Method for producing boehmite by using washing liquor

A technique of pseudo-boehmite and washing liquid, which is applied in the field of producing pseudo-boehmite by using washing liquid, can solve the problems such as affecting the balance of alumina production liquid, large restriction of alumina production, affecting the output of finished alumina, etc. , to achieve the effect of low production raw material cost, abundant raw material quantity, and production raw material cost reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

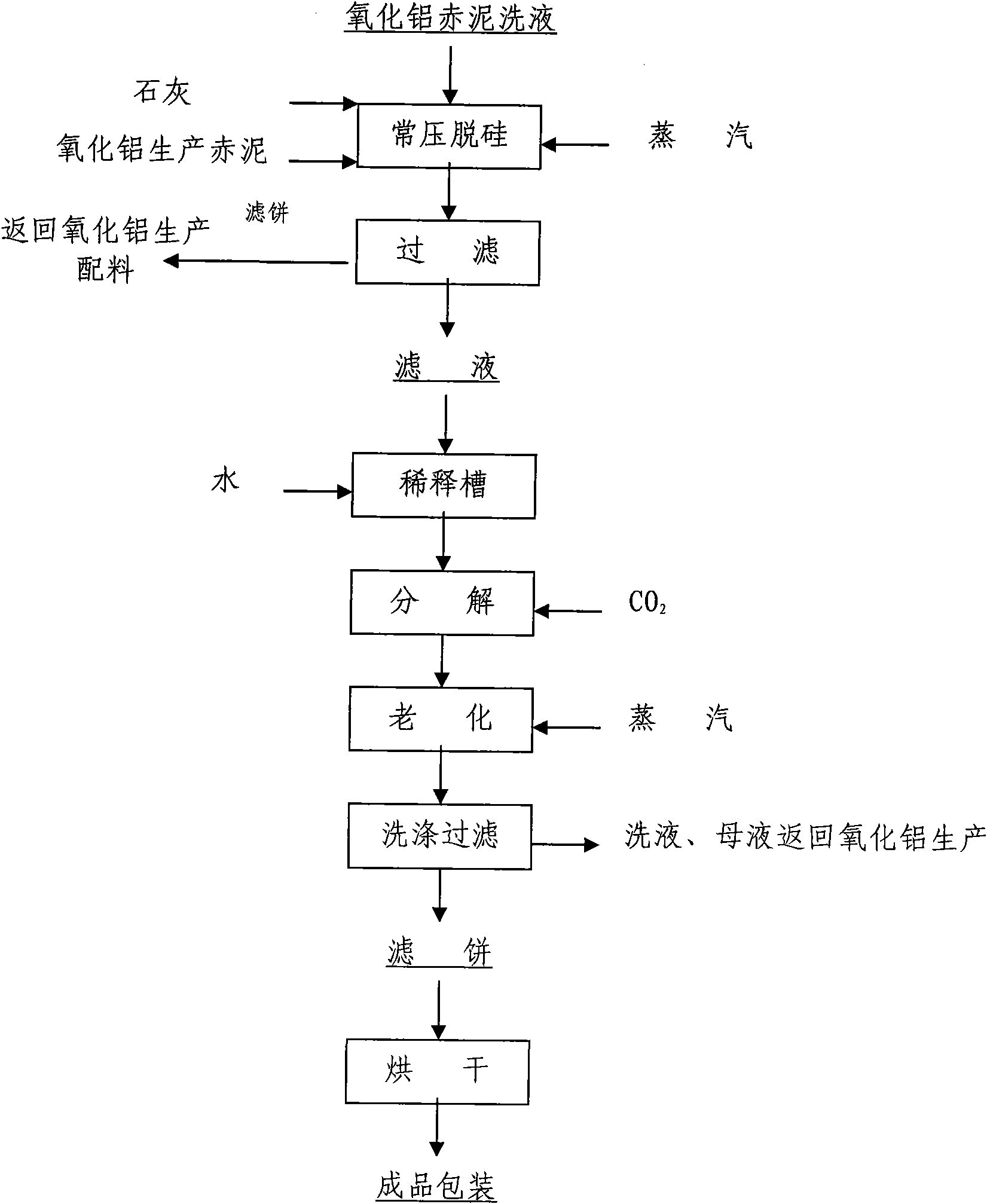

[0024] A method for producing pseudo-boehmite by using alumina to produce washing liquid for washing red mud, comprising the following steps:

[0025] The first step: Alumina is produced as a washing solution for washing red mud (Al 2 o 3 Concentration (weight) is 35g / L, Na 2 O concentration (weight) is 30g / L) into the desiliconization tank, add 5g of red mud and 5g of lime per liter of washing liquid, stir evenly, heat up to 75°C with steam, and keep it warm for 1 hour for desilication;

[0026] Second step: when the desiliconization amount index reaches the requirement ≥ 400, the product after the above-mentioned desilication treatment is filtered to obtain the filtrate (Al 2 o 3 Concentration (weight) is 35g / L) and filter cake, and filter cake returns alumina production and carries out batching;

[0027] The third step: transport the above filtrate to the dilution tank to cool down, cool down to a temperature of 30°C, and then use alumina to produce CO 2 After the exha...

Embodiment 2

[0032] A method for producing pseudo-boehmite by using alumina to produce washing liquid for washing red mud, comprising the following steps:

[0033] The first step: Alumina is produced as a washing solution for washing red mud (Al 2 o 3 Concentration (weight) is 50g / L, Na 2 O concentration (weight) is 35g / L) into the desiliconization tank, add 25g red mud and 25g lime for each liter of washing liquid, stir evenly, heat up to 85°C with steam, and keep warm for 3 hours for desilication;

[0034] Second step: when the desiliconization amount index reaches the requirement ≥ 400, the product after the above-mentioned desilication treatment is filtered to obtain the filtrate (Al 2 o 3 Concentration (weight) is 50g / L) and filter cake, and filter cake returns alumina production and carries out batching;

[0035] Step 3: Transport the above filtrate to the dilution tank to cool down, cool down to a temperature of 45°C, and then use alumina to produce CO 2 After the exhaust gas i...

Embodiment 3

[0040] A method for producing pseudo-boehmite by using alumina to produce washing liquid for washing red mud, comprising the following steps:

[0041] The first step: Alumina is produced as a washing solution for washing red mud (Al 2 o 3 Concentration (weight) is 65g / L, Na 2 O concentration (weight) is 55g / L) into the desiliconization tank, add 35g red mud and 35g lime per liter of washing liquid, stir evenly, heat up to 95°C with steam, and keep warm for 1 hour for desiliconization;

[0042] Second step: when the desiliconization amount index reaches the requirement ≥ 400, the product after the above-mentioned desilication treatment is filtered to obtain the filtrate (Al 2 o 3 Concentration (weight) is 65g / L) and filter cake, and filter cake returns alumina production and carries out batching;

[0043] The third step: transport the above filtrate to the dilution tank to cool down, cool down to a temperature of 55°C, and then use alumina to produce CO2 After the exhaust g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com