High-efficiency synthetic desulphurization technique without waste liquid

A desulfurization process, waste liquid technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of poor dry effect, sewage discharge, energy consumption and water consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

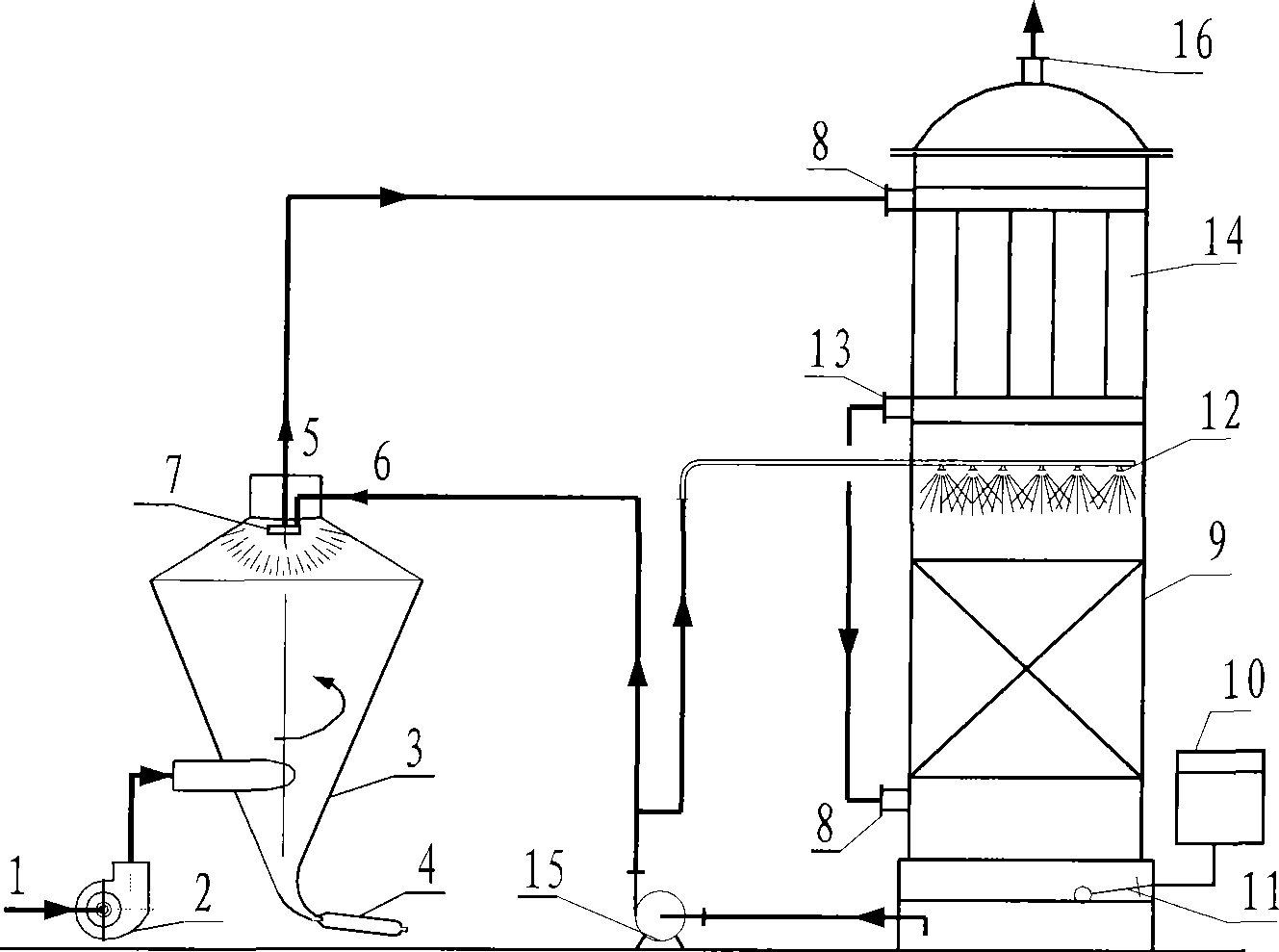

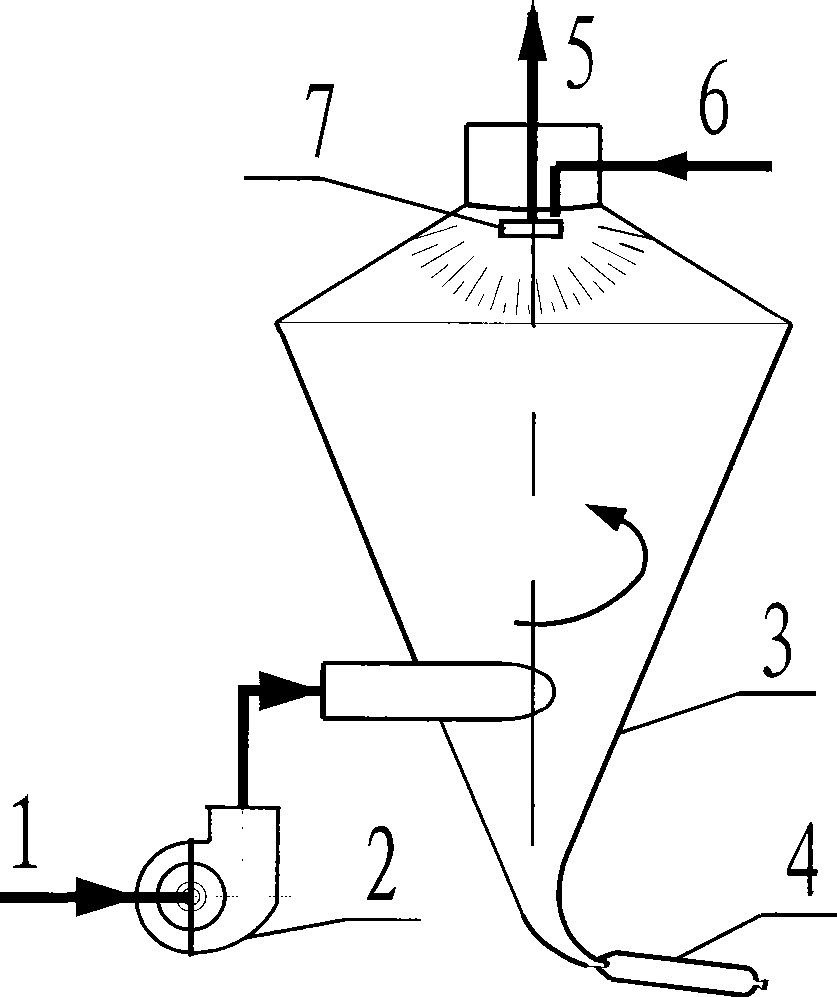

[0016] In the figure 1. The initial sulfur-containing flue gas to be treated, 2. Induced fan, 3. Spray drying and desulfurization and dust removal integrated machine, 4. Collection bag, 5. Intermediate flue gas, 6. Alkaline liquid, 7. Centrifugal fog 8. Intermediate flue gas inlet, 9. Wet spray tower, 10. Liquid storage tank, 11. Liquid level control float valve, 12 nozzle, 13 outlet, 14 gas heat exchanger, 15 pump, 16 purify flue gas exit.

[0017] In the embodiment shown in the figure, the sulfur-containing high-temperature waste heat gas (1) is pressurized by the induced draft fan (2) and enters the integrated equipment (3) for spray drying and dust removal, and runs upward in a rotating manner from the middle and lower parts, and the lye (6) Enter the integrated evaporation equipment (3) from the top, flow into a rotating disk (7) shaped like a plate, and scatter downward in the form of mist, and the SO in the treated initial sulfur-containing flue gas (1) 2 A chemical re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com