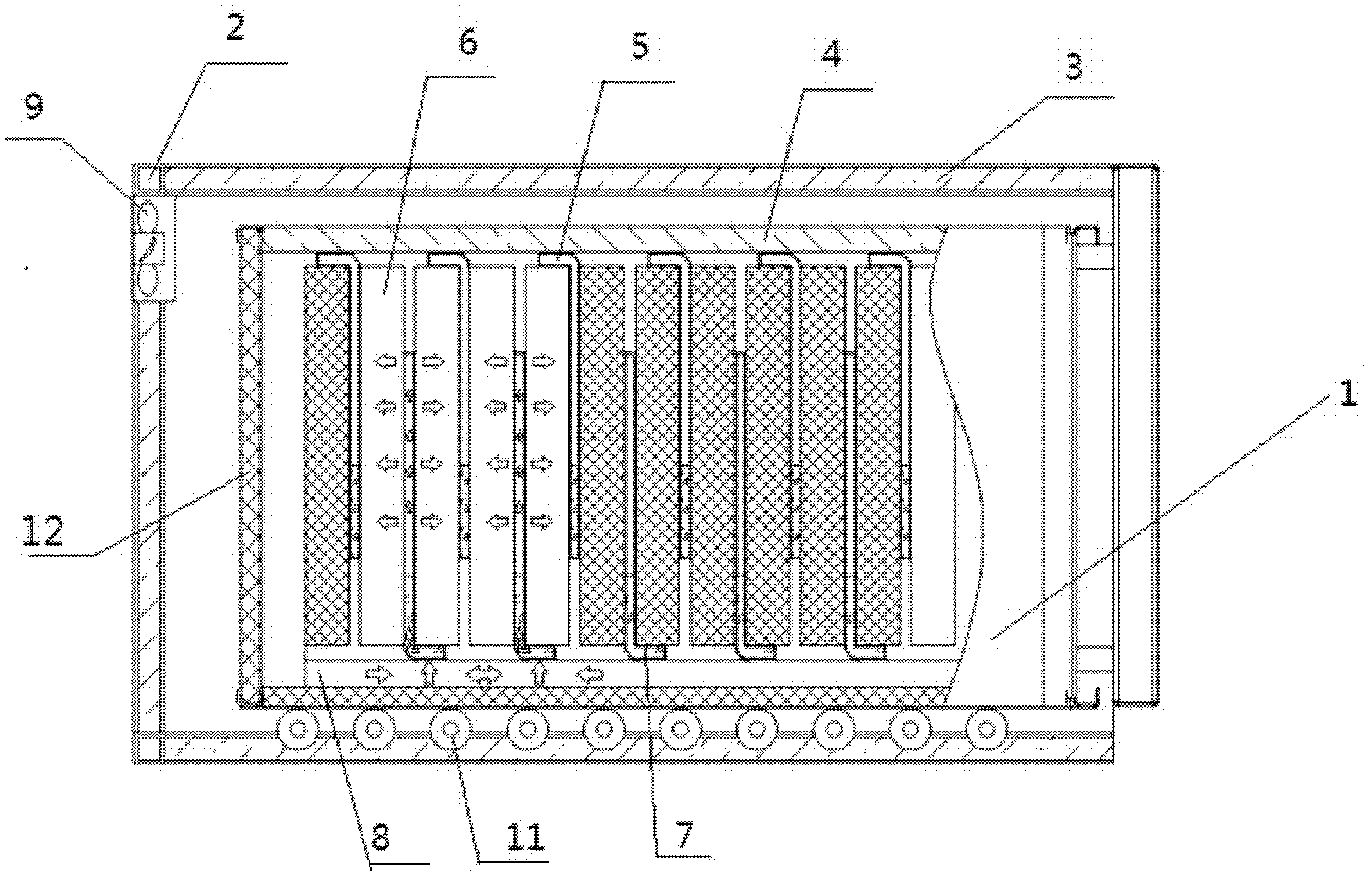

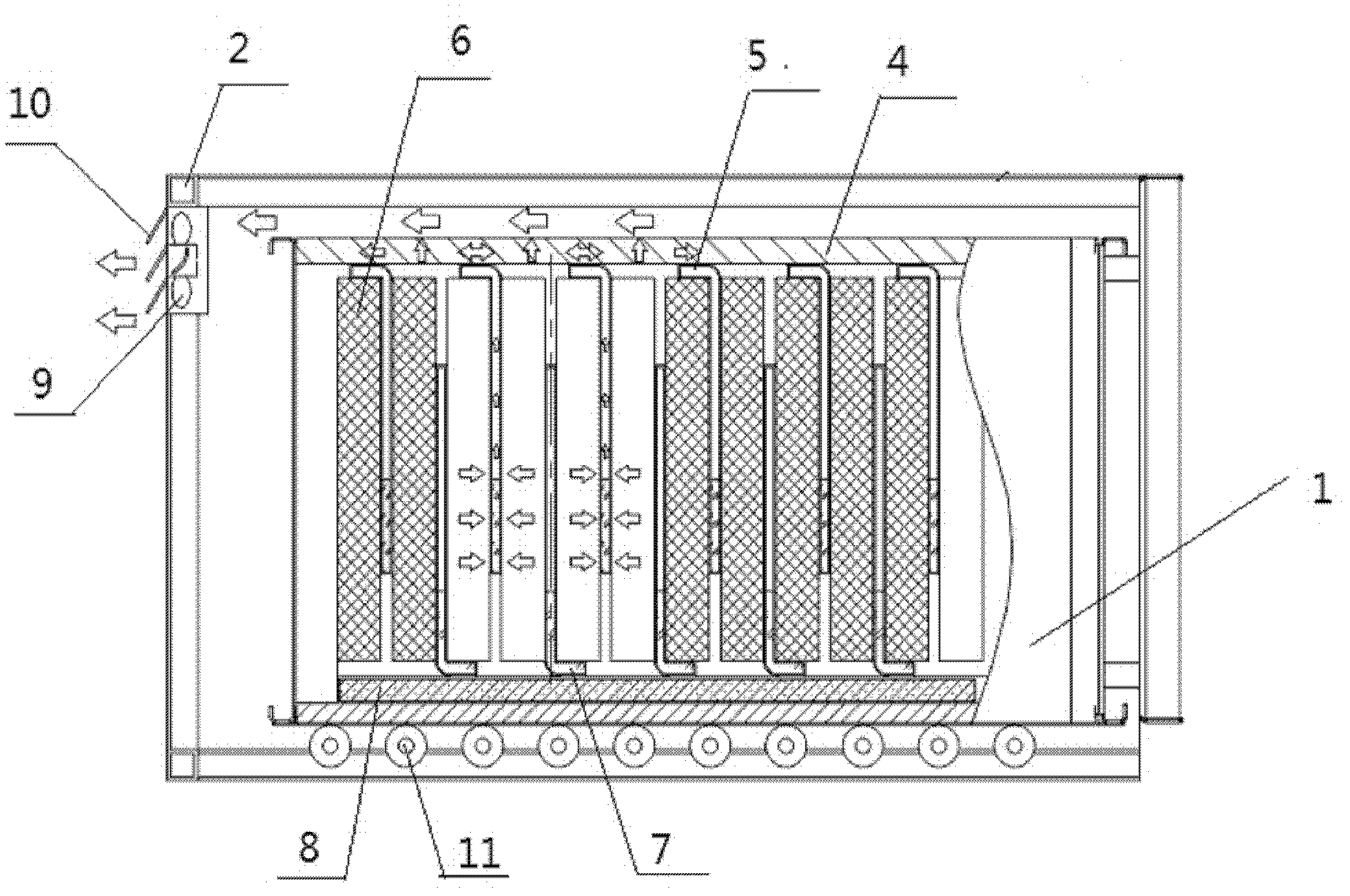

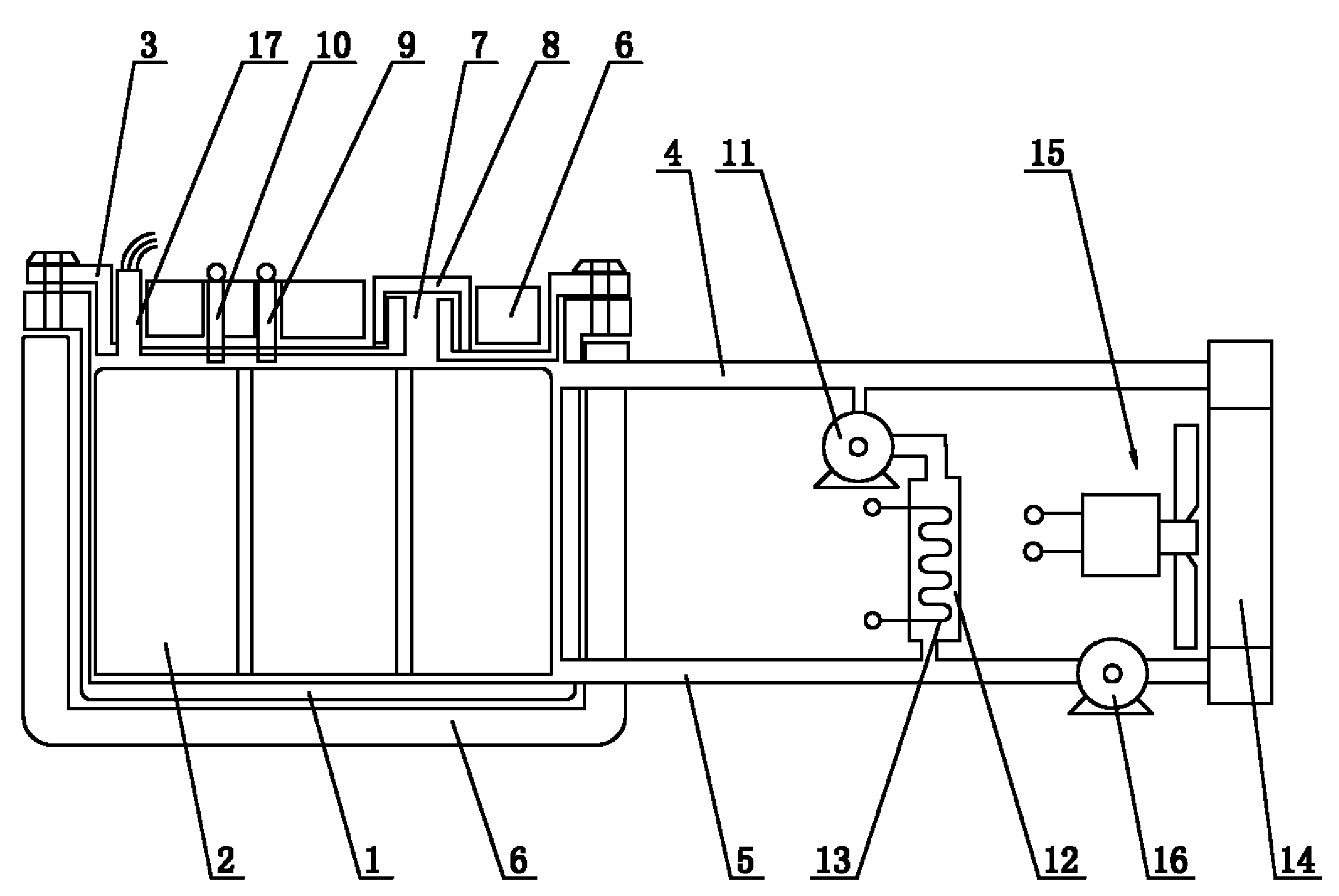

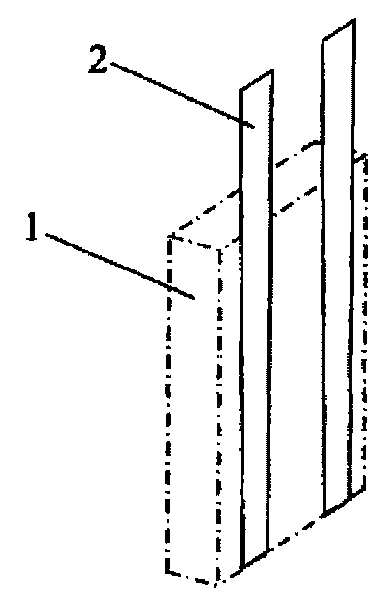

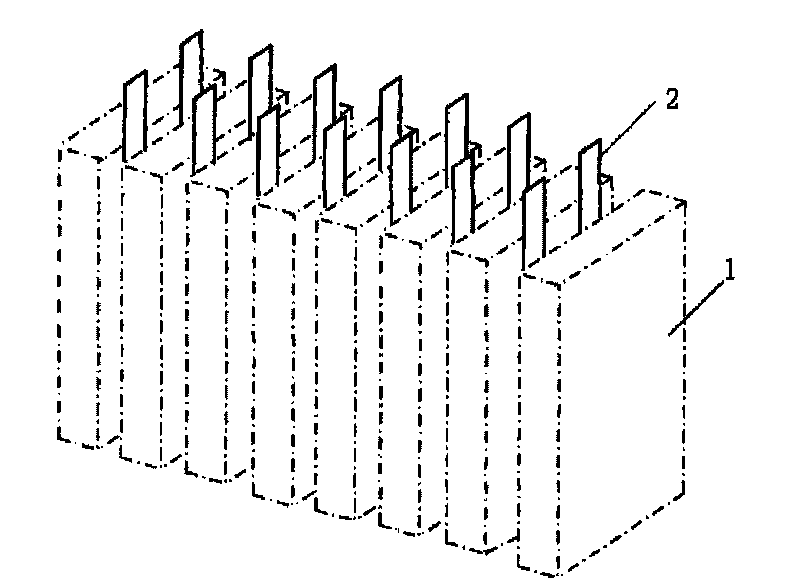

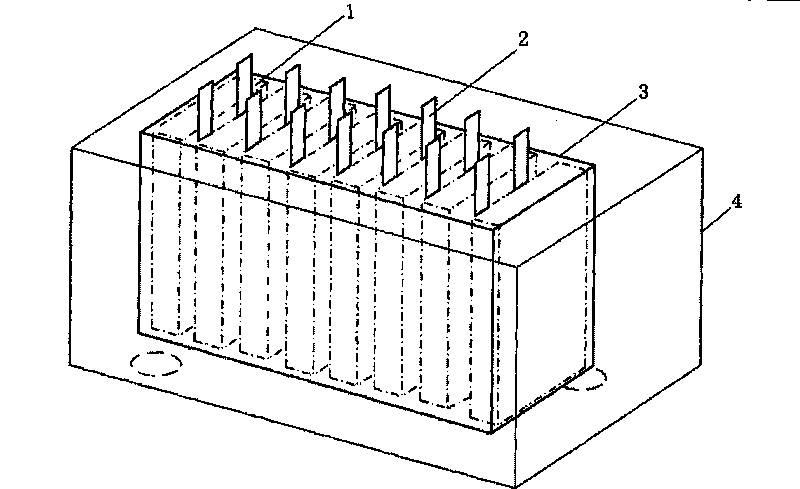

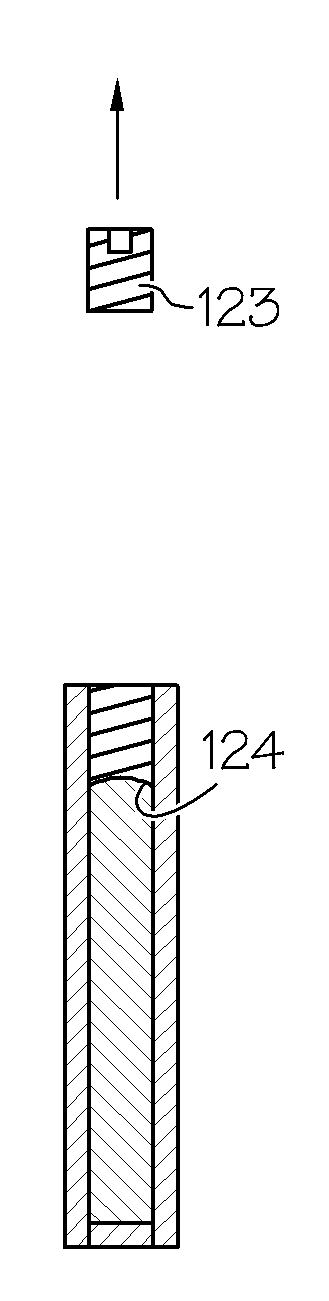

A heat pipe temperature control system for a vehicle power battery box

ActiveCN102280672ASolve problems that are greatly affected by temperatureEasy to useBattery isolationCell temperature regulationHeat sinkOperating environment

The present invention relates to the technical field of electrically powered automobiles, and in particular relates to a temperature control system with thermal tubes for a vehicle power battery box. The temperature control system with thermal tubes comprises an outer battery box, an inner battery box, and a plurality of battery cells provided inside the inner battery box, with heat-sink thermal tubes or heating thermal tubes closely clamped between the battery cells; the heat-sink thermal tubes or heating thermal tubes are separated from each other; a heat-preserving plate for the outer box is provided on the body of the outer battery box, and a cover plate for the inner box is provided on the top of the body of the inner battery box; the other parts of the body of the inner battery box are provided with heat-preserving plates for the inner box; heating devices are provided on the bottom of the inner battery box; heat-sink fans are provided on the outer battery box. The temperature control system with thermal tubes can be used to heat the battery during subzero winters in northern regions as well as to dissipate heat from the battery during hot weather in summers, providing a good operating environment for the battery cells and playing an important role in improving the service performance and the safety of the battery cells.

Owner:CHINA ELECTRIC POWER RES INST +1

Battery systems, battery modules, and method for cooling a battery module

Owner:LG ENERGY SOLUTION LTD

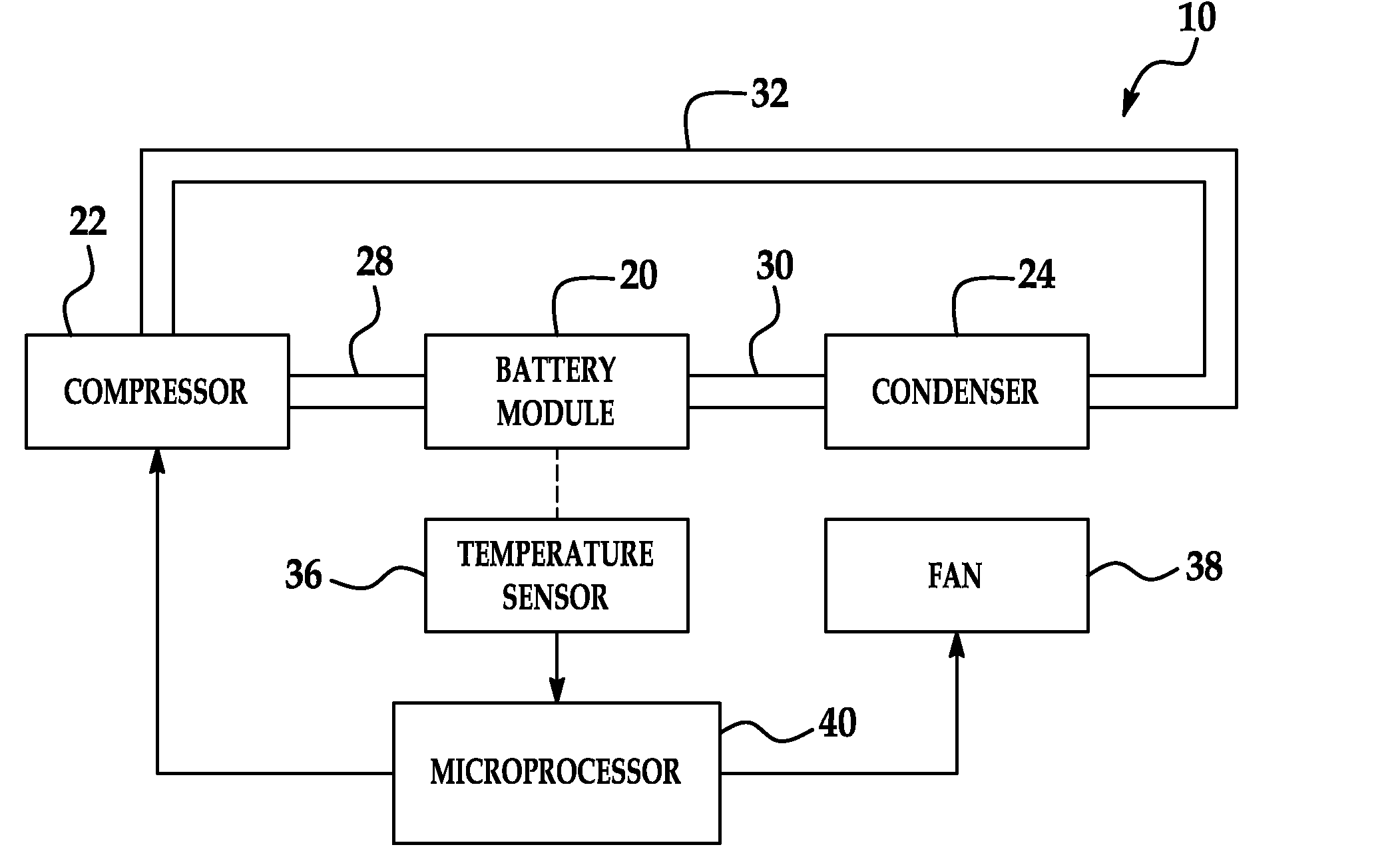

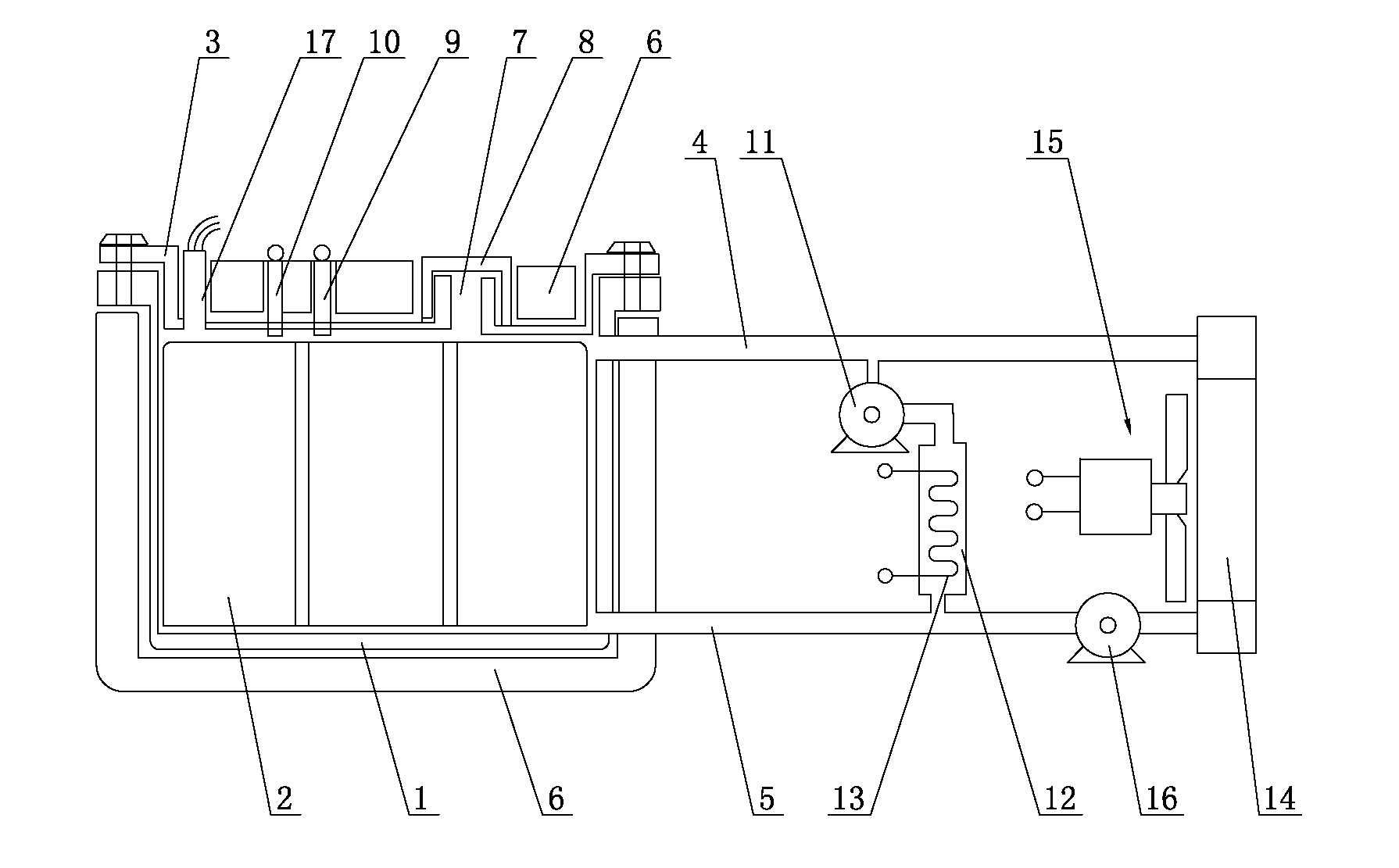

Constant temperature control battery pack

InactiveCN102324591AIncrease capacityExtend your lifeCell temperature regulationTemperature controlElectric aircraft

The present invention relates to the technical field of power supplies of electric vehicles, hybrid electric vehicles and electric aircrafts, especially to a constant temperature control battery pack. The constant temperature control battery pack comprises an inner box and a battery pack. Heat exchange liquid is arranged inside the inner box. A temperature detection device is arranged on an upper cover of the box. The constant temperature control battery pack further comprises a heating apparatus, a cooling apparatus, a first pipeline and a second pipeline. According to the present invention, the automatic constant temperature control system is provided for the relation between the electrochemical characteristics of the battery pack and the temperature changing, wherein the automatic constant temperature control system can be provided for heating the battery pack, cooling the battery pack, and holding the temperature of the battery pack to enable the battery pack to work in an optimal temperature range; the battery pack is prevented from influence due to the environmental temperature changing; the battery pack using is prevented from influence due to the using area; the performance of the battery pack can be provided at maximum at any temperature; the generated heat can be rapidly dissipated when the battery has the short-circuit fault, such that the misfire and the burning can not be generated; the capacity, the efficiency, the service life and the safety of the battery pack are improved; the constant temperature control battery pack provided by the present invention provides significant advances than the battery pack in the prior art.

Owner:DONGGUAN LONGXING AVIATION TECH

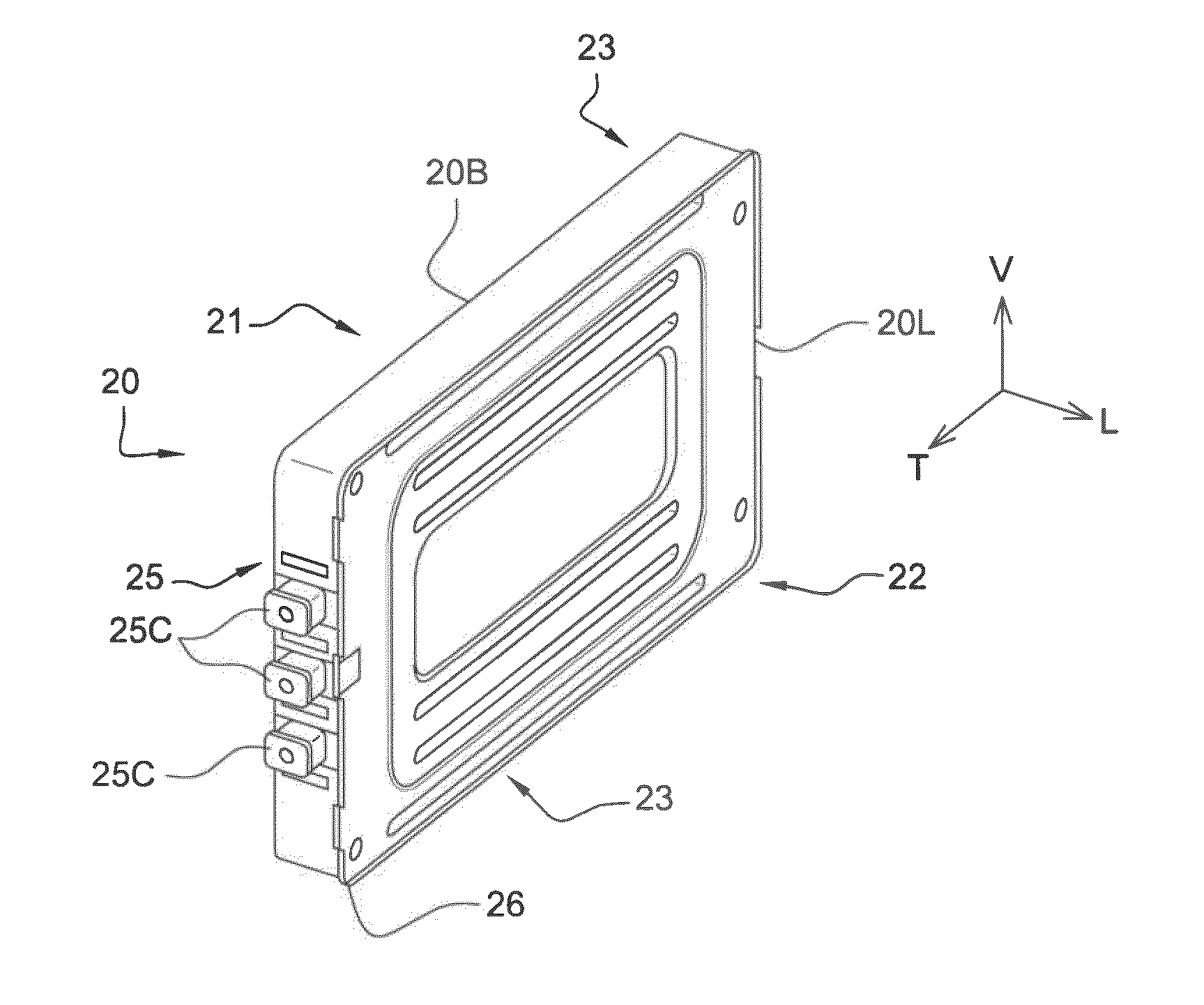

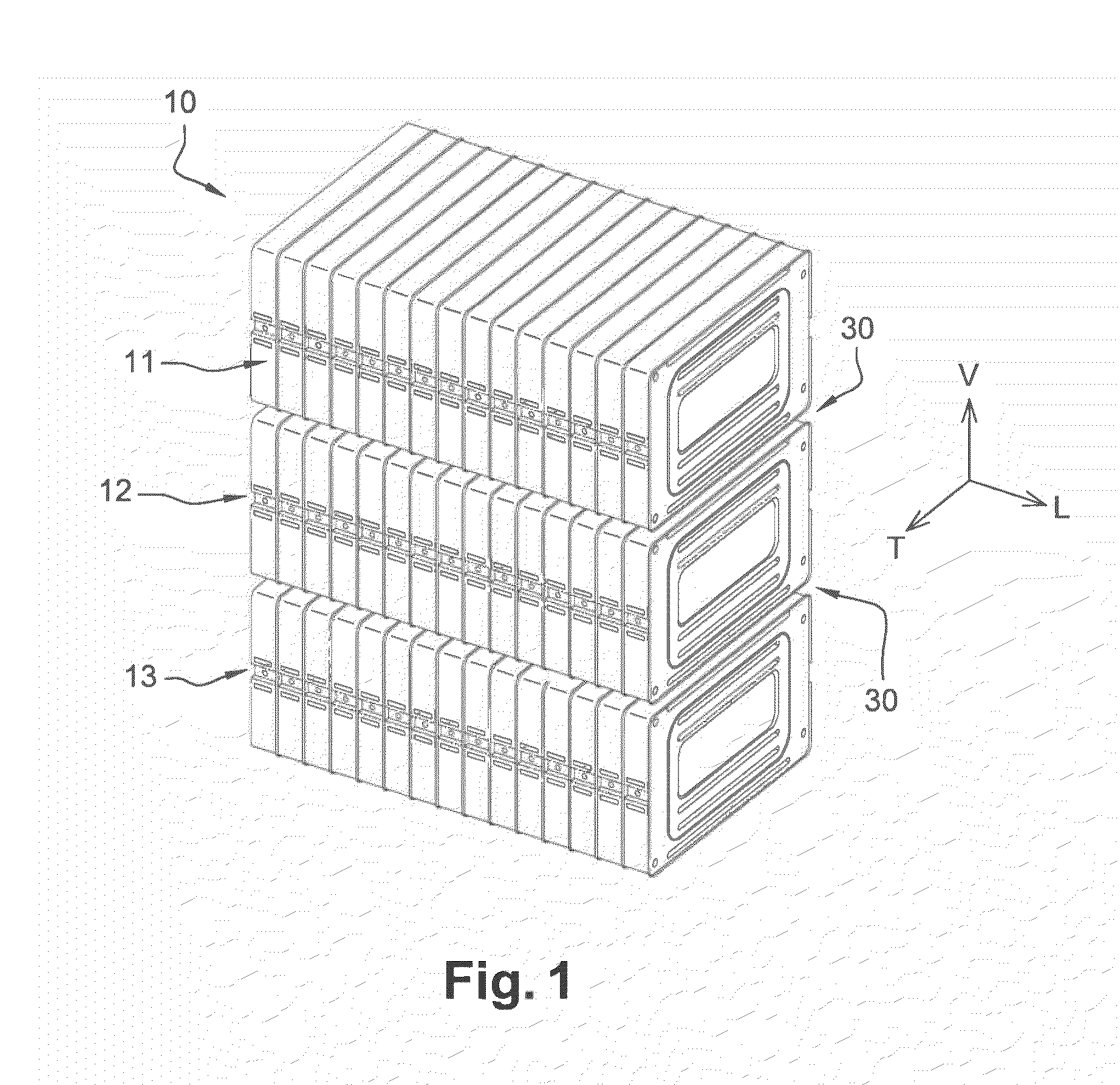

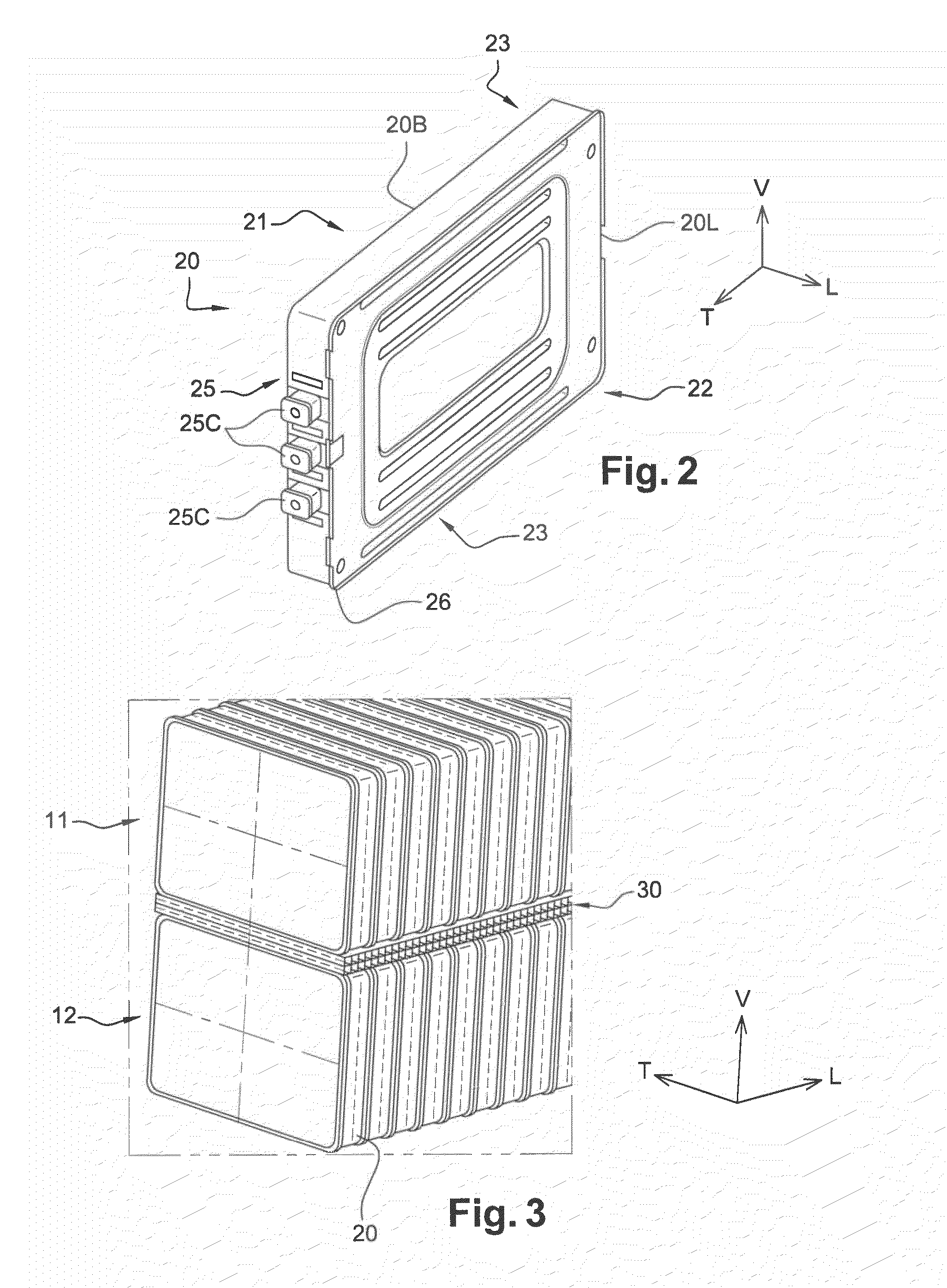

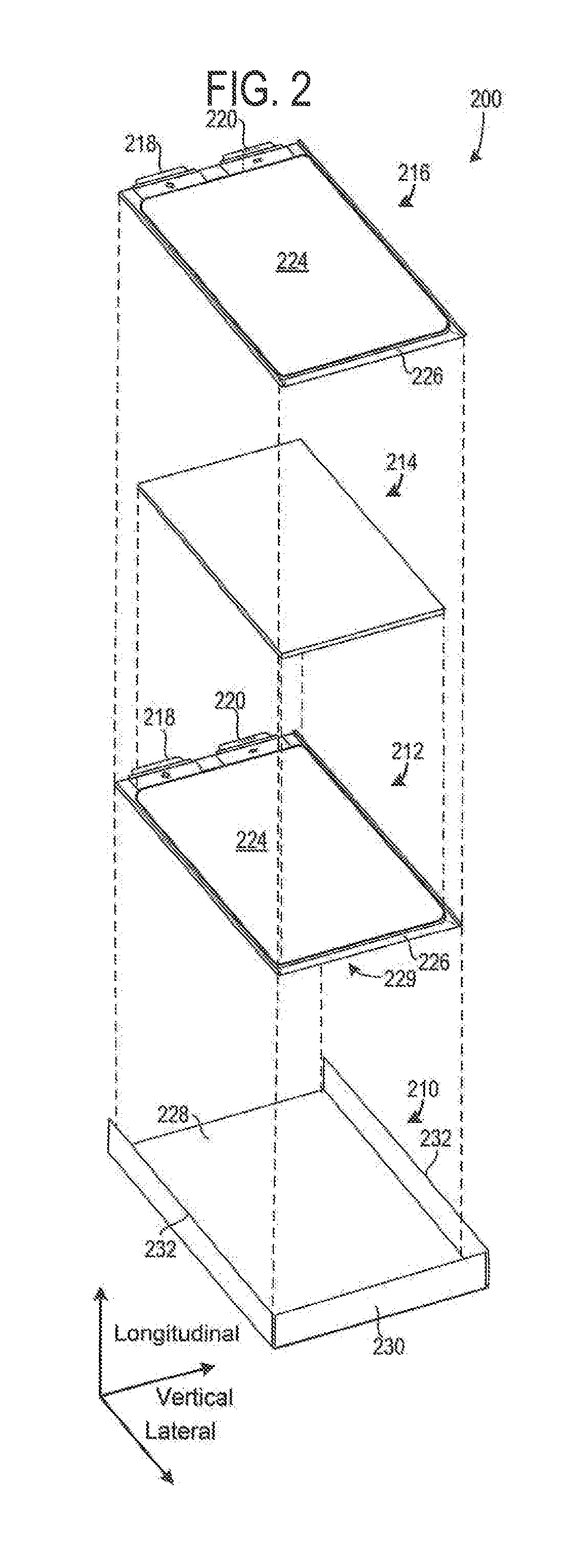

Battery pack for an electric powertrain vehicle

InactiveUS20110189524A1Cell temperature controlCell temperature regulationElectrical batteryThermal contact

A battery pack includes at least a first stack of battery modules, and a second stack of battery modules, each stack including a plurality of battery modules arranged in parallel in side by side relationship extending in a longitudinal direction, the battery pack further including at least one heat exchanger interposed between the first and second stacks, the heat exchanger being in thermal contact with interstack coupling surfaces extending in a longitudinal and transversal plan [L-T] of the battery modules. The invention also relates to a corresponding heat exchanger.

Owner:RENAULT SA

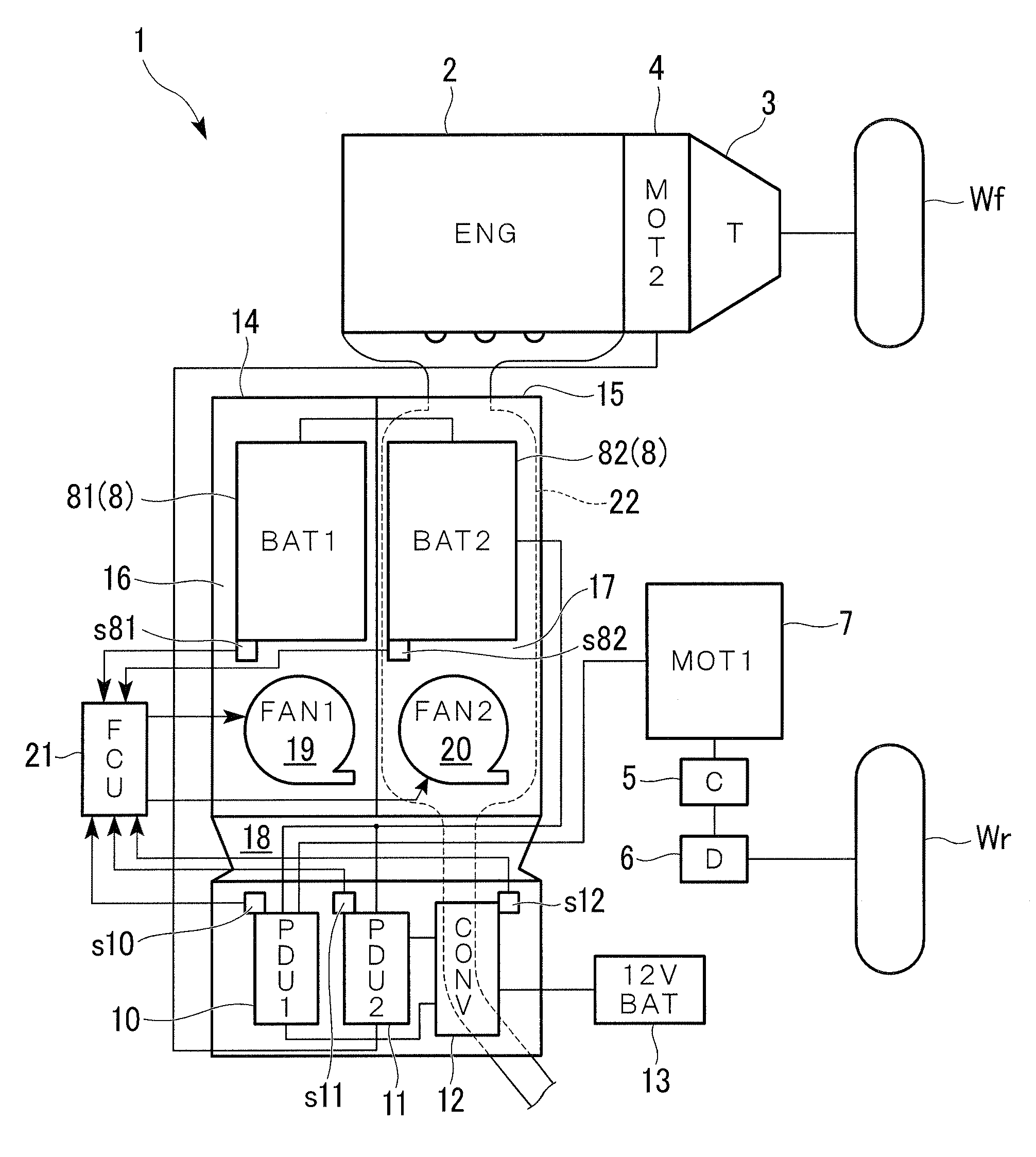

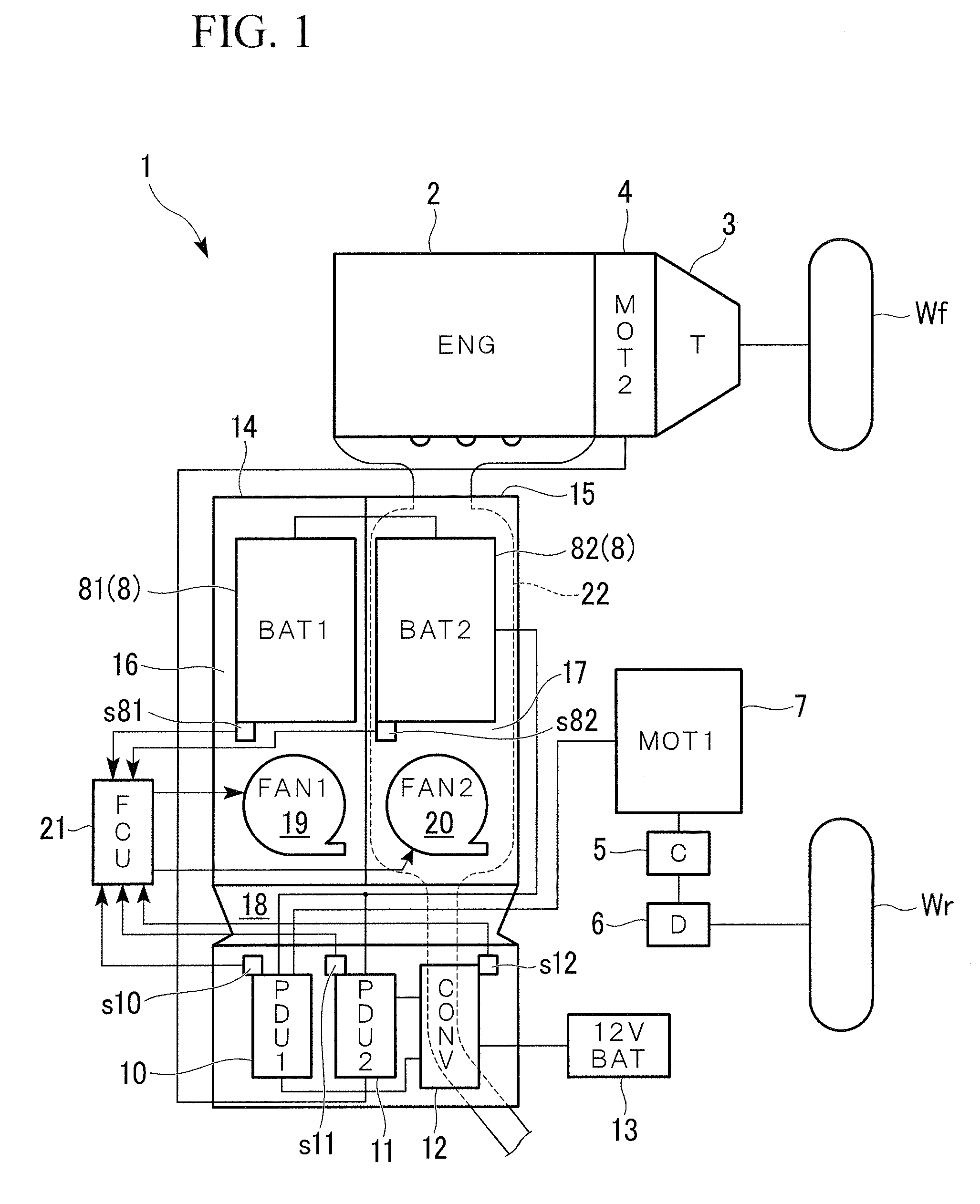

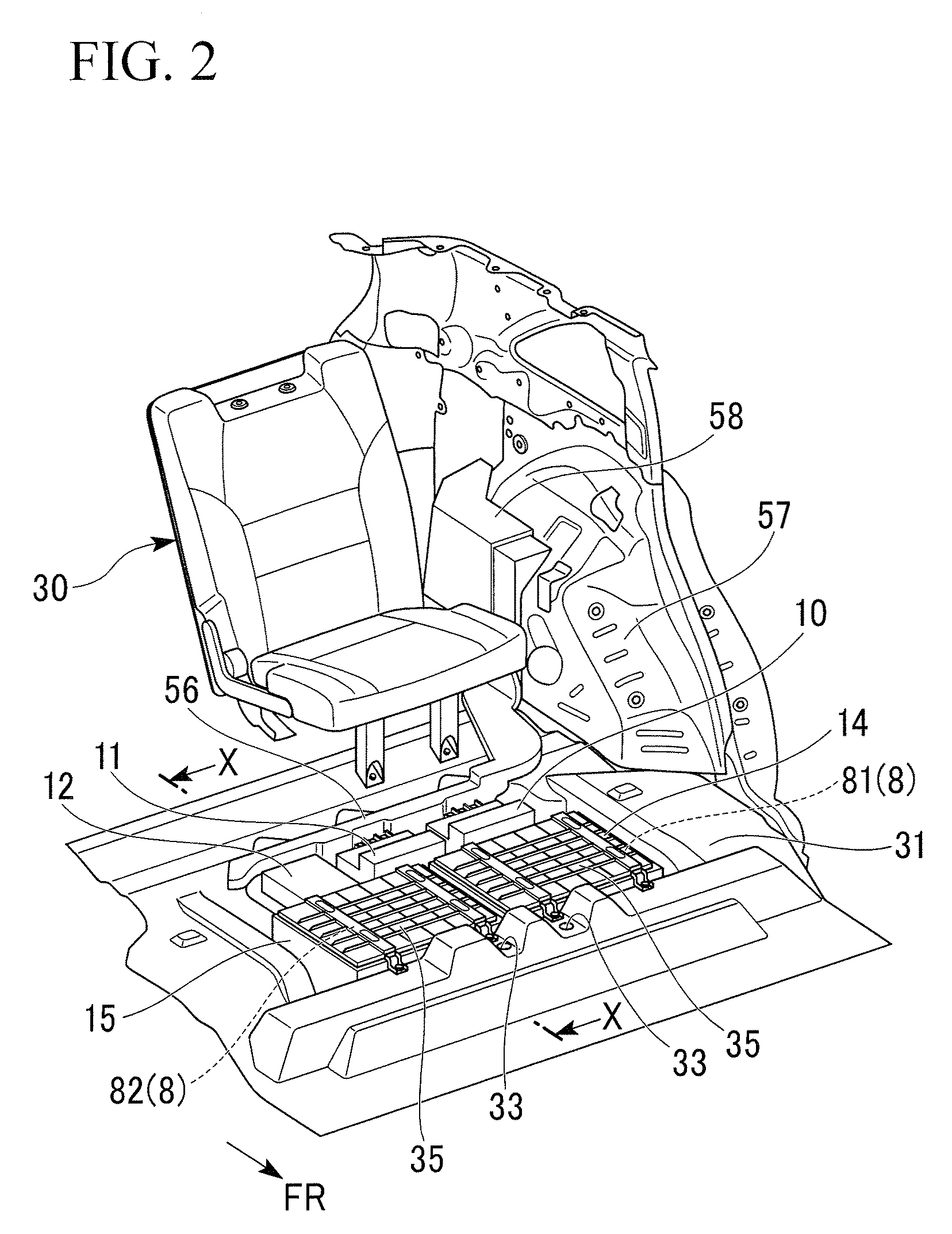

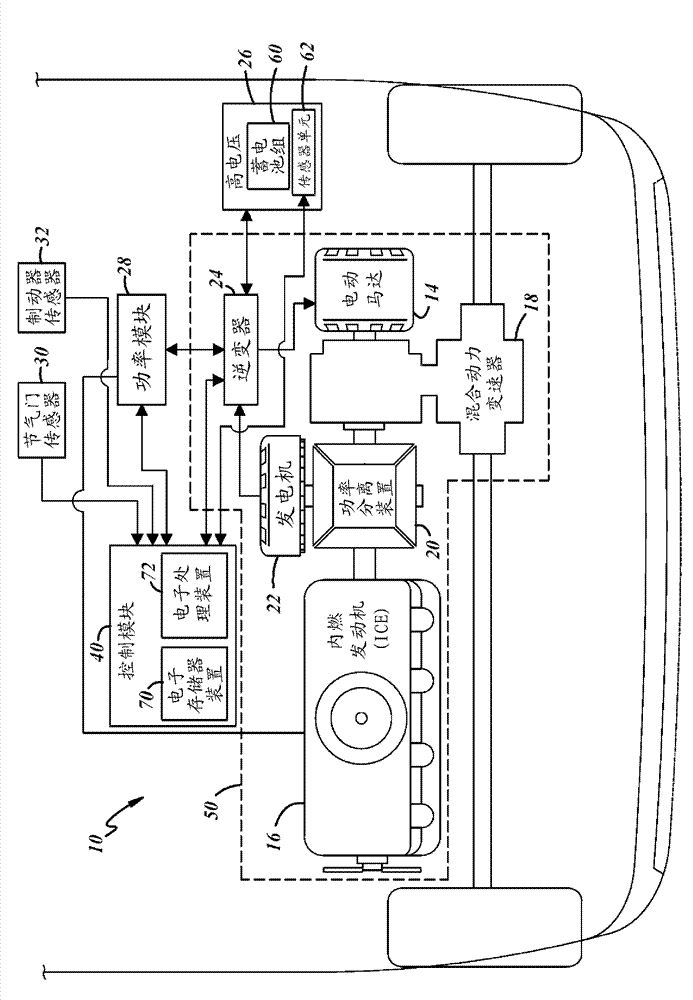

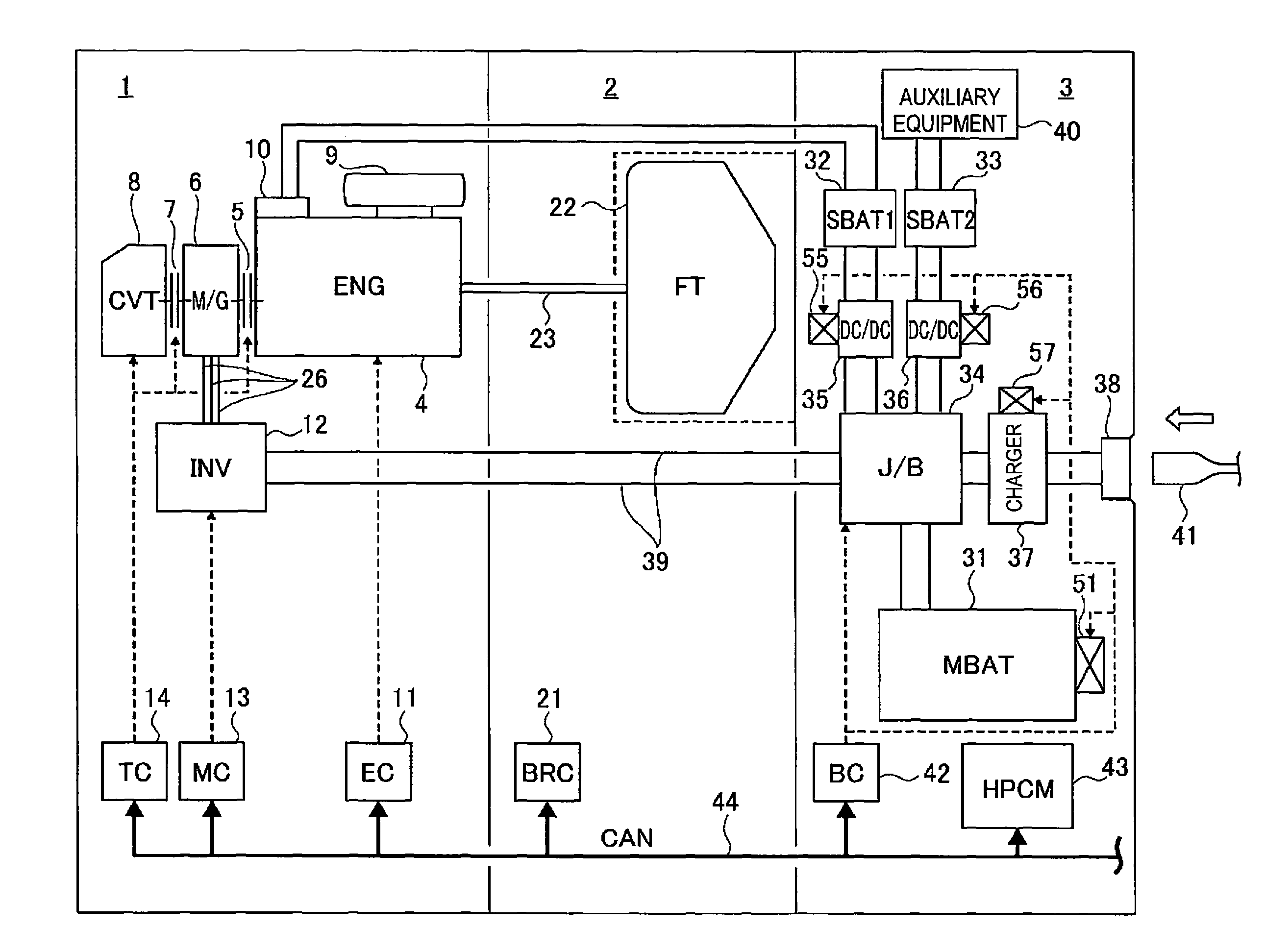

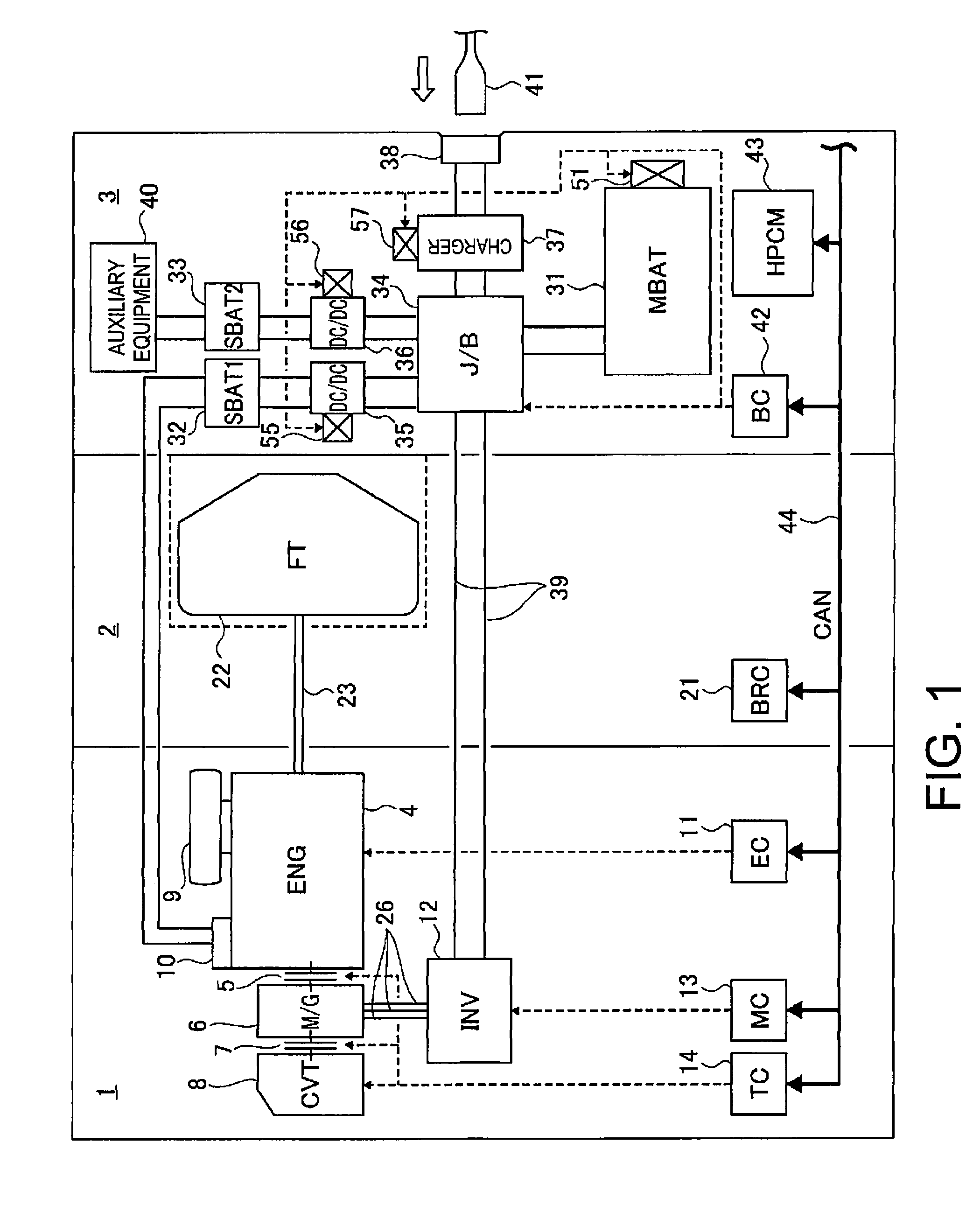

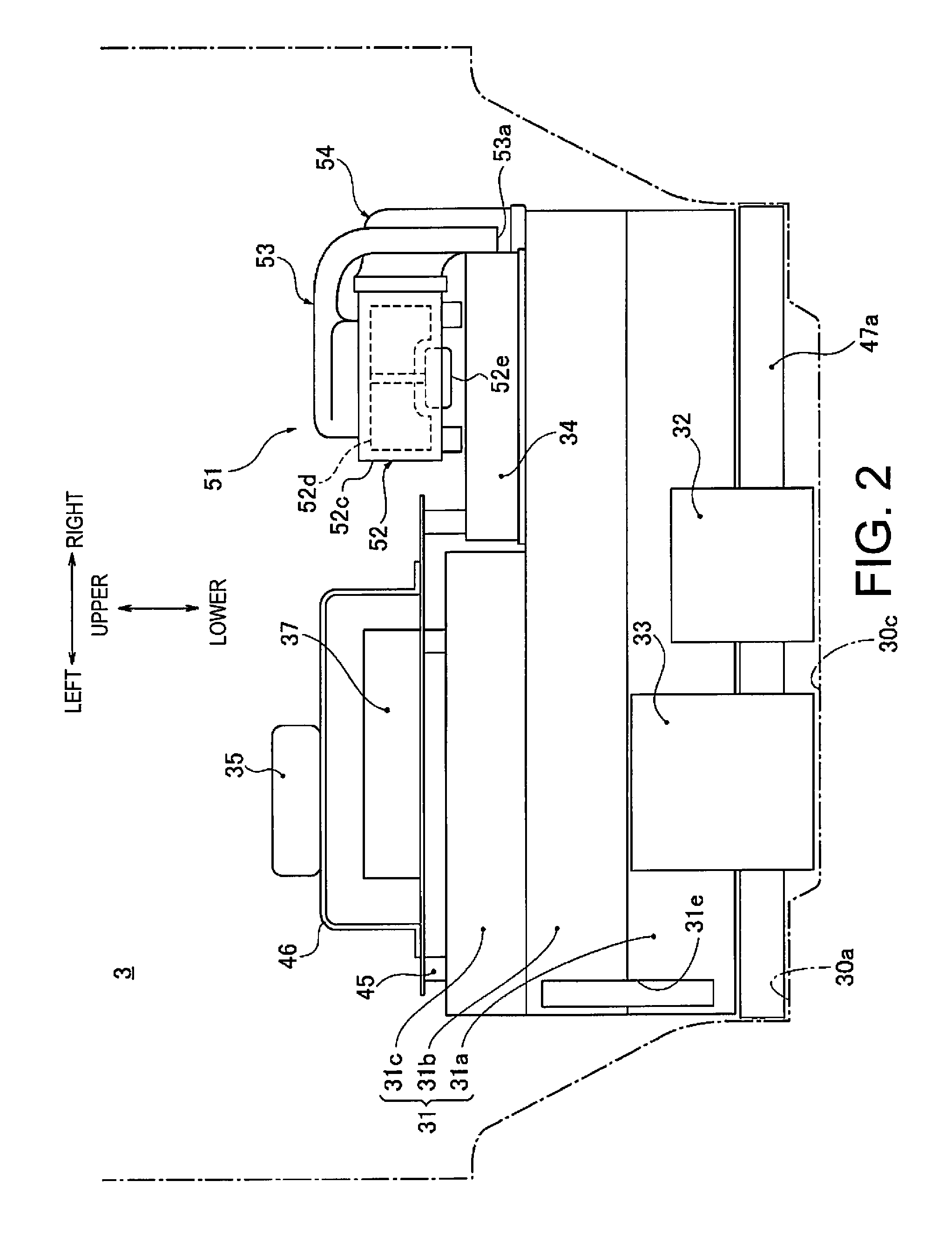

Battery system component layout structure for electrically driven vehicle

ActiveUS9090218B2Cell temperature controlCell temperature regulationBattery systemAutomotive engineering

A vehicle battery system component layout structure is basically provided with a center room, a rear room, a vehicle propulsion battery and an auxiliary battery. The center room of a vehicle is configured to seat a driver and a passenger. The rear room of the vehicle is disposed rearward of the center room. The vehicle propulsion battery is disposed in a vehicle front side space in the rear room. The auxiliary battery is disposed in a vehicle rear side space in the rear room rearward of the propulsion battery and in a position in which the auxiliary battery overlaps with the propulsion battery in a vehicle longitudinal direction as viewed from a rear end of the vehicle.

Owner:NISSAN MOTOR CO LTD

Battery Pack Including Fluid Resistant Over Mold

ActiveUS20140356651A1Increase the output voltageIncrease battery capacityCell temperature controlBattery isolationThermoplasticBattery pack

A battery pack for supplying energy to propel a vehicle is disclosed. In one example, a battery pack includes a thermoplastic over mold for providing resistance to liquid is disclosed. The battery pack may have increased resistance to battery pack degradation.

Owner:A123 SYSTEMS LLC

High-efficiency heat-radiation dynamic cell, temperature control system of electric vehicle and electric vehicle

ActiveCN101764249AReduce the temperatureImprove performanceCell temperature controlCell temperature regulationTemperature controlCombustion

The invention provides a high-efficiency heat-radiation dynamic cell, a temperature control system of an electric vehicle and an electric vehicle. The dynamic cell comprises a cell unit and one or more flat heat pipes of micro heat pipe arrays, wherein the flat heat pipes are bonded at the single face or double faces of the cell unit; and heat accumulated in the dynamic cell is led out of the dynamic cell by the flat heat pipes and is emitted into an environment outside a cell box by a mode of arranging an air passage in the cell box, the temperature in the dynamic cell is lowered, and the combustion or the explosion of the dynamic cell because of the accumulation of the heat is avoided. In the invention, the temperature in the cell box is regulated and controlled in an intellectualized way under a sealed condition by a mode of arranging a valve and a refrigeration fin on the air passage when the environmental temperature exceeds the range of the safety temperature of the dynamic cell, and the influence on the dynamic cell in the cell box because of environmental factors is avoided.

Owner:CHANGZHOU HETONG PURUN ENERGY TECH CO LTD

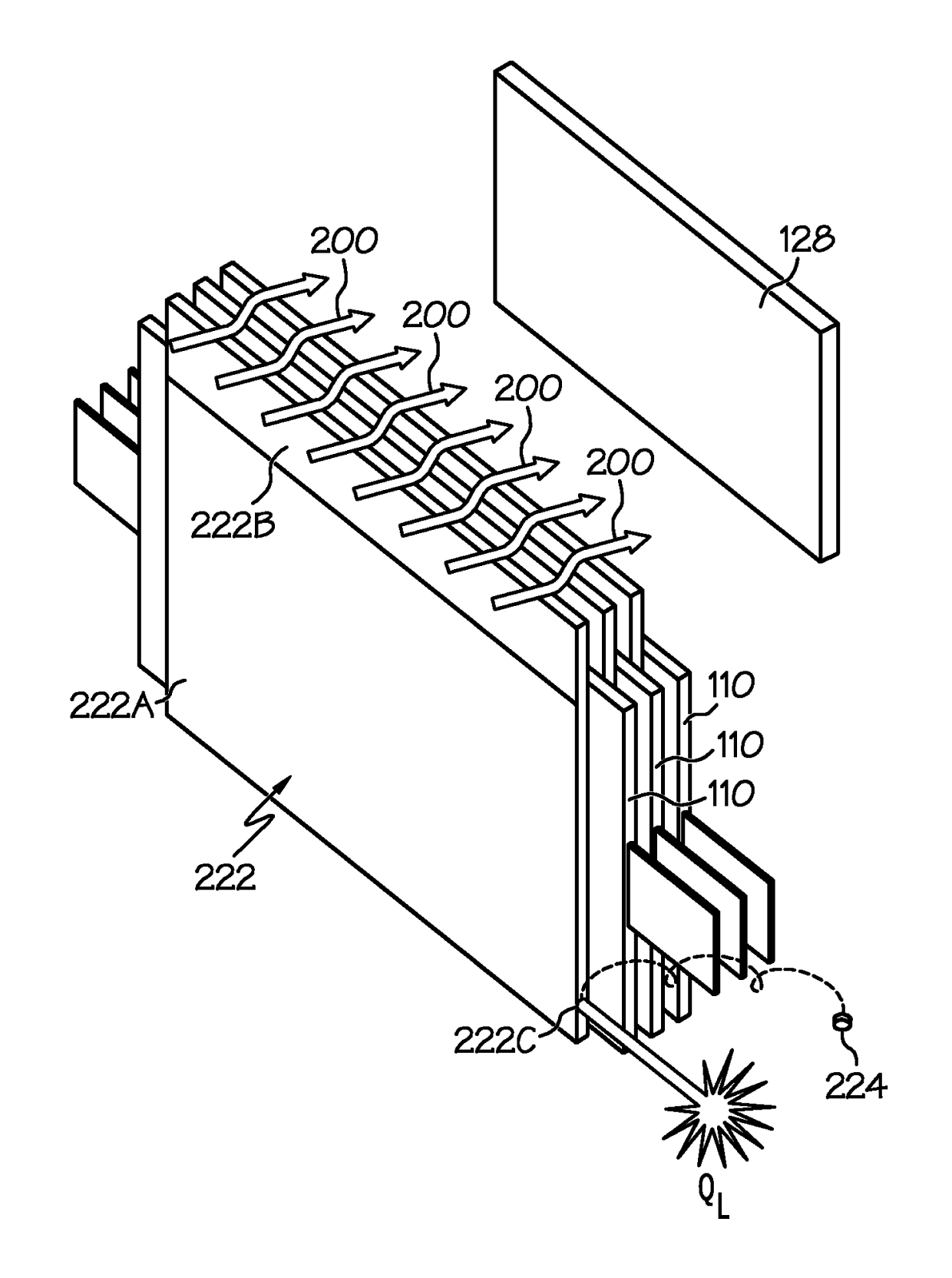

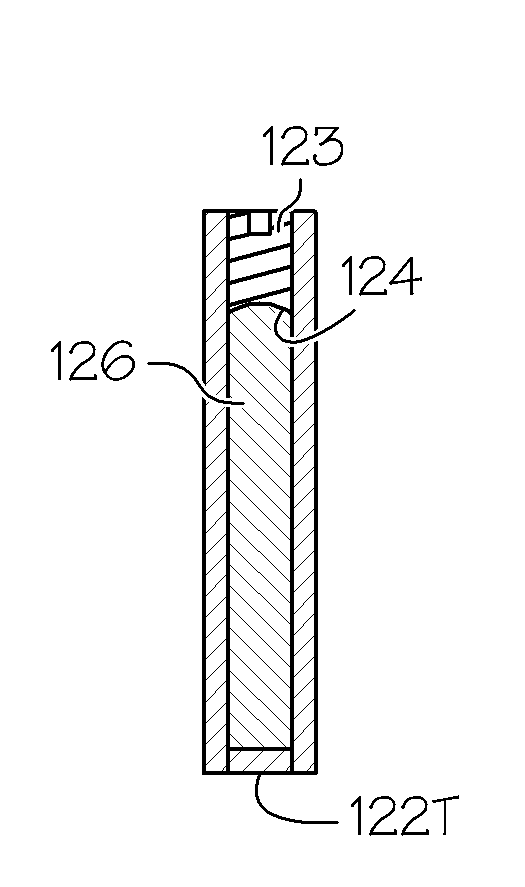

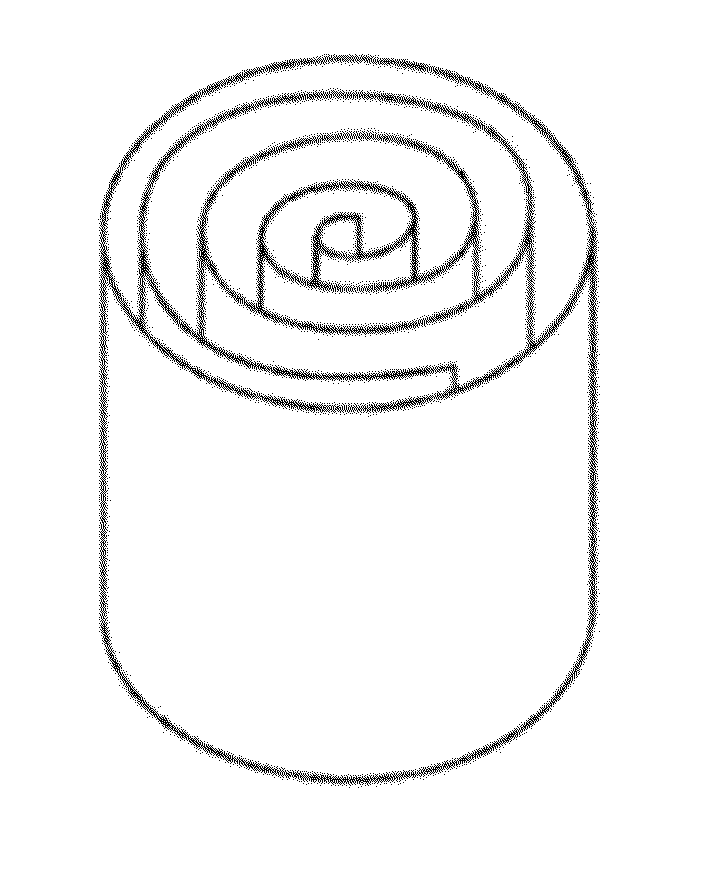

Method for mitigating thermal propagation of batteries using heat pipes

A battery module with one or more battery cells and a heat exchange member placed in thermal communication with the battery cell, and a method of making a heat pipe system from the heat exchange member. The heat exchange member includes a container with a heat transfer fluid disposed therein. In one form, the heat transfer fluid is capable of going through a phase change as a way to absorb at least a portion of heat present in or generated by battery cell. A pressure control device cooperates with the container and heat transfer fluid such that upon attainment of a predetermined thermal event within the battery cell, the pressure control device permits liberation of at least a portion of the heat transfer fluid to an ambient environment, thereby relieving pressure on the container and removing some of the excess heat caused by the thermal event.

Owner:GM GLOBAL TECH OPERATIONS LLC

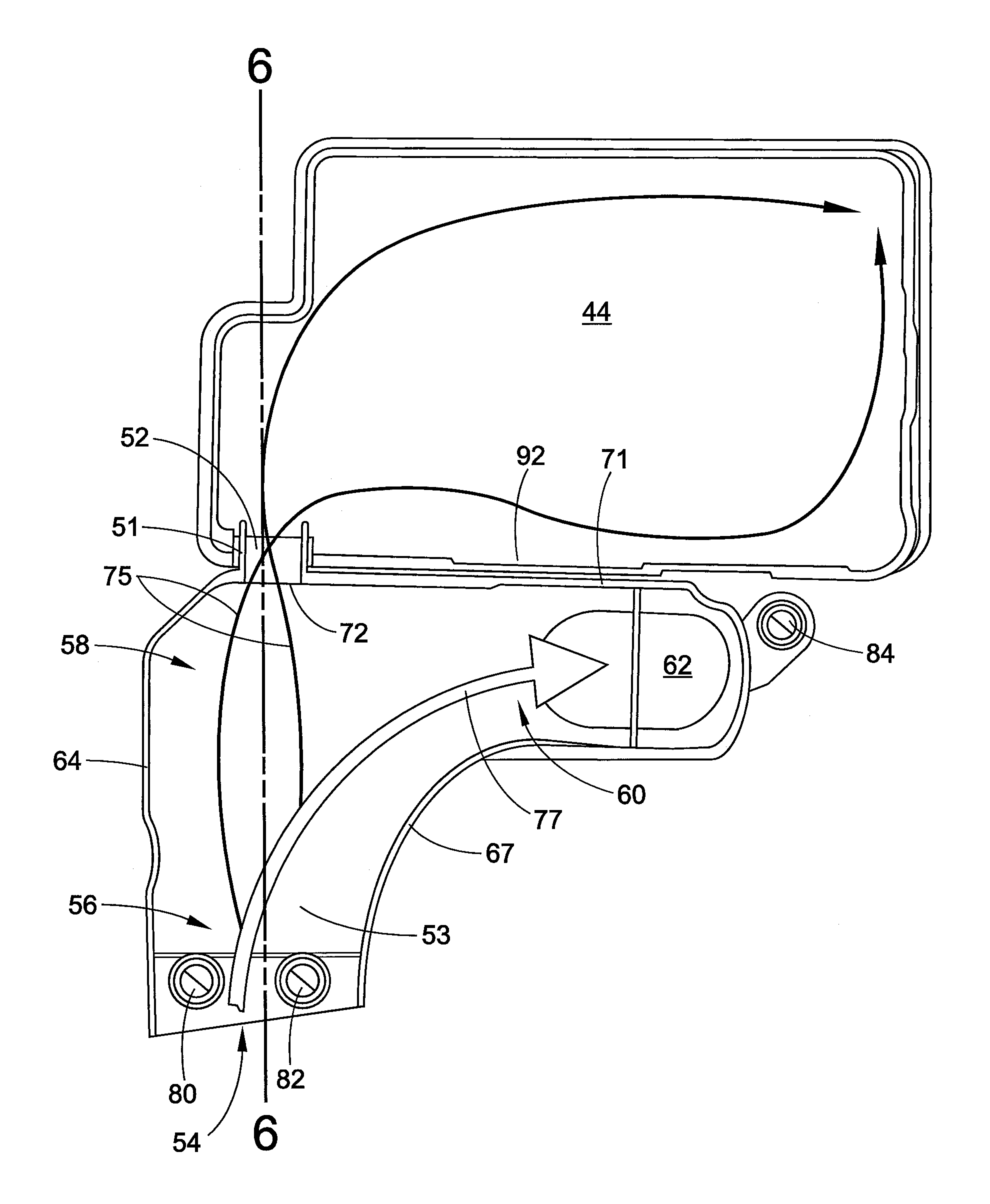

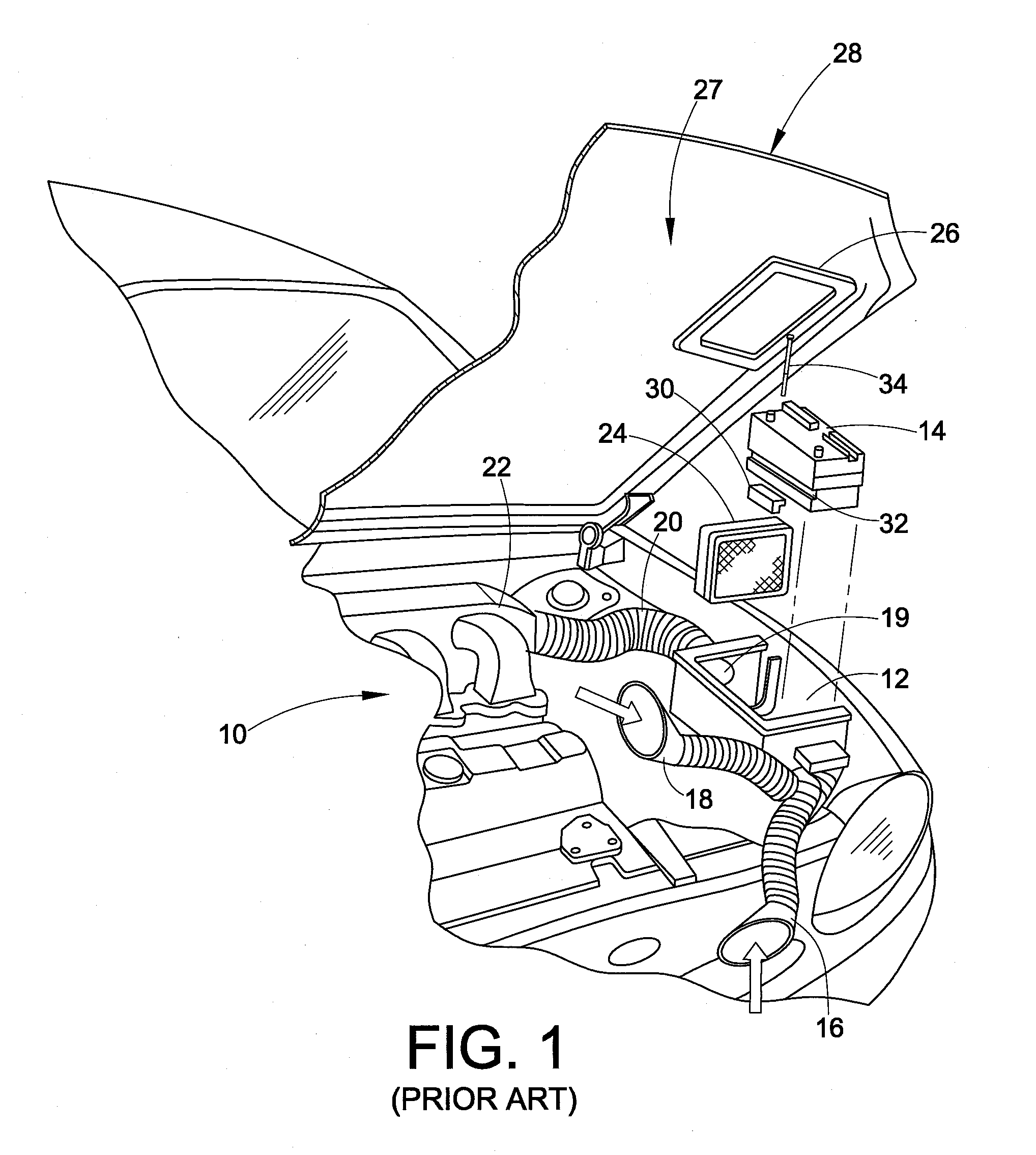

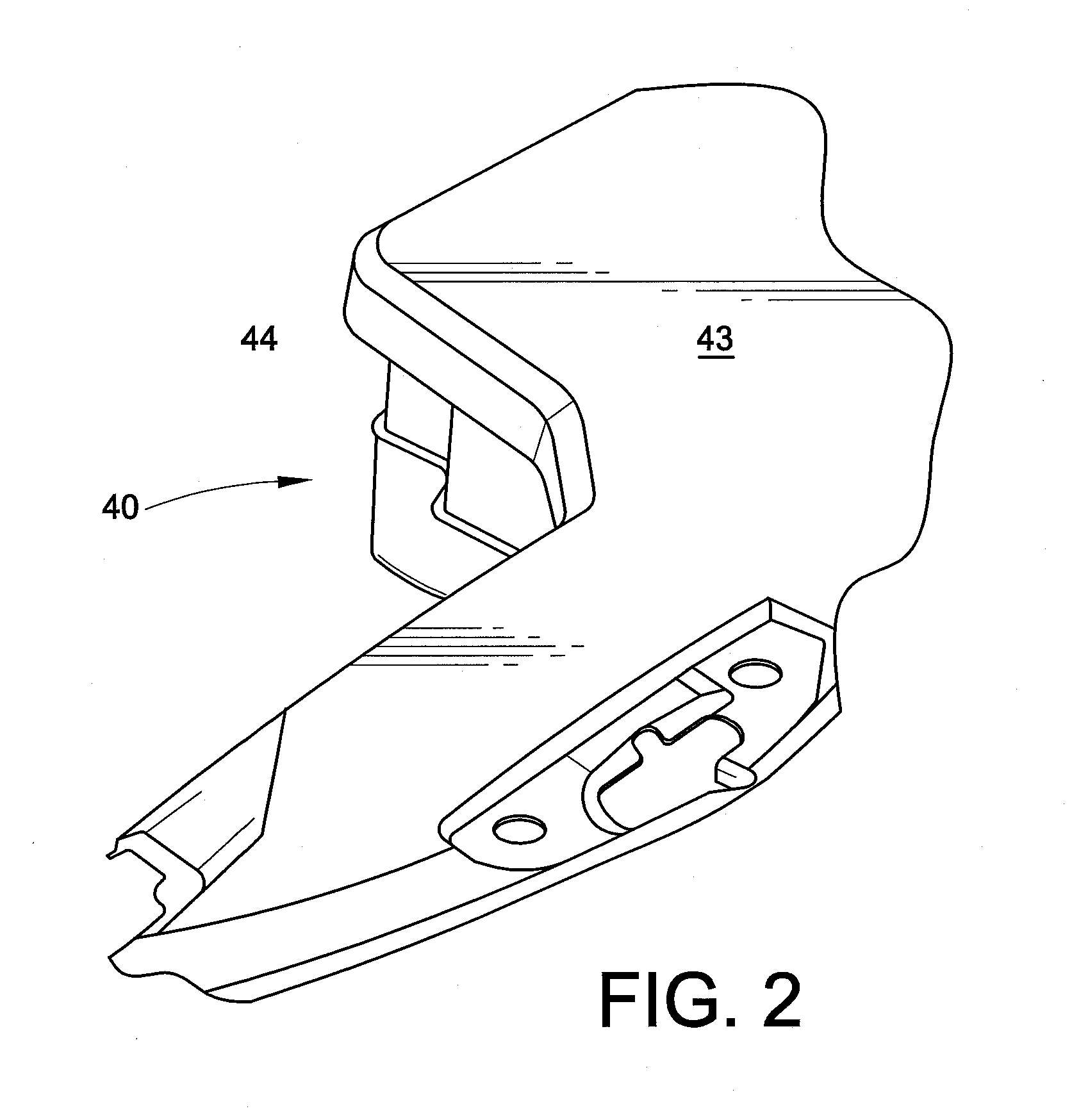

Symbiotic engine intake system and battery box

An engine compartment of an automotive vehicle is provided. The compartment comprises an internal combustion engine including an air intake manifold and an electrical storage battery. The battery is housed in a storage box and an air intake system supplies air to the air intake manifold and the battery storage box. The air intake system has an inlet supplying air to a flow diverter. The flow diverter has a main channel including a bend dividing the main channel into a first passage and a second passage tangential to the first passage. The second passage is in fluid communication with the air intake manifold. The flow diverter includes an outlet facing the first passage which is in fluid communication with the battery storage box.

Owner:HONDA MOTOR CO LTD

Electric vehicle propulsion system and method utilizing solid-state rechargeable electrochemical cells

ActiveUS20130266827A1Eliminate generationPrimary cell to battery groupingSolid electrolytesElectricityDrivetrain

A vehicle propulsion system comprising a plurality of solid state rechargeable battery cells configured to power a drivetrain is disclosed. In accordance with one aspect of the invention, a transportation system that is powered at least in part by electricity stored in the form of rechargeable electrochemical cells. According to an embodiment of the present invention, these cells are combined in series and in parallel to form a pack that is regulated by charge and discharge control circuits that are programmed with algorithms to monitor state of charge, battery lifetime, and battery health.

Owner:SAKTI3

Cooling system for battery systems and a method for cooling battery systems

ActiveCN102396098ALower temperature levelLighting and heating apparatusCurrent conducting connectionsBattery systemHeating energy

Owner:LG ENERGY SOLUTION LTD

Battery pack device

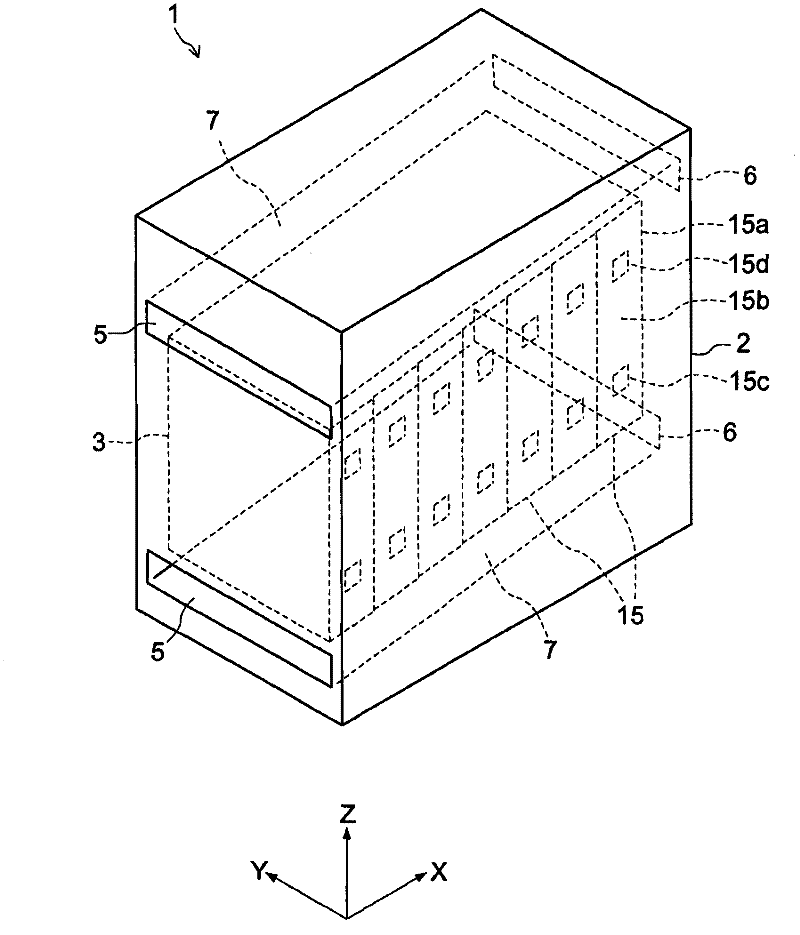

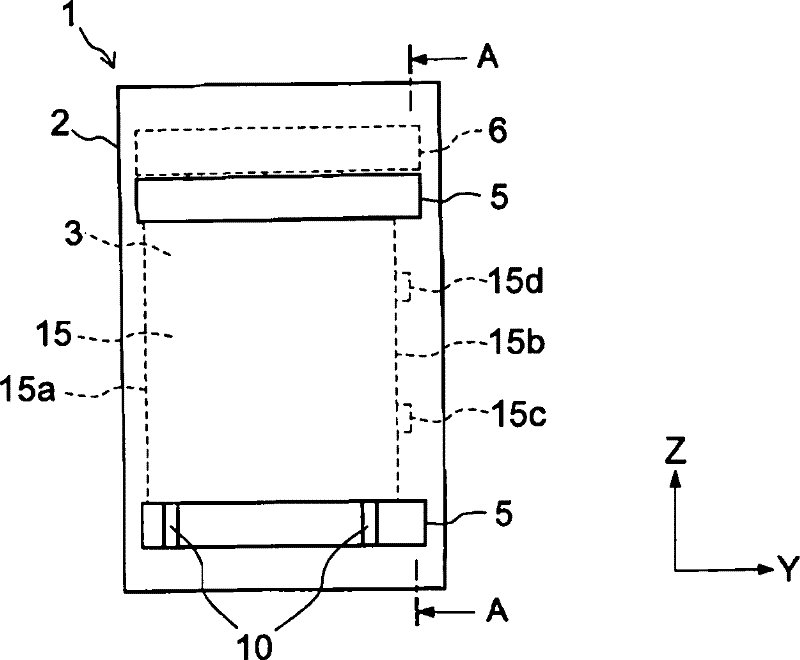

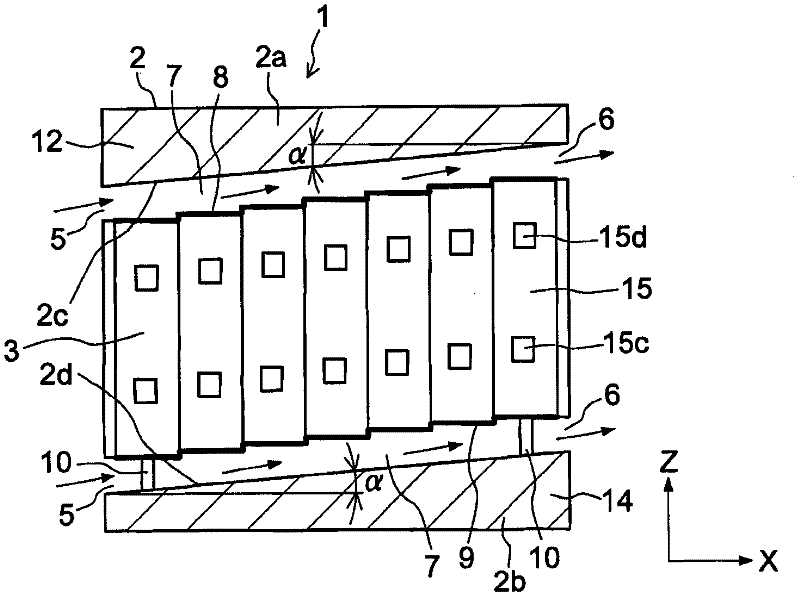

InactiveCN102479986AImprove cooling effectSmall-sized cells cases/jacketsCell temperature controlBattery cellBattery pack

A battery pack device of an embodiment includes a battery module, a casing, an air inlet, an air outlet, and a ventilation channel. In the battery module, a plurality of battery cells stacked one on another are disposed. The casing is installed while housing the battery module therein. The air inlet is provided in the casing and lets an outside air into the casing. The air outlet is provided in the casing, disposed at a position higher than a position of the air inlet, and lets the air out of the casing. The ventilation channel, in the casing, connects the air inlet and the air outlet, and inclines with respect to a horizontal direction.

Owner:KK TOSHIBA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com