Obverse flotation collecting agent for low temperature-resistant collophanite and preparation method thereof

A technology of collophosphate and positive flotation, applied in flotation, solid separation and other directions, can solve the problems of high energy consumption in flotation, and achieve the effect of good sorting adaptability and good low temperature adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

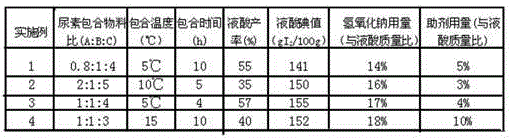

[0025] Examples 1-4 are shown in Table 1 below.

[0026] Table 1 Preparation conditions and raw material ratio of positive flotation collectors for low temperature resistant collophane ore

[0027]

[0028] In Table 1: A-vegetable oil feet acidified oil hydrolyzed fatty acid; B-urea; C-95% ethanol. The iodine value of hydrolyzed fatty acid of vegetable oil feet acidified oil: 123gI 2 / 100g, the acid value is 190mgKOH / g. According to the examples in the above table, collophanite positive flotation collectors can be obtained under low temperature conditions with stable properties, good collection capacity and selectivity.

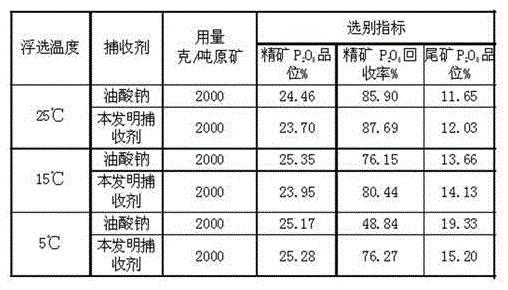

[0029] The flotation example description of collophanite collector of the present invention:

[0030] 1. A certain siliceous collophane in Yunnan, P 2 O 5 The content is 21.08%, SiO 2 The content is 34.80%. When the water temperature is 15°C, the agent of Example 3 of the present invention is used as a positive flotation collector, and a coarse-fine open-circuit flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com