Application of an annular gap centrifugal extractor in the extraction of cobalt chloride

An extractor and annulus-type technology, which is applied in the field of application of an annular-gap centrifugal extractor in the extraction of cobalt chloride, can solve problems such as incomplete extraction and low extraction rate, and achieve improved process control level and on-site environment improvement , the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

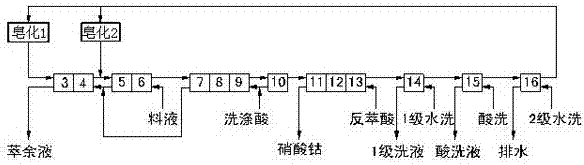

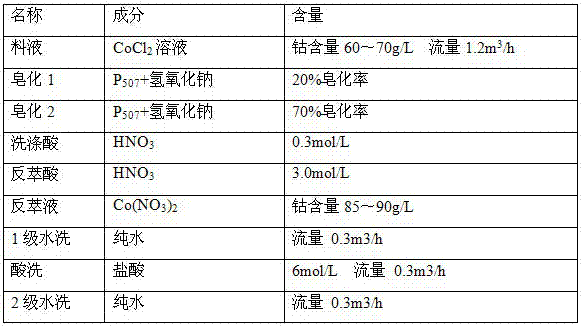

[0013] Such as figure 1 As shown, the application of the Φ300 fiberglass centrifugal extractor in the extraction of cobalt chloride includes saponification, extraction, re-extraction, acid washing empty spin, back extraction empty spin, primary water washing, pickling and secondary water washing in sequence. Saponification in the first case 1 and the second case 2, the extraction stage is 2 in the fifth case 5 and the sixth case 6, and the supplementary extraction stage is 2 in the third case 3 and the fourth case 4, The acid washing series is 3 in the seventh box 7, the eighth box 8, and the ninth box 9, and the air-spinning series is 1 in the tenth box 11; the stripping series is 3 in the eleventh box Carry out in box 11, the twelfth box 12, the thirteenth box 13, and carry out in the 14th box 4 of the 1st level of air-spinning series; carry out in the 14th box 14 of the 1st-level water washing, and carry out the 1st-level pickling in the 10th box Carry out in five cases 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com