Preparation method of organopolysiloxane resin

The technology of polysiloxane resin and organosilane is applied in the field of preparation of organopolysiloxane resin, which can solve the problems of poor process repeatability, long production cycle, poor environmental protection performance, etc., to simplify the production process and reduce labor intensity. , the effect of easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

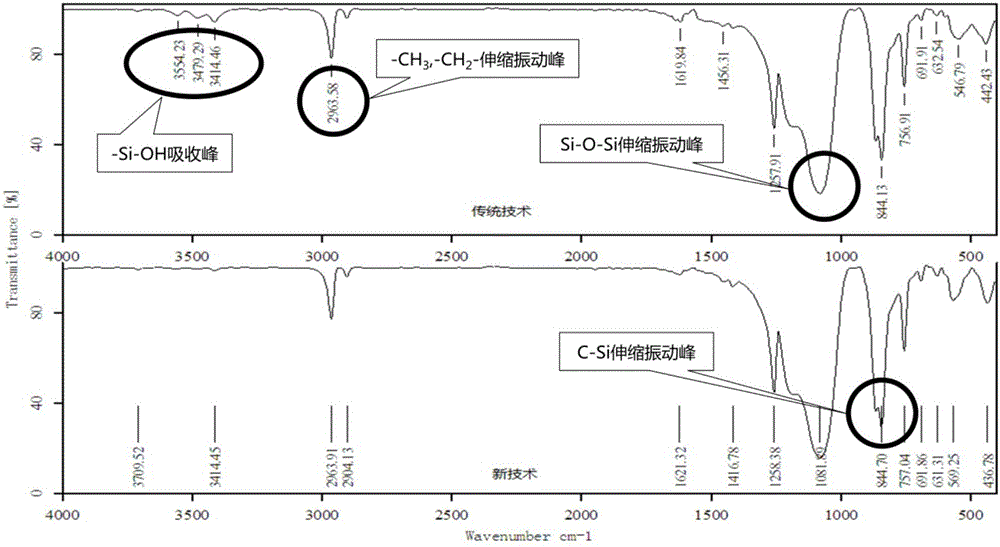

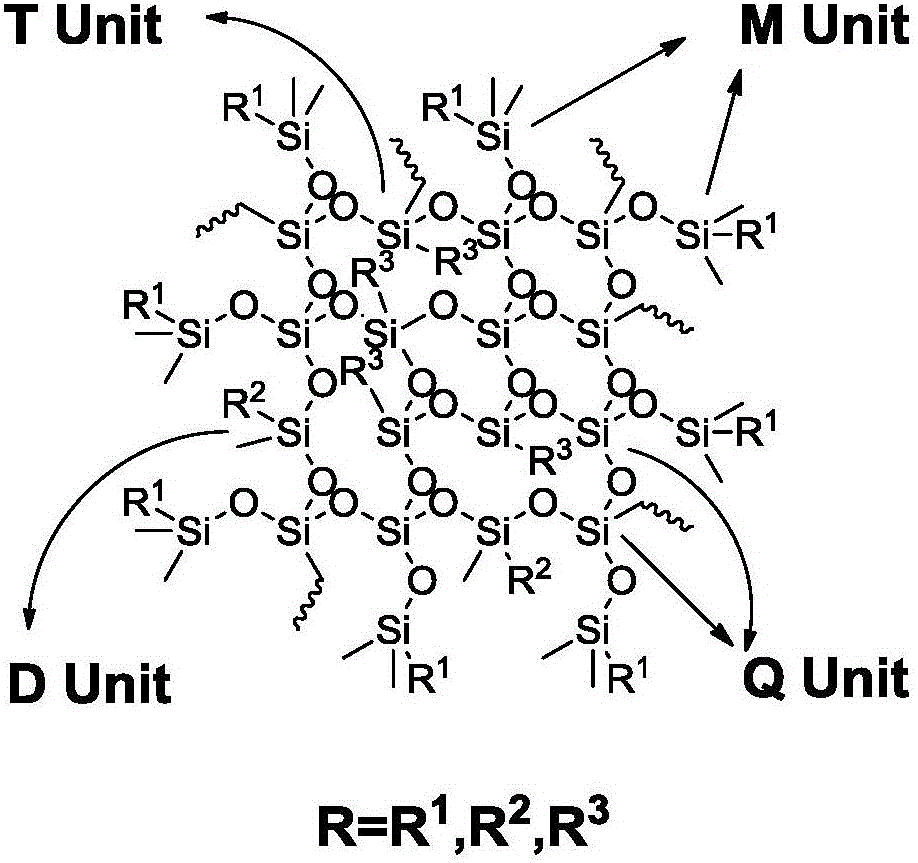

Method used

Image

Examples

Embodiment 1-21

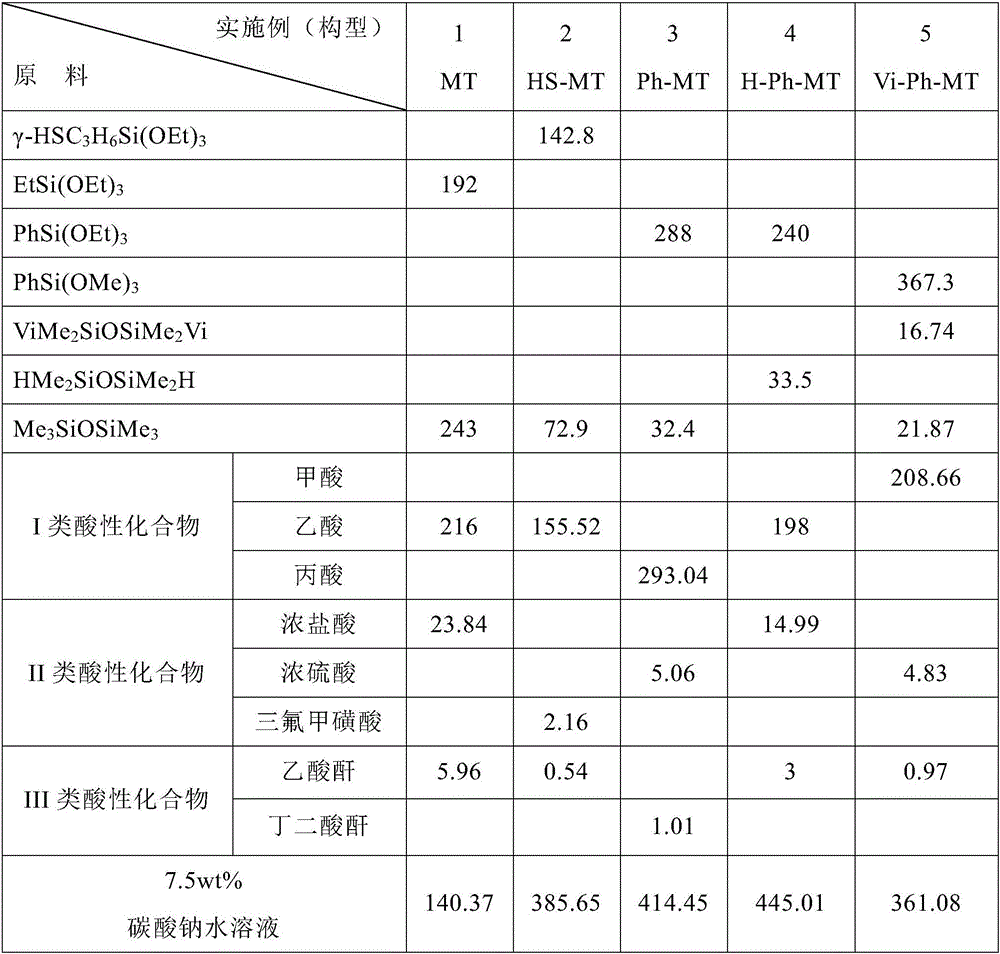

[0052] The amount of reactants is listed in Table 1, and the reaction conditions are listed in Table 2. Add the silane monomer and type I acidic compound into the reactor, and after stirring for 15 minutes, add the type II acidic compound and type III acidic compound into the silane monomer. After stirring for 30 minutes, react at (reaction temperature) for a certain period of (reaction time). After cooling to room temperature, the reactant is washed and separated by aqueous sodium carbonate solution, and the upper layer is dried and filtered. The filtrate is at (distillation temperature) Distilled under reduced pressure to prepare polysiloxanes containing different functional units, the results are listed in Table 3.

[0053] Table 1: The charging amount (gram) of preparation raw material in each embodiment

[0054]

[0055] Continued Table 1

[0056]

[0057] Continued Table 1

[0058]

[0059]

[0060] Continued Table 1

[0061]

[0062]

[0063] The re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com