Preparation method of pseudo-boehmite easy to peptize

A pseudo-boehmite, peptizing technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc. Solubility, less acid consumption for gel formation, and the effect of reducing equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

[0029] A kind of preparation method of easy peptization pseudo-boehmite of the present invention, it comprises the following steps:

[0030] Step 1: Configure ammonium aluminum sulfate crystals into a solution with an alumina concentration of 20-90g / l and an ammonia concentration of 15-20%. 3+ Mix with molar ratio (7~15):1, control pH value 10~12 and mixing temperature 20~60℃ after mixing;

[0031] Step 2: After mixing, the materials enter the aging kettle, the aging time is 2-8 hours, and the aging temperature is 60-130°C;

[0032] Step 3: After aging, the slurry is filtered, the filter cake is washed with water several times, and the washed filter cake is dried at a drying temperature of 60-120°C;

[0033] Step 4: After drying, the filter cake is crushed and ground to obtain a pseudo-boehmite product.

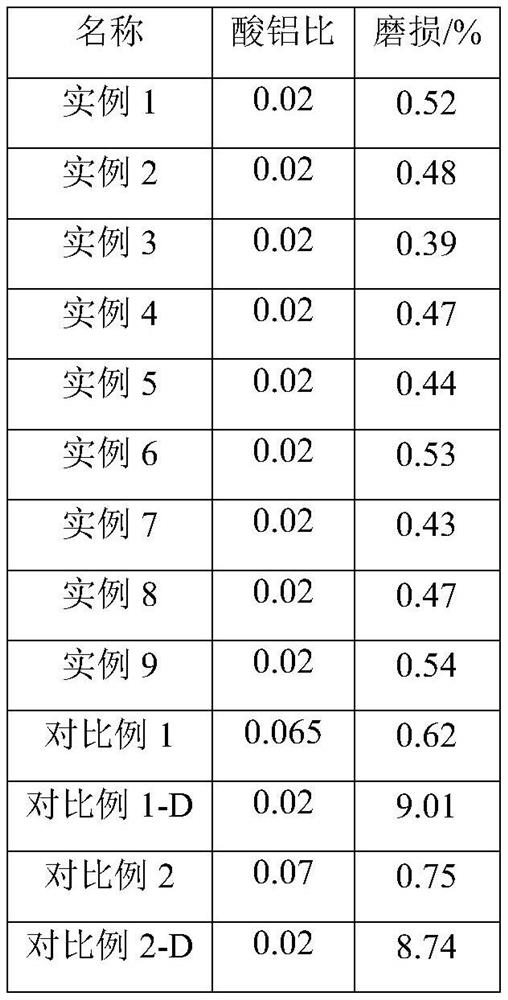

[0034] The peptization index of the obtained easily peptized pseudoboehmite can reach 99%-100%, and the specific surface area is 470-510m 2 / g, when preparing catalytic cr...

Embodiment 1

[0036] Ammonium aluminum sulfate is configured into a solution with an alumina concentration of 40g / l, and 17% concentrated ammonia water and ammonium aluminum sulfate are based on the ammonium root and Al3+ The molar ratio is 7:1, and it flows into the mixer in parallel. After the mixing, the pH value of the slurry is controlled to be greater than 10.5. The material enters the aging kettle, the aging time is 3 hours, and the aging temperature is 70°C. After aging, the slurry is filtered, and the filter cake is washed continuously for many times. The washed filter cake is dried at a drying temperature of 80° C. and a drying time of 24 hours. The dried filter cake is crushed and ground to obtain a pseudo-boehmite product.

Embodiment 2

[0038] Ammonium aluminum sulfate is configured into a solution with an alumina concentration of 40g / l, and 17% concentrated ammonia water and ammonium aluminum sulfate are based on the ammonium root and Al 3+ The molar ratio is 11:1, and flow into the mixer in parallel. After the mixing, the pH value of the slurry is controlled to be greater than 10.5. The material enters the aging kettle, the aging time is 3 hours, and the aging temperature is 70°C. After aging, the slurry is filtered, and the filter cake is washed continuously for many times. The washed filter cake is dried at a drying temperature of 80° C. and a drying time of 24 hours. The dried filter cake is crushed and ground to obtain a pseudo-boehmite product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com