Temperature control method for electric heating pad

A temperature control method and electric heating pad technology, which is applied in the direction of temperature control using electric methods, electric heating devices, ohmic resistance heating parts, etc., can solve the problems of electric heating pads or blankets on fire, complicated internal wiring, and reliability discounts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

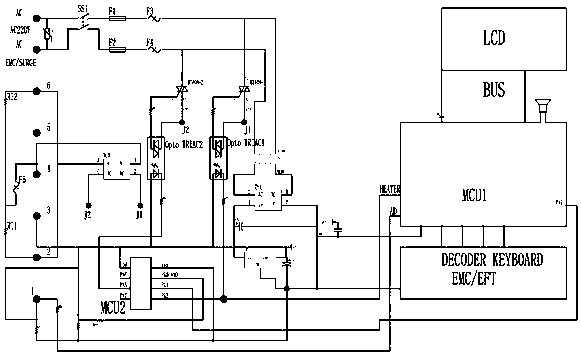

[0029] For the control device adopted in the temperature control method of the electric heating pad in this embodiment, see figure 1 As shown, including the power supply for the heating wire (or wire) in the electric heating pad, the electric heating pad has a one-time thermal fuse F5. The power supply is connected to the control device by the mains 220V and then transformed and rectified to form a power supply output. The first temperature sensor ResThermal-1 and the first temperature control processor MCU1 are used to measure the real-time temperature of the electric heating pad. The first electronic switch BTA08-1 and the second electronic switch BTA08-2 are arranged between the power supply and the heating line. An AND gate is formed between the electronic switch BTA08-1 and the second electronic switch BTA08-2. It also includes the second temperature control processor MCU2, and the keyboard decoder through DECODER KEYBOARD. The input terminal of the first electronic swi...

Embodiment 2

[0049] The temperature control method of the electric heating pad in this embodiment is an improvement on the basis of Embodiment 1, except that it is the same as Embodiment 1. The difference is:

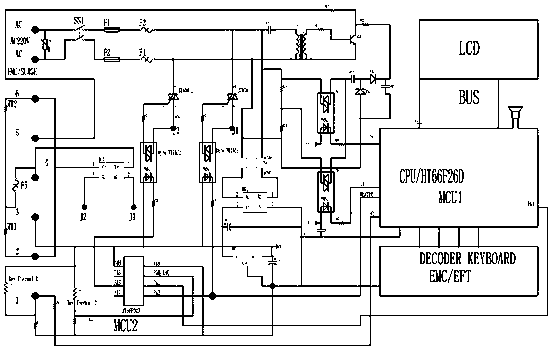

[0050] 1) if figure 2 As shown, the second temperature sensor ResThermal-2 for measuring the real-time temperature of the environment is added, and the limit value of the ambient temperature is set in the second temperature control processor MCU2, and the real-time temperature of the environment is measured at the same time. When the real-time temperature of the environment is greater than or equal to the limit value of the ambient temperature , control the electric heating pad to stop powering on, the ambient temperature limit in this embodiment is 35°C, the ambient temperature limit is selected according to human experience, and is not limited to 35°C;

[0051] 2) if figure 2 As shown, a negative potential generating unit is added. The mains 220V is output to the negative pote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com