Patents

Literature

33results about How to "Good peptization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

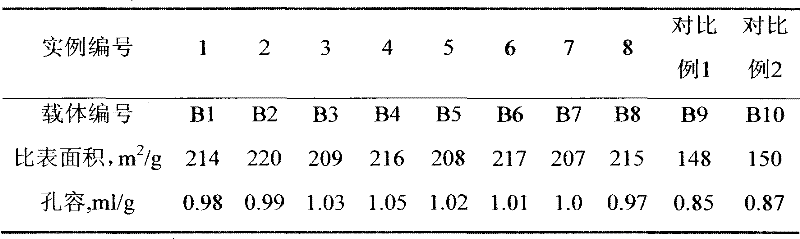

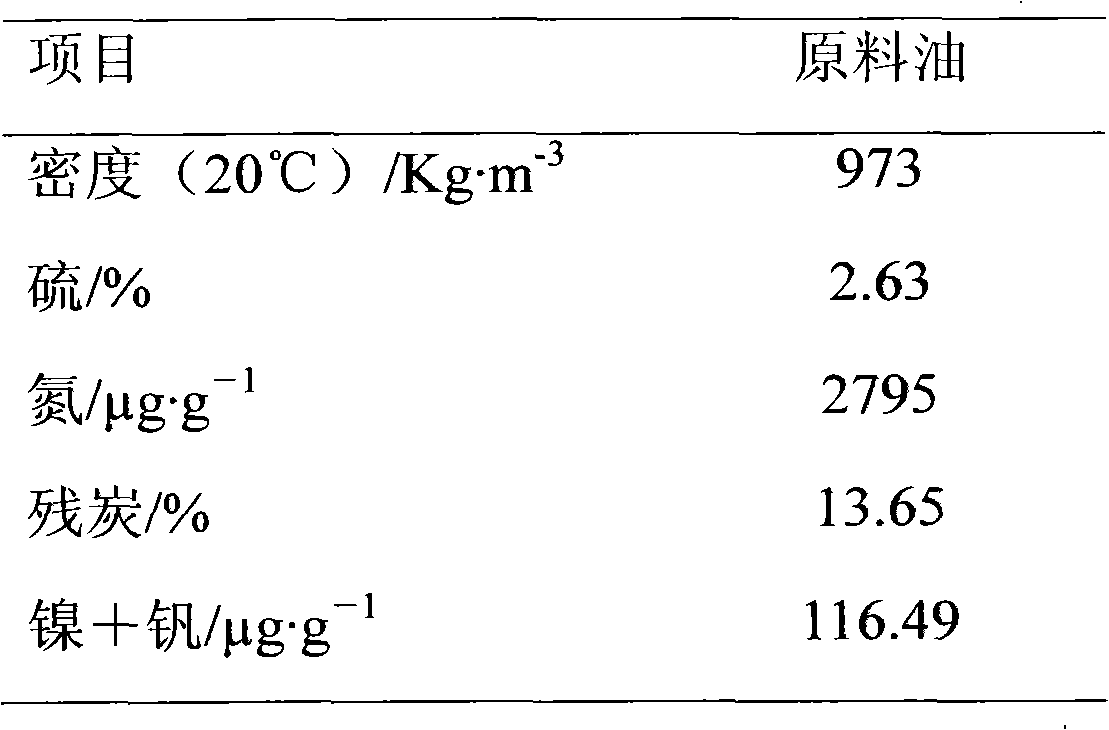

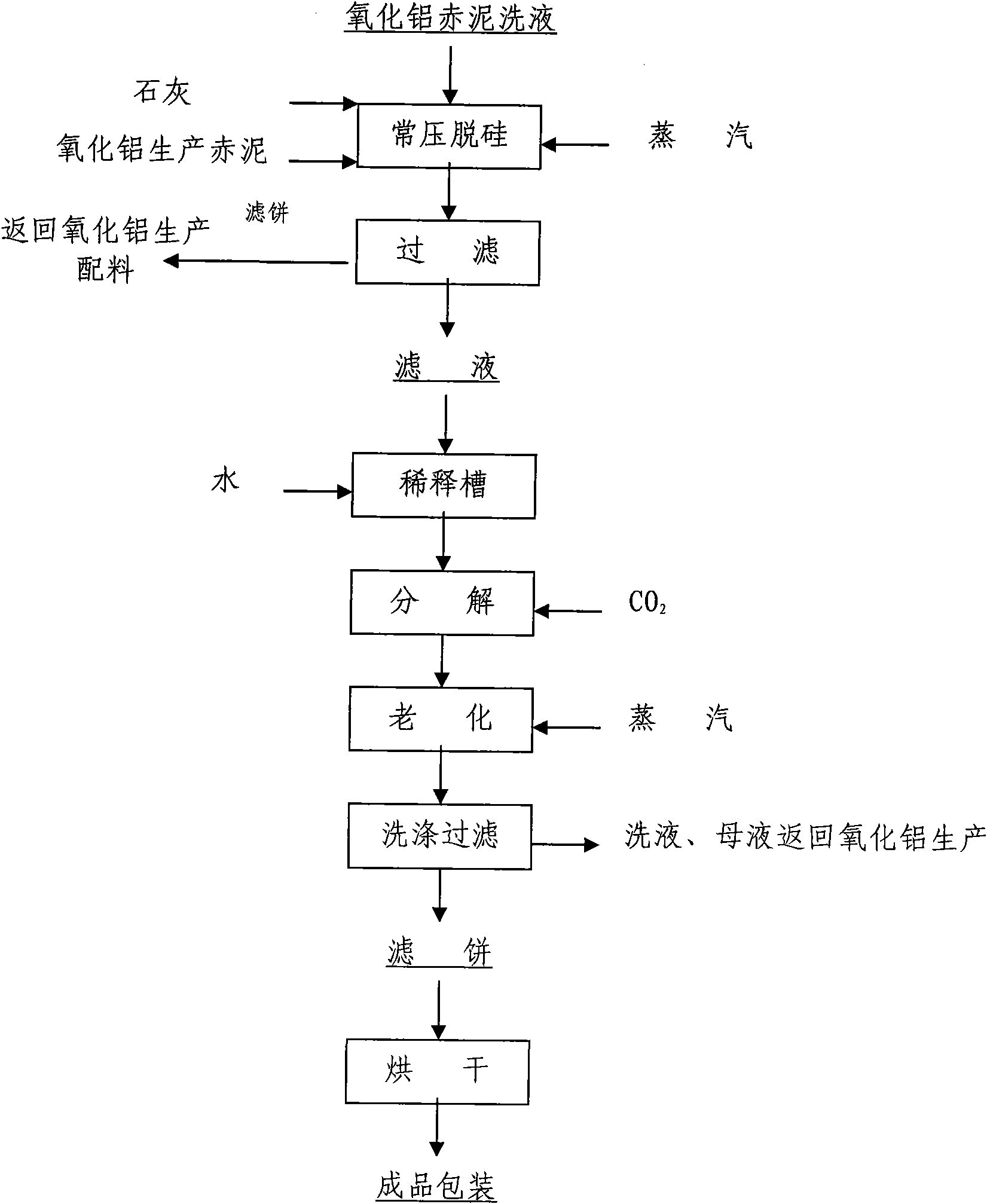

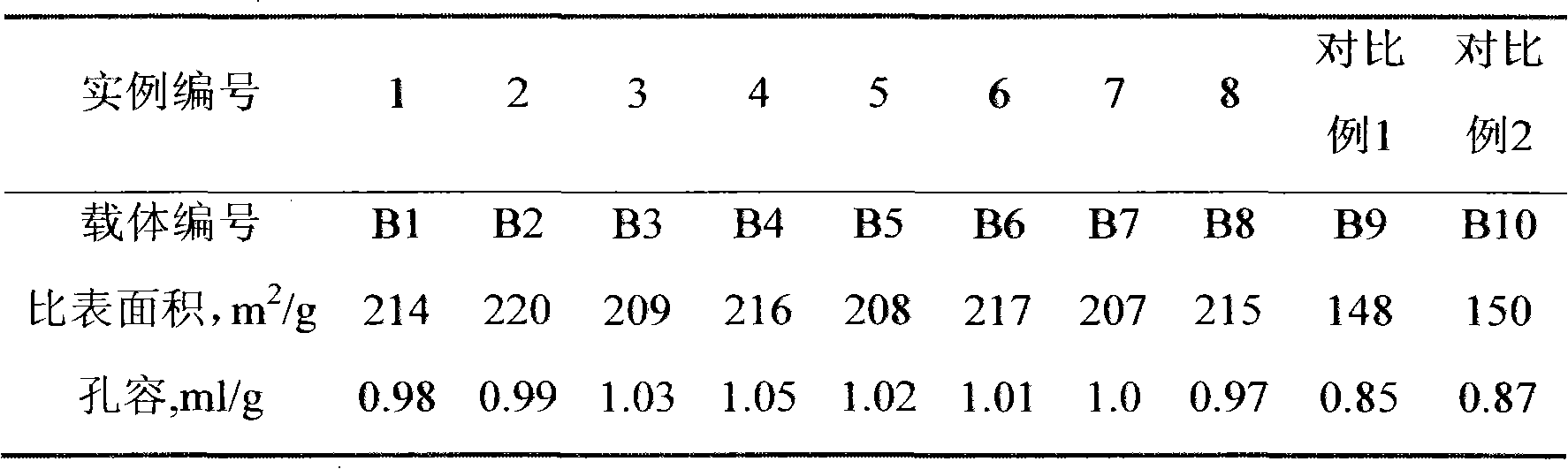

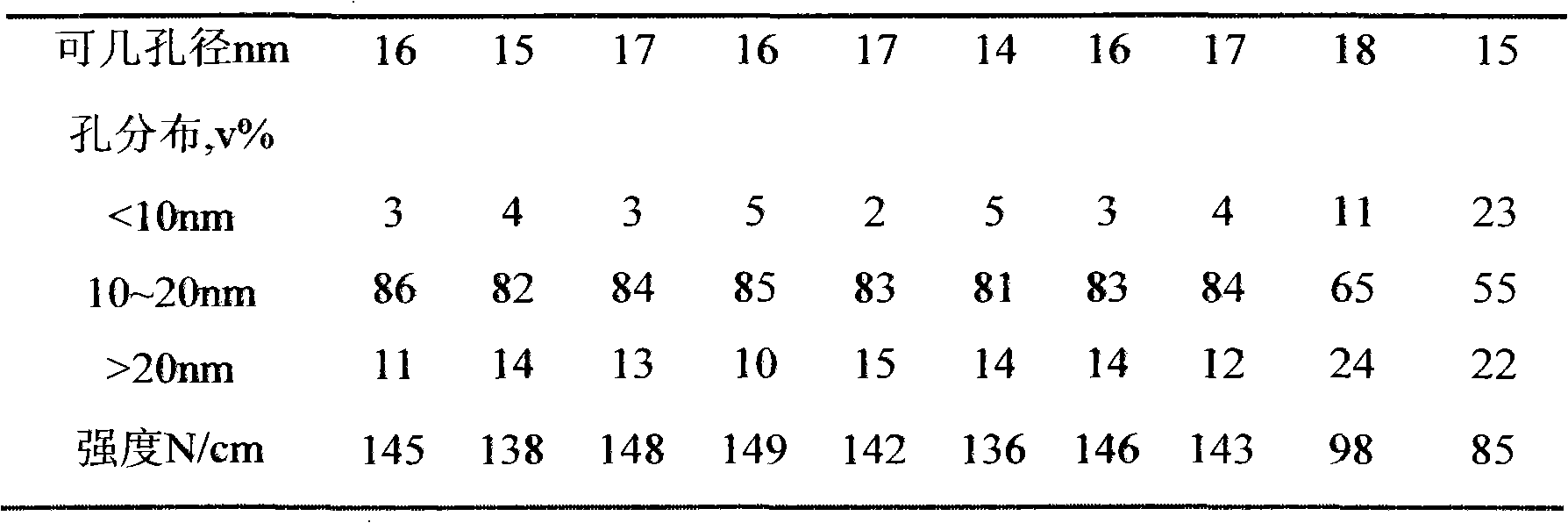

Preparation methods for macroporous alumina carrier and hydrodemetallization catalyst

ActiveCN102441437AModerate mechanical strengthModerate bulk densityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPseudoboehmiteMetal catalyst

The invention discloses preparation methods for a macroporous alumina carrier and a hydrodemetallization catalyst. The preparation method for the macroporous alumina carrier includes the following steps: (1) dry pseudoboehmite gel powder is hydrothermally processed under high pressure; (2) the dry pseudoboehmite gel powder obtained in step 1 is kneaded into a plastic, and pore-expanding agent is added in step 1 or step 2; (3) the plastic obtained in step 2 is shaped, the shaped material is dried and baked, and thereby the macroporous alumina carrier is obtained. The impregnation method is adopted to prepare the hydrodemetallization catalyst. The hydrodemetallization catalyst prepared by the method has large pore volume and pore diameter, centrally distributed pores, moderate mechanical strength and high activity and activity stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

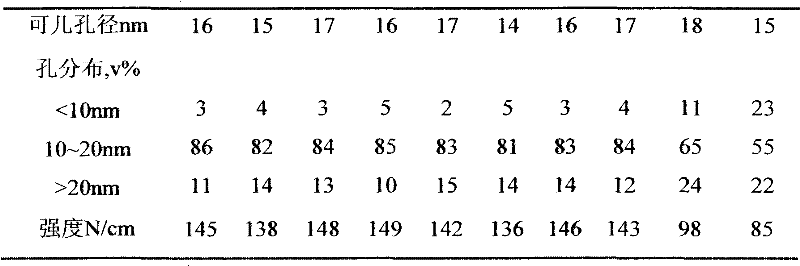

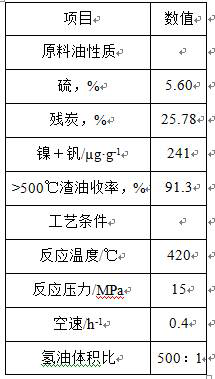

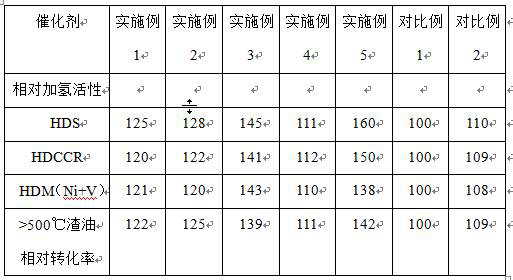

Heavy oil or residual oil hydrogenation catalyst and preparation method thereof

ActiveCN102039138AIncrease acidityImprove cracking capacityCatalyst carriersCatalyst activation/preparationFuel oilSolvent

The invention discloses a heavy oil or residual oil hydrogenation catalyst and a preparation method thereof. The catalyst carrier is prepared from silicon-containing aluminum hydroxide prepared by using a clay modified raw material as a crystal seed, active metal ingredients comprise VIII and VIB metals, and the silicon dioxide content of the catalyst is 0.1 to 45 weight percent. The preparation method for the catalyst comprises the following processes of: preparing the silicon-containing aluminum hydroxide, then adding proper glue solvent and additive for molding, performing drying and roasting to obtain the heavy oil or residual oil hydrogenation catalyst carrier, soaking the residual oil hydrogenation catalyst carrier into the active hydrogenation metal ingredients, and then performingdrying and roasting to obtain the heavy oil or residual oil hydrogenation catalyst. The physical and chemical properties and the use performance of the catalyst, particularly the use performance in the heavy oil or residual oil hydrogenation process, can be obviously improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

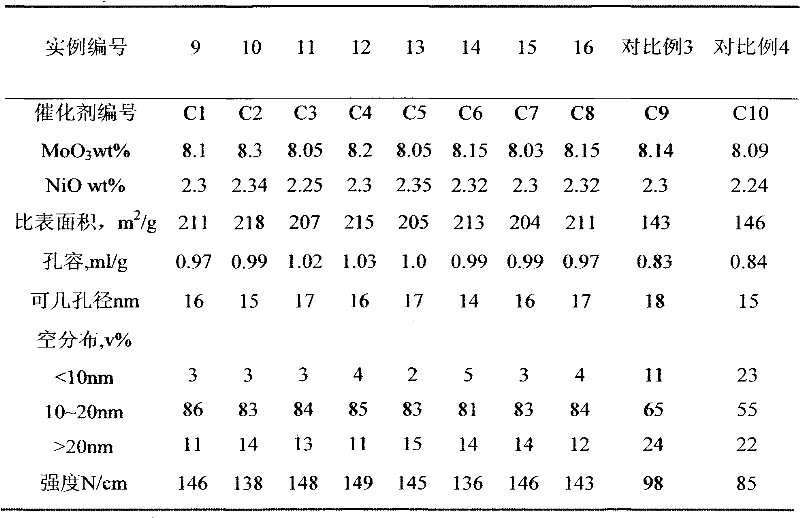

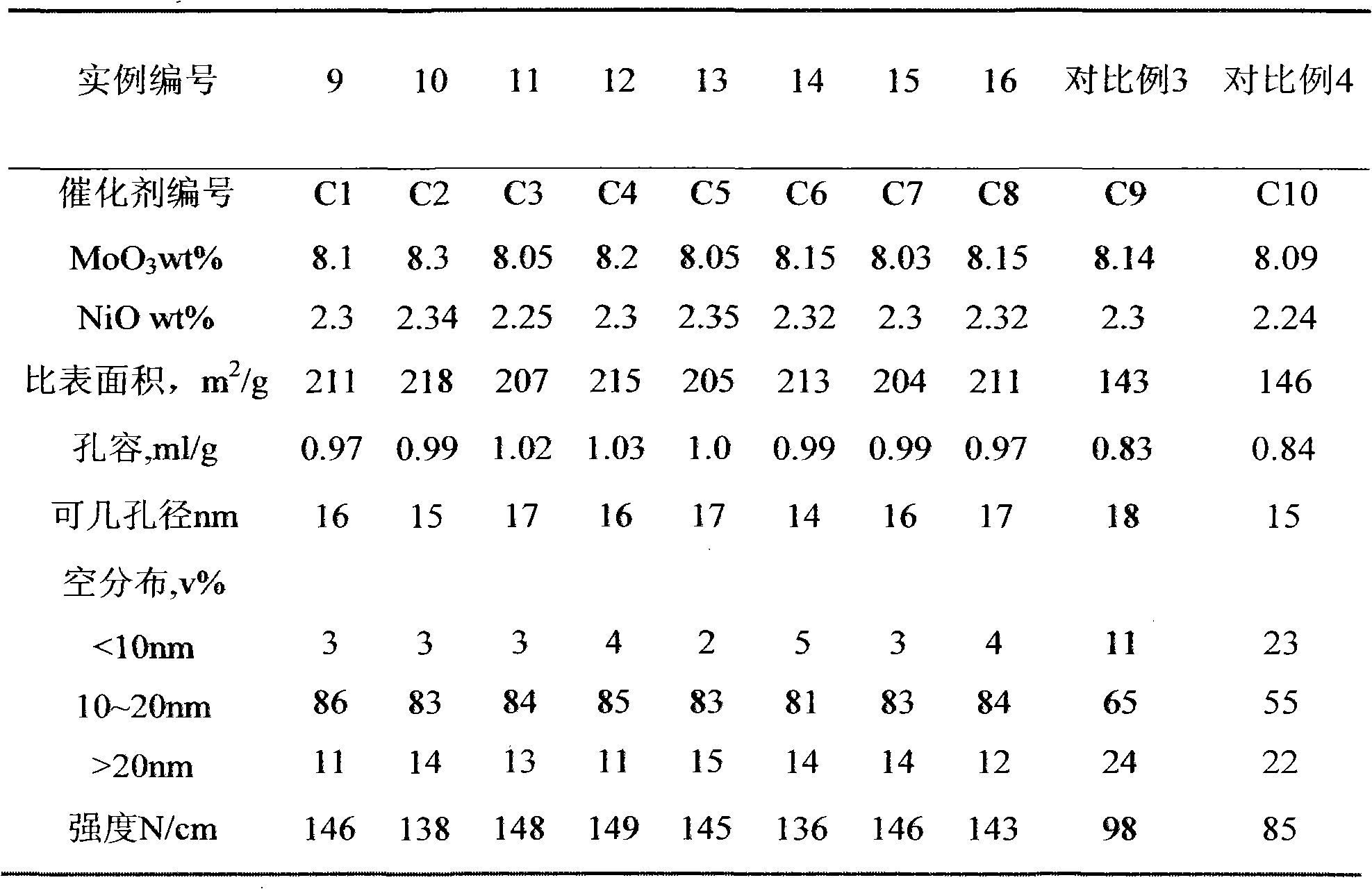

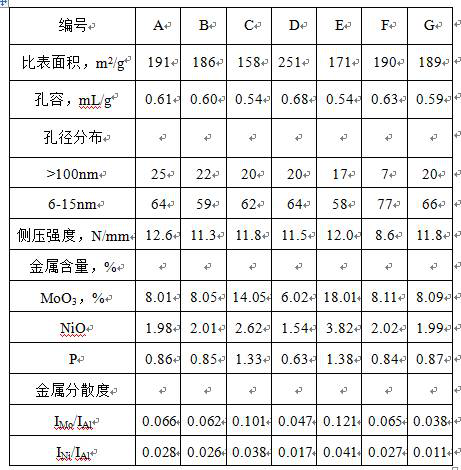

Hydroprocessing catalyst for heavy oil and preparing method thereof

InactiveCN1488718AReduce dosageAvoid damageRefining to eliminate hetero atomsPtru catalystHydrodesulfurization

The present invention relates to a preparation method of hydrogenation treatment catalyst. Said catalyst is prepared by loading molybdenum, nickel and phosphorus on a phosphorus and silicon contained alumina carrier prepared by adopting a special method, and said carrier prepared by special method is prepared by adding phosphorus adjuvant in the course of precipitation and ageing process and adding nano silicon-containing compound in the course of carrier forming process, for example, adding silicon dioxide. As compared with existent catalyst it has higher activity for hydro-desulfurization and hydro-denitrification of heavy oil, specially heavy fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

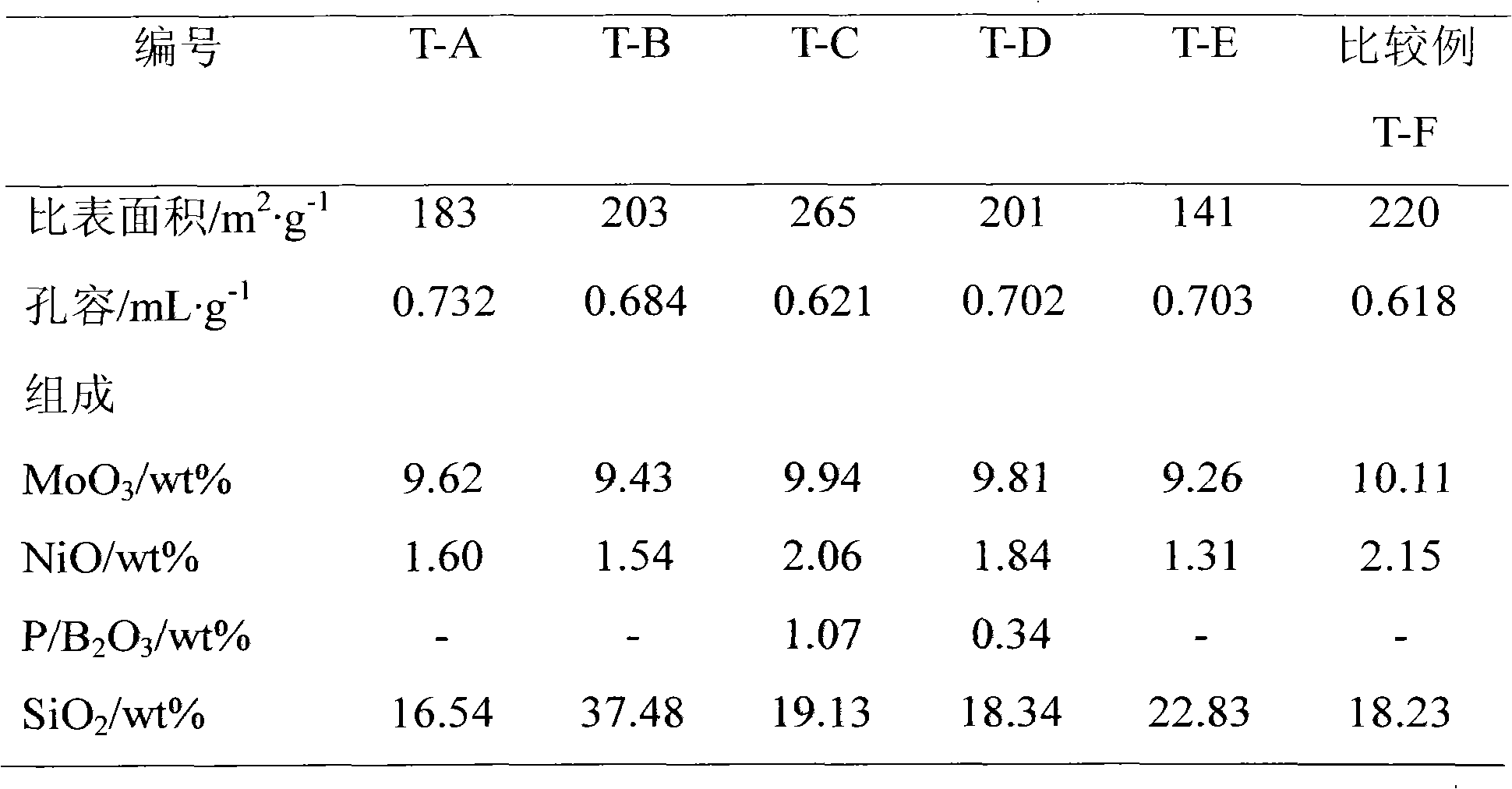

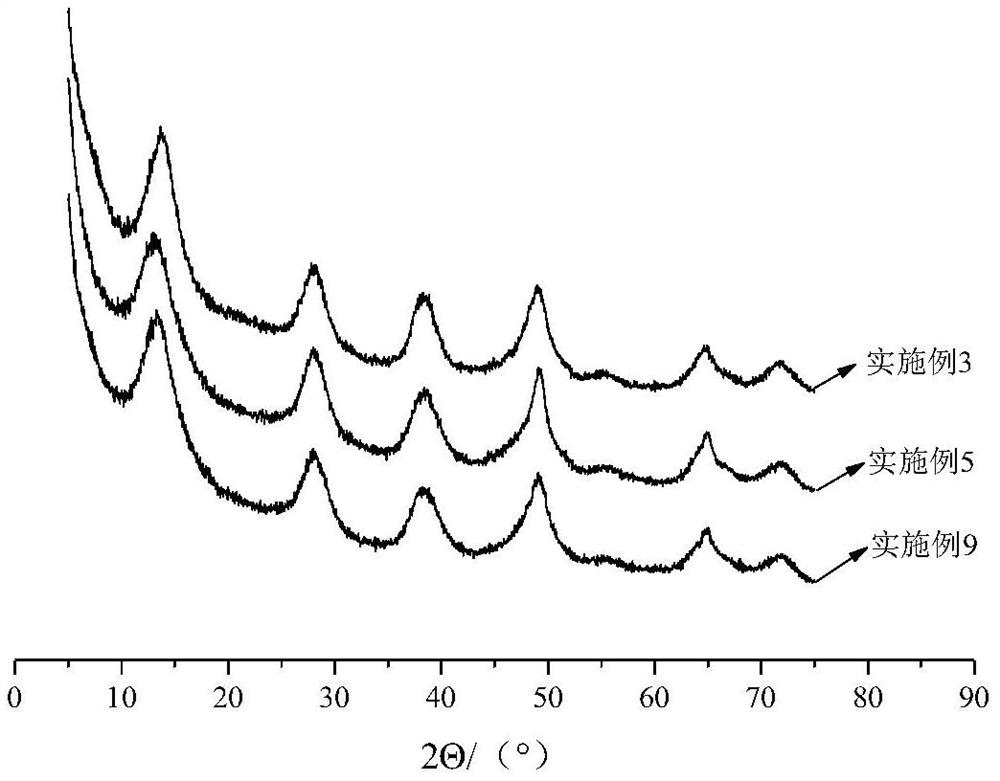

Heavy oil hydrocracking catalyst, and preparation method and applications thereof

ActiveCN105709789AImprove performanceGood peptizationHydrocarbon oil crackingMetal/metal-oxides/metal-hydroxide catalystsPtru catalystRoasting

The invention discloses a heavy oil hydrocracking catalyst, and a preparation method and applications thereof. According to the heavy oil hydrocracking catalyst, high-silicon aluminium oxide is taken as a carrier; VIII family metals and VIB family metals are taken as active metal ingredients. A preparation method of the high-silicon aluminium oxide carrier comprises following steps: modified clay obtained via high temperature roasting is added into an aluminum-containing alkaline liquor so as to obtain a suspension liquid; the suspension liquid and acidic silica sol are subjected to parallel flow gel forming; an alkaline solution is added for further gel forming; and the high-silicon aluminium oxide carrier is obtained via aging, filtering, and drying. The high-silicon aluminium oxide carrier is excellent in comprehensive performance such as pore structure and acidic properties; the heavy oil hydrocracking catalyst prepared by taking the high-silicon aluminium oxide carrier as a carrier is high in impurity removing rate and heavy oil conversion rate, and long in running period in heavy oil ebullated bed hydrocracking technological process.

Owner:CHINA PETROLEUM & CHEM CORP +1

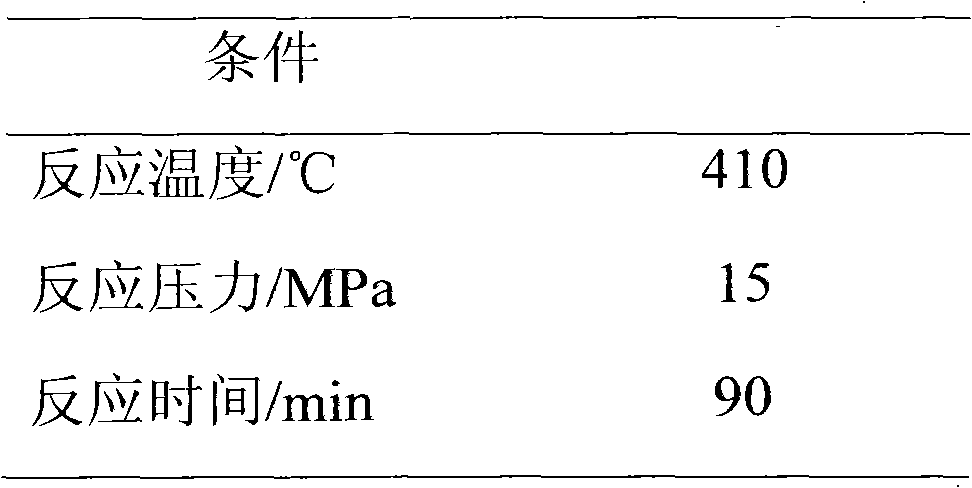

Method for preparing pseudo-boehmite by pulverized fuel ash

InactiveCN102849764AReduce pollutionImprove economyAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationCarbonate preparationPulverized fuel ashFly ash

The invention relates to a method for preparing pseudo-boehmite by pulverized fuel ash, which comprises the steps of: pretreating the pulverized fuel ash; roasting the pretreated pulverized fuel ash and Na2CO3 at the high temperature to obtain silicon-rich gel and a coarse AlCl3 solution; preparing a purified sodium metaaluminate solution by the coarse AlCl3 solution; adjusting the concentration of the purified sodium metaaluminate solution to be 0.8-2.0mol / L, adding a NaHCO3 solution with the concentration of 0.8-2.0mol / L, and carrying out reaction to obtain gel; carrying out ageing on the product for 10-30hours under the conditions that the temperature is 50-100 DEG C and the pH value is 7-11; filtering and separating to obtain a filter cake and a filtrate; and washing the filter cake by deionized water and drying to obtain the pseudo-boehmite finished product. The invention provides a new technical route for preparing the pseudo-boehmite with high added-value by the low-cost pulverized fuel ash, and the pulverized fuel ash is processed and treated, so that the environmental pollution caused by the pulverized fuel ash is reduced.

Owner:NORTHEAST GASOLINEEUM UNIV

Sodium hydrosulfite composition and preparation method thereof

ActiveCN102493233AReduce lossImprove hard water resistanceDyeing processInorganic saltsPolyvinyl alcohol

The invention provides a sodium hydrosulfite composition and a preparation method thereof. The sodium hydrosulfite composition contains the following steps of: sodium hydrosulfite, an inorganic salt coating agent and a polymer coating agent, wherein the inorganic salt coating agent contains sulfate and hydrochloride; the polymer coating agent is selected from one or more of polyethylene glycol, poval, polyacrylate and a maleic acid-acrylic acid copolymer. Compared with the conventional sodium hydrosulfite composition, the sodium hydrosulfite composition has the advantages of safety and stability in transportation and storage, slow and sustained release in the using process and low using amount during use.

Owner:ZHEJIANG JIACHENG CHEM

Method for preparing catalytic cracking catalyst

ActiveCN101624536AStable pore volumeHigh strengthCatalytic crackingMolecular sieve catalystsSlurryAluminium

The invention discloses a method for preparing a catalytic cracking catalyst, which comprises steps of mixing and pulping aluminum binder and acid. The method is characterized by also comprising steps of adding alkali into slurry to improve the pH value of the slurry, and then adding the acid into the slurry to reduce the pH value of the slurry. The method can stabilize the quality of the prepared catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

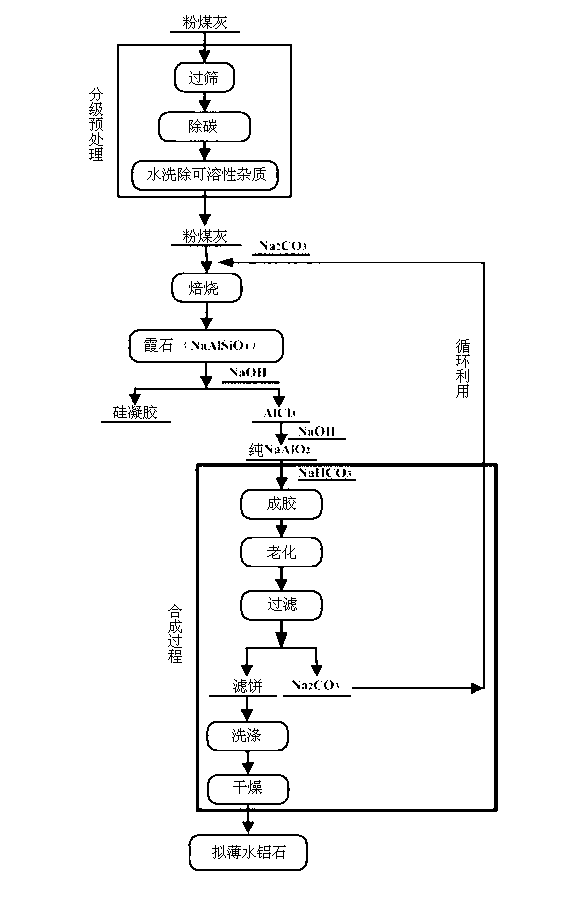

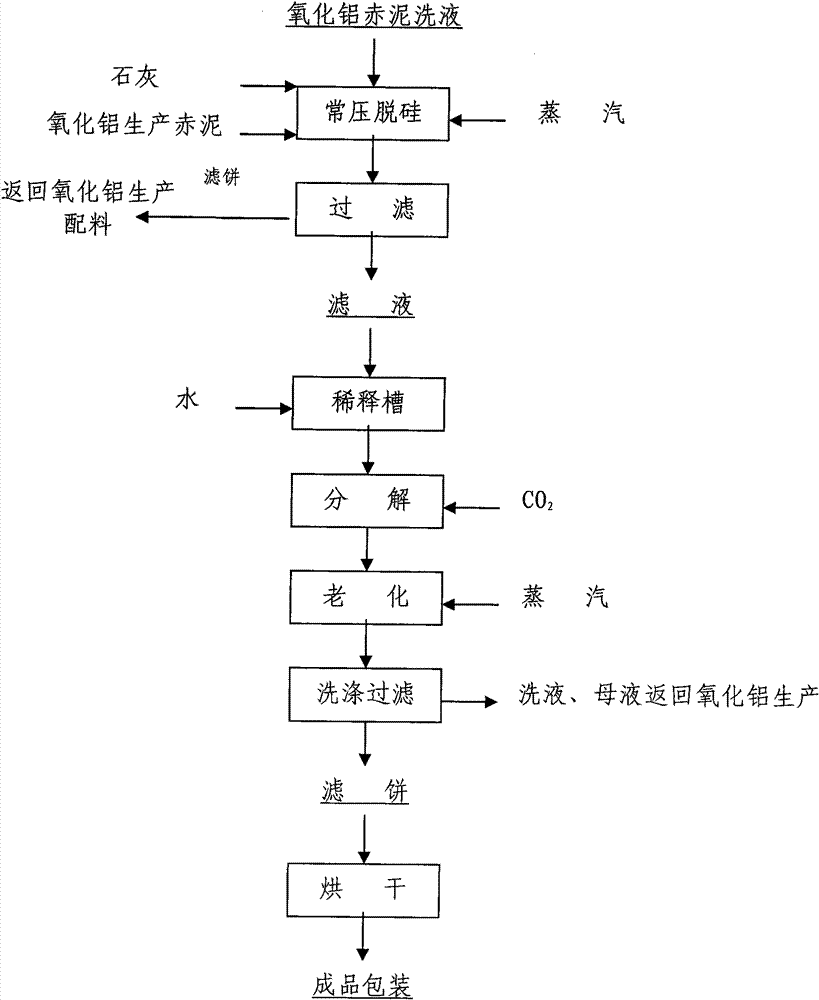

Method for producing boehmite by using washing liquor

InactiveCN101920978AReduce the cost of raw materials for productionAbundant amount of raw materialsAluminium oxides/hydroxidesCarbonationFilter cake

The application relates to a method for producing boehmite by using washing liquor from the production of washing red mud by alumina, which comprises the following steps: delivering washing liquor from the production of the washing red mud by alumina to a desilicication tank, and adding red mud and lime to perform desilicication; when a desilicication index is more than or equal to 400 as required, filtering the product of the desilicication, transferring filtrate to a diluting tank for cooling, cooling to 20 to 60 DEG C, performing carbonation gelatinizing by using 20 to 60 volume percent CO2 gas obtained by concentrating and enriching CO2 waste gas generated in the production of alumina as a precipitator; heating the gelatinized slurry to 70 to 100 DEG C, keeping the temperature for 1 to 6 hour and aging; and washing the aged slurry with washing equipment, filtering the aged slurry to obtain filtrate and filter cake, and drying the filter cake by using drying equipment to obtain powdery boehmite. The method has the advantages of low production raw material cost and rich raw material source, is favorable for alumina production liquid balance, improvement on finished alumina yield, reduction of Al2O3 content of red mud discharged to the outside and recovery of alumina CO2 waste gas and is in accordance with the national circulating economy and waste recycling principle. The product produced has high crystalline phase purity and high peptizing performance and can be used as a binder, a drier, a purifier, a catalyst, a catalyst carrier and the like.

Owner:SHANXI ALUMINUM FACTORY TECH CHEM

Phosphor and silicon-containing alumina supporter and preparing method thereof

InactiveCN1488440AMaintain structural propertiesHigh strengthCatalyst carriersRefining to eliminate hetero atomsPhosphorNitrogen

The invention refers to a kind of aluminium oxide carrier containing phosphorus and silicon and the manufacturing method, the silicon disperses evenly on the surface of the carrier, the 3~15nm hole capacity accounts for over 90% of the whole hole capacity. The adding mode of assistant is: adds in assistant phosphorus in the sediment and aging process, adds in assistant silicon in the forming period, the assistant silicon is nano silicon dioxide. The craft is easy, the cost is low; and it has a good performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

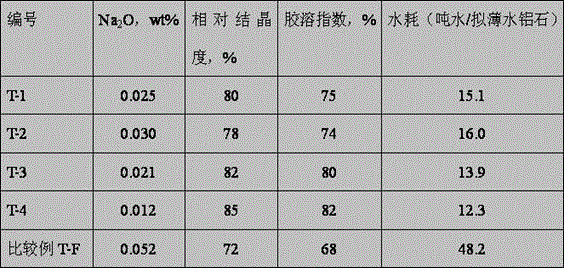

Pseudo-boehmite preparation method

ActiveCN110655096ALow impurity contentGood peptizationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationBoehmiteAluminium salts

The invention discloses apseudo-boehmite preparation method, which comprises: (1) preparing a sodium metaaluminate solution; (2) simultaneously adding the sodium metaaluminate solution with the prepared Al2O3 concentration and an aluminum sulfate solution into a reaction kettle in a parallel flow manner according to a certain ratio, carrying out a reaction, transferring the slurry into another gas-liquid reaction kettle after the reaction, introducing carbon dioxide gas into the gas-liquid reaction kettle, controlling the volume ratio of air to carbon dioxide, and carrying out a reaction; and(3) carrying out aging, exchange washing, filtering and drying on the obtained product to obtain the special pseudo-boehmite dry powder special for ceramic corundum abrasive materials. According to the invention, the prepared pseudo-boehmite is low in impurity content, good in peptization, good in gelling property, good transparency in gel, high in gel viscosity and good in adhesive property, andis special pseudo-boehmite for ceramic corundum abrasive materials; and by adopting the method, the yield of the single-kettle pseudo-boehmite can be greatly improved, so that the production cost is greatly reduced.

Owner:湖南约瑟夫科技有限公司

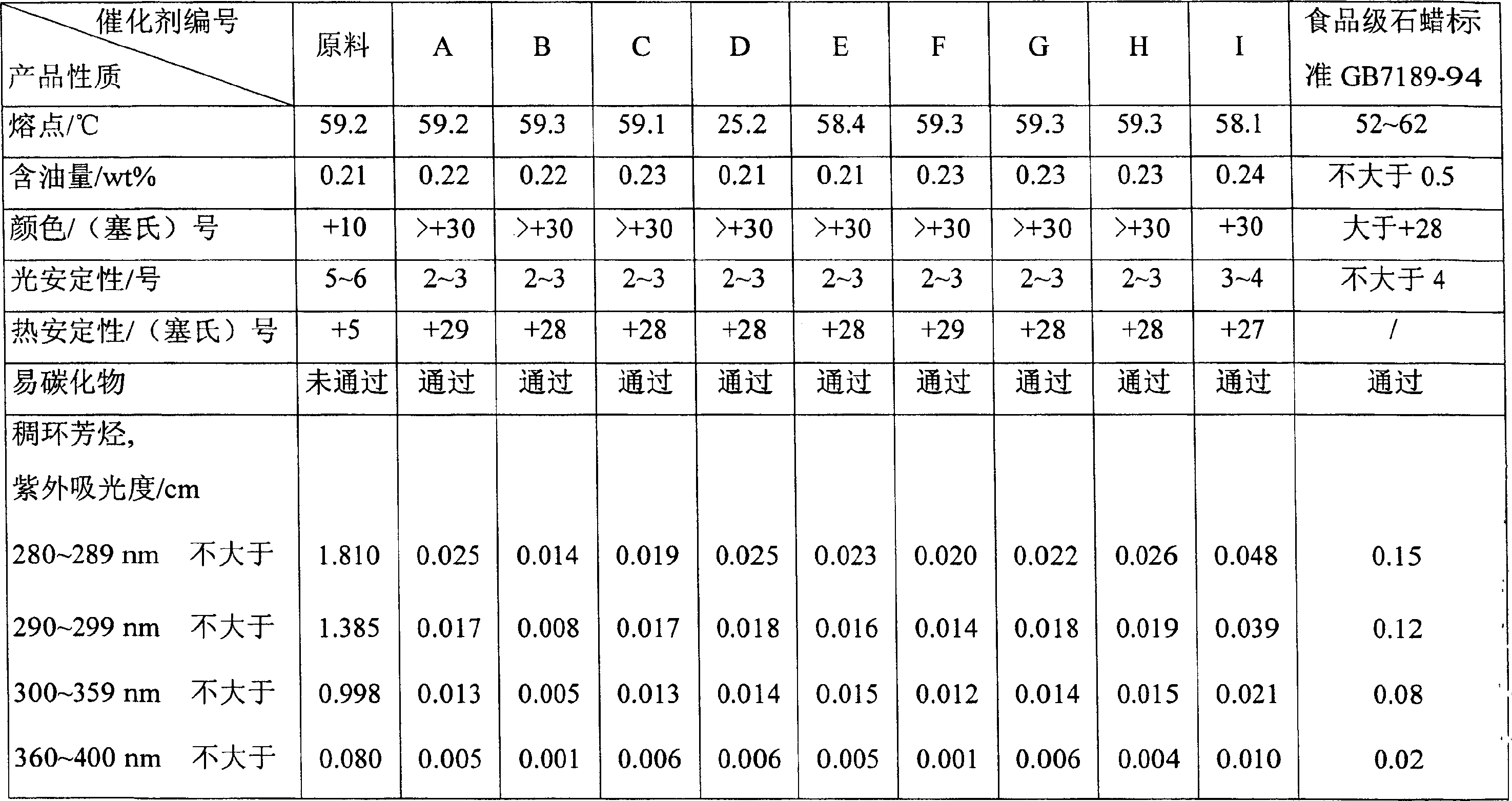

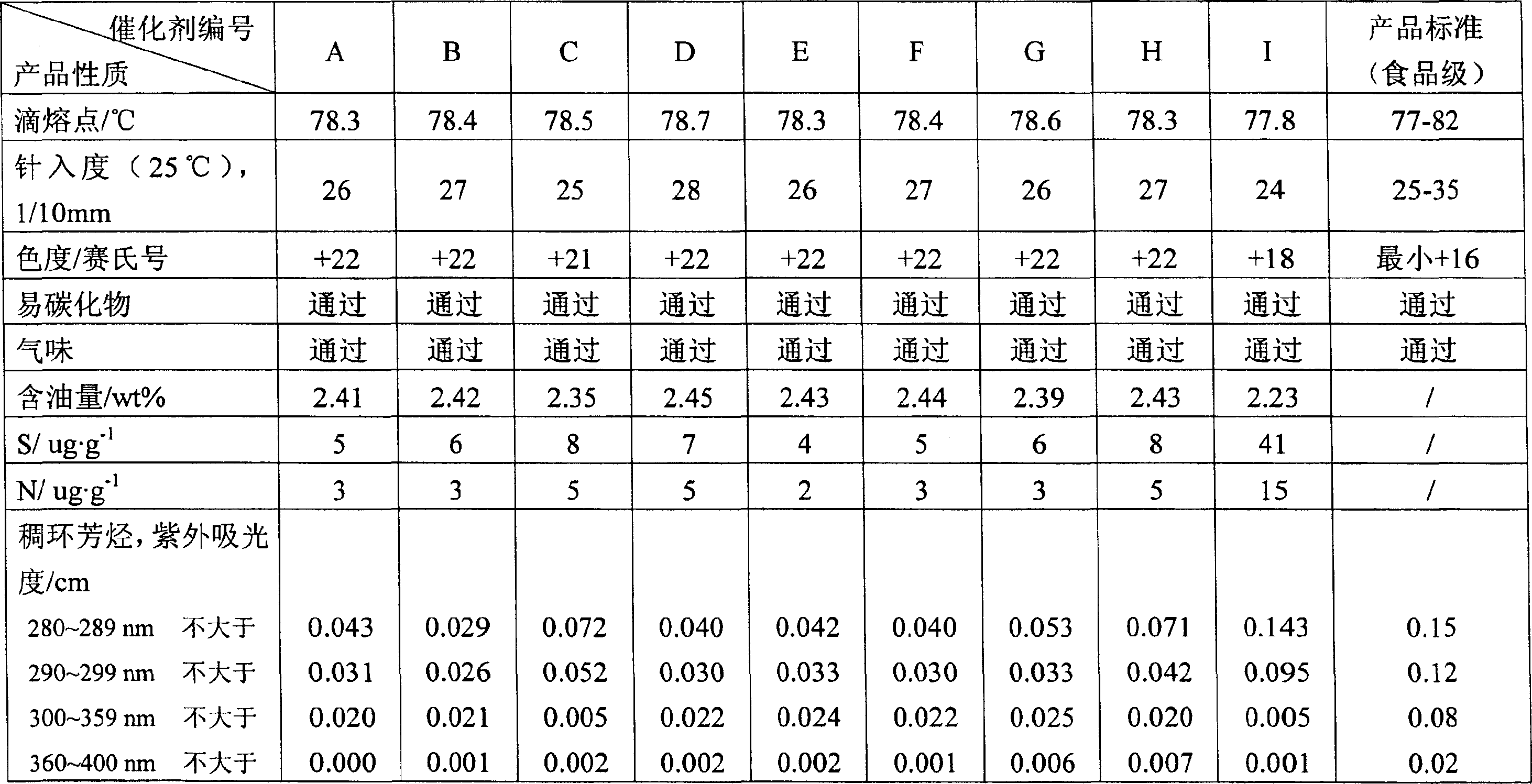

Hydrogenating catalyst for petroleum wax and its preparation process

InactiveCN1268722CGood physical and chemical propertiesLarge aperturePetroleum wax refiningAluminateWax

The invention discloses a petroleum wax hydrogenation catalyst and its preparing method, adopting the Si- and P- containing aluminum hydroxide prepared by CO2 netur neutralization process to act as a carrier material of catalyst, where the Si and P auxiliaries are added in steps, some Si- and P- containing compounds mix with sodium meta-aluminate solution to form a glue, some Si-containing compounds are added after the glue is formed or in the ageing process, and most P-containing compounds are added in the process of peptizing or pulping the produced aluminum hydroxide after washed, thus making most Si and P are distributed on the surface of aluminum hydroxide, effectively give full play to the Si and P cooperatively regulating surface physico-chemical property and hole structure of the catalyst. Its preparing process is simple and low-cost. It has good activity and selectivity as processing petroleum waxes including high-melting point petroleum wax.

Owner:CHINA PETROLEUM & CHEM CORP +1

Haze-reduction paint for building wall surfaces and preparation method

ActiveCN109897575ALarger than surfaceLarge hole volumeCovering/liningsNon-macromolecular adhesive additivesAcrylic resinSorbent

The invention provides haze-reduction paint for building wall surfaces and a preparation method. The method includes the steps: firstly, preparing pseudo-boehmite sol coated tourmaline loaded zinc oxide nano-crystalline composite spherical fine particles to serve as photocatalysts; secondly, preparing slurry from the particles, nano-silicon dioxide, nano-wollastonite, super-fine talcum powder, defoaming agents, dispersing agents, coalescing agents, preservatives and water; finally, matching the slurry, organosilicone acrylic resin and thickening agents to form the haze-reduction paint for thebuilding wall surfaces. By the aid of a pseudo-boehmite sol coated tourmaline loaded zinc oxide nano-crystalline composite material with the advantages of large specific surface, high pore volume andthe like, outward flow of catalytic active matters is avoided, the haze-reduction paint is provided with a adsorbent with excellent performance, the paint and the zinc oxide nano-crystalline are compound, high adsorption capacity of the adsorbent and visible light drive photocatalysis to degrade cationic organic pollutants, air quality is improved, the paint has remarkable effects on control of large-area haze, and further, and the paint is simple in preparation process, low in raw material cost and suitable for large-scale popularization.

Owner:中烯新材料(福建)股份有限公司

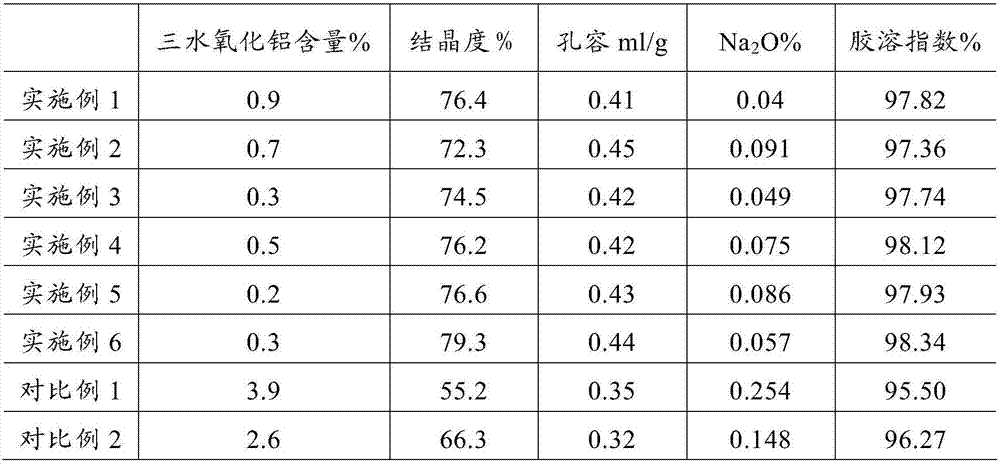

Aging method for preparing pseudo-boehmite by carbonation method

ActiveCN105645446BHigh crystallinityCrystal phase pureAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium oxides/hydroxidesAge methodCrystallinity

The invention discloses an aging method of pseudo-boehmite prepared by a carbonation method. The method concretely comprises the steps of enabling the pseudo-boehmite prepared by the carbonation method to form gel, and then rapidly carrying out on solid-liquid separation; after that, putting a filter cake attached with mother liquor into a closed container, heating and aging. The aging method is simple in technology, low in energy consumption, high in productivity and low in production cost; the prepared pseudo-boehmite product is pure in crystalline phase, high in degree of crystallinity, good in gel dissolubility, less in impurity and wide in use.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

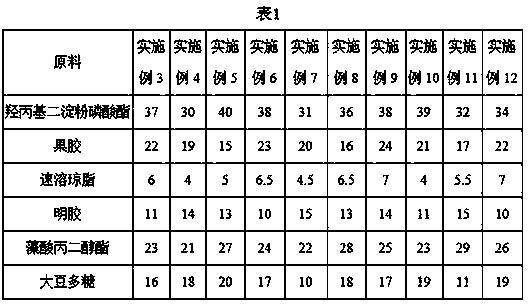

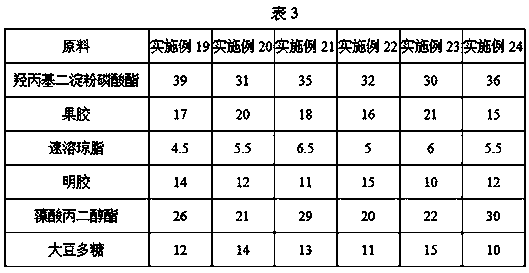

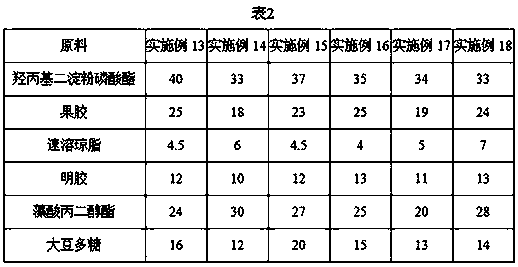

Stabilizer for pasteurized yoghurt, pasteurized yoghurt and preparation method of pasteurized yoghurt

InactiveCN109221407AThickenGood peptization effectMilk preparationLactobacillusChemistryPropylene glycol alginate

The invention provides a stabilizer for pasteurized yoghurt, the pasteurized yoghurt and a preparation method of the pasteurized yoghurt. The stabilizer is prepared from the following raw materials inparts by weight: 30-40 parts of hydroxypropyl distarch phosphate, 15-25 parts of pectin, 4-7 parts of instant agar, 10-15 parts of gelatin, 20-30 parts of propylene glycol alginate and 10-20 parts ofsoybean polysaccharide. By means of a compounding technology, a plurality of suitable thickeners are selected for compounding, so that a synergistic effect can be achieved between raw materials, stability, thickness, smoothness and the like of the prepared yoghurt can also be obviously improved under the condition of lower consumption of the stabilizer, smoothness of the yoghurt can be increased,precipitation of whey in the yoghurt can be reduced, the change of total acidity of the yoghurt in the shelf life is obviously reduced, the shelf life of the yoghurt is prolonged, the state of the yoghurt in the shelf life of three months is unchanged, and the system is uniform and free of water bleeding.

Owner:HENAN KINGYUEN FOOD SCI & TECH

Phosphor and silicon-containing alumina supporter and preparing method thereof

InactiveCN1201865CMaintain structural propertiesHigh strengthCatalyst carriersRefining to eliminate hetero atomsAdjuvantPore distribution

The invention relates to a phosphorus- and silicon-containing alumina carrier and a preparation method thereof. Silicon is uniformly dispersed on the surface of the alumina carrier, and the pores of the carrier with a diameter of 3 to 15 nm account for more than 90% of the total pore volume. The method of adding the carrier auxiliary agent in the present invention is as follows: adding auxiliary agent phosphorus during the precipitation aging process, adding auxiliary agent silicon during the carrier molding process, and the raw material of the auxiliary agent silicon is nano silicon dioxide. Adopting the method of the invention to prepare the phosphorus-containing and silicon-alumina carrier, the molding is easy, the process is simple, and the cost is low; at the same time, it has excellent physical and chemical properties and performance, especially has concentrated pore distribution and suitable surface acidity, and is suitable for heavy fractions Carrier for catalysts such as oil hydrodesulfurization and denitrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of pseudo-boehmite

ActiveCN110655096BLow impurity contentGood peptizationAluminium compoundsGas liquid reactionAluminum sulphate

Owner:湖南约瑟夫科技有限公司

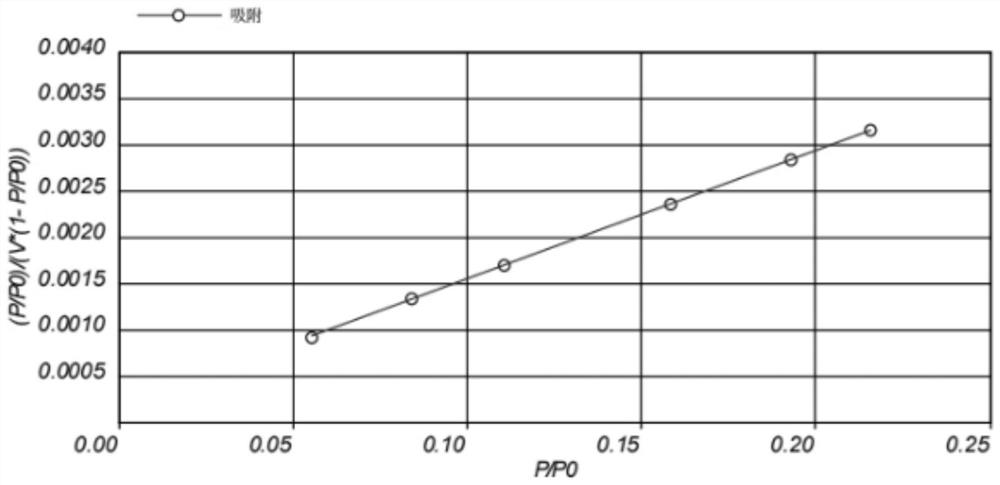

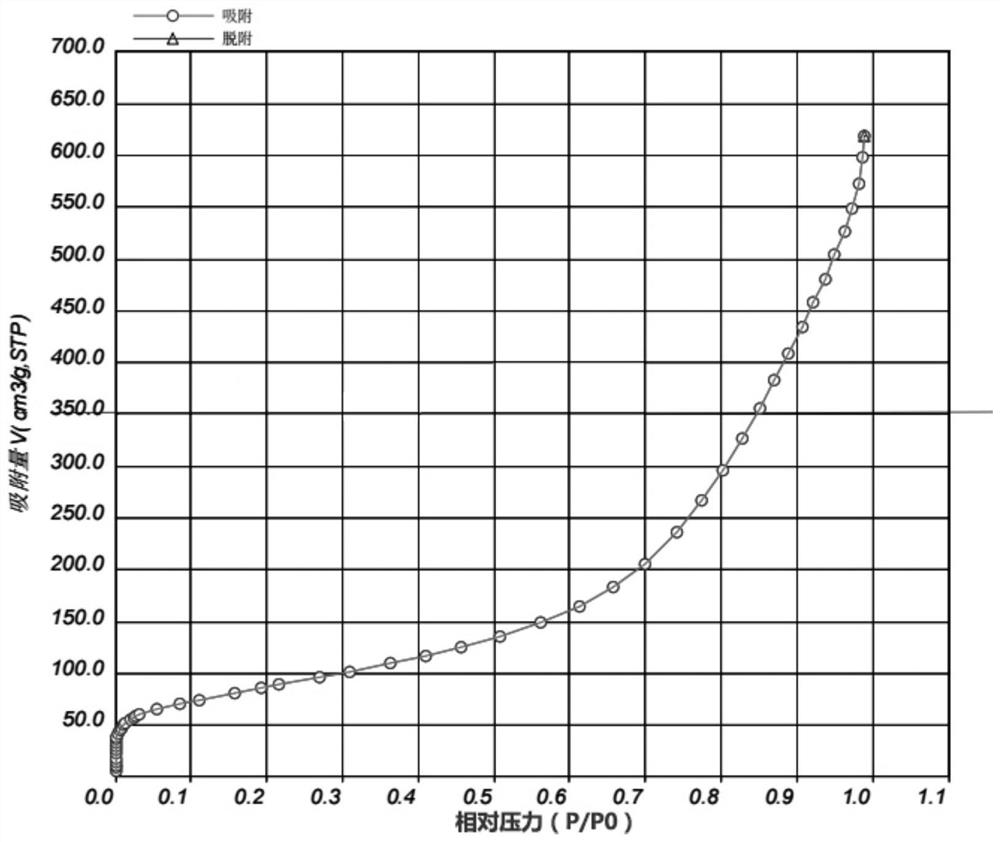

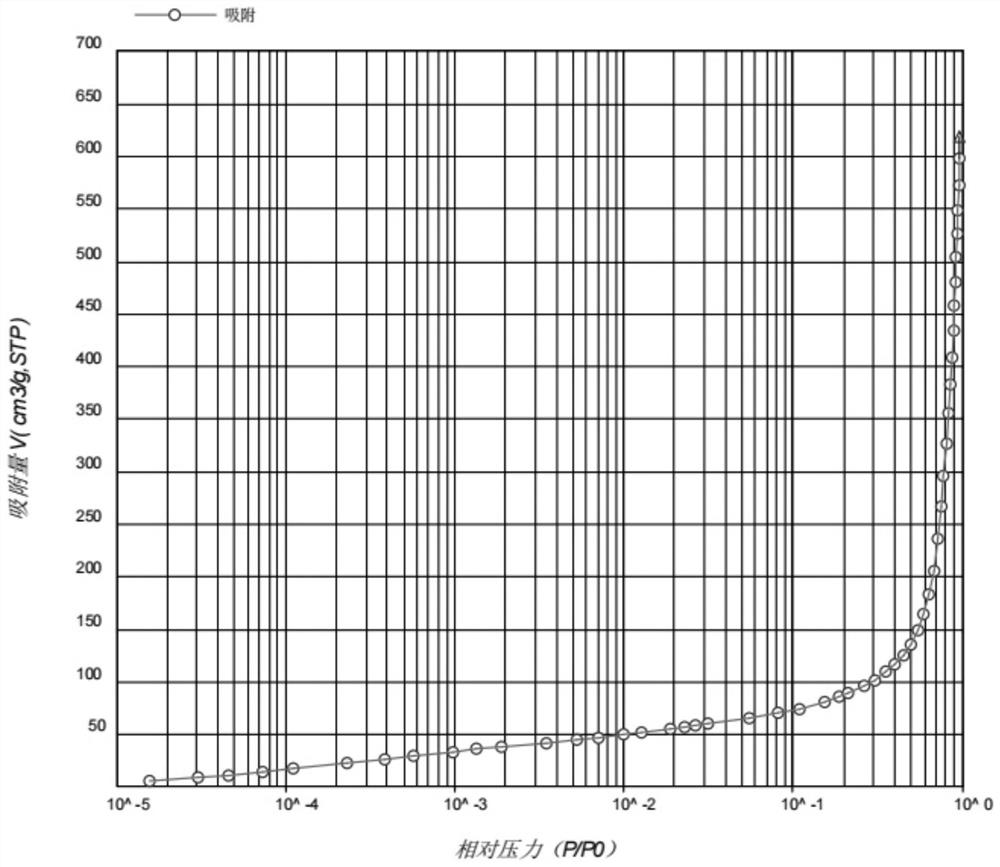

Preparation method of macroporous active alumina dry glue with high peptizing index

ActiveCN113060747AGood peptizationPore structure highAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminum sulphateSodium aluminate

The invention provides a preparation method of macroporous active alumina dry glue with a high peptizing index. The preparation method comprises the following steps: step 1, neutralizing an aluminum sulfate solution and a sodium metaaluminate solution in a parallel flow manner to gelatinize; and step 2, aging, water-washing, drying and crushing the finished product gelatinized in the step 1 to obtain the activated aluminum oxide. The preparation method has the beneficial effects that the active aluminum oxide product with high peptizing index, large pore volume and large specific surface area can be obtained by controlling the gelatinizing process, raw material indexes and the like.

Owner:天津凯文特科技有限公司

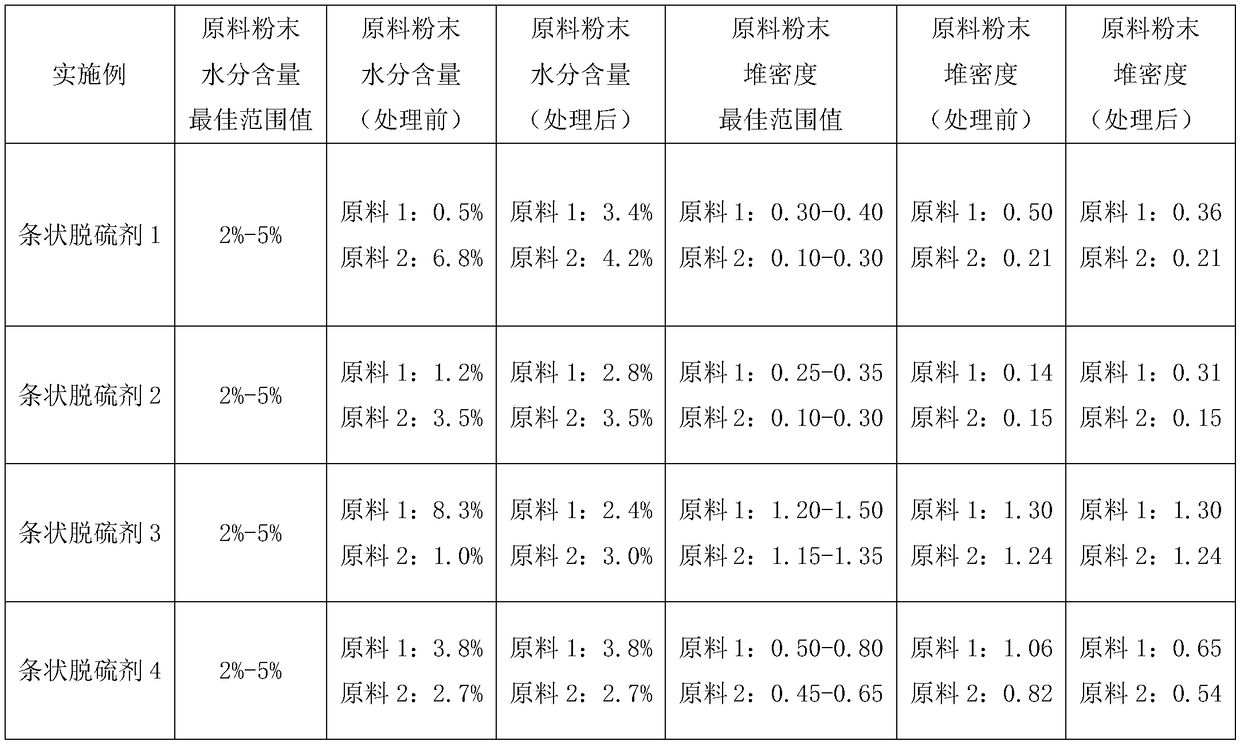

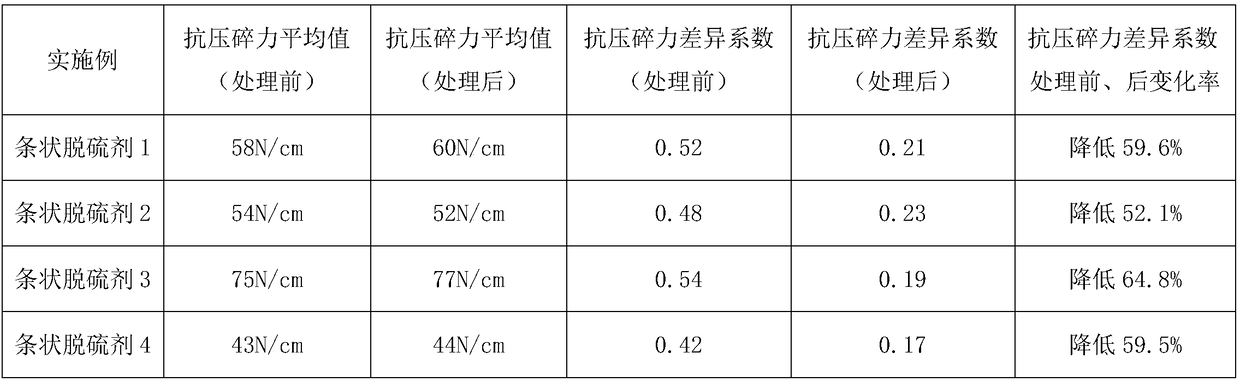

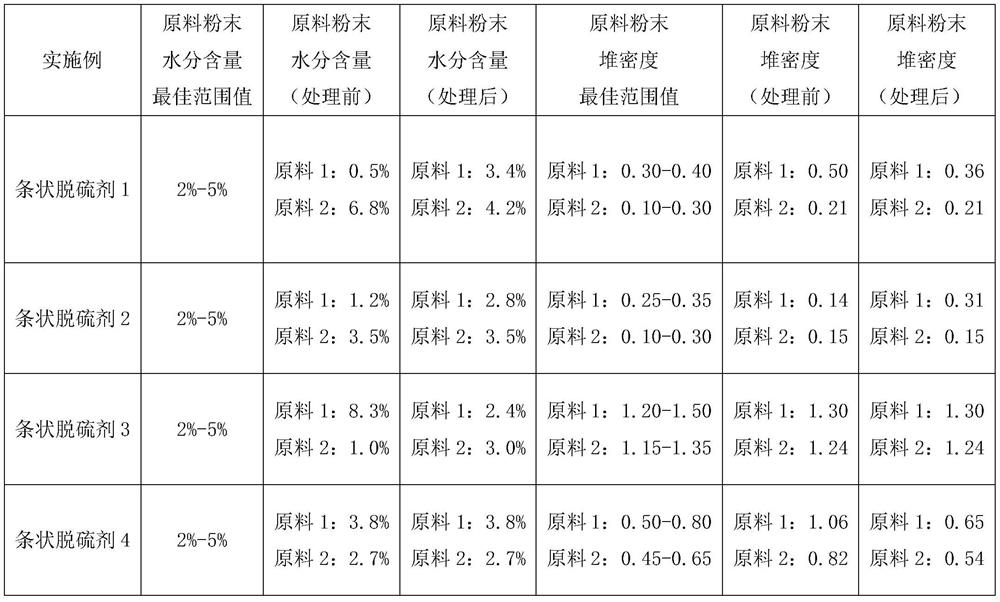

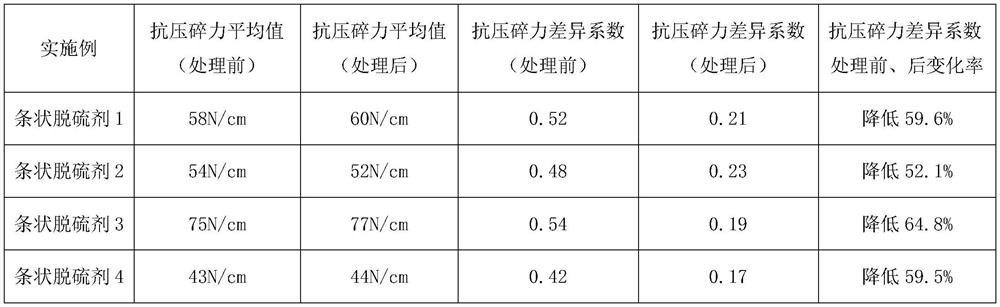

Strip desulfurizing agent and preparation method thereof

ActiveCN109433181AReduced coefficient of variation in crush resistanceQuality improvementDispersed particle separationCatalyst activation/preparationWater contentMetallurgy

The invention relates to a strip desulfurizing agent and a preparation method thereof. The preparation method comprises the following steps: respectively determining the water content of all raw material powder, comparing the water content and adjusting the water contents of the all the raw material powder within the optimal range of the water content; respectively determining the bulk density ofall the raw material powder, comparing the bulk density of all the raw material powder and adjusting the bulk density of all the raw material powder within the corresponding optimal range of the bulkdensity of all the raw material powder; according to the ratio of the raw materials of the strip desulfurizing agent, mixing all the raw material powder, milling the mixed raw material powder and extruding the milled raw material powder into strips, and then sequentially drying and roasting the strips, so as to obtain a finished product strip desulfurizing agent. According to the preparation method, through the synergism of effects achieved by control on the water content and the bulk density of the raw material powder, the diversity factor of crushing strength of the strip desulfurizing agentproduct is greatly decreased, and the quality of the strip desulfurizing agent product is improved.

Owner:HUNAN HUANDA ENVIRONMENTAL PROTECTION

Hydro-conversion catalyst for heavy oil and residual oil and its preparing process

InactiveCN1221637CIncrease acidityHigh acid strengthCatalytic naphtha reformingStrong acidsResidual oil

The present invention belongs to the field of heavy oil and residual oil hydrotransforming technology. The heavy oil and residual oil hydrotransforming catalyst has siliceous alumina carrier, relatively strong acidity and especially protonic acid amount higher than that in available residual oil hydrotransforming catalyst. The siliceous alumina carrier is prepared through one colloid forming process, during and after which silicon is added to make alumina possess more strong acid centers and ideal pore structure. The catalyst of the present invention is used in the hydrotransforming treatment of heavy oil, residual oil and other inferior oil material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing catalytic cracking catalyst

ActiveCN101624536BHigh strengthStable peptization effectCatalytic crackingMolecular sieve catalystsSlurryChemistry

The invention discloses a method for preparing a catalytic cracking catalyst, which comprises steps of mixing and pulping aluminum binder and acid. The method is characterized by also comprising steps of adding alkali into slurry to improve the pH value of the slurry, and then adding the acid into the slurry to reduce the pH value of the slurry. The method can stabilize the quality of the prepared catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation methods for macroporous alumina carrier and hydrodemetallization catalyst

ActiveCN102441437BLarge hole volumeLarge apertureCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPseudoboehmiteMetal catalyst

The invention discloses preparation methods for a macroporous alumina carrier and a hydrodemetallization catalyst. The preparation method for the macroporous alumina carrier includes the following steps: (1) dry pseudoboehmite gel powder is hydrothermally processed under high pressure; (2) the dry pseudoboehmite gel powder obtained in step 1 is kneaded into a plastic, and pore-expanding agent is added in step 1 or step 2; (3) the plastic obtained in step 2 is shaped, the shaped material is dried and baked, and thereby the macroporous alumina carrier is obtained. The impregnation method is adopted to prepare the hydrodemetallization catalyst. The hydrodemetallization catalyst prepared by the method has large pore volume and pore diameter, centrally distributed pores, moderate mechanical strength and high activity and activity stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydroprocessing catalyst for heavy oil and preparing method thereof

InactiveCN1282732CReduce dosageAvoid damageRefining to eliminate hetero atomsPtru catalystHydrodesulfurization

The invention relates to a preparation method of a hydrogenation catalyst. The catalyst is prepared by loading molybdenum, nickel and phosphorus on a phosphorus-containing and silicon-alumina carrier prepared by a special method. The carrier prepared by the special method is obtained by aging It is prepared by adding phosphorus additives during the process and adding nano-silicon-containing compounds such as silicon dioxide during the carrier molding process. Compared with the existing catalysts, the catalyst of the present invention has a large pore volume, a high specific surface area and a more concentrated pore size distribution under the premise of ensuring that it contains a relatively high hydrogenation active metal component, and is suitable for the hydrotreating of heavy oil, especially Shows higher activity in hydrodesulfurization and denitrogenation of heavy distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

Technology for preparing pseudo-boehmite by sodium bicarbonate neutralization method

ActiveCN101665261BWill not negatively affectCause negative impactAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationChemical industrySodium bicarbonate

The invention discloses a technology for preparing pseudo-boehmite by a sodium bicarbonate neutralization method, which comprises steps: using NaHCO3 solution and sodium aluminate solution to carry out acid-alkali neutralizing reaction so as to prepare pseudo-boehmite; and after neutralizing reaction, separating, ageing, washing, drying and grinding material to prepare pseudo-boehmite. As reaction mother solution does not contain acid radical ions, processes and devices are not corroded, and simultaneously CO2 gas is pumped into mother solution for depth carbonization to form NaHCO3 solution,and neutralization reaction can be conducted repeatedly, thus fully using production raw material and reducing production cost. The pseudo-boehmite prepared by the technology has good peptization property, fast peptization speed, high peptization rate, low peptization viscosity, concentrated product pore diameter distribution, good caking property and wide application in oil refining, petroleum and chemical industries, environmental protection and chemical fertilizer catalytic agent manufacture.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for producing boehmite by using washing liquor

The application relates to a method for producing boehmite by using washing liquor from the production of washing red mud by alumina, which comprises the following steps: delivering washing liquor from the production of the washing red mud by alumina to a desilicication tank, and adding red mud and lime to perform desilicication; when a desilicication index is more than or equal to 400 as required, filtering the product of the desilicication, transferring filtrate to a diluting tank for cooling, cooling to 20 to 60 DEG C, performing carbonation gelatinizing by using 20 to 60 volume percent CO2 gas obtained by concentrating and enriching CO2 waste gas generated in the production of alumina as a precipitator; heating the gelatinized slurry to 70 to 100 DEG C, keeping the temperature for 1 to 6 hour and aging; and washing the aged slurry with washing equipment, filtering the aged slurry to obtain filtrate and filter cake, and drying the filter cake by using drying equipment to obtain powdery boehmite. The method has the advantages of low production raw material cost and rich raw material source, is favorable for alumina production liquid balance, improvement on finished alumina yield, reduction of Al2O3 content of red mud discharged to the outside and recovery of alumina CO2 waste gas and is in accordance with the national circulating economy and waste recycling principle. The product produced has high crystalline phase purity and high peptizing performance and can be used as a binder, a drier, a purifier, a catalyst, a catalyst carrier and the like.

Owner:SHANXI ALUMINUM FACTORY TECH CHEM

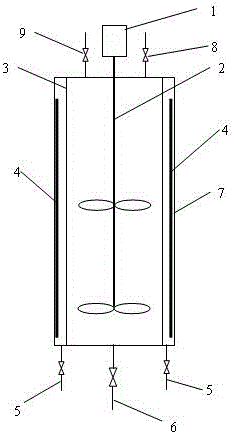

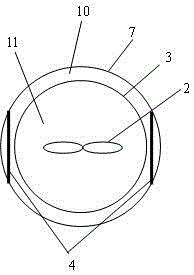

A kind of preparation method of pseudo-boehmite

ActiveCN104671263BReduce in quantityParticle integrityAluminium oxides/hydroxidesAluminium hydroxideAluminium oxides

The invention discloses a preparation method of pseudo-boehmite. The method comprises preparing aluminum hydroxide precipitation, aging, washing, and drying, wherein the aging is carried out in the following container: a filter cloth is arranged in the container along the axial direction, so that the aging container is divided into a sandwich area and a central area, and the central area is arranged There is a stirrer, and the negative and positive electrodes that generate the electric field are placed oppositely in the interlayer area, and the aging conditions are controlled. The method can improve the performance of the pseudo-boehmite and reduce the water consumption in the subsequent washing process.

Owner:CHINA PETROLEUM & CHEM CORP +1

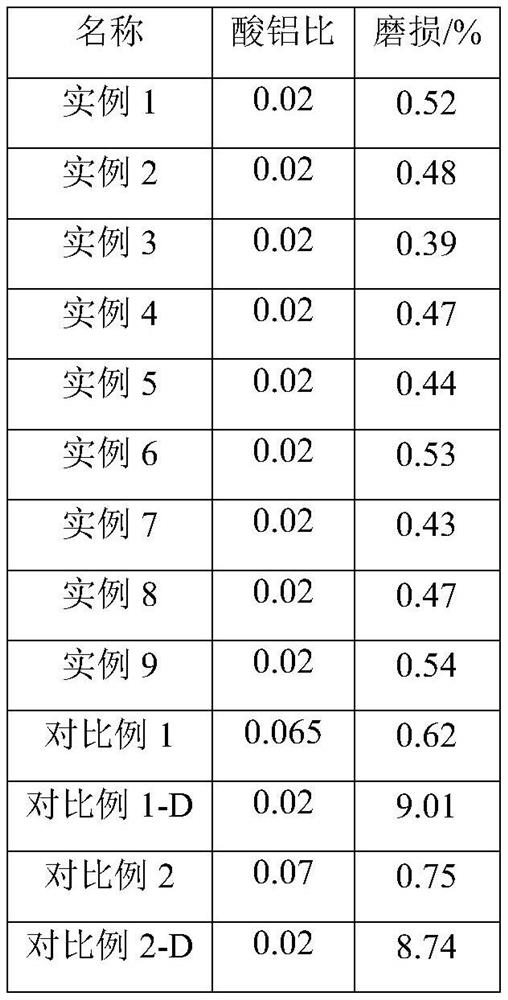

A kind of hydrogenation catalyst and preparation method thereof

ActiveCN112742425BImprove mechanical propertiesHigh lateral compressive strengthCatalyst activation/preparationBulk chemical productionPtru catalystFluidized bed

The invention discloses a hydrogenation catalyst and a preparation method thereof. The catalyst preparation method first prepares a wet filter cake material, then mixes it with an industrial pseudo-boehmite raw material, adds an extrusion aid and kneads it, and then it is dried and roasted to obtain hydrogenation Catalyst carrier; after further supporting active metal components, drying and calcining to obtain a hydrogenation catalyst. The hydrogenation catalyst prepared by the method of the invention has good mechanical properties, high strength and good wear resistance, and is especially suitable for the fluidized bed hydrogenation process. The preparation method of the hydrogenation catalyst has simple process and low energy consumption, and is suitable for large-scale production of the fluidized bed catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Prepn. of titanium-containing aluminium hydroxide

InactiveCN1107534CEvenly dispersedGood peptizationPhysical/chemical process catalystsAluminium hydroxideTitanium

The preparation method of aluminium hydroxide containing titanium is characterized by adding cheap titanium-contained compound in the course of preparing aluminium hydroxide. Said preparation process is simple, low in cost, at the same time the titanium oxide can be uniformly dispersed on the surface of aluminium oxide, so that the influence of the preparation process to aluminium oxide microstructure can be eliminated. Said aluminium hydroxide possesses good peptization property, when it is used for preparing catalyst carrier or catalyst, it can make catalyst easily form and can reduce its cost, and when it is used to prepare catalyst carrier and hydrogenation catalyst, it possesses good physical and chemical properties and application property.

Owner:CHINA PETROCHEMICAL CORP +1

A kind of strip desulfurizer and preparation method thereof

ActiveCN109433181BEasy to spreadRelieve stressDispersed particle separationCatalyst activation/preparationMetallurgyWater content

The invention relates to a strip desulfurizing agent and a preparation method thereof. The preparation method comprises the following steps: respectively determining the water content of all raw material powder, comparing the water content and adjusting the water contents of the all the raw material powder within the optimal range of the water content; respectively determining the bulk density ofall the raw material powder, comparing the bulk density of all the raw material powder and adjusting the bulk density of all the raw material powder within the corresponding optimal range of the bulkdensity of all the raw material powder; according to the ratio of the raw materials of the strip desulfurizing agent, mixing all the raw material powder, milling the mixed raw material powder and extruding the milled raw material powder into strips, and then sequentially drying and roasting the strips, so as to obtain a finished product strip desulfurizing agent. According to the preparation method, through the synergism of effects achieved by control on the water content and the bulk density of the raw material powder, the diversity factor of crushing strength of the strip desulfurizing agentproduct is greatly decreased, and the quality of the strip desulfurizing agent product is improved.

Owner:HUNAN HUANDA ENVIRONMENTAL PROTECTION

A kind of heavy oil hydrocracking catalyst and its preparation method and application

ActiveCN105709789BImprove performanceGood peptizationHydrocarbon oil crackingMetal/metal-oxides/metal-hydroxide catalystsFuel oilImpurity

The invention discloses a heavy oil hydrocracking catalyst, and a preparation method and applications thereof. According to the heavy oil hydrocracking catalyst, high-silicon aluminium oxide is taken as a carrier; VIII family metals and VIB family metals are taken as active metal ingredients. A preparation method of the high-silicon aluminium oxide carrier comprises following steps: modified clay obtained via high temperature roasting is added into an aluminum-containing alkaline liquor so as to obtain a suspension liquid; the suspension liquid and acidic silica sol are subjected to parallel flow gel forming; an alkaline solution is added for further gel forming; and the high-silicon aluminium oxide carrier is obtained via aging, filtering, and drying. The high-silicon aluminium oxide carrier is excellent in comprehensive performance such as pore structure and acidic properties; the heavy oil hydrocracking catalyst prepared by taking the high-silicon aluminium oxide carrier as a carrier is high in impurity removing rate and heavy oil conversion rate, and long in running period in heavy oil ebullated bed hydrocracking technological process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of pseudo-boehmite easy to peptize

InactiveCN112452316AGood peptizationEasy to manufacturePhysical/chemical process catalystsPtru catalystPhysical chemistry

Owner:QINGDAO HUICHENG PETROCHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com