Pseudo-boehmite preparation method

A pseudo-boehmite, aluminum sulfate technology, applied in chemical instruments and methods, alkali metal aluminate/alumina/aluminum hydroxide preparation, aluminum compounds, etc., to improve yield, good peptization, and gel-forming properties Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

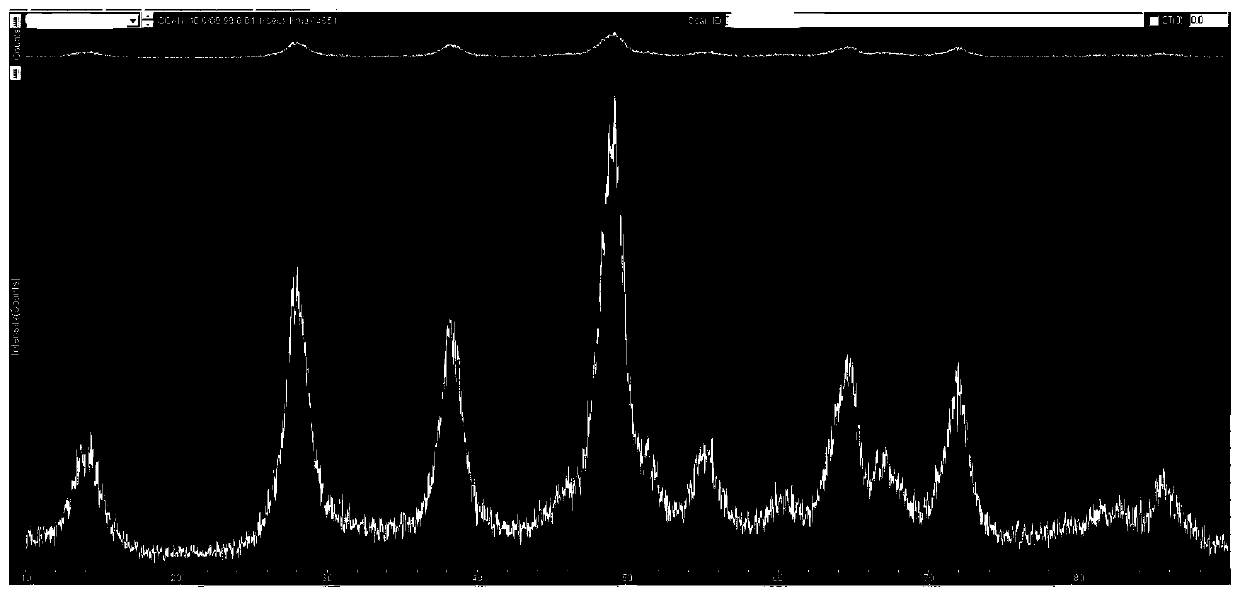

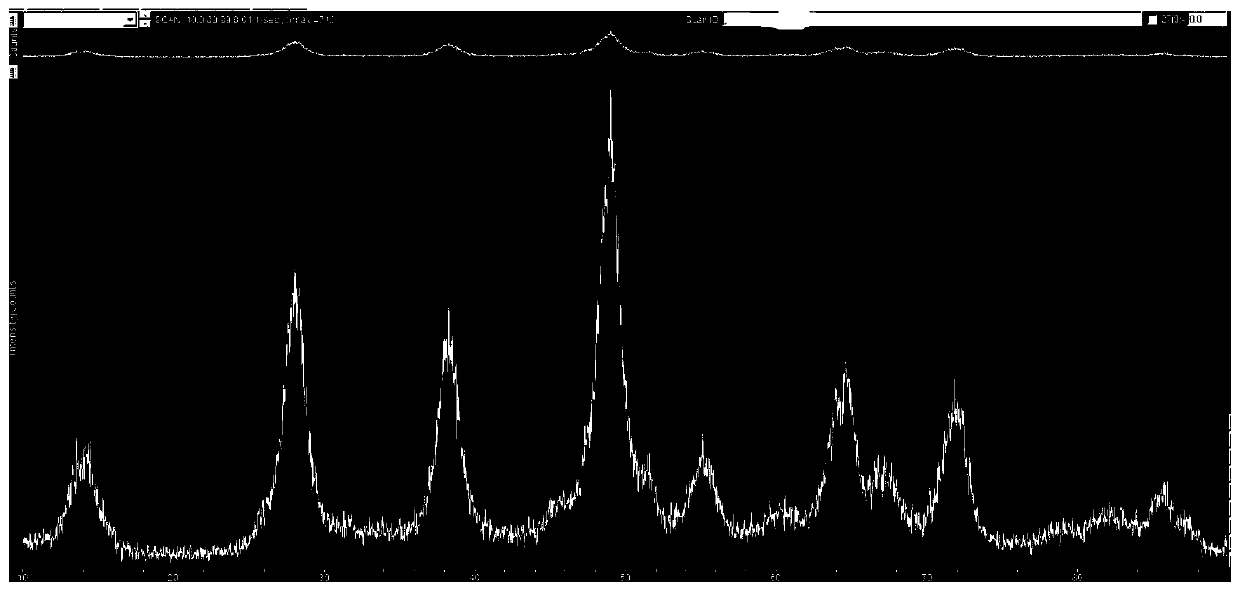

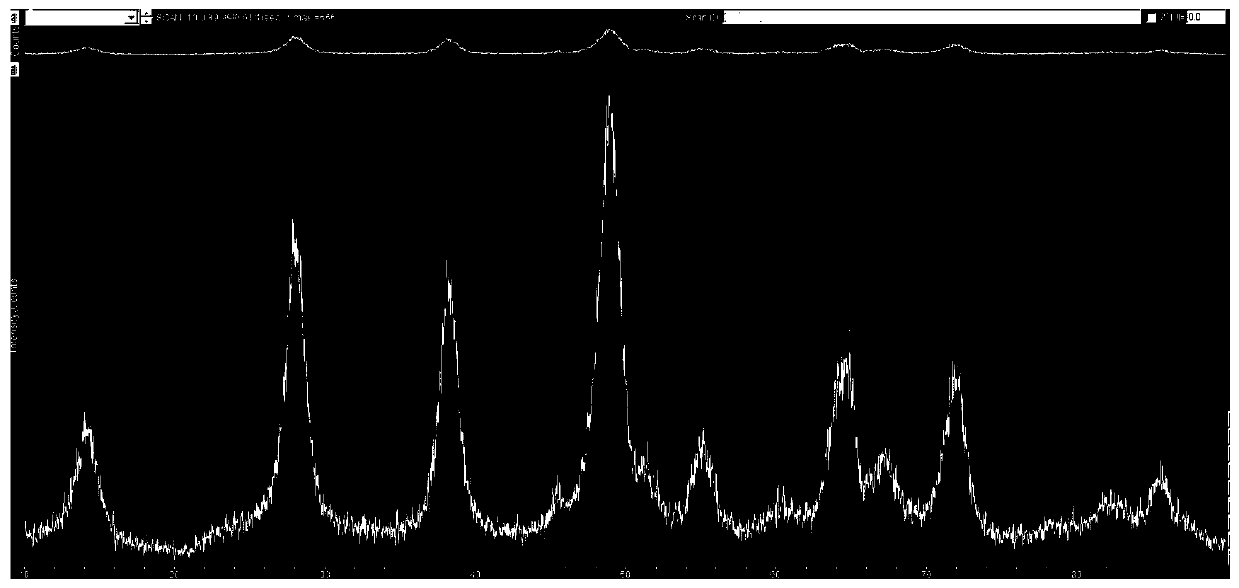

Image

Examples

Embodiment 1

[0031] A method for preparing pseudo-boehmite special for ceramic corundum abrasives, comprising the steps of:

[0032] (1) Preparation of sodium metaaluminate solution for the production of pseudo-boehmite specially used for ceramic corundum abrasives: 32% sodium hydroxide solution and Al 2 o 3 Aluminum hydroxide powder with a content of 62.7% was added to the reactor with stirring to control the Al 2 o 3 :Na 2 O molar ratio is 1:1.35; Reaction pressure is 0.2MPa; Reaction temperature is 120 ℃, and the reaction time is 6 hours, prepares the sodium metaaluminate solution that ceramic corundum abrasive special-purpose pseudo-boehmite is produced;

[0033] (2) Prepare Al 2 o 3 The sodium metaaluminate solution with a concentration of 20g / L and the prepared Al 2 o 3 The aluminum sulfate solution with a concentration of 20g / L is added to a stirred reactor at a volume ratio of 0.4:1. The reaction temperature is 33°C. The reacted slurry is transferred to another gas-liquid re...

Embodiment 2

[0041] A method for preparing pseudo-boehmite special for ceramic corundum abrasives, comprising the steps of:

[0042] (1) Preparation of sodium metaaluminate solution for the production of pseudo-boehmite specially used for ceramic corundum abrasives: 32% sodium hydroxide solution and Al 2 o 3Aluminum hydroxide powder with a content of 62.7% was added to the reactor with stirring to control the Al 2 o 3 :Na 2 O molar ratio is 1:1.45; Reaction pressure is 0.2MPa; Reaction temperature is 125 ℃, and the reaction time is 6 hours, prepares the sodium metaaluminate solution that ceramic corundum abrasive material special-purpose pseudo-boehmite is produced;

[0043] (2) Prepare Al 2 o 3 The sodium metaaluminate solution with a concentration of 50g / L and the prepared Al 2 o 3 The aluminum sulfate solution with a concentration of 50g / L is added to a stirred reactor at a volume ratio of 0.5:1. The reaction temperature is 35°C. The reacted slurry is transferred to another gas-l...

Embodiment 3

[0051] A method for preparing pseudo-boehmite special for ceramic corundum abrasives, comprising the steps of:

[0052] (1) Preparation of sodium metaaluminate solution for the production of pseudo-boehmite specially used for ceramic corundum abrasives: 32% sodium hydroxide solution and Al 2 o 3 Aluminum hydroxide powder with a content of 62.7% was added to the reactor with stirring to control the Al 2 o 3 :Na 2 O molar ratio is 1:1.25; Reaction pressure is 0.2MPa; Reaction temperature is 120 ℃, and the reaction time is 6 hours, prepares the sodium metaaluminate solution that ceramic corundum abrasive special-purpose pseudo-boehmite is produced;

[0053] (2) Prepare Al 2 o 3 The sodium metaaluminate solution with a concentration of 100g / L and the prepared Al 2 o 3 The aluminum sulfate solution with a concentration of 90g / L is added to a stirred reactor at a volume ratio of 0.6:1, and the reaction temperature is 36°C. The reacted slurry is added to another gas-liquid rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com