Preparation method of pyrolysis oil resorcinol formaldehyde resin adhesive for wood structure building materials

A technology of oil resorcinol formaldehyde resin and adhesive, which is applied in the field of preparation of pyrolysis oil resorcinol formaldehyde resin adhesive for wood structure building materials. Expensive, expensive modified raw materials, etc., to achieve the effect of saving raw material costs, strong adhesive force, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

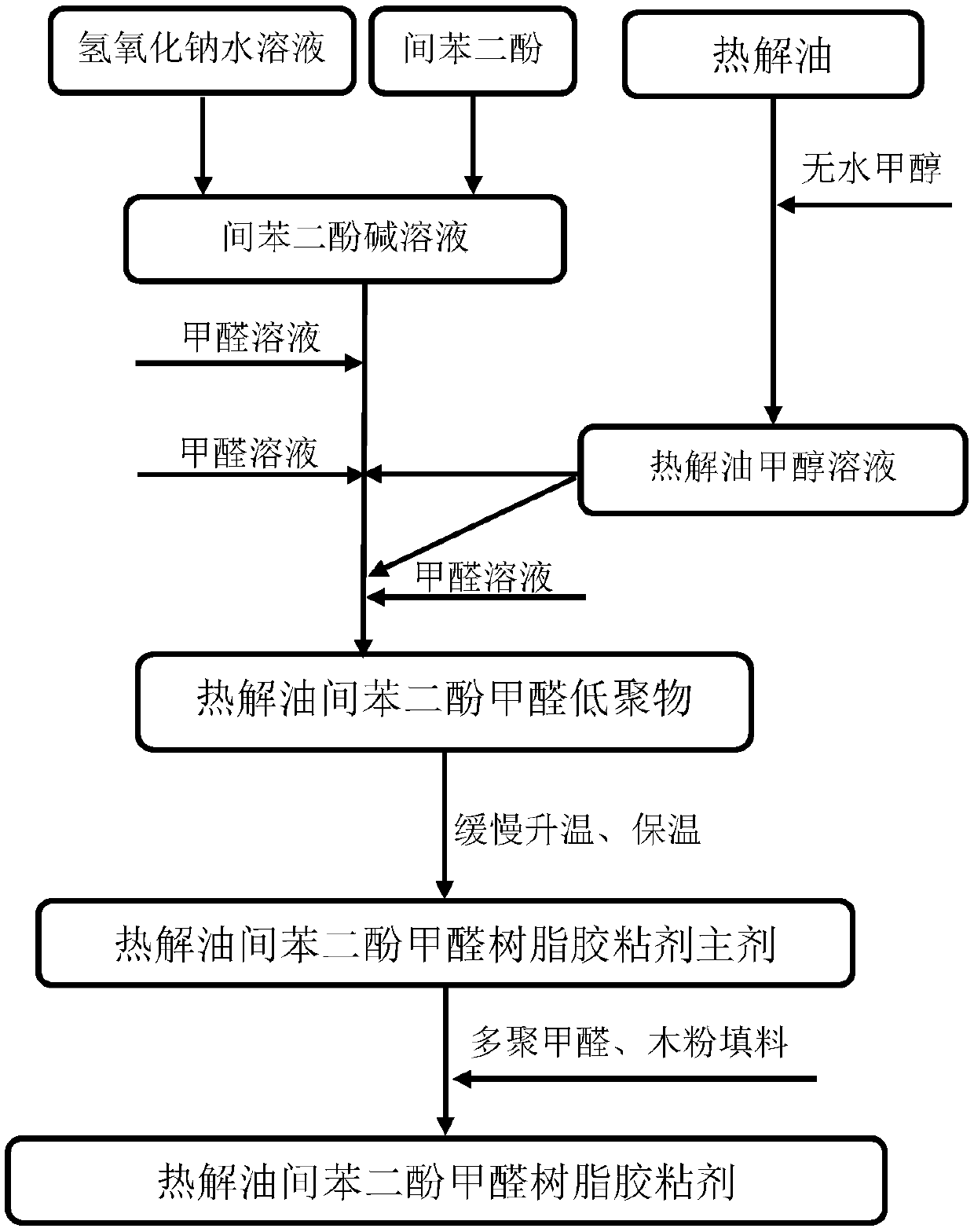

[0020] The preparation method of pyrolysis oil resorcinol formaldehyde resin adhesive for wooden structure building material that the present invention proposes comprises the following steps:

[0021] (1) Add 70-90 parts of water and 2-5 parts of sodium hydroxide to the reaction kettle, heat to 40-60 ° C, add 70-80 parts of resorcinol under stirring, completely dissolve and cool to room temperature 20-25 ℃;

[0022] (2) Add the first batch of 10-20 parts of formaldehyde solution to the reaction kettle of step (1), react for 5-15 minutes, then cool to 25-30°C, and keep for 10-15 minutes;

[0023] (3) Add 20-30 parts of biomass pyrolysis oil to 40-60 parts of anhydrous methanol to prepare a pyrolysis oil methanol solution. The volume ratio of pyrolysis oil to anhydrous methanol is 1:2. The prepared Pyrolysis oil methanol solution is fed twice;

[0024] (4) Add the prepared first batch of 30-45 parts of pyrolysis oil methanol solution and the second batch of 10-20 parts of form...

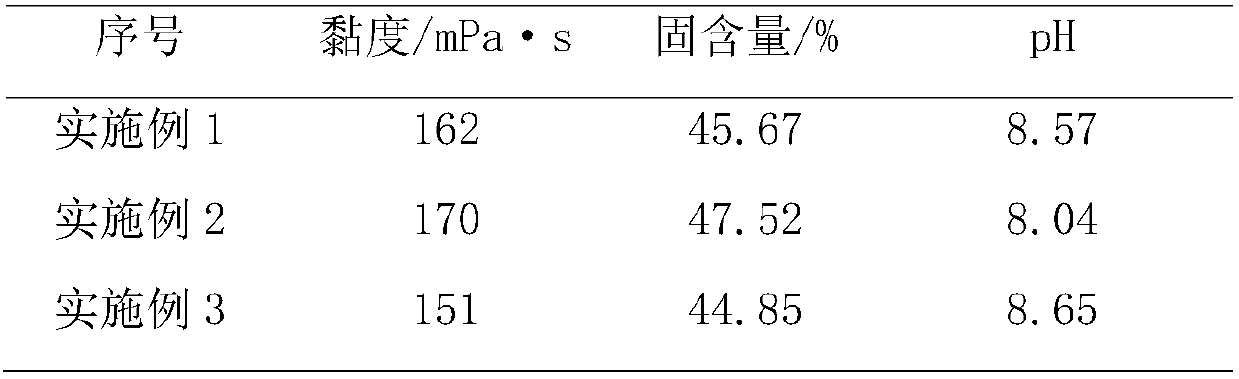

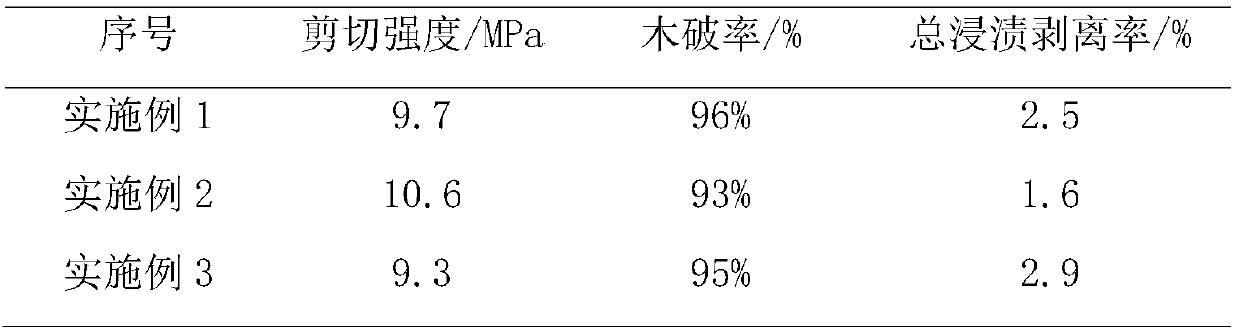

Embodiment 1

[0030] (1) Add 75 parts of water and 3.5 parts of sodium hydroxide to the reaction kettle, heat to 45°C, add 70 parts of resorcinol under stirring, and cool to room temperature 23°C after it is completely dissolved;

[0031] (2) Add the first batch of 10 parts of formaldehyde solution to the reaction kettle of step (1), react for 8 minutes, heat up due to exothermic reaction, then cool to 25°C, and keep it for 10 minutes;

[0032] (3) Add 20 parts of biomass pyrolysis oil to 40 parts of anhydrous methanol to prepare a methanol solution of pyrolysis oil. The volume ratio of pyrolysis oil to anhydrous methanol is 1:2, and the pyrolysis oil methanol solution Feed twice;

[0033] (4) Add the prepared first batch of 30 parts of pyrolysis oil methanol solution and the second batch of 10 parts of formaldehyde solution into the resorcinol reaction kettle, stir evenly and react for 10 minutes, and cool the temperature of the reactant to 25°C , keep for 10min;

[0034] (5) Add 30 part...

Embodiment 2

[0038] (1) Add 72 parts of water and 3 parts of sodium hydroxide to the reaction kettle, heat to 45°C, add 80 parts of resorcinol under stirring, and cool to room temperature 23°C after it is completely dissolved;

[0039] (2) Add the first batch of 15 parts of formaldehyde solution into the reaction kettle of step (1), react for 10 minutes, then cool to 25°C, and keep it for 10 minutes;

[0040] (3) Add 20 parts of biomass pyrolysis oil to 40 parts of anhydrous methanol to prepare a methanol solution of pyrolysis oil. The volume ratio of pyrolysis oil to anhydrous methanol is 1:2, and the pyrolysis oil methanol solution Feed twice;

[0041] (4) Add the prepared first batch of 30 parts of pyrolysis oil methanol solution and the second batch of 15 parts of formaldehyde solution into the reaction kettle of step (2), stir evenly, react for 6 minutes, and cool the temperature of the reactant to 25 ℃, keep for 10min;

[0042] (5) Add the second batch of 30 parts of pyrolysis oil ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com