Method and system for heating a vehicle battery

A battery and vehicle technology, applied in lithium battery, battery/battery traction, non-aqueous electrolyte battery, etc., can solve problems such as affecting performance, battery unable to fully receive or provide electrical power, increasing battery internal resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

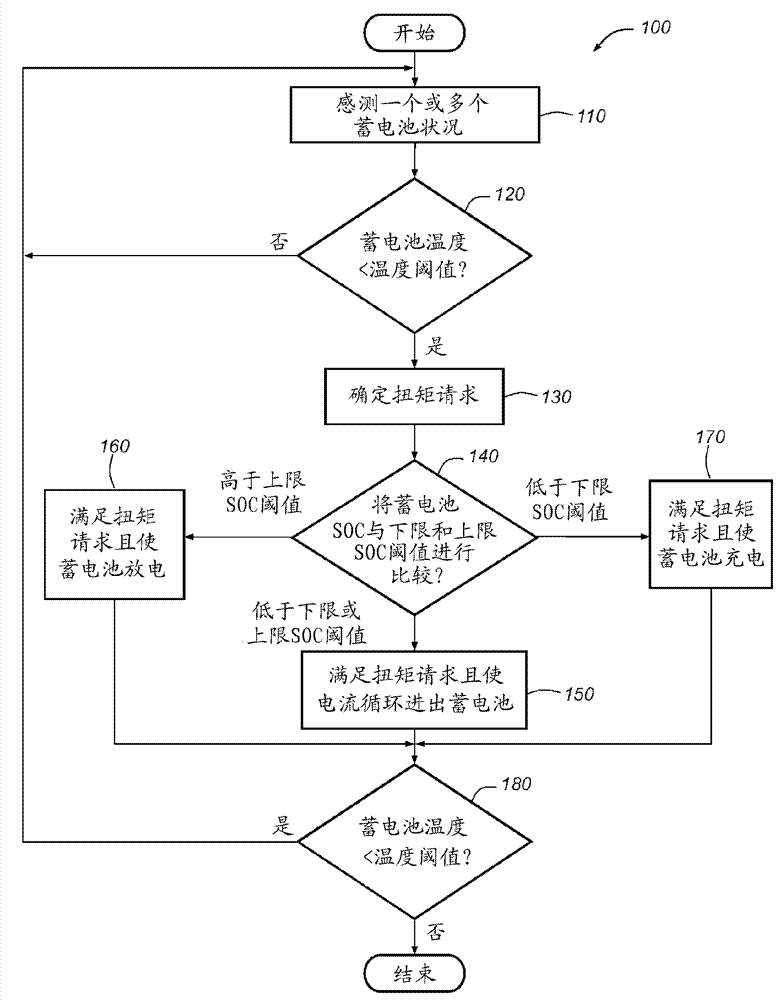

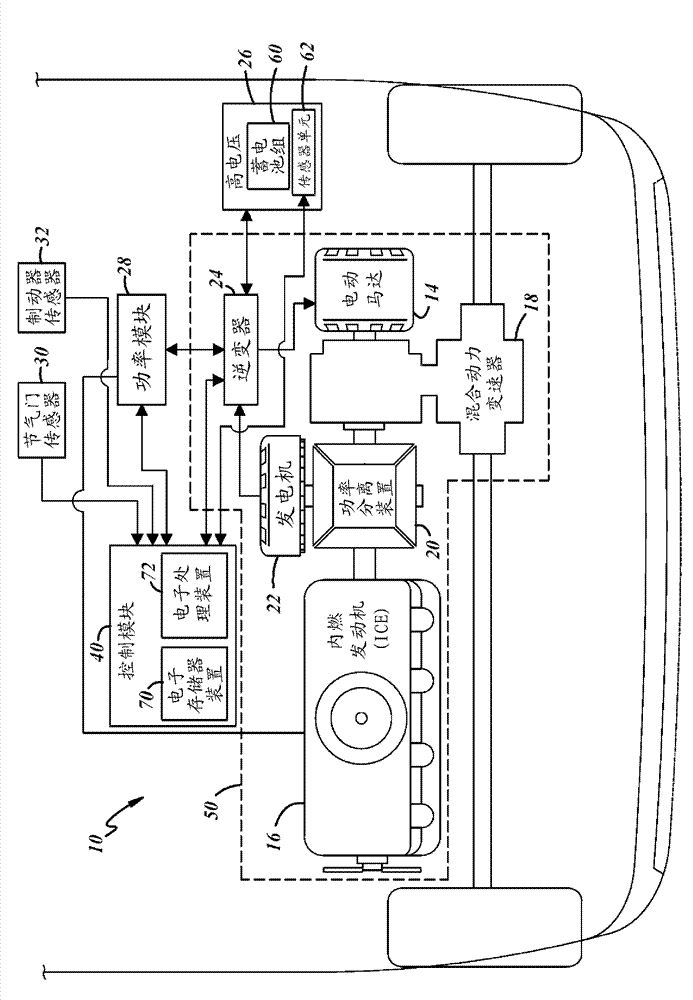

[0042]The methods described herein may be used to heat a vehicle battery, such as the type used for vehicle propulsion in a hybrid electric vehicle (HEV). Depending on the battery chemistry involved, such batteries may not perform well in extremely cold environments. For example, lithium-ion batteries may exhibit high internal resistance when the battery is extremely cold, which in turn may negatively affect the battery's usable power or other capabilities. Reduced battery power may affect electric mode propulsion, hinder regenerative braking, or negatively affect vehicle fuel economy, among other things. Additionally, the power provided by these types of batteries is often used not only for propulsion, but also to operate transmission components such as clutches and gears during shifts and other fast transient events. The drivability of the vehicle may also be negatively affected if the available battery power is significantly reduced. According to an exemplary embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com