Heating circuit of battery

A technology for heating circuits and batteries, applied in battery circuit devices, ohmic resistance heating, circuits, etc., can solve problems such as increased battery impedance, enhanced polarization, and decreased battery capacity, and achieve the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

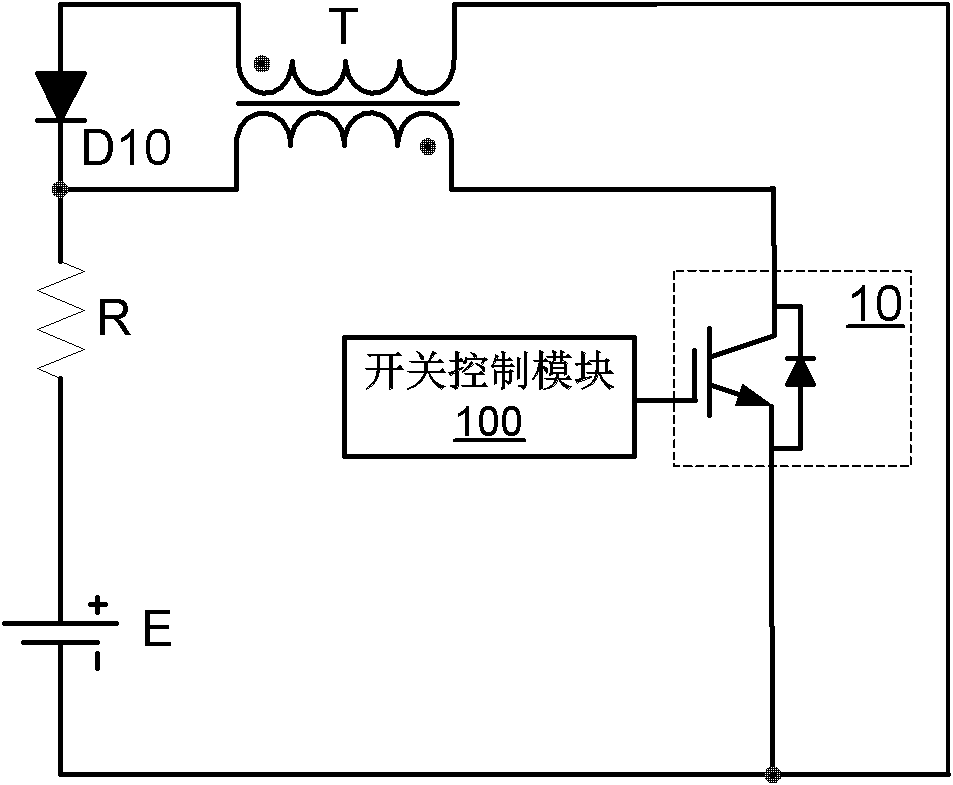

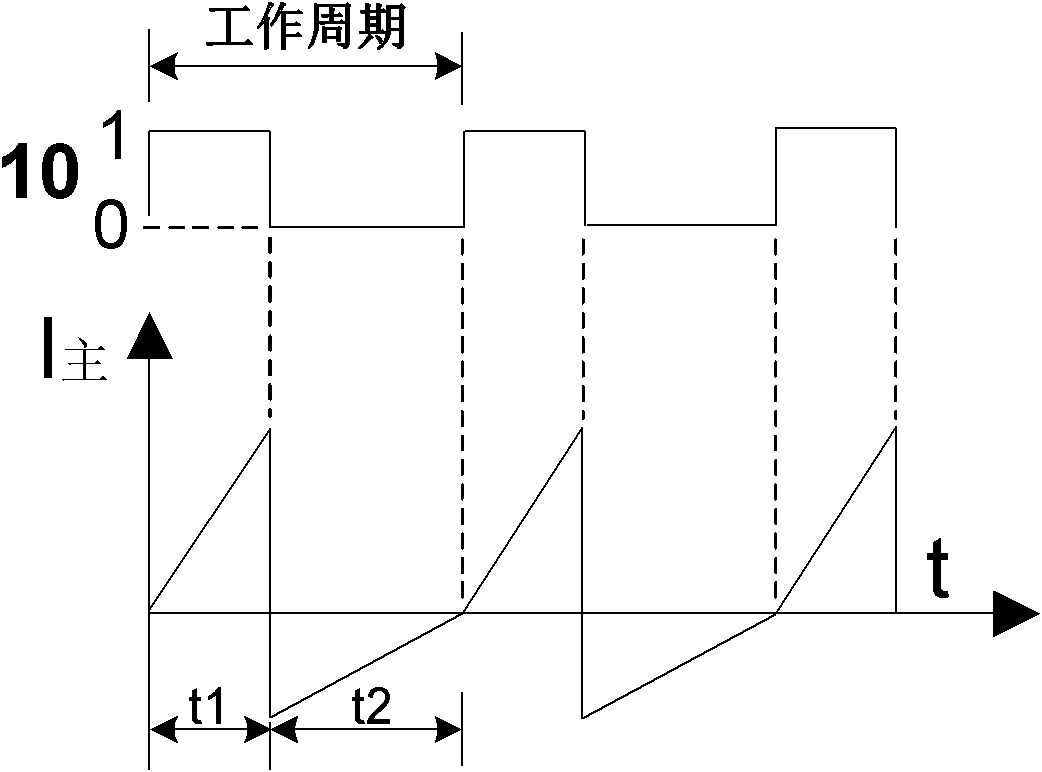

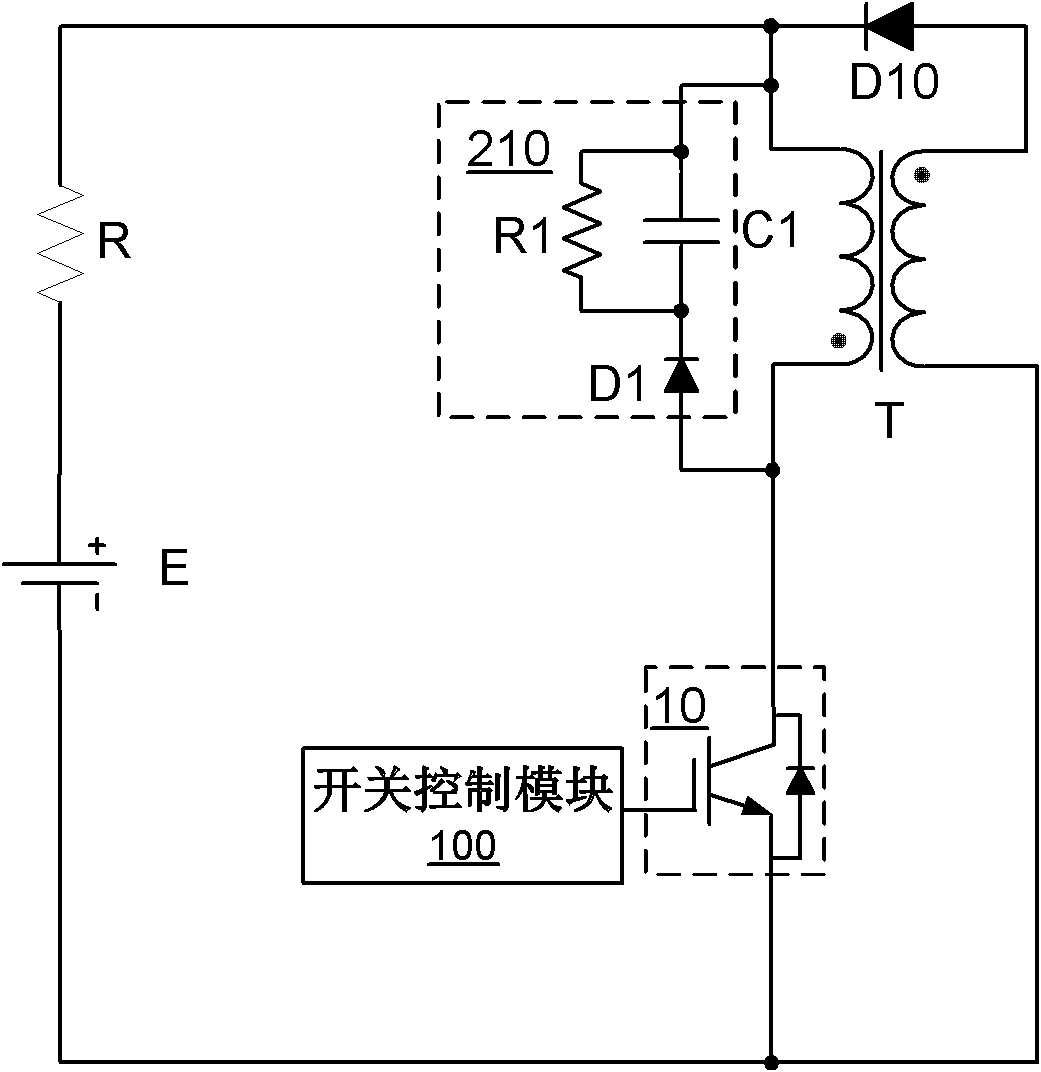

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0019] It should be pointed out that, unless otherwise specified, when mentioned below, the term "switch control module" refers to any control command (such as a pulse waveform) that can output control commands (such as pulse waveforms) according to set conditions or set moments to control the corresponding switching devices connected to it. The on-off controller, for example, can be a PLC; when mentioned below, the term "switch" refers to a switch that can realize on-off control through electrical signals or realize on-off control according to the characteristics of the components themselves, either It is a unidirectional switch, such as a unidirectional switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com