A kind of preparation method of pseudo-boehmite

A pseudo-boehmite and aluminum hydroxide technology, applied in the direction of alumina/aluminum hydroxide, can solve the problem that the pseudo-boehmite index does not change significantly, increase the load of washing and filtering equipment, and increase the pseudo-boehmite Cost and other issues, to achieve the effect of shortening the growth time, particle integrity, and improving crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

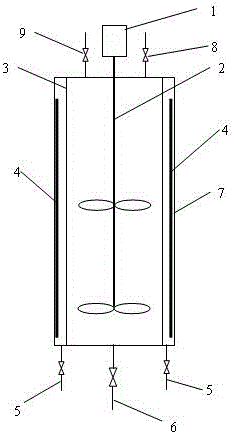

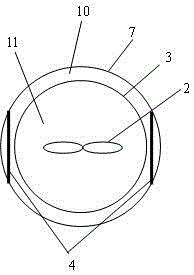

Method used

Image

Examples

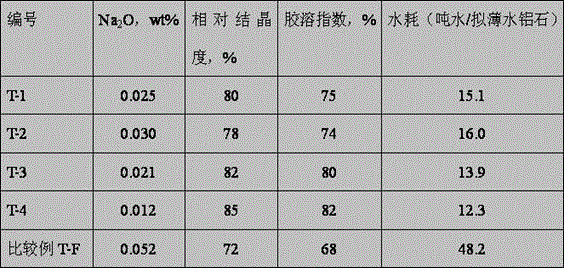

Embodiment 1

[0031] Prepare sodium metaaluminate solution concentration to be 200gAl 2 o 3 / L, a total of 1L, heated to 70°C for use, the concentration of aluminum sulfate solution is 80gAl 2 o 3 / L, a total of 2L, heated to 70°C for use.

[0032] Add 1.0L of distilled water into the gelling tank, heat to 70°C, and flow into the above two slurries to keep the pH value at 8.0, and keep the temperature at 70°C during the gelling process. After the gelation is completed, it enters the aging stage. After gelling, the slurry enters the aging container 7 from the feed port 8. Under the condition of a stirring speed of 150rpm and an electric field strength of 80N / C, the pH value is 8.0, the temperature is 70°C and the time is 60min. Aging is carried out under certain conditions. After the aging is over, open the drain port 5 at the bottom of the interlayer area, and then inject 65°C deionized water from the washing water inlet 9, and wash the aged slurry at a stirring rate of 200rpm. After wa...

Embodiment 2

[0034] The preparation process is the same as that in Example 1, except that the gelling pH value is controlled to 7.0, the gelling temperature is 80°C, the aging time is 100min, and the electric field strength during the aging process is 50N / C, and pseudoboehmite T-2 is prepared. The physical and chemical properties are listed in Table 1.

Embodiment 3

[0036] The preparation process was the same as in Example 1, except that the aging pH value was adjusted to 9.5, the aging time was 30 minutes, and the electric field strength during the aging process was 100 N / C. Pseudo-boehmite T-3 was prepared, and its physical and chemical properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com