Patents

Literature

49results about How to "Improve process control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous long fiber reinforced fire-retardant thermoplastic resin and its prepn

ActiveCN1810862ASimple recipeSimple process controlLong-fiber-reinforced thermoplasticPolymer chemistry

The present invention discloses one kind of continuous long fiber reinforced fire-retardant thermoplastic resin and its preparation process. It is prepared through mixing continuous long fiber reinforced thermoplastic resin agglomerate, which has reinforcing fiber content of 30-80 wt% and agglomerate length of 3-30 mm, and fire-retardant agglomerate, which has thermoplastic resin as carrier, fire retardant in 20-60 wt%, fire-retarding synergist 5-20 wt% and other additive 0-5 wt%. The continuous long fiber reinforced fire-retardant thermoplastic resin has continuous long fiber content of 5-60 wt%. The continuous long fiber reinforced fire-retardant thermoplastic resin has excellent mechanical performance, especially impact resistance, and excellent fire-retarding performance.

Owner:KINGFA SCI & TECH CO LTD +1

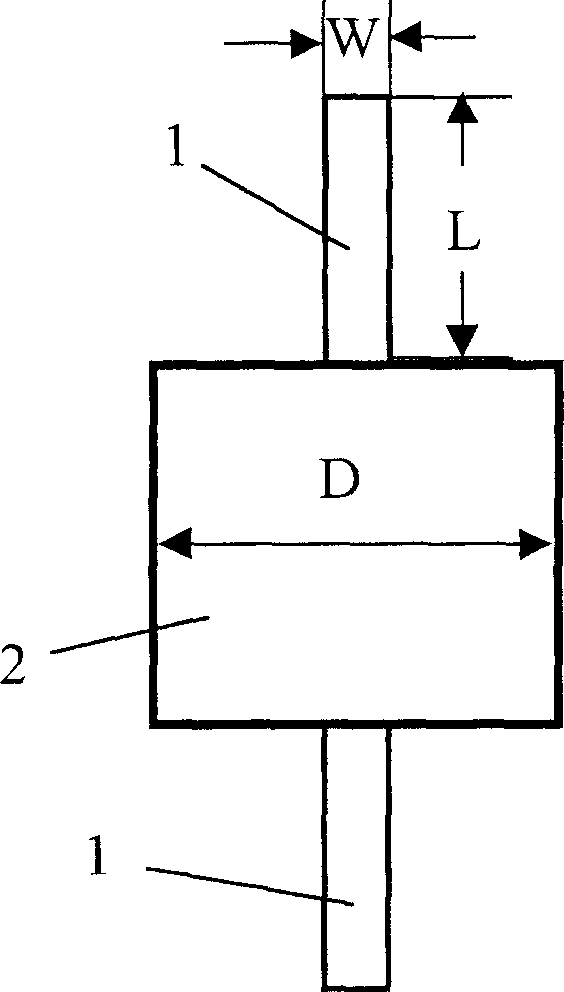

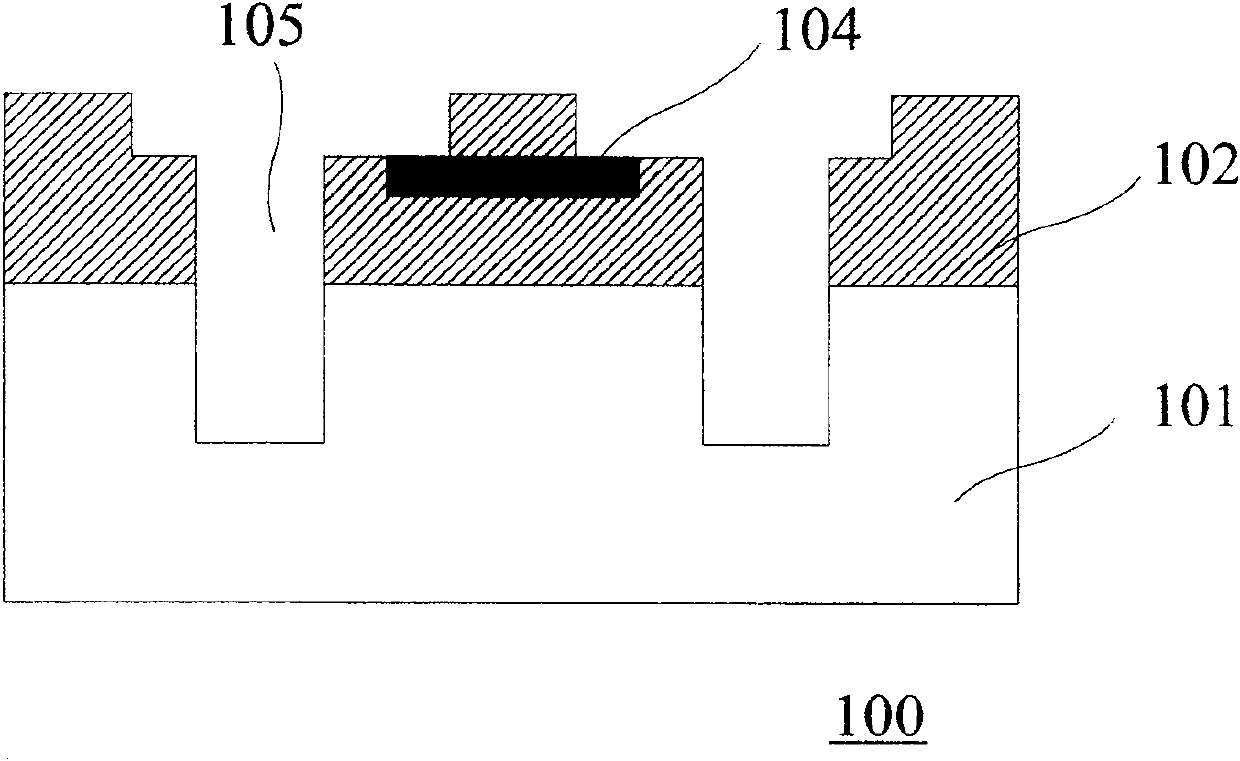

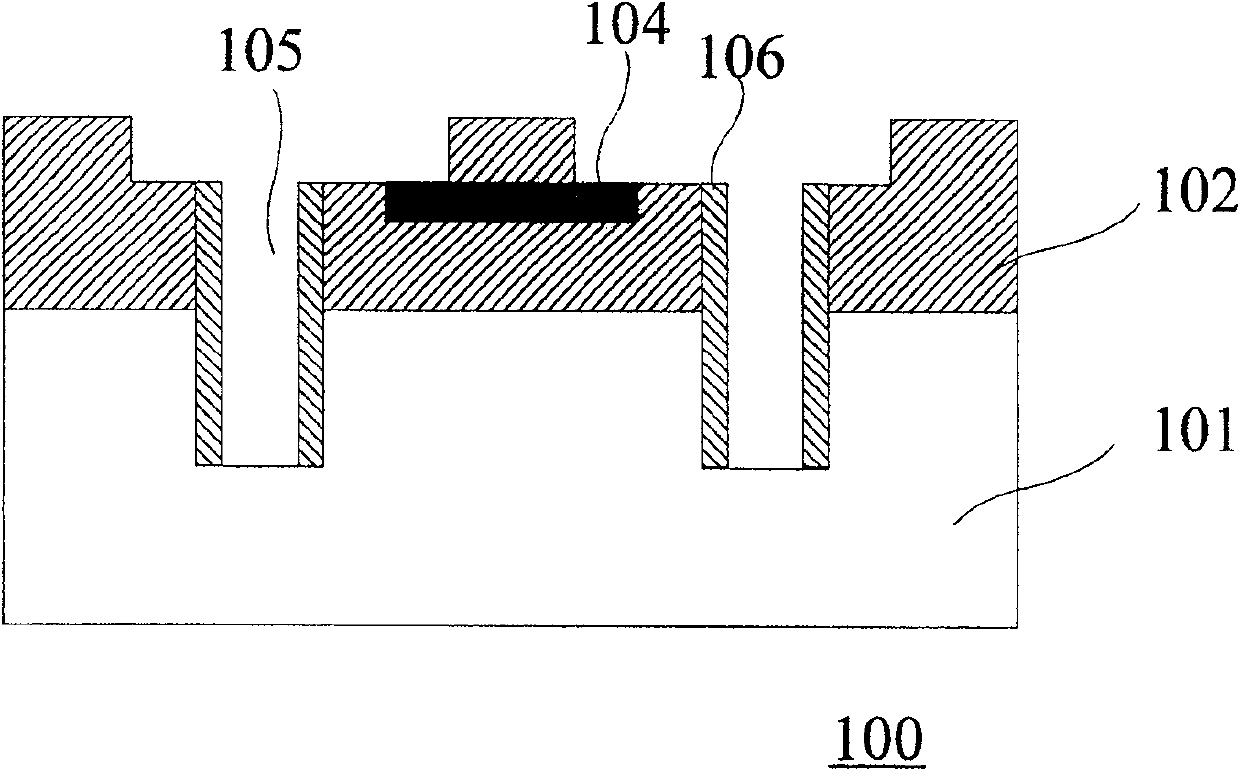

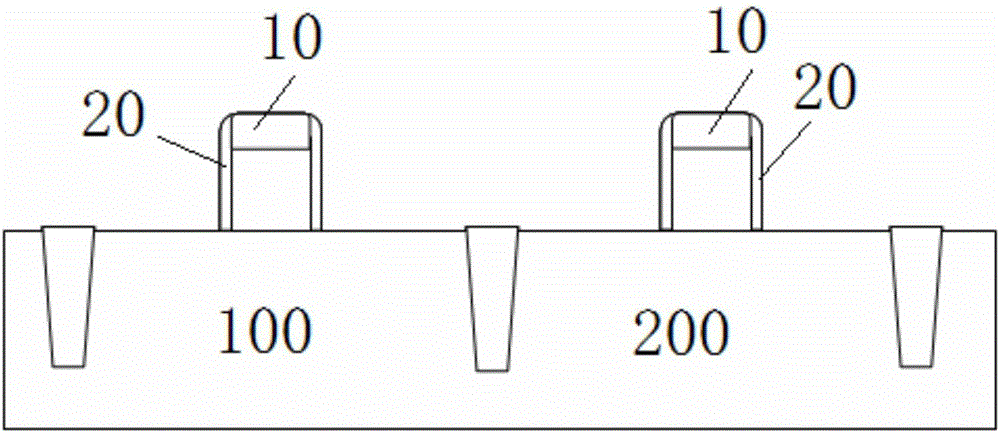

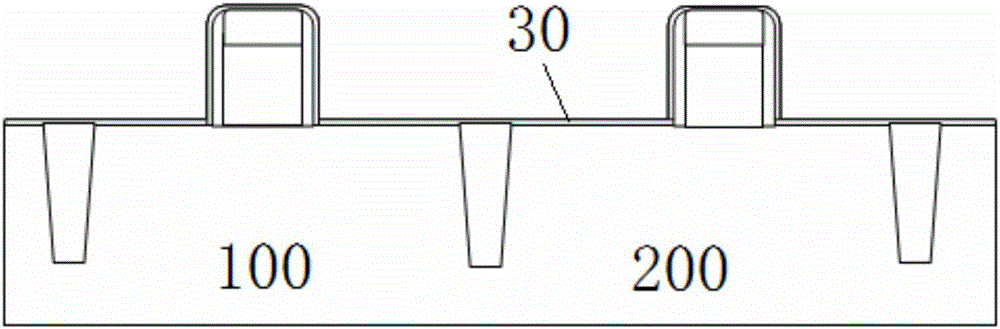

Wafer press welding and bonding method and structure thereof

ActiveCN101197297AWon't breakIncreasing the thicknessSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorBonding process

A three-dimensional interconnection method between wafers comprises the following steps that: firstly, two semiconductor wafers are bonded face to face, secondly the back of one of two semiconductor wafers is thinned to complete the three-dimensional interconnection between the wafers, thirdly the backs of the semiconductor wafers which complete interconnection are bonded spoon-fashion, thinned, and interconnected and the bonding spoon-fashion-thinning-interconnecting technique is repeated; the surfaces of a plurality of semiconductor wafers are overlaid in order. The invention also provides a three-dimensional interconnection structure between the wafers; the surfaces of two semiconductors are bonded face to face; a second connecting welding block is formed on a back underlay of one of the semiconductor wafers; a plurality of semiconductor wafers in order are overlaid on the semiconductor wafer underlay with the second connecting welding block. The method of the invention can not cause the damage to the wafer in a bonding process; a formed semiconductor wafer bonding structure can save the chip area of the semiconductor wafer.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

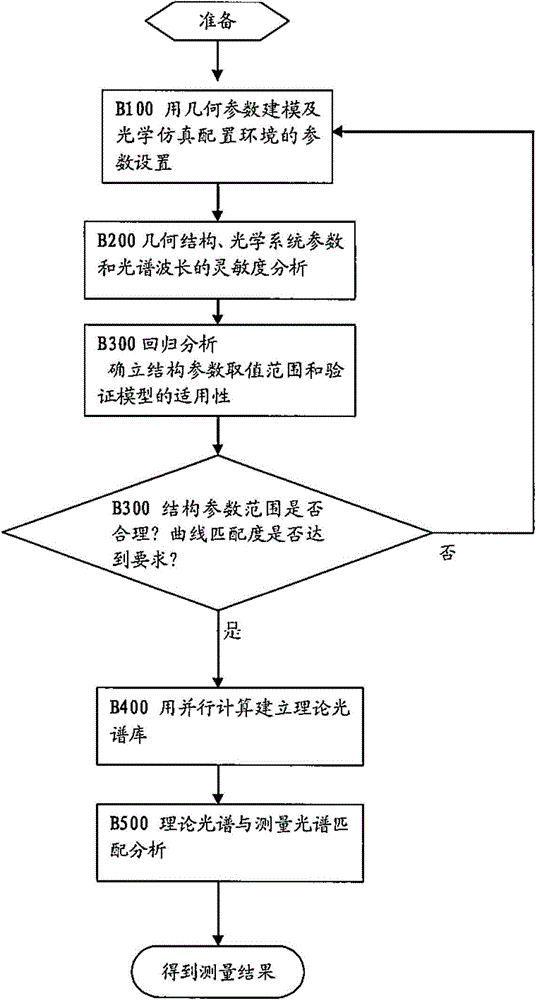

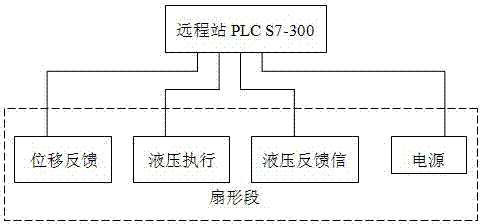

Method and device for measuring OCD (optical critical dimension)

The invention discloses a method and device for improving the matching reliability and measurement precision of a spectrum curve in OCD measurement equipment. The method comprises the steps: carrying out the sensitivity analysis of theoretical spectrums of all to-be-measured structure parameters at full-wavelength points, and obtaining the sensitivity wavelength distribution; carrying out the normalization processing of the sensitivity wavelength distribution of all to-be-measured structure parameters; flexibly configuring a normalized weighting coefficient, and carrying out the normalized processing of the sensitivity wavelength distribution after normalization; setting a matching weighting coefficient in the matching process of a theoretical spectrum and a measurement spectrum, and carrying out the estimation optimization operation of the theoretical spectrum and the measurement spectrum, so as to judge the matching degree of the theoretical spectrum and the measurement spectrum. Therefore, the method achieves the optimized design of matching estimation, and achieves the improvement of the fitting value precision of the to-be-measured structure parameters.

Owner:RAINTREE SCI INSTR SHANGHAI

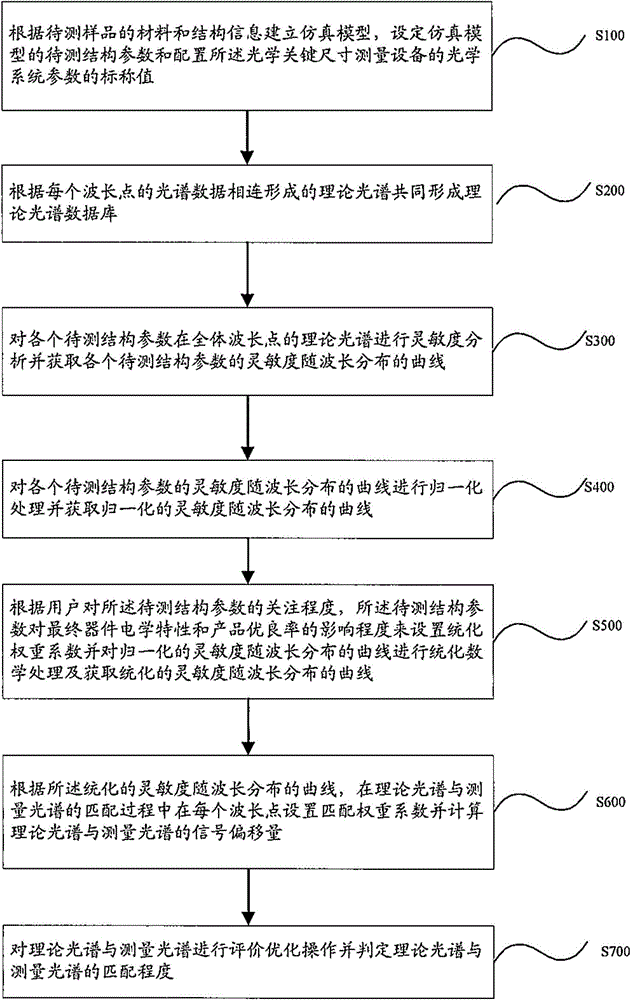

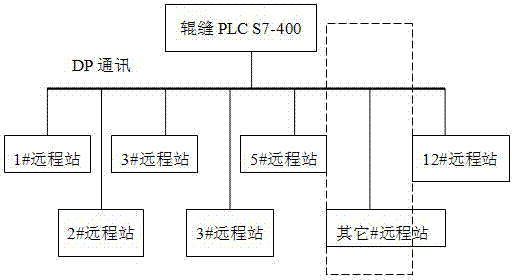

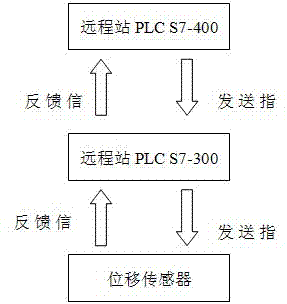

On-line fault judgment and early-warning method for displacement sensor based on dynamic soft reduction

InactiveCN102343426AAvoid abnormal changesStable continuous casting productionControl systemControl engineering

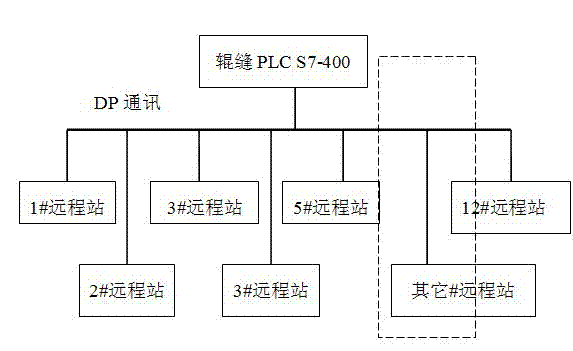

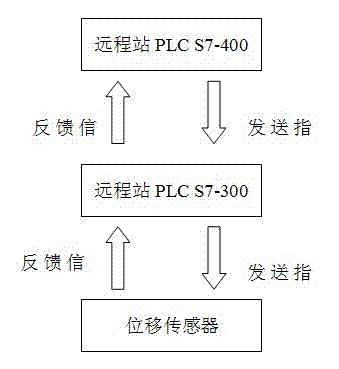

The invention relates to an on-line fault judgment and early-warning method for a displacement sensor based on dynamic soft reduction, and belongs to the technical field of continuous casting equipment maintenance in the metallurgical industry. The technical scheme is as follows: operation and judgment are carried out in a central system-roll gap control system PLC (programmable logical controller) S7-400 of a continuous casting machine; and by presetting judgment conditions in advance, the roll gap control system PLCS7-400 judges the fault status of the displacement sensor, sends a signal toan execution mechanism at a sector segment so as to take measures and meanwhile sends early-warning prompt to a continuous-casting master control system. By adopting the method, faults at the sector segment can be pre-warned in advance and on-line fault judgment can be carried out on the displacement sensor, thus effectively preventing abnormal change of the roll gap at the sector segment caused by the faults of the displacement sensor, realizing comprehensive monitoring and automated management of key equipment during the whole continuous casting production process, keeping stable continuouscasting production, improving the process control level and the product quality and creating economic benefit.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

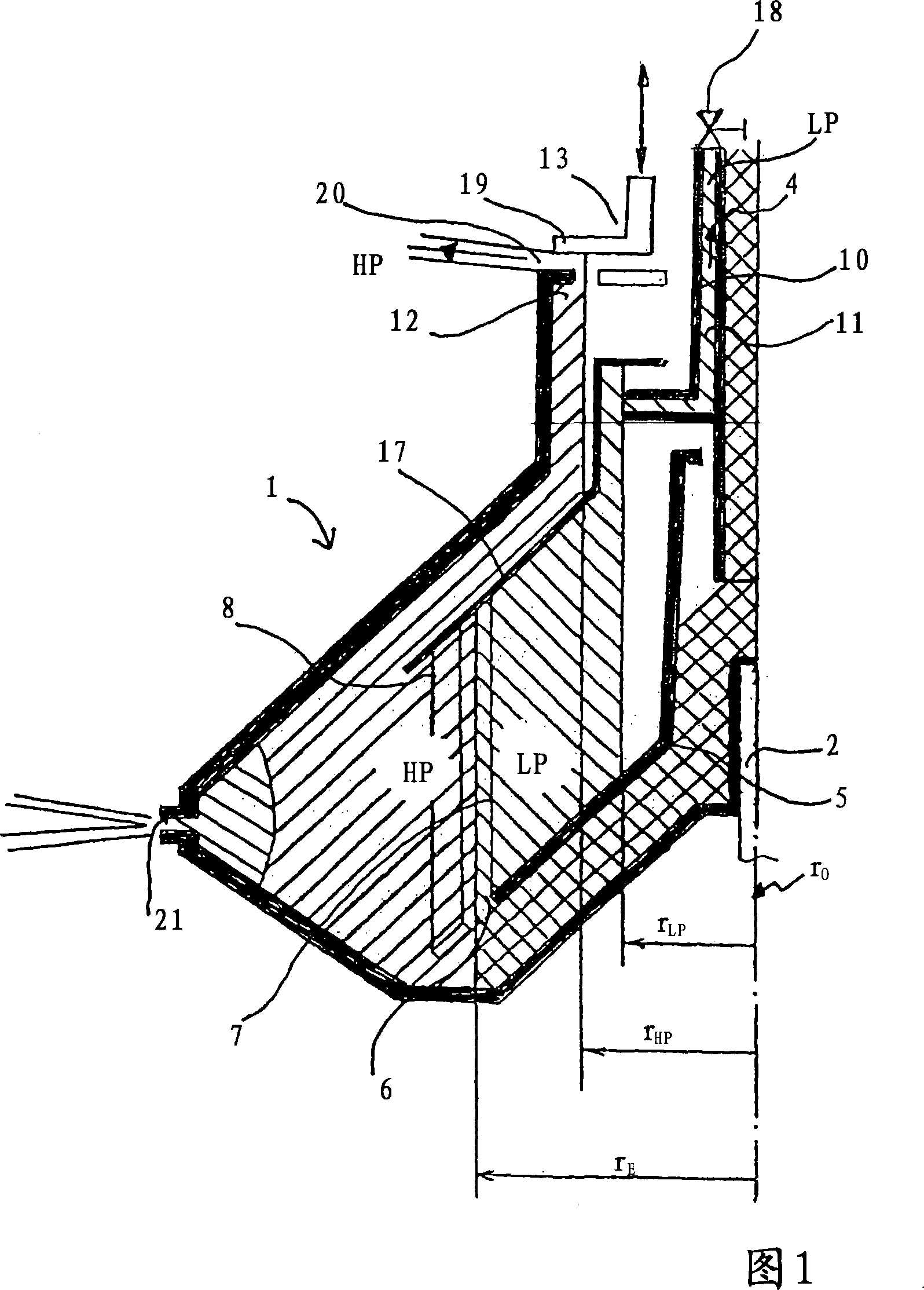

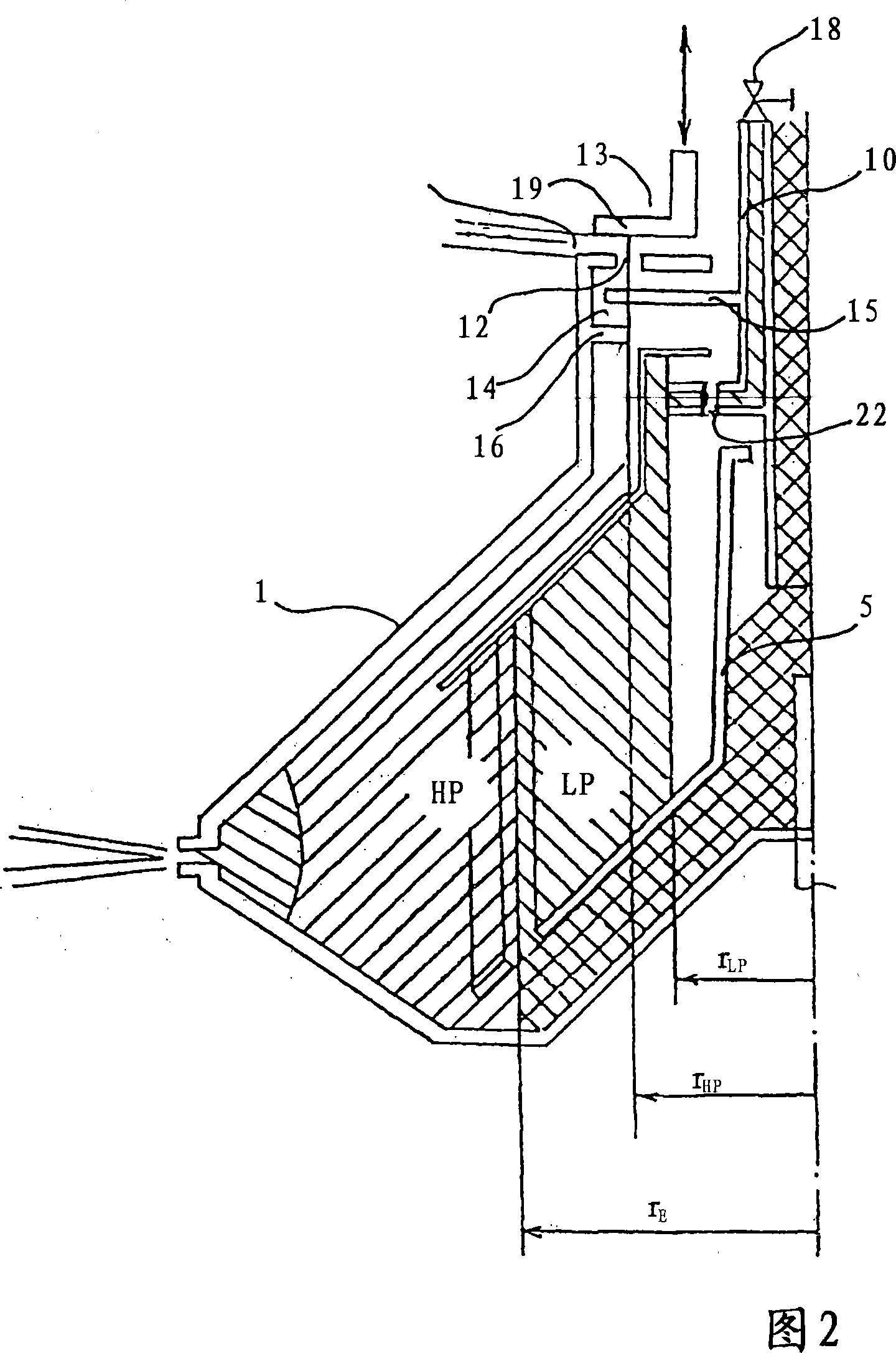

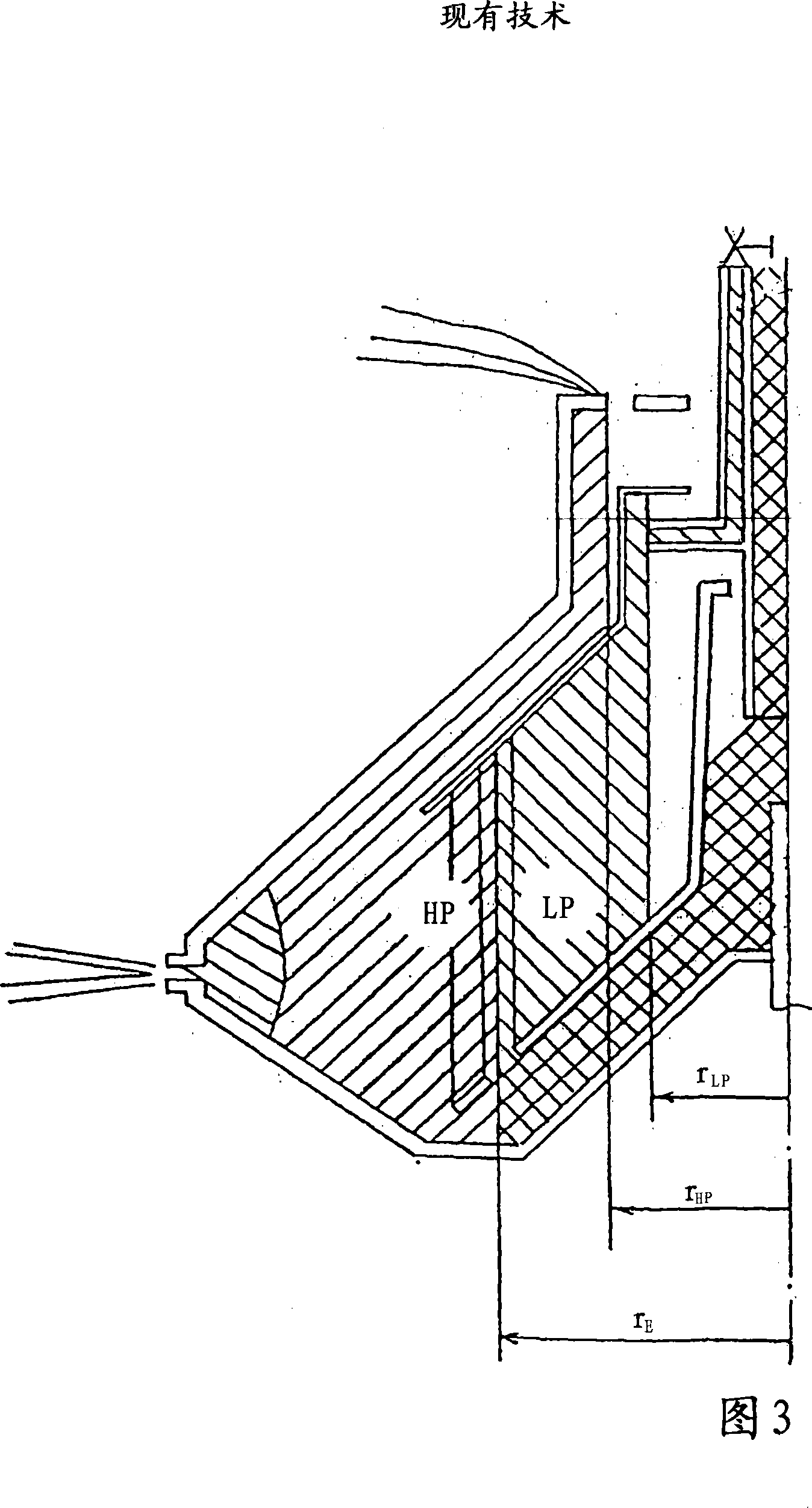

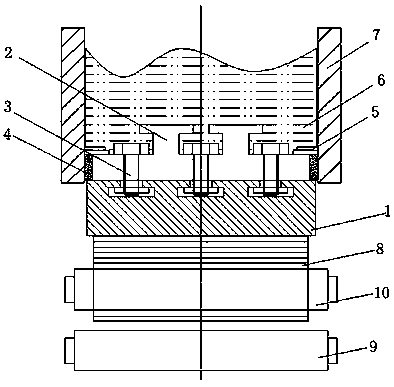

Three-phase separator comprising a skimming disc and solid discharge orifices

ActiveCN101189068AExtended service lifeImprove process controlRotary centrifugesRotational axisThree-phase

A separator comprising an at least internally single or double-conical separator drum (1) which is mounted rotatably only on one of its axial ends and which has a vertical rotational axis and which also has the following: only at its lower end or at its upper end, a rotary spindle for driving the separator drum, which is mounted so as to oscillate about an articulation point (G), a feed tube (4) for a product to be processed, at least two liquid outlets for a lighter phase (LP) and a heavier phase (HP), wherein the liquid outlet for the lighter phase (LP) is provided with a skimming disc, preferably solid discharge orifices in the region of its greatest internal circumference, a separating pan assembly arranged in the separator drum, wherein an adjustable throttle device (13) is arranged downstream of the liquid outlet of the heavier phase (HP) (12) outside the drum and preferably has an annular disc (19) and is designed to shift the liquid radius R(HP), up to which the heavy phase in the drum extends by changing the exit cross section for the heavy liquid phase - i.e. by partial throttling.

Owner:WESTFALIA SEPARATOR AG

Dynamic slight press fan-shaped section hydraulic system leakage fault on-line judging and early warning method

InactiveCN102310179AAvoid production accidentsAvoid getting out of controlControl systemControl engineering

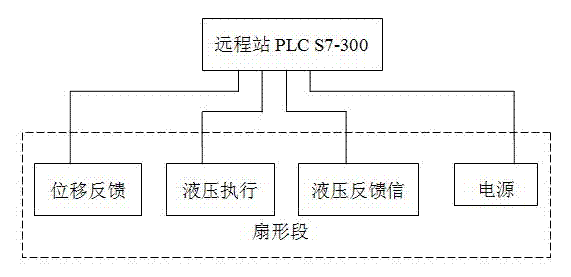

The invention relates to a dynamic slight press fan-shaped section hydraulic system leakage fault on-line judging and early warning method, which belongs to the technical field of continuous casting equipment maintenance in the metallurgical industry. The method has the technical scheme that (1) a roll gap control system PLCS7-300 sends a 'fan-shaped section hydraulic system locking' order to a remote station PLCS7-300; (2) the pressure value of the fan-shaped section hydraulic system is fed back; (3) the value of a fan-shaped section displacement sensor is fed back; (4) the roll gap control system PLCS7-400 judges the feedback pressure value of the hydraulic system and the value of the fan-shaped section displacement sensor combinedly; and further the results are output to a continuous casting master control system. With the method disclosed by the invention, roll gap control loss caused by the leakage fault of the hydraulic system can be prevented, the actual roll gap is controlledto meet the scope designed by the technology, the contraction taper of the roller gap is ensured to guarantee casting blank quality, an early warning function is played to protect fan-shaped section equipment, key equipment is monitored comprehensively and managed automatically in the whole continuous casting production process, the continuous casting production is stabilized, the technical control level is improved, the product quality is improved, and economic benefits are created.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Remedying and repairing method for flaw of thin-specification flat roll

The invention belongs to the technical field of ferrous metallurgy rolling, and particularly relates to a remedying and repairing method for a flaw of a thin-specification flat roll. The method specifically comprises the following steps that a, the inner diameter of the flat roll is measured; b, the direction of the flat roll is adjusted; c, the inner diameter of the flat roll is subjected to external force correction; d, the flat roll is manually coiled to a coiling block of an uncoiler, and coiling is finished; and e, production control parameters of the flat roll are input. The remedying and repairing method solves the problems that due to thin-specification steel roll rolling abnormality, in the horizontal stacking and cooling process, the inner diameter of an inner ring of a flat roll formed in the manner that an inner ring of a steel roll collapses is irregular, the flat roll cannot get on a unit to be remedied or sold externally, and consequently the product can only be judged to return to a furnace, and the technology control level of a flat roll splitting unit is improved. The technology control technique is widely applied, delivery of externally entrusted products on schedule is ensured, the production cost is reduced, and the operation current situation that according to a conventional flat roll treatment operation manner, a large amount of labor / a large number of material resources are consumed, time is long, and serious safety hidden danger exists is avoided.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

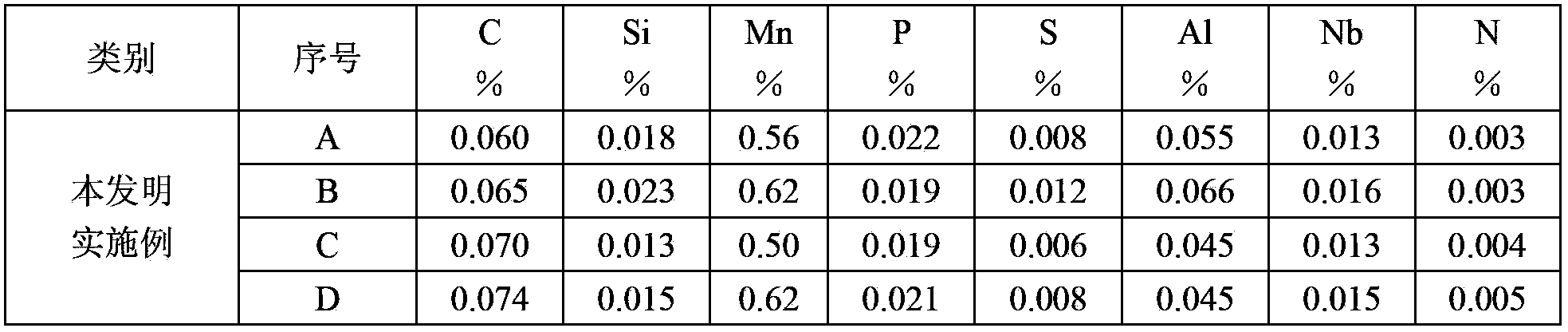

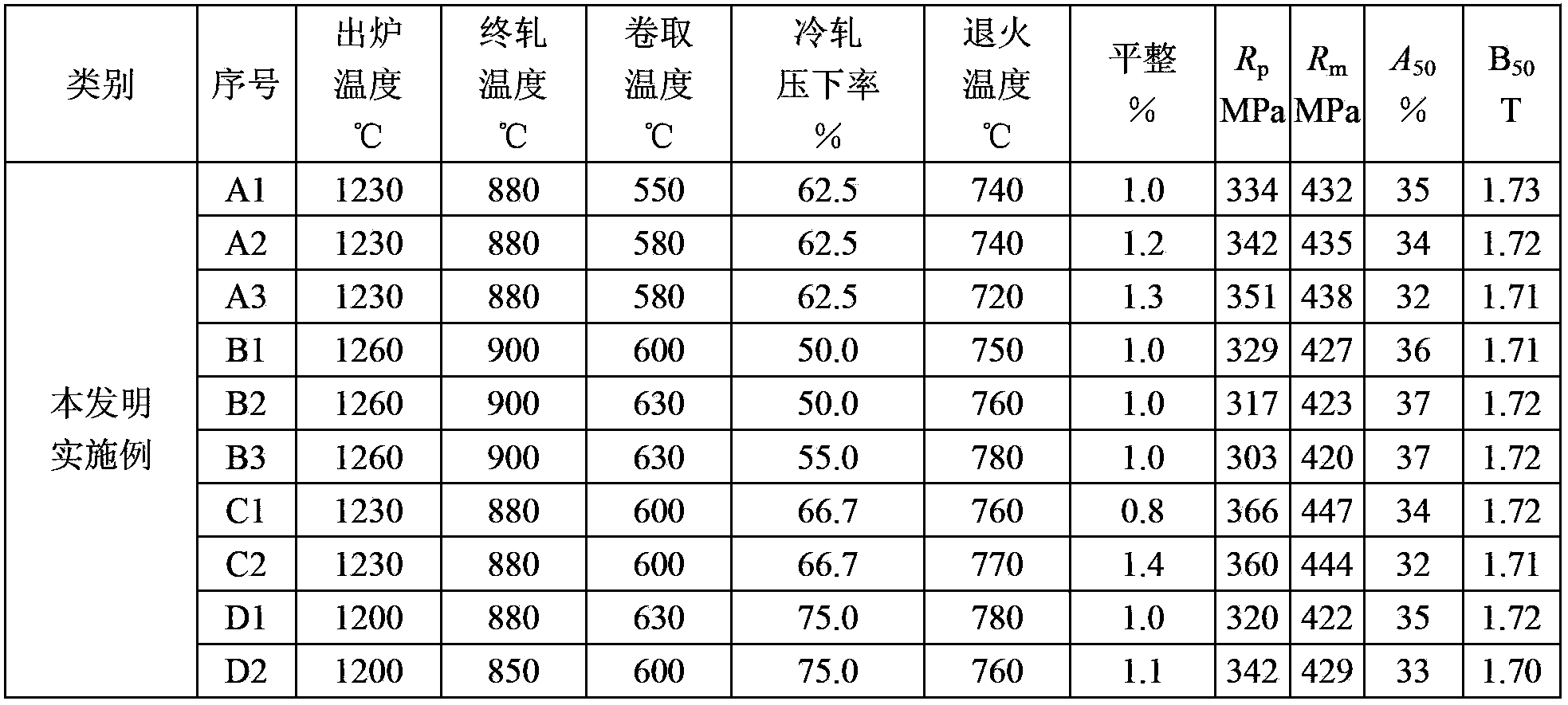

Manufacturing method for high-magnetic induction low-cost 250 MPa cold-rolled magnetic pole steel

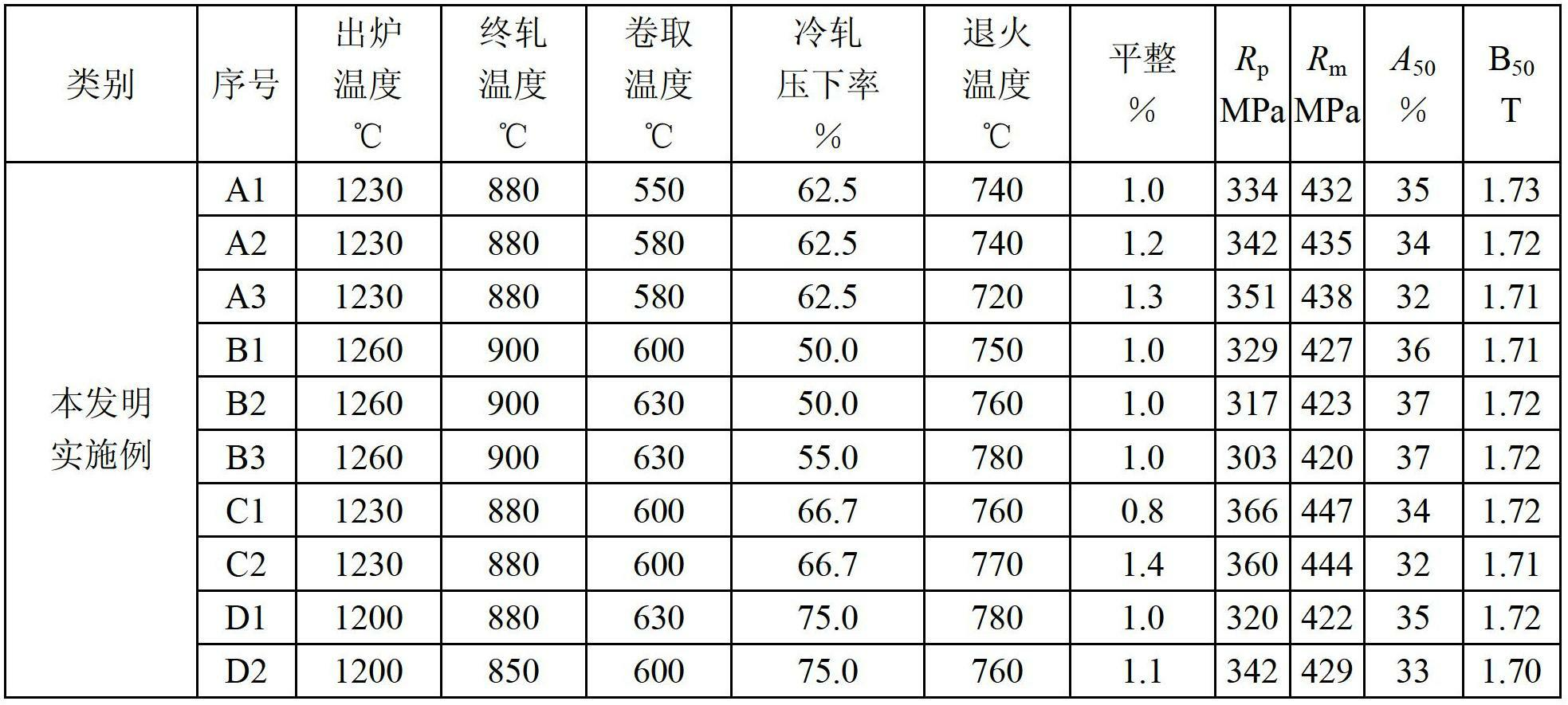

ActiveCN102650016AFully exert the strengthening effectImprove shape qualityRoll mill control devicesMetal rolling arrangementsReduction rateHeating time

The invention discloses a manufacturing method for high-magnetic induction low-cost 250 MPa cold-rolled magnetic pole steel. The manufacturing method comprises the steps as follows: heating a plate blank to be 1200-1260 DEG C and insulating; hotly rolling, wherein the final rolling temperature is 850-900 DEG C, the coiling temperature is 550-630 DEG C and a jet water cooling way is adopted as a cooling way; cooling to be 60-80 DEG C for acid washing, wherein an air cooling way is adopted as the cooling way; coldly rolling, wherein the cold rolling reduction rate is 50-75%; continuously annealing, wherein the temperature of an uniform heating section is 720-780 DEG C and the uniform heating time is 60-200 s; and flattening by a flattening elongation rate of 0.8-1.4% to prepare the 250 MPa cold-rolled magnetic pole steel. The produced magnetic pole steel has lower yield strength ReL of more than 250 MPa and magnetic induction strength B50 of more than 1.70 T, and is suitable for manufacturing a magnetic pole iron core of a rotor body of a large water-wheel generator.

Owner:BAOSHAN IRON & STEEL CO LTD

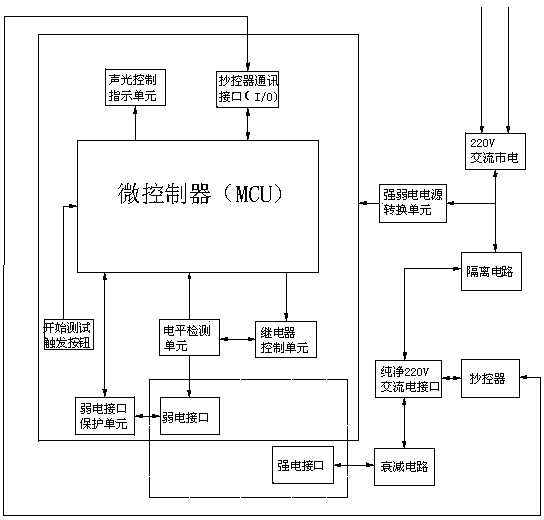

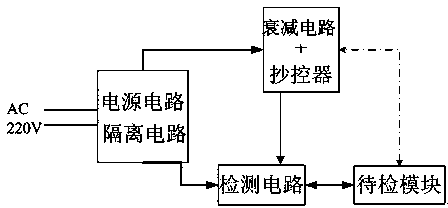

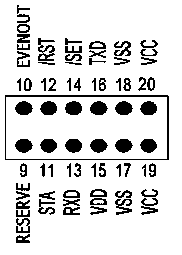

Detection equipment and detection method for single-phase carrier module of intelligent meter

ActiveCN104240493AQualified communicationQualified Power Consumption TestTransmission systemsMicrocontrollerCommunication interface

The invention discloses detection equipment and a detection method for a single-phase carrier module of an intelligent meter. The detection equipment consists of a strong and weak current converting unit, an isolating circuit of an alternating current power supply, a pure 220V alternating current interface, an attenuation circuit and a detection circuit, wherein the detection circuit comprises a strong current interface, a microcontroller, a 'test start triggering' button at a triggering end, a relay control unit, a level detection unit, a reading controller communication interface, a weak current interface, a weak current interface protection unit and a sound and light alarm circuit connected at a judgment output end of the microcontroller, the reading controller communication interface is connected with the pure 220V alternating current interface through a reader, a control end of the sound and light alarm circuit is connected with an output end of the microcontroller, and the 'test start triggering' button is connected with the microcontroller. The equipment is used for detecting newly-mounted modules, and the modules which are detected to be normal are taken to sites to be mounted newly; modules to be sent to the sites to replace fault modules are also required to be detected, so that fault modules are prevented from being brought to the sites.

Owner:STATE GRID CORP OF CHINA +1

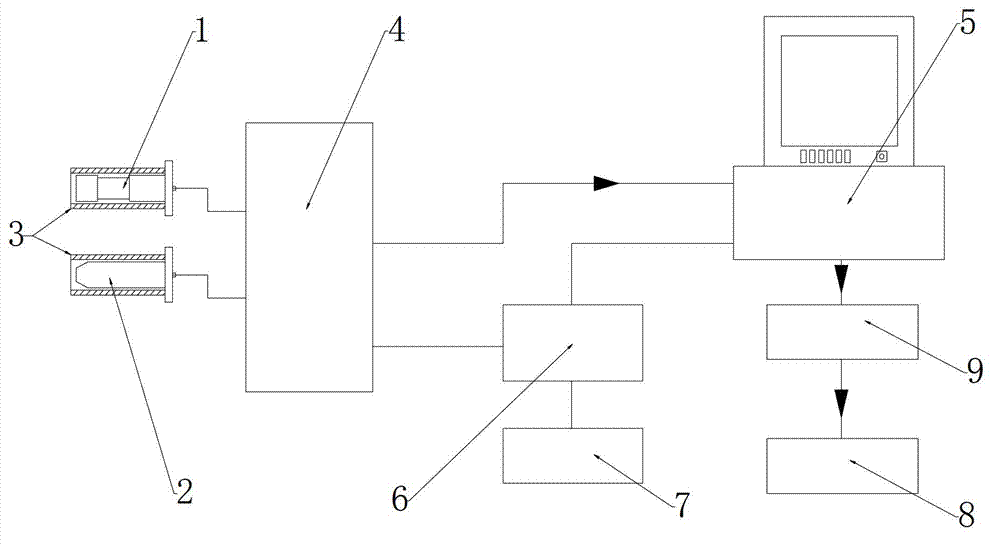

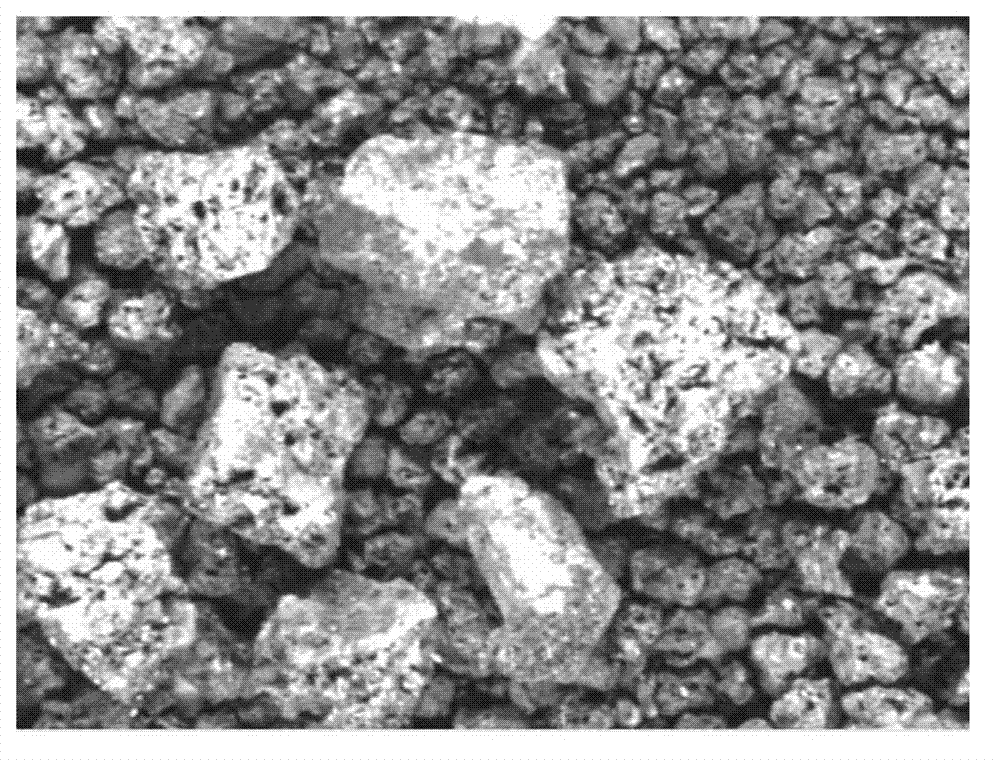

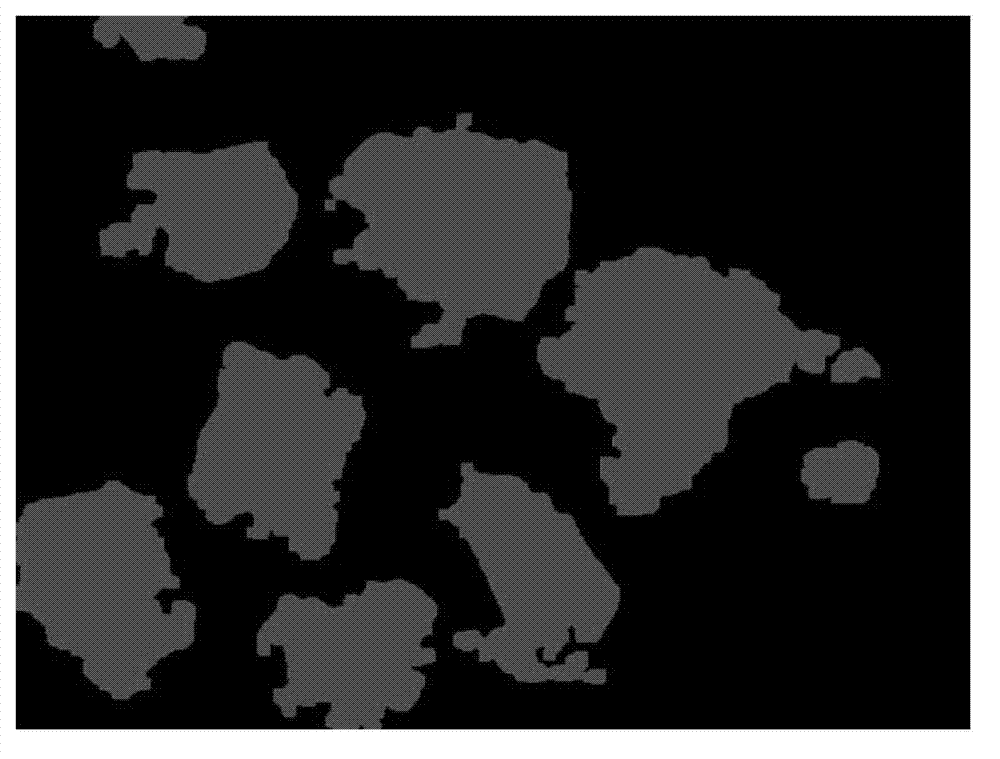

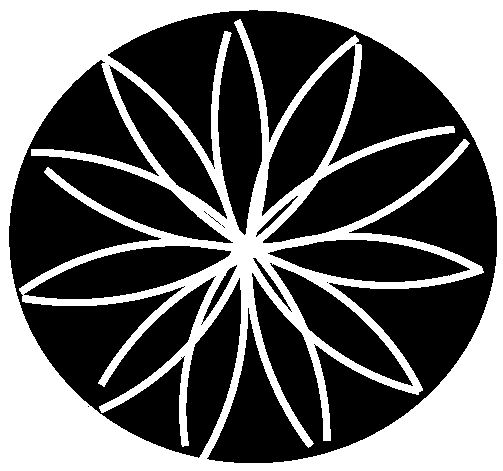

Blast furnace burden granularity video detection device and blast furnace burden granularity video detection method

The invention discloses a blast furnace burden granularity video detection device and a blast furnace burden granularity video detection method. The blast furnace burden granularity video detection device comprises an imaging device, an illuminating device, a protection sleeve, an on-site control box, a video image processing and display device, an indoor control box, a purification power supply, a sound and light alarm device and a signal converter, wherein the imaging device and the illuminating device are arranged above a conveying belt machine of a blast furnace feeding system, and the signal converter is arranged between the video image processing and display device and the sound and light alarm device. After the structure is adopted, the imaging device is utilized for carrying out image collection on furnace burden on the conveying belt machine, then, the video image processing and display device is used for analyzing and processing video data, the furnace burden granularity size and the distribution condition are calculated, and blast furnace operators can fast and accurately obtain relative information of the furnace burden granularity. The device has the characteristics of accuracy, high speed and efficiency, the existing outdated detection process can be replaced, and important effects of guiding the blast furnace operation and improving the process control level are realized.

Owner:天津市三特电子有限公司

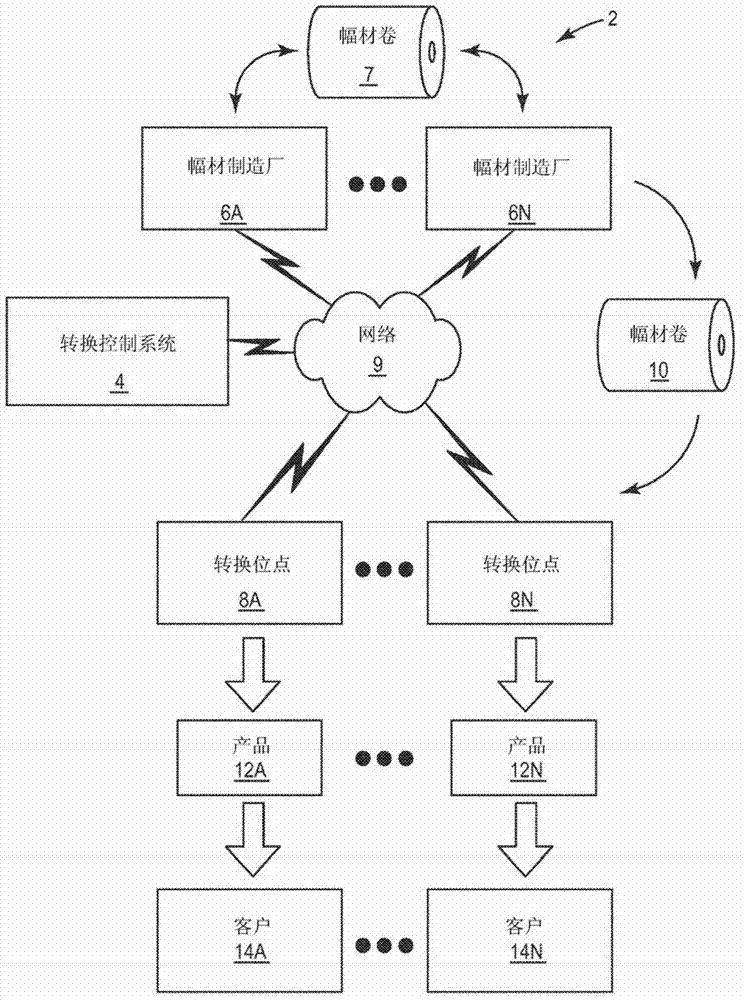

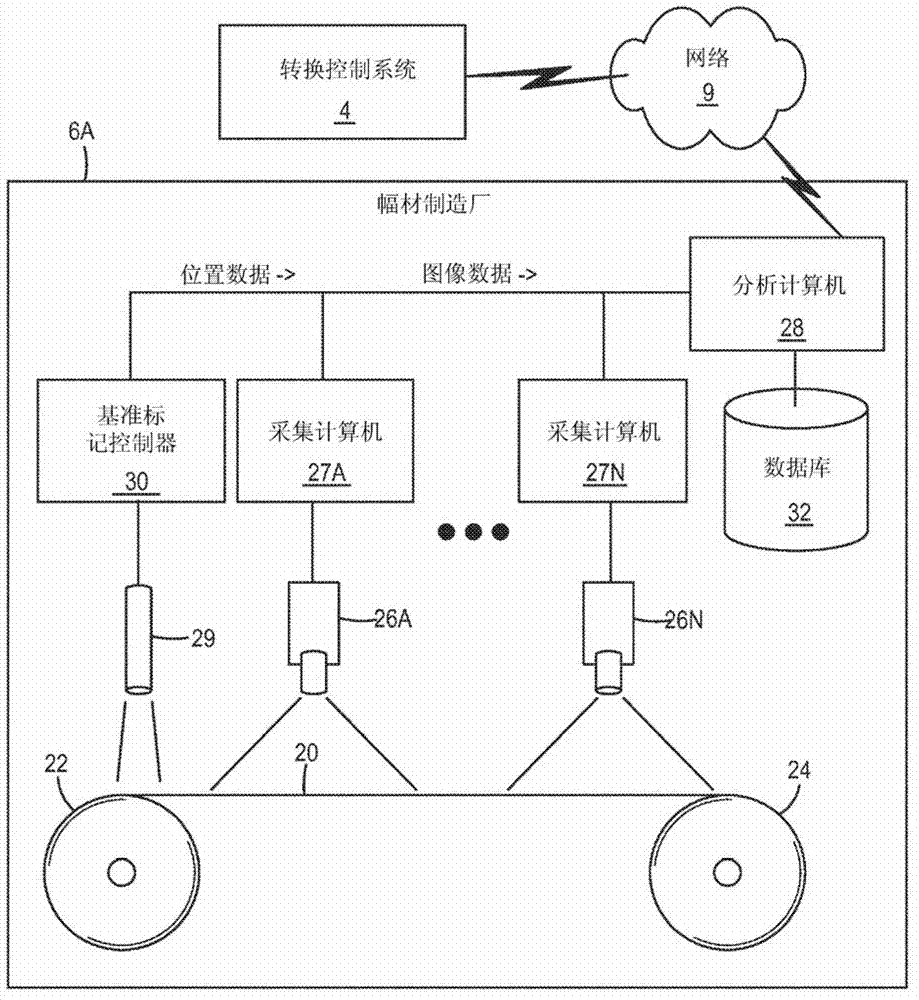

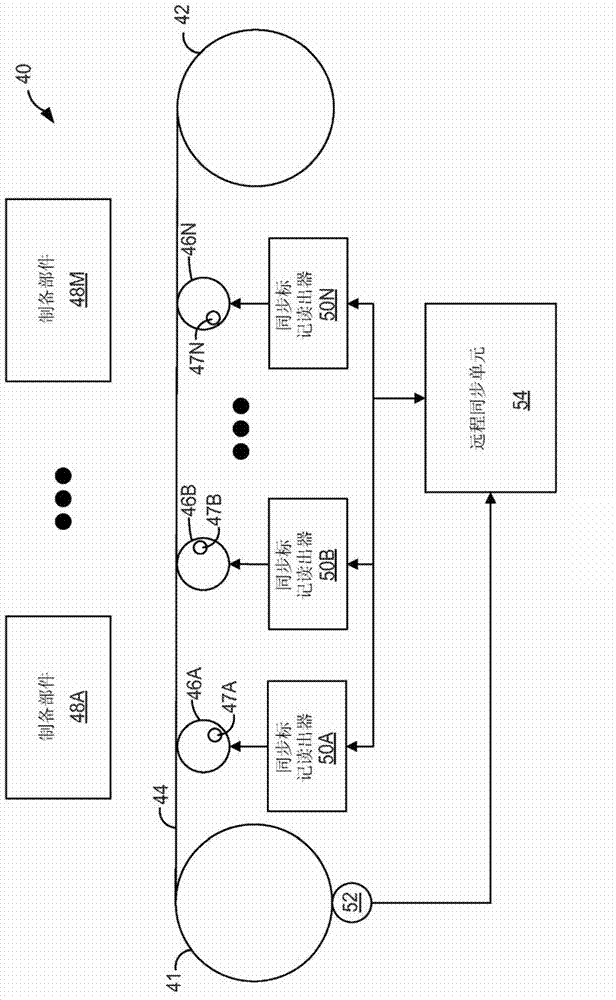

Application-specific repeat defect detection in web manufacturing processes

ActiveCN102792154AHigh speedHigh precisionInspecting textilesOptically investigating flaws/contaminationControl systemApplication specific

Techniques are described for inspecting a web and controlling subsequent conversion of the web into one or more products. A system, for example, comprises an imaging device, an analysis computer and a conversion control system. The imaging device images the web to provide digital information. The analysis computer processes the digital information to identify regions on the web containing anomalies. The conversion control system subsequently analyzes the digital information to determine which anomalies represent actual defects for a plurality of different products. The web inspection system may preferentially apply different application-specific defect detection recipes depending on whether a given anomaly is a repeating or random anomaly.

Owner:3M INNOVATIVE PROPERTIES CO

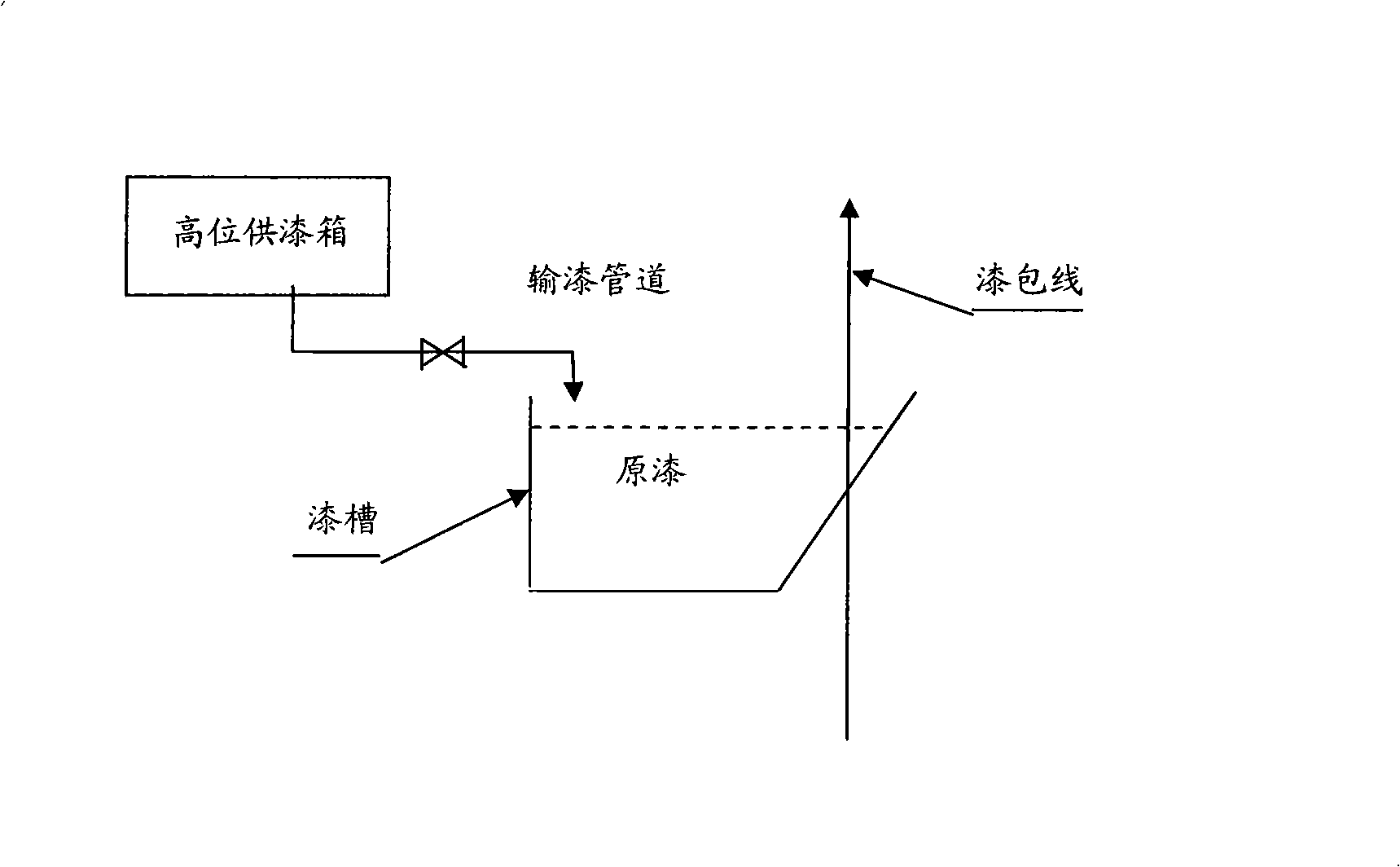

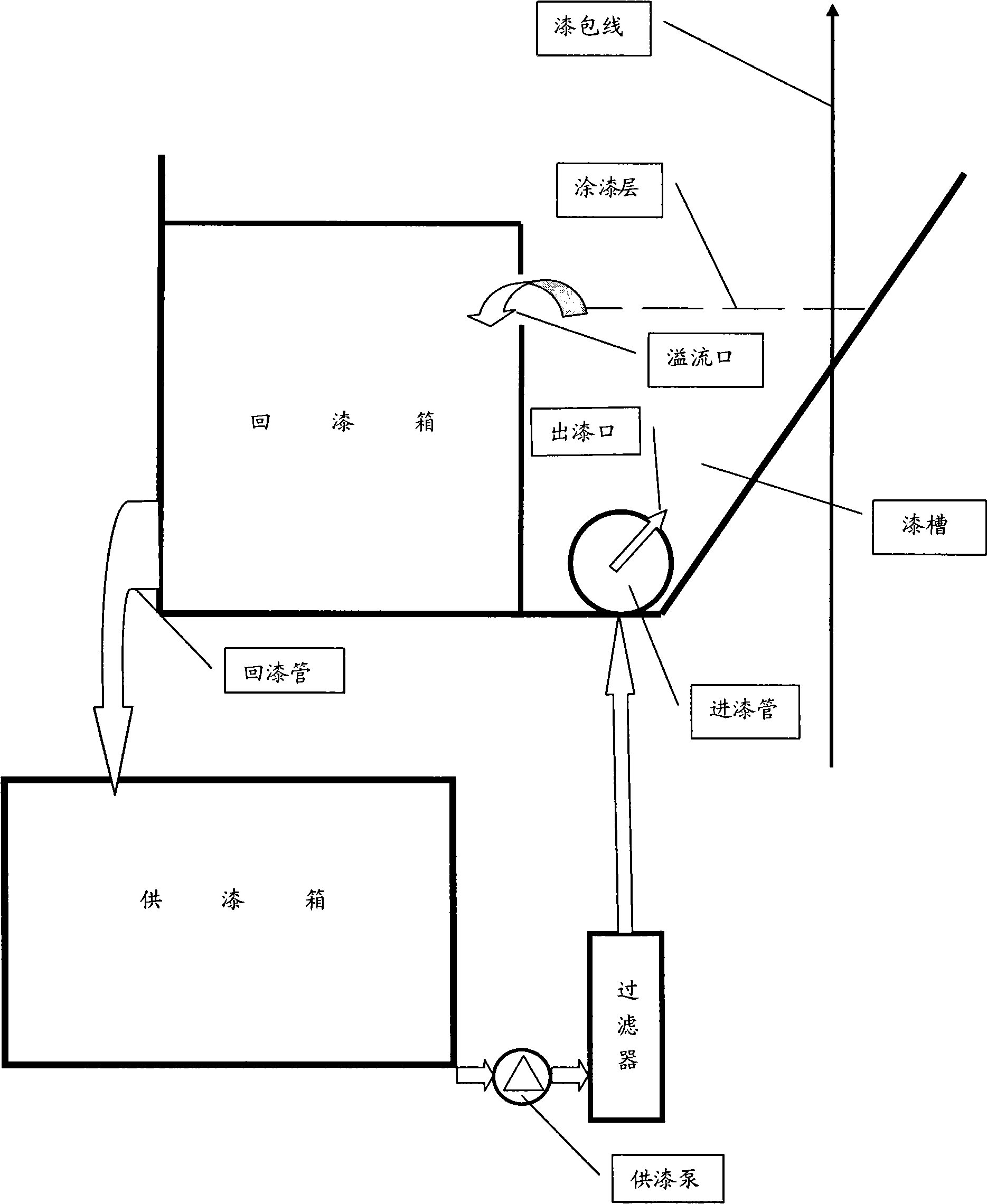

Method and apparatus for cleanness continuously supplying paint to varnished wire painting groove

InactiveCN101299360AUniform viscosity distributionLow variabilityInsulating conductors/cablesLacquerEvaporation

The invention provides a continuous cleaning paint supply method of the enameled wire paint groove, wherein a paint supply case is provided. The original paint is continuously pressed into a filter through a paint supply pump. Two sets of pipe filters are provided at the outside of the paint supply pump. The compound filtering is performed through using a melting spray filter core, so that the original paint is transmitted to paint intake pipes after being filtered. The original paint flows into a paint groove evenly from a paint outlet arranged axially of the paint intake pipes. A paint return chamber is arranged on one side of the paint groove. An overflow port is arranged above a baffle plate arranged between the paint return chamber and the paint groove. When the height of the paint is higher than the overflow port, the original paint flows into the paint return chamber from the overflow port and then returns to the paint supply case through the paint return pipe, which completes a primary circulation. Since the paint intake pipes are arranged along the length direction at the bottom of the paint groove, the original paint flows into the paint return chamber along the length direction of the paint return chamber. Thus, the viscosity of the original paint in the paint groove keeps in line. The paint return chamber is made of steel plate, connected with the paint supply case through the paint return chamber, without exposing the return paint in the air, thereby reducing the evaporation of the original paint for more than1 / 2. When reflowing, the original paint on the coating layer turns over the overflow port, and carries the paint with impurity into the paint return chamber, enters the paint intake pipe again through the paint supply pump and the filter from the paint supply case, which ensures the cleaness of the original paint and increase the quality of the paint surface.

Owner:NANXIANG GROUP

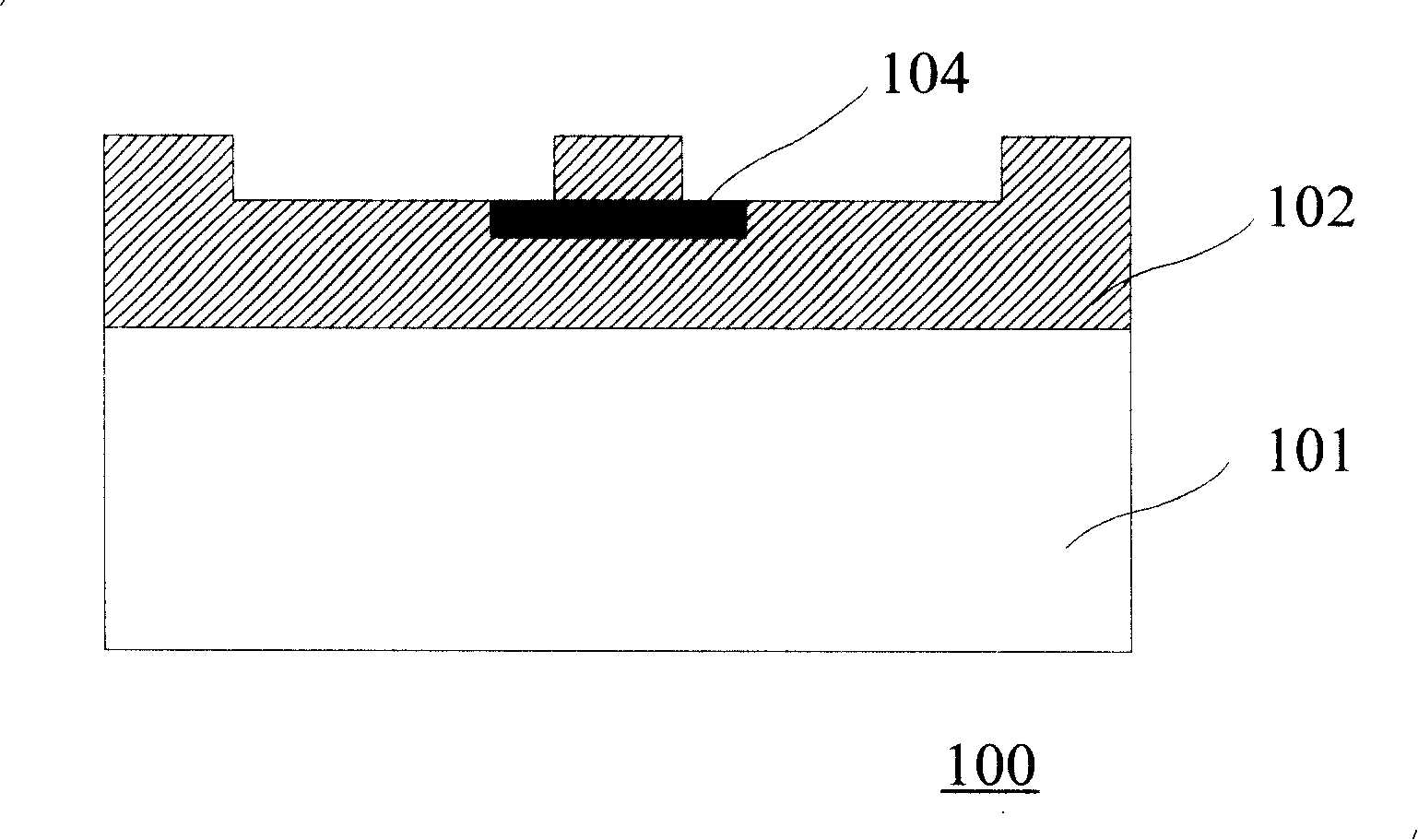

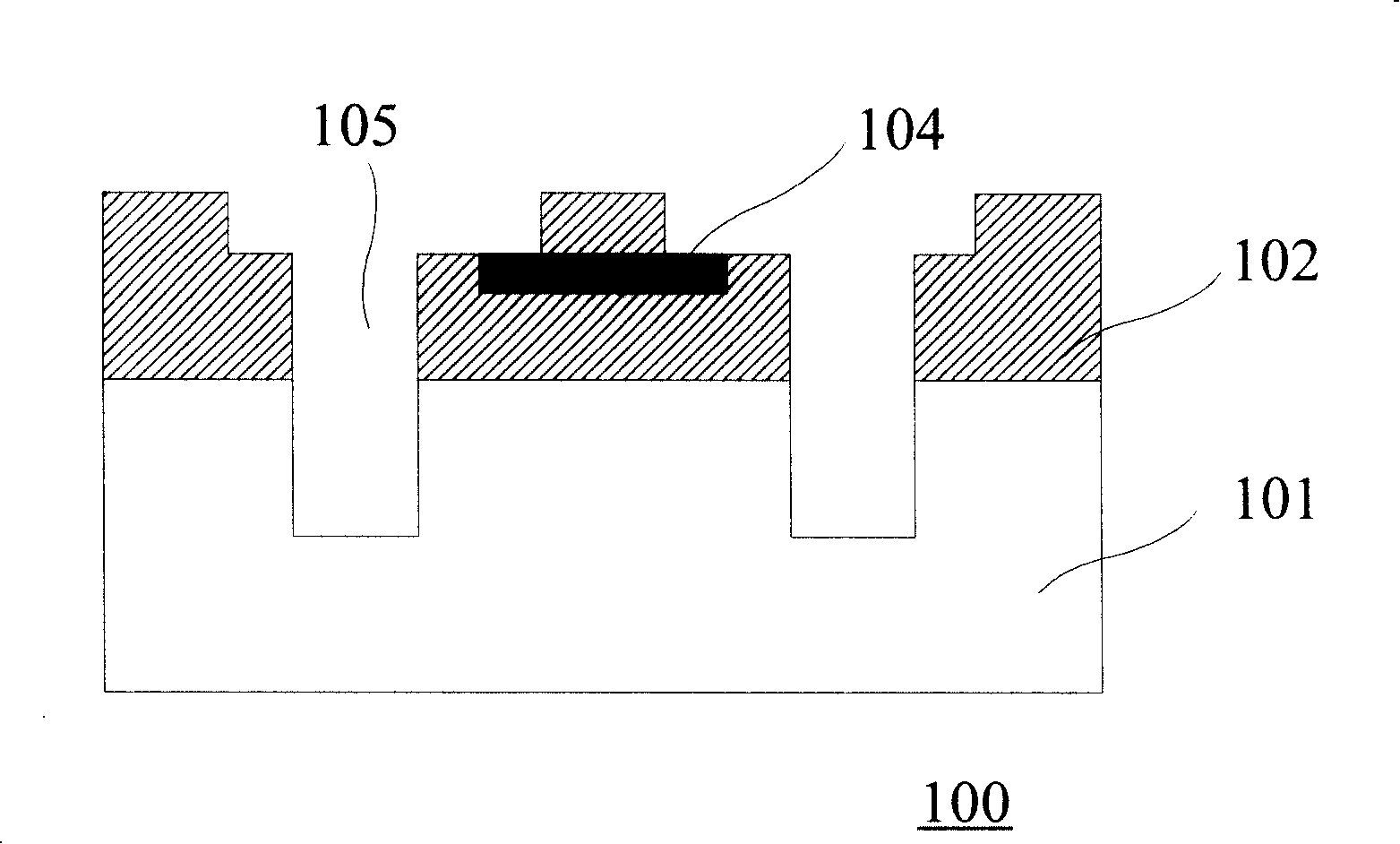

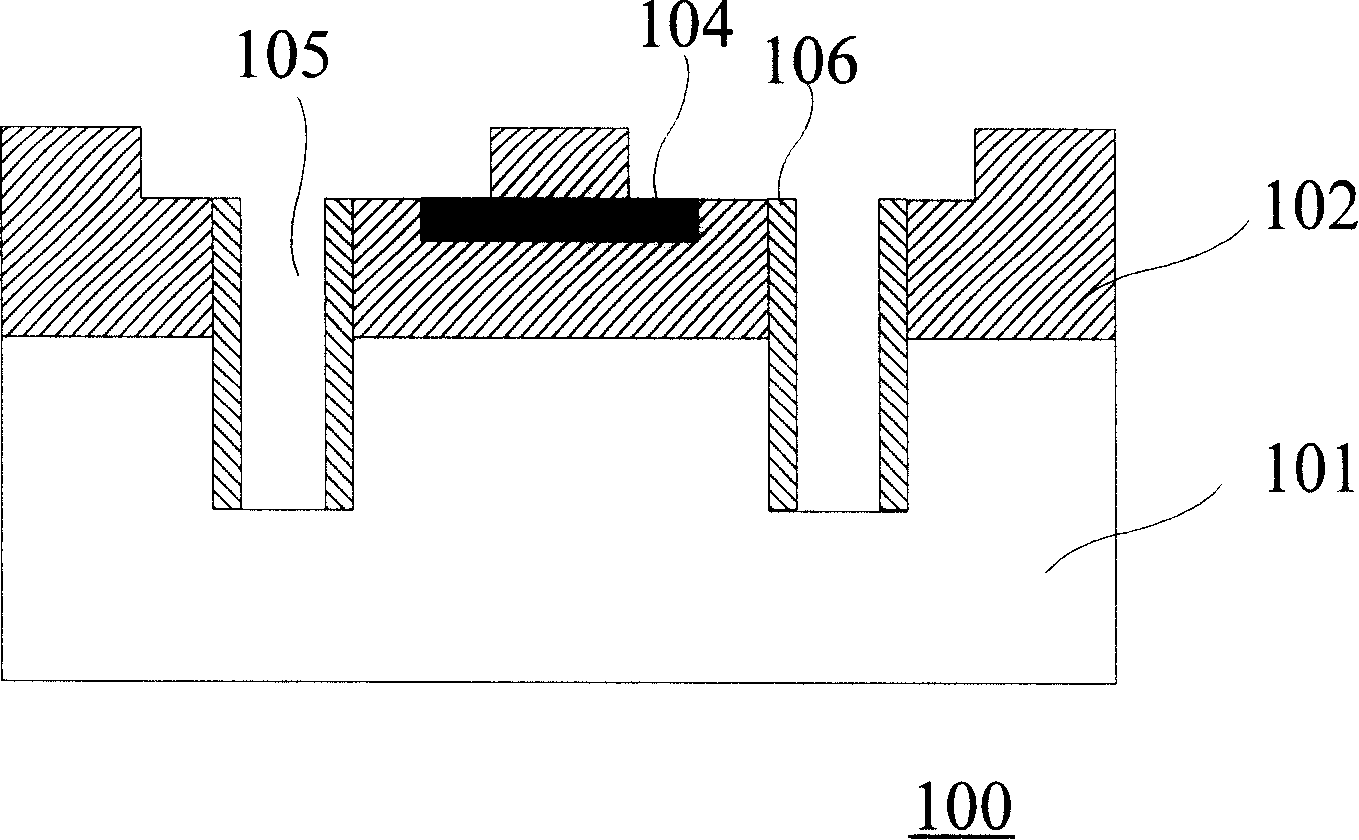

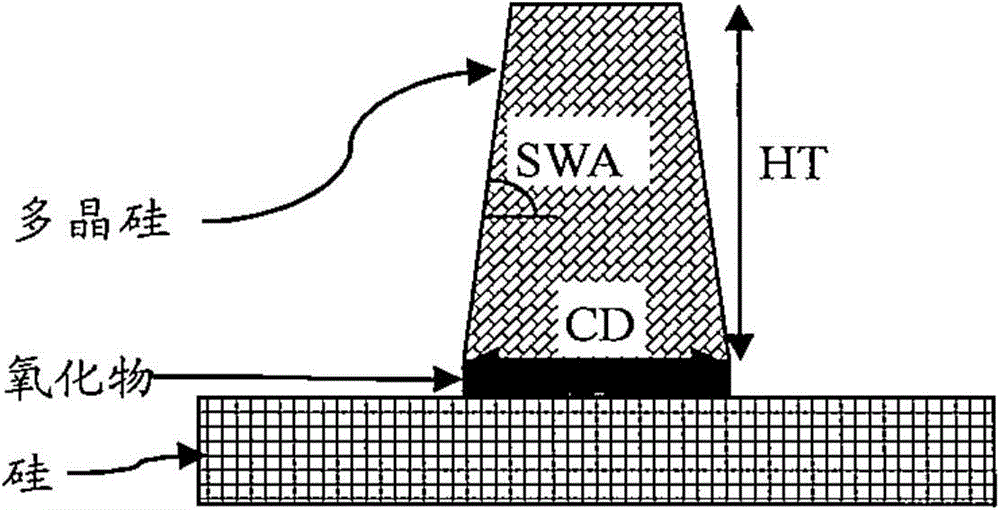

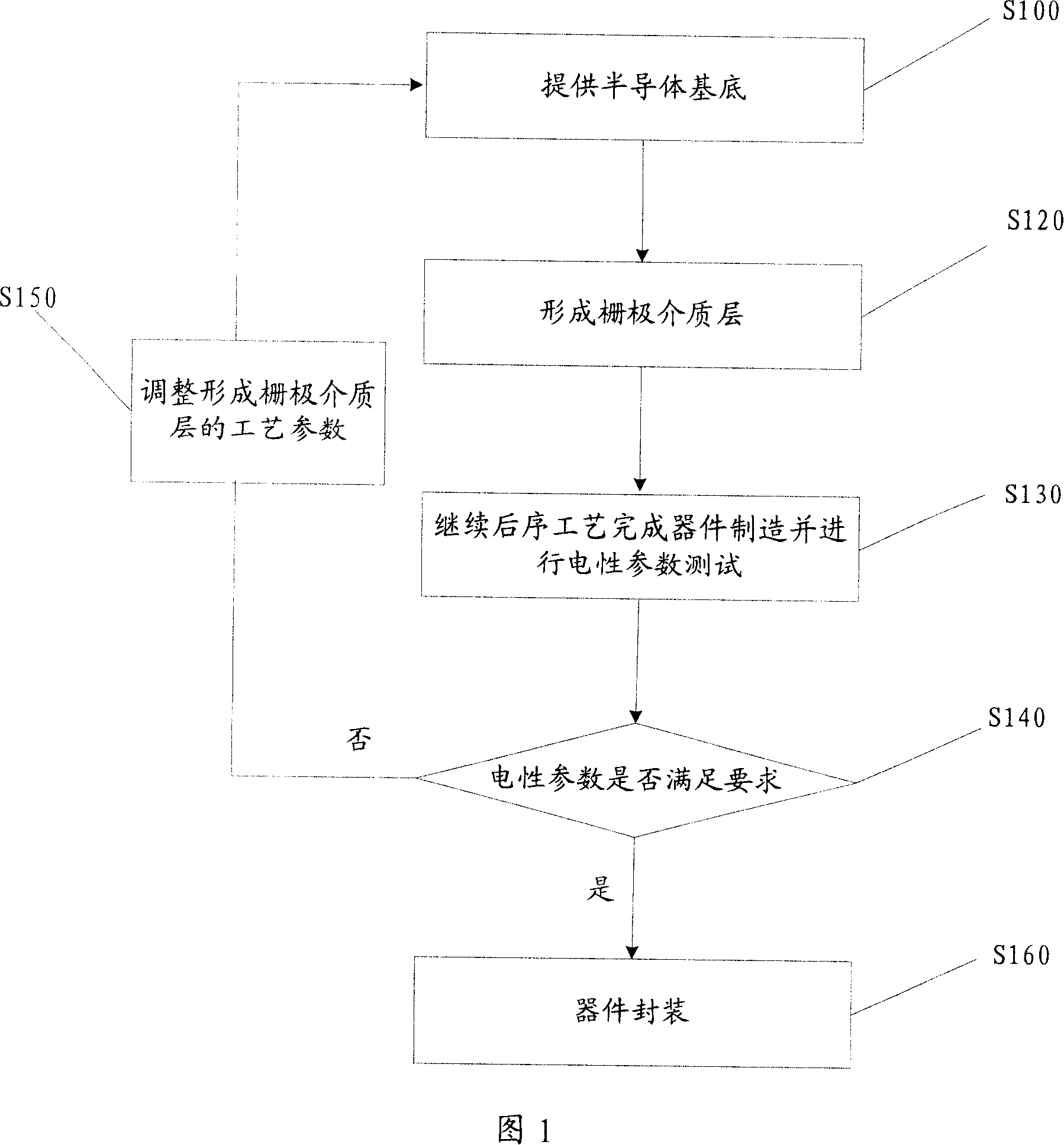

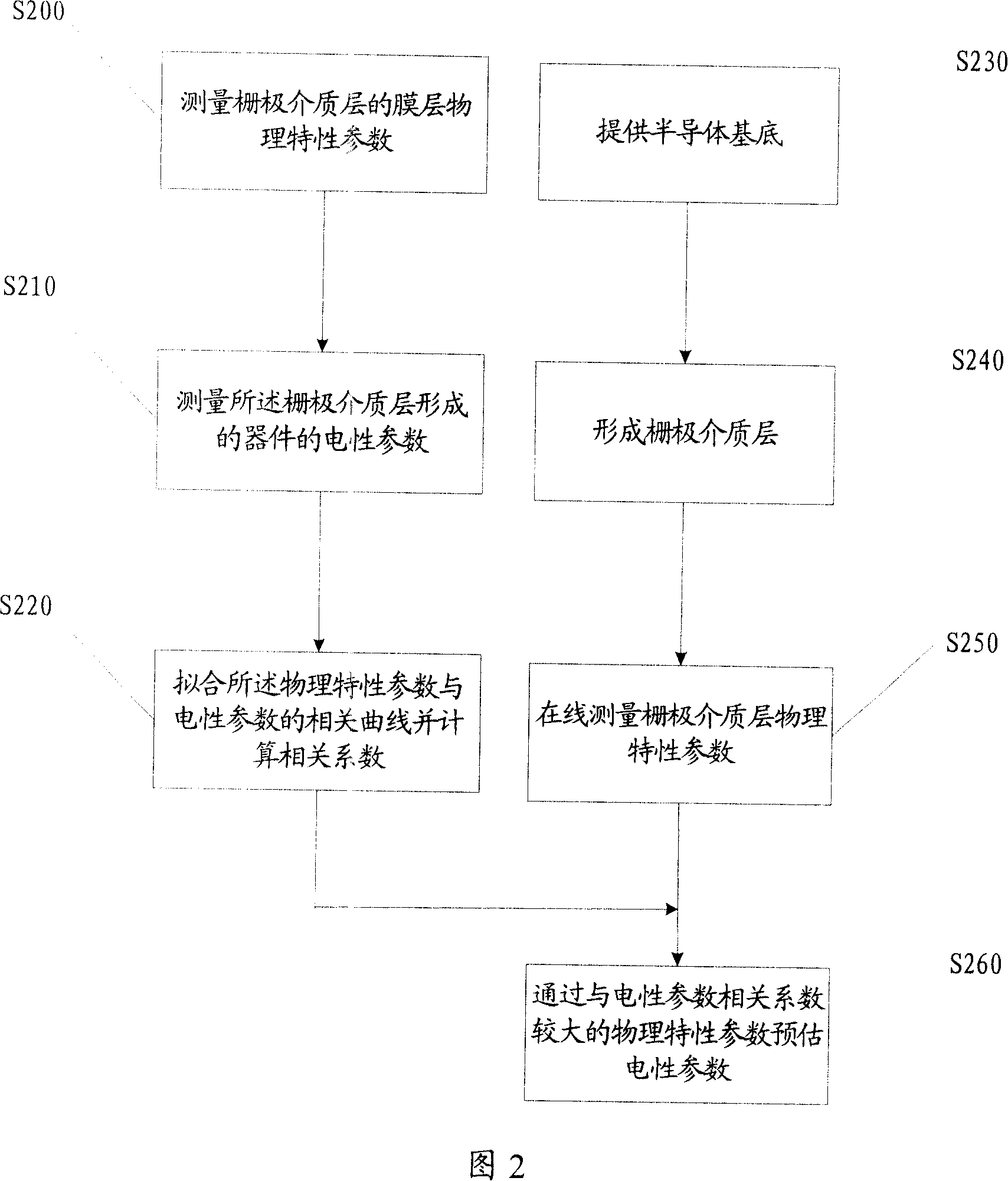

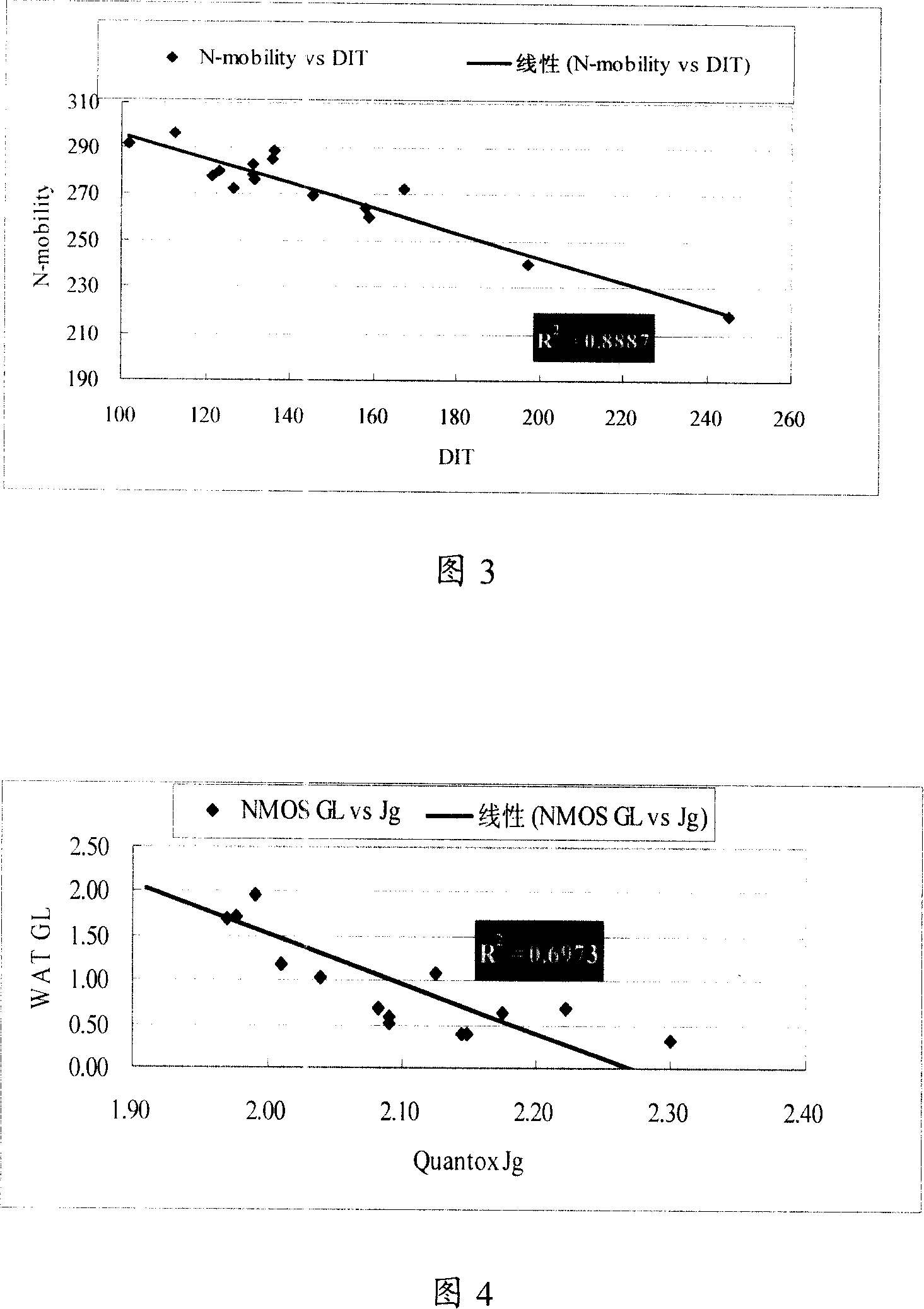

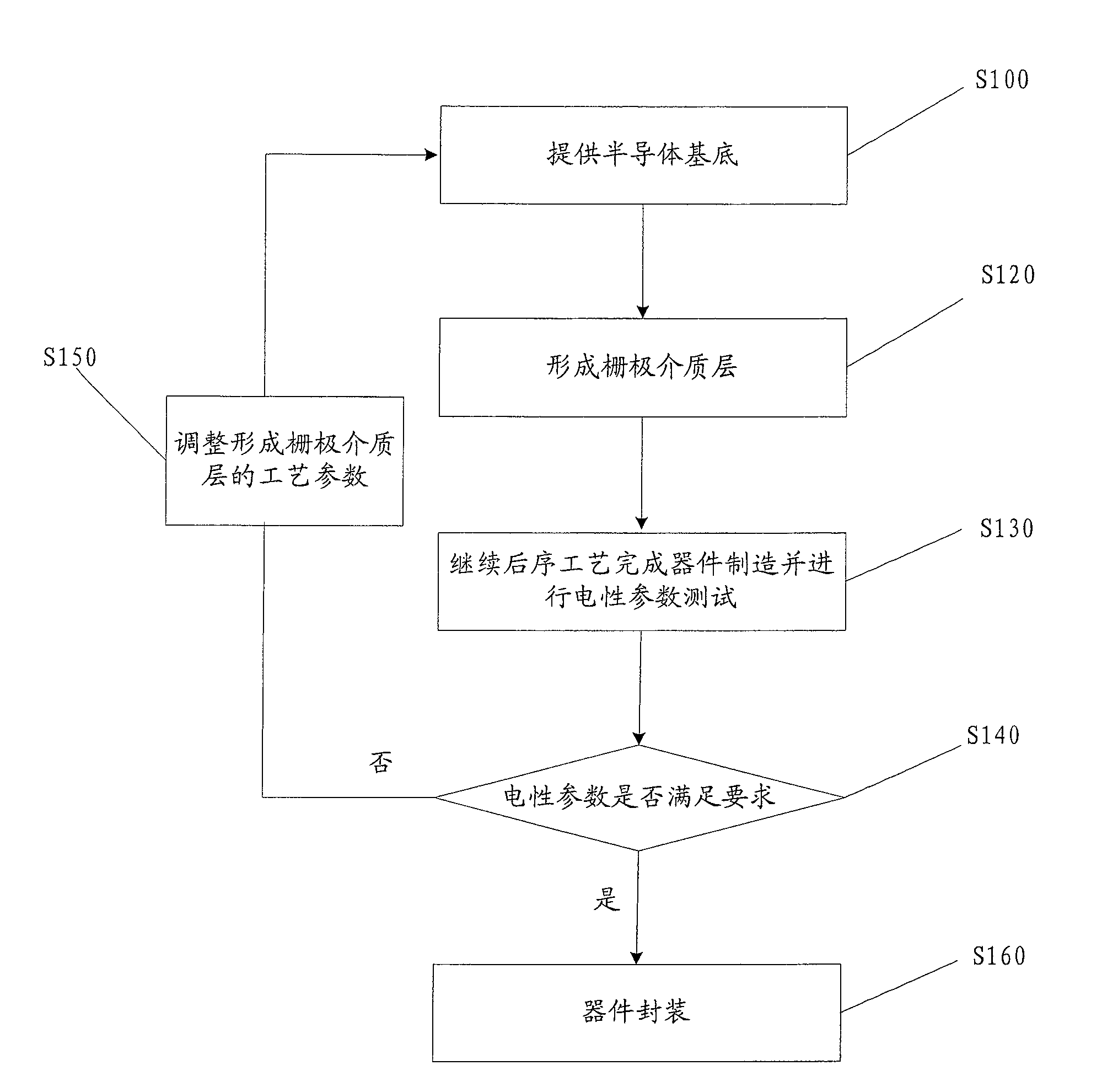

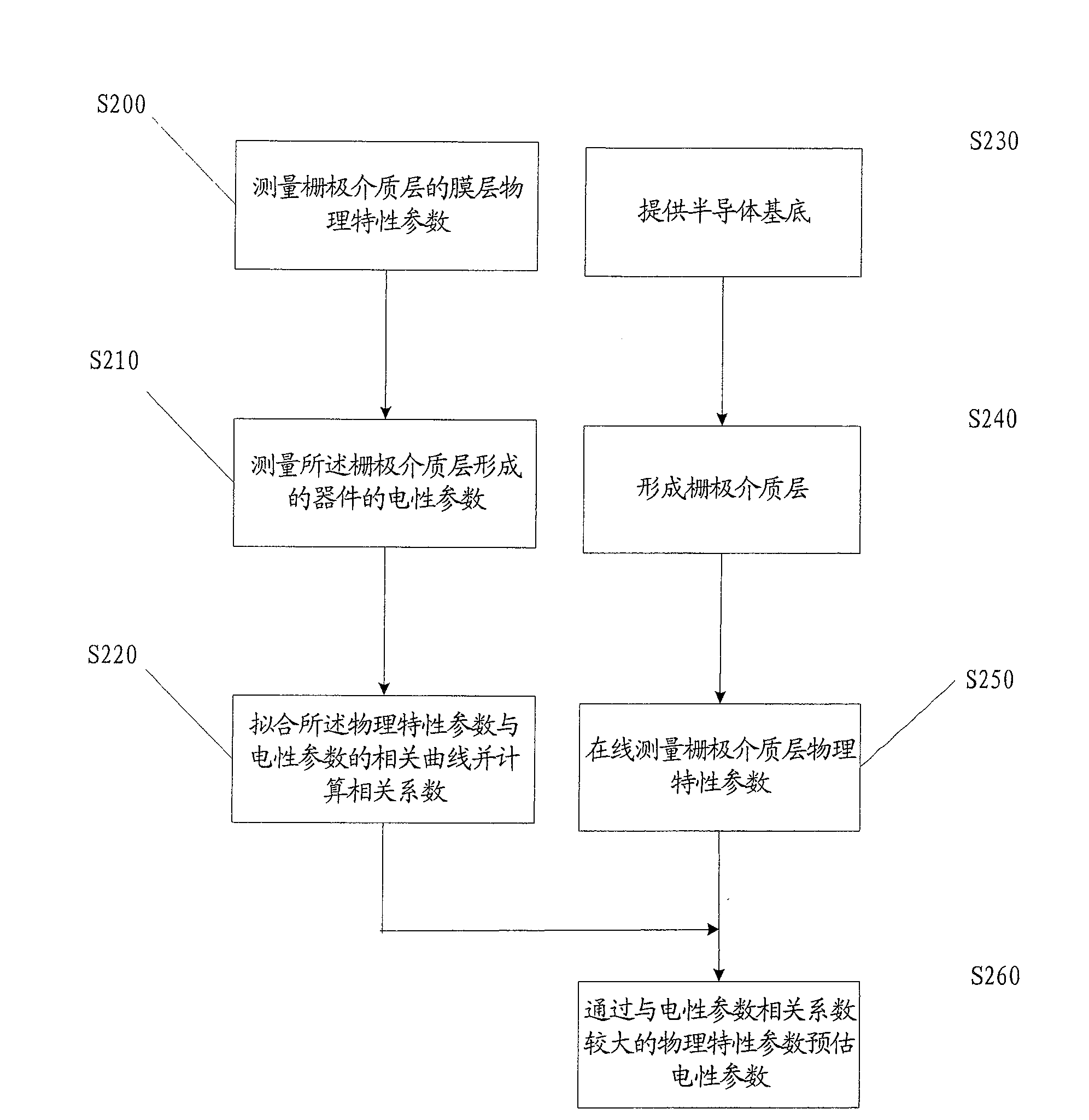

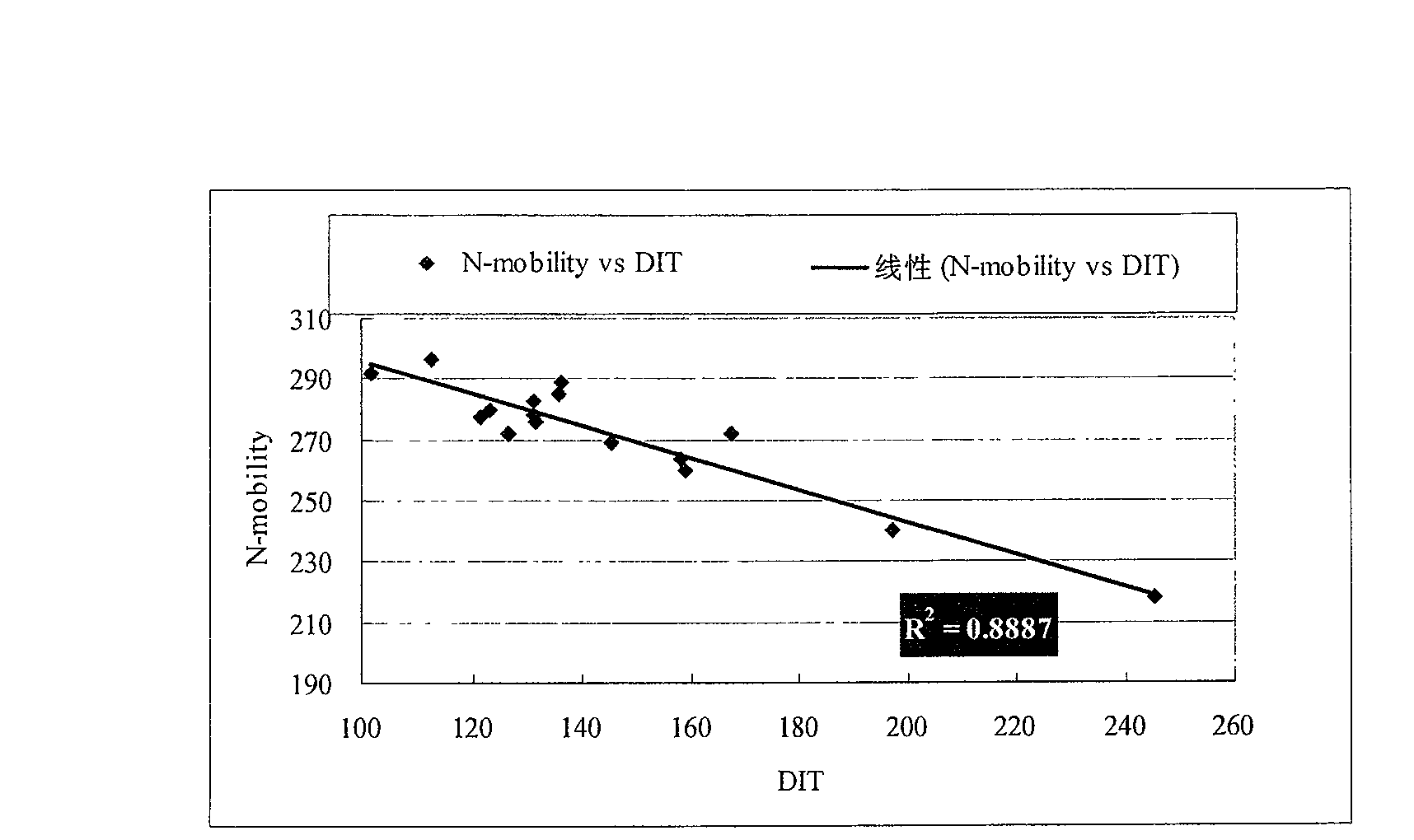

Method for forming grid medium layer and estimating its electrical parameter

InactiveCN101154608AShorten the development cycleLow costSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingCorrelation coefficientDevice form

A method for evaluating electrical parameters of grid dielectric layer comprises that: the film physical characteristic parameters of a grid dielectric layer and the electrical parameters of a device formed by the grid dielectric layer are measured; the correlation curves between the physical characteristic parameters and the electrical parameters are fitted and correlation coefficients are calculated; the physical characteristic parameters having closer relationship with electrical parameter phases are found out; the physical characteristic parameters of the grid dielectric layer is measured on line; the electrical parameters are predicted through the physical characteristic parameters having closer relationship with the electrical parameter phases. The method of the present invention can evaluate the electrical parameters of the grid dielectric layer on line.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Printing preparation of mini gap reversed-mounting welded convex templates with lead/tin or leadless solder

InactiveCN1553480AImprove process controlImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesWaferingSolder ball

The invented technique of preparing solder ball for encapsulating semiconductor includes following steps: preparing metal level and back flow leading metal level under salient point by using technique of nickel-vanadium alloy and float pulling off technique; designing and preparing printing template based on size of solder ball and technological requirements; printing soldering paste on chip by using printing machine; based on requirement of soldering paste material, forming solder ball under certain temperature by back flow. The invention raises possibility of technical control for preparing solder ball through template printing technique, reduces space between solder balls and provides reliable solder ball for upside down mounting solder in different sizes and materials.

Owner:THE HONG KONG UNIV OF SCI & TECH

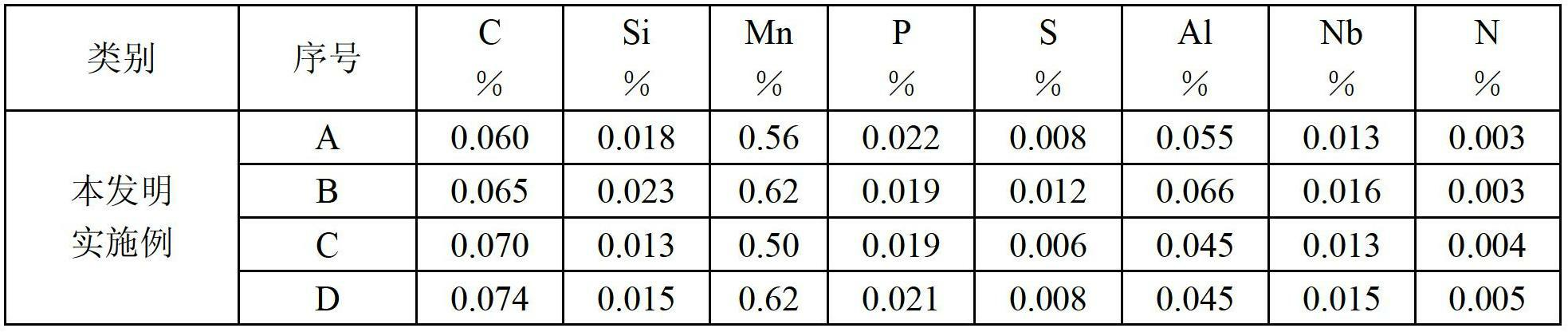

Technique control method for preventing CSP continuous casting machine from cast-on breakout

The invention discloses a technique control method for preventing a CSP continuous casting machine from cast-on breakout. The technique control method for preventing the CSP continuous casting machinefrom the cast-on breakout comprises steps of controlling the chemical composition and superheat degree of the continuous casting tundish liquid steel, sealing the seepage-proof steel of a continuouscasting cast-on dummy bar head sealing kit, adding special protective slags for the cast-on, and controlling the cast-on time of the continuous casting machine. The chemical composition of the continuous casting tundish steel liquid is set to comprises less than or equal to 0.06wt% of the low-carbon steel series C, and more than or equal to 0.17wt% of the medium carbon steel series C, the gas N isless than or equal to 50 ppm, and superheat degree of the liquid steel is controlled to be 15-40 DEG C. The technique control method for preventing the CSP continuous casting machine from the cast-onbreakout can effectively prevent cast-on breakout accidents of a thin slab-billet continuous casting machine, thereby improving the product quality and realizing the production of high-quality defect-free continuous casting billets.

Owner:HANDAN IRON & STEEL GROUP +1

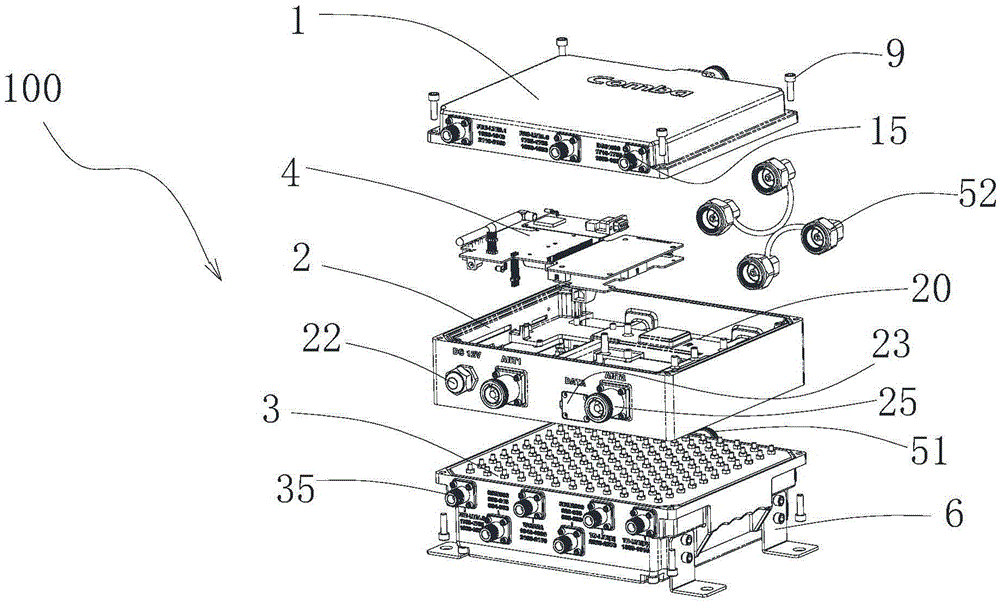

Integrated point of interface (POI)

ActiveCN105489992AReduce investmentImprove product qualityWaveguide type devicesClassical mechanicsMechanical engineering

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD +1

Continuous long fiber reinforced fire-retardant thermoplastic resin and its preparation

ActiveCN100463934CSimple recipeSimple process controlLong-fiber-reinforced thermoplasticFire retardant

Owner:KINGFA SCI & TECH CO LTD +1

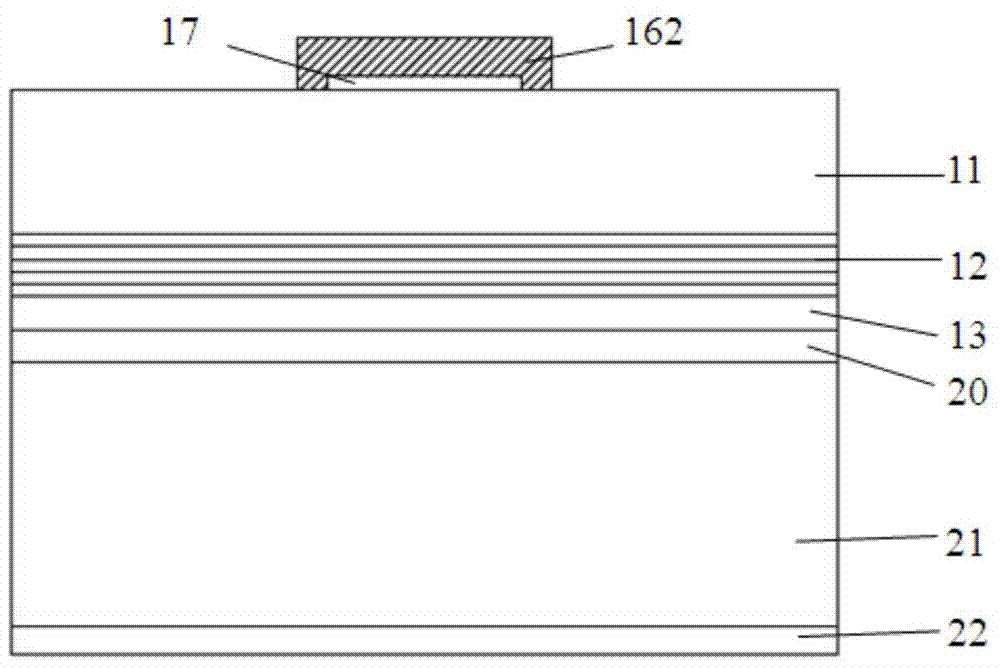

Preparation method of TOPCon battery

ActiveCN113851559AProtect the front structureMeet high capacity needsFinal product manufacturePhotovoltaic energy generationDopantPhysical chemistry

The invention discloses a preparation method of a TOPCon battery, which comprises the following steps of preparing a tunneling oxide layer on the back surface of a silicon wafer through LPCVD and depositing intrinsic amorphous silicon, firstly removing amorphous silicon winding plating on the front surface of the silicon wafer, then coating a liquid dopant on the back surface of the silicon wafer and drying, then annealing the silicon wafer, crystallizing the amorphous silicon through annealing and activating impurities. The method can realize single-sided diffusion without winding expansion, is a process scheme for preparing an n + POLO structure, meets the requirement of high productivity, optimizes a process window, avoids the winding expansion risk, can realize removal of amorphous silicon winding plating before annealing, simplifies process steps, protects the front surface structure of a silicon wafer, improves process controllability, and the contradiction between the diffusion concentration and the tunneling layer effect can be solved.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

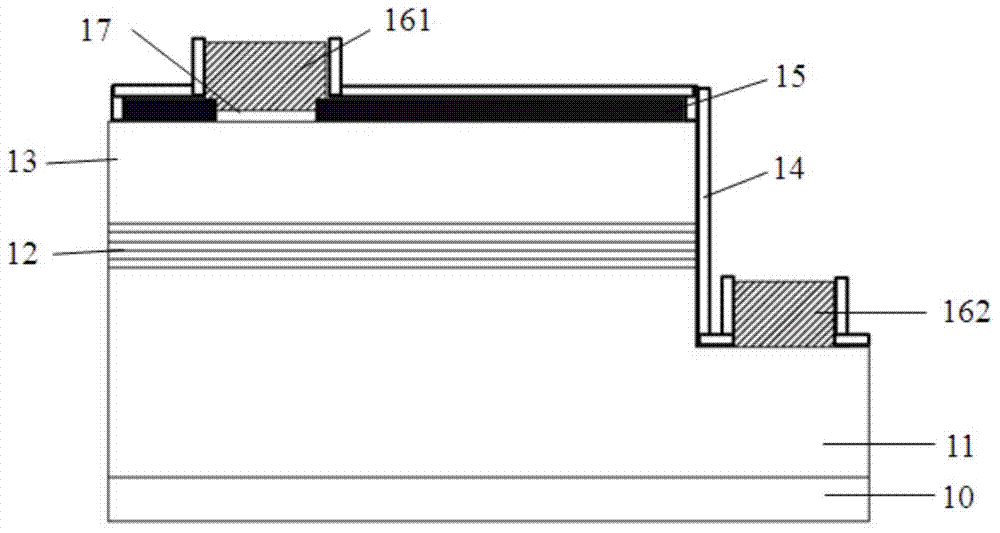

GaN-based light emitting diode and preparation method thereof

InactiveCN103715339AIneffective luminescence reductionEasy to makeSemiconductor devicesHigh resistancePower flow

The invention discloses a GaN-based light emitting diode and a preparation method thereof. The GaN-based light emitting diode includes an X type GaN layer and an X type electrode arranged on the X type GaN layer; a current obstruction area is formed on the X type GaN layer under the X type electrode; the area of the current obstruction area is smaller than that of the X type electrode; and the X type GaN layer is an N type GaN layer or a P type GaN layer, and the X type electrode corresponding to the X type GaN layer is an N type electrode or a P type electrode. The preparation method uses photoetching and plasma dry etching technology, enables a processed surface to from a high-resistance area, finally achieves the purpose of branching guidance of current, and enables invalid light emission of an LED electrode area is greatly reduced.

Owner:XI AN JIAOTONG UNIV

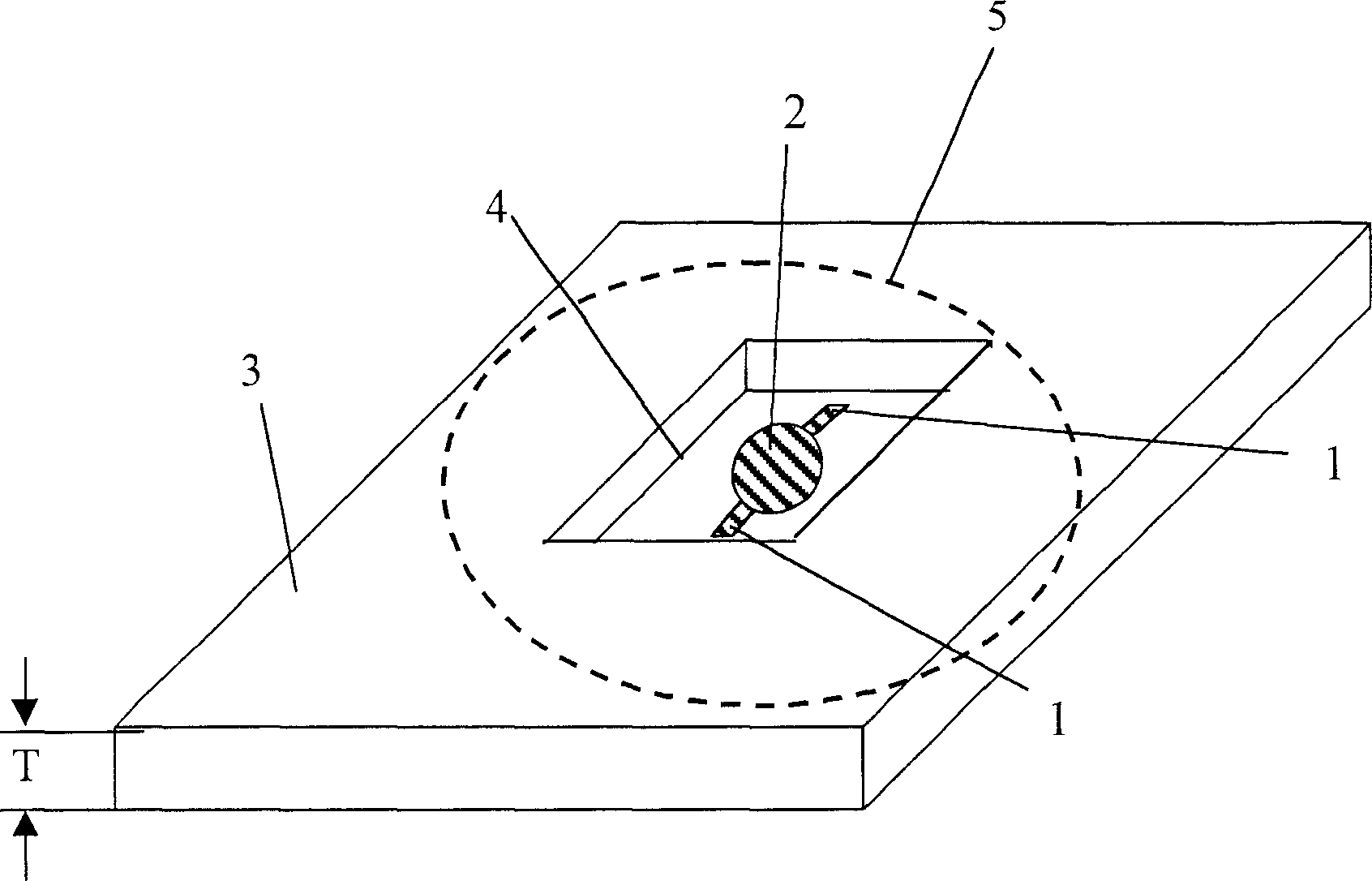

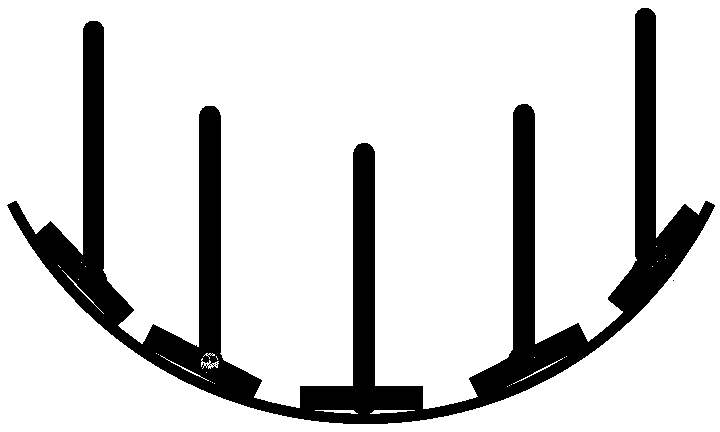

Edge and arc chamfering device machining for precision quartz crystal resonator

ActiveCN108857689AGuaranteed design complianceEnsure shape symmetryEdge grinding machinesQuartz crystal resonatorEngineering

An embodiment of the invention provides an edge and arc chamfering machining device for a precision quartz crystal resonator. The edge and arc chamfering machining device comprises a machining platform, a grinding disc arranged on the machining platform and used for bearing a wafer, a driving mechanism for driving the grinding disc to rotate, a wafer buckle pressurized and fixed on the wafer and including a counter bore, and a pressing mechanism pressed on the wafer buckle, wherein the pressing mechanism comprises a thimble and a first rotating mechanism, and the thimble can be inserted into the counter bore to be secured to the wafer in an inserting manner. The edge and arc chamfering machining device for the precision quartz crystal resonator can guarantee that a curved surface of the wafer is stably ground, and can also guarantee the design conformity and the shape symmetry. The perpendicularity and fixation relationships among a support rod, the thimble and a horizontal plane of the wafer can be adjusted and controlled. The grinding center of gravity of the wafer in a grinding process can be kept unchanged.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

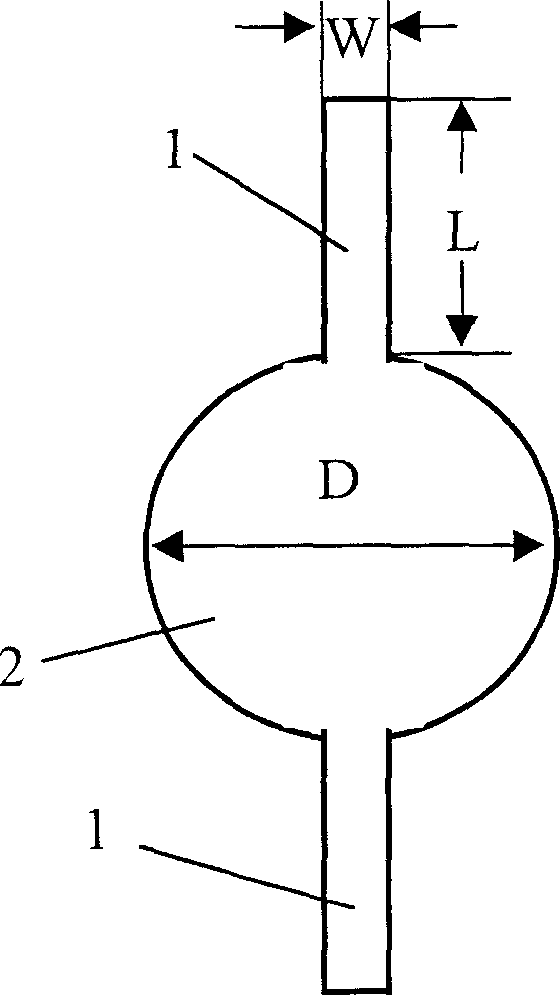

Method for forming grid medium layer and estimating its electrical parameter

InactiveCN100561700CShorten the development cycleLow costSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingCorrelation coefficientGate dielectric

A method for evaluating the electrical parameters of the gate dielectric layer, comprising: measuring the film physical characteristic parameters of the gate dielectric layer and the electrical parameters of the device formed by the gate dielectric layer; fitting the physical characteristic parameters and electrical parameters The correlation curve between the electrical parameters and the calculation of the correlation coefficient; Find out the physical characteristic parameters that have a large correlation with the electrical parameters; Online measurement of the physical characteristic parameters of the gate dielectric layer; Through the physical characteristic parameters with a large correlation coefficient with the electrical parameters Estimate electrical parameters. The method of the invention can evaluate the electrical parameters of the grid dielectric layer on-line.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

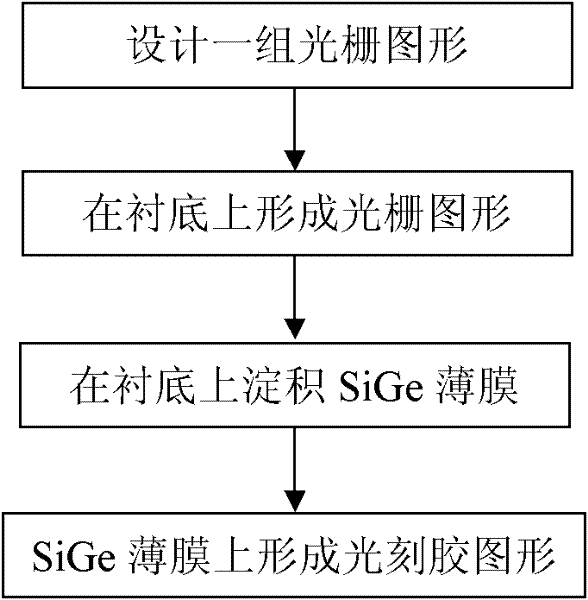

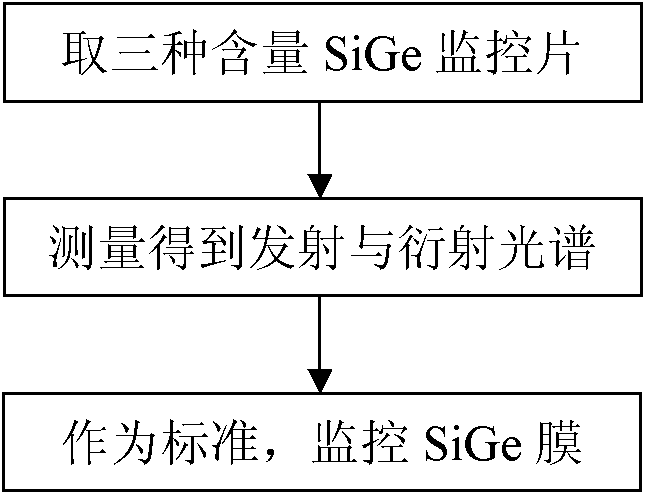

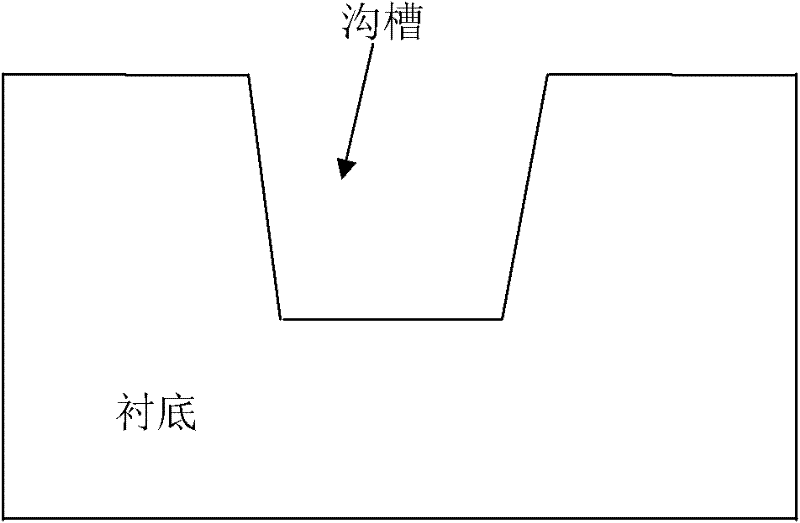

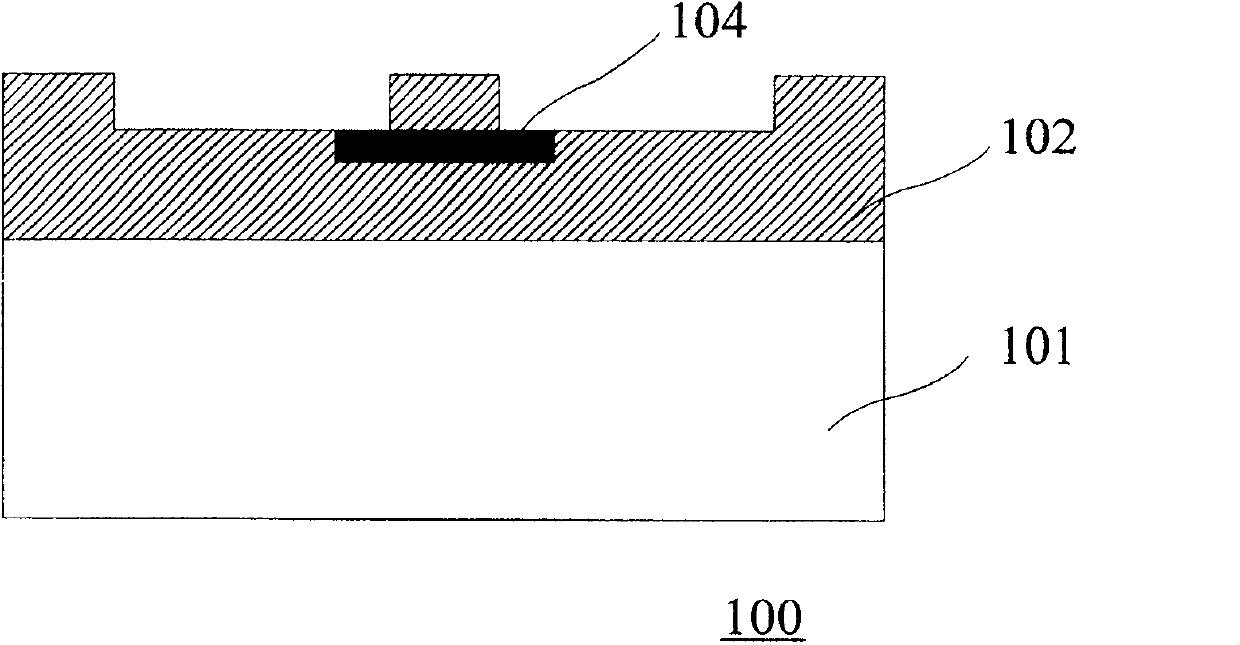

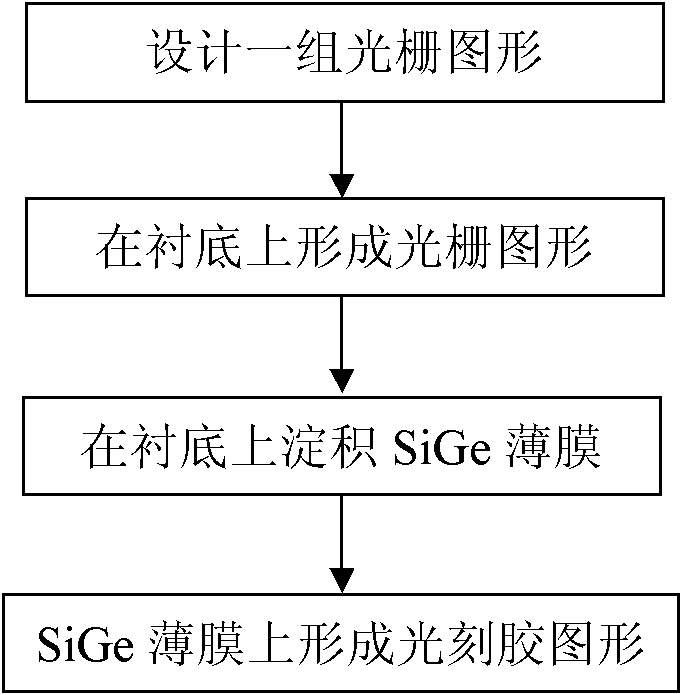

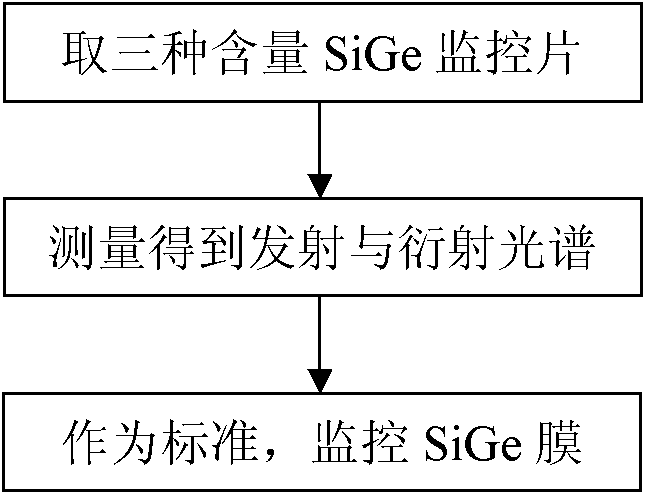

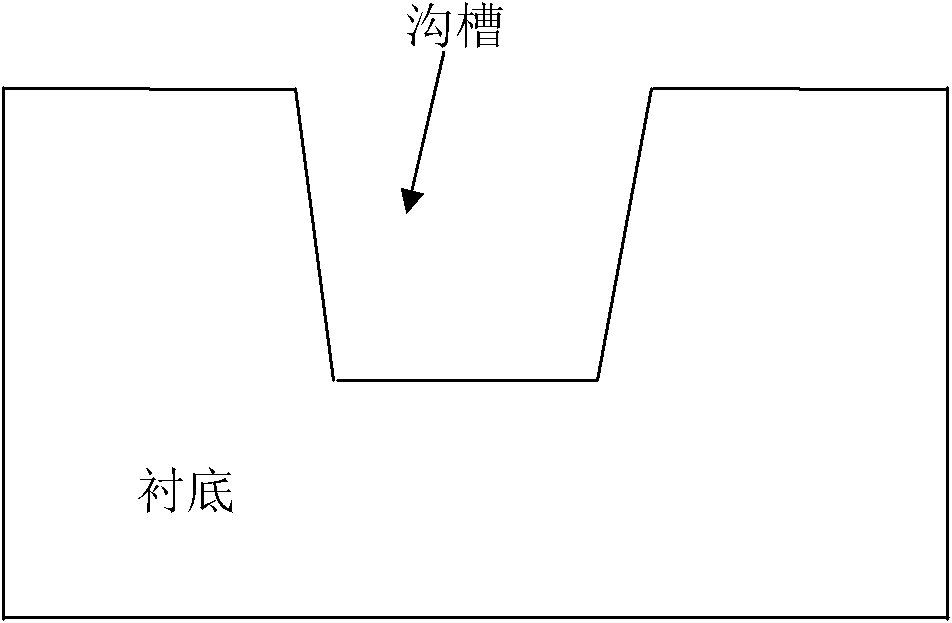

Preparation method for silicon germanium (SiGe) monitoring chip and monitoring method adopting chip

ActiveCN102456539AAccurate and convenient monitoringImprove sex-to-noise ratioSemiconductor/solid-state device detailsSolid-state devicesGraphicsGrating

The invention discloses a preparation method for a silicon germanium (SiGe) monitoring chip. The preparation method comprises the following steps of: 1) at least designing a group of raster graphics; 2) defining the raster graphics designed by the step 1) on a substrate, and etching the substrate to form a raster graphics consisting of a plurality of regularly arranged trenches; 3) depositing a SiGe thin film with specific content on the substrate to form the SiGe thin film with the raster graphics; and 4) preserving a photoresist on middle parts at the bottoms of the trenches of the raster graphics of the SiGe thin film to form a photoresist raster graphics. The SiGe monitoring chip prepared by the method is highly sensitive to optical characteristic changes caused by lattice mismatchingin pre-bake, and the changes of a pre-bake process can be accurately and conveniently monitored. The invention also discloses a monitoring method for the SiGe thin film.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Wafer press welding and bonding method and structure thereof

ActiveCN100517623CWon't breakIncreasing the thicknessSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorBonding process

A three-dimensional interconnection method between wafers comprises the following steps that: firstly, two semiconductor wafers are bonded face to face, secondly the back of one of two semiconductor wafers is thinned to complete the three-dimensional interconnection between the wafers, thirdly the backs of the semiconductor wafers which complete interconnection are bonded spoon-fashion, thinned, and interconnected and the bonding spoon-fashion-thinning-interconnecting technique is repeated; the surfaces of a plurality of semiconductor wafers are overlaid in order. The invention also provides a three-dimensional interconnection structure between the wafers; the surfaces of two semiconductors are bonded face to face; a second connecting welding block is formed on a back underlay of one of the semiconductor wafers; a plurality of semiconductor wafers in order are overlaid on the semiconductor wafer underlay with the second connecting welding block. The method of the invention can not cause the damage to the wafer in a bonding process; a formed semiconductor wafer bonding structure can save the chip area of the semiconductor wafer.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

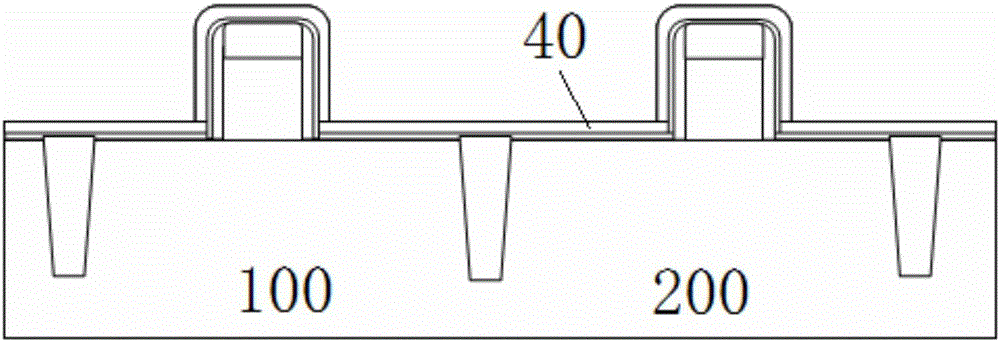

Method for preventing growth of redundant SiGe in shoulder part of grid

InactiveCN106340492AImprove protectionAvoid generatingSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSemiconductor

The invention provides a method for preventing growth of redundant SiGe in the shoulder part of a grid. The method comprises that a semiconductor substrate including a PMOS area and an NMOS area is provided, an NMOS grid structure and a PMOS grid structure are formed on the substrate, first hard masks are formed on the NMOS grid structure and the PMOS grid structure respectively, and first sidewalls are formed in the sidewalls of the NMOS grid structure and the PMOS grid structure respectively; a first material layer is formed on the PMOS area and the NMOS area; a second material layer is formed on the first material layer; the second material layer is etched to form second sidewalls in the sidewalls of the NMOS grid structure and the PMOS grid structure respectively; a second hard mask layer is formed on the PMOS area and the NMOS area; the second hard mask layer is patterned to remain only part of hard mask layer on the NMOS area, and the part of hard mask layer is etched to form a SiGe source-drain U-shaped trench in the PMOS area; and the SiGe source-drain U-shaped trench is etched for form a similarly E-shaped trench, and epitaxial growth of SiGe in the PMOS source-drain area is executed.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

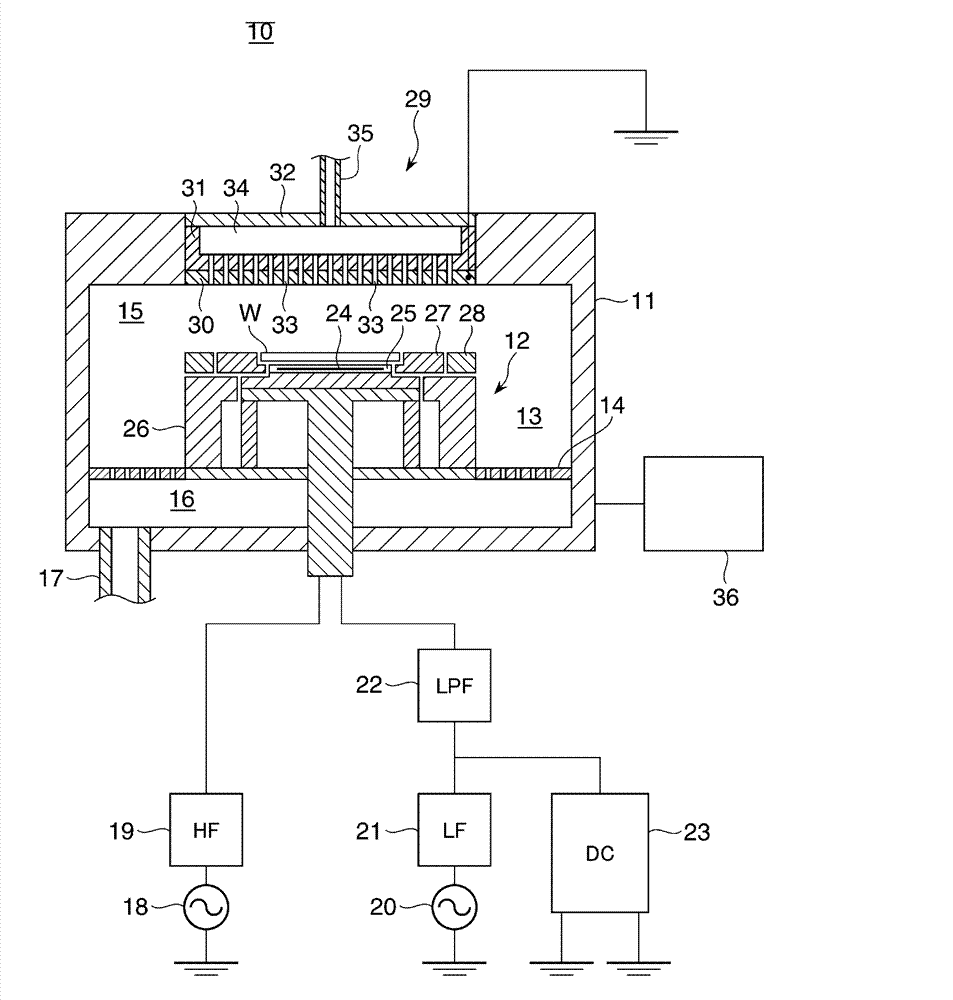

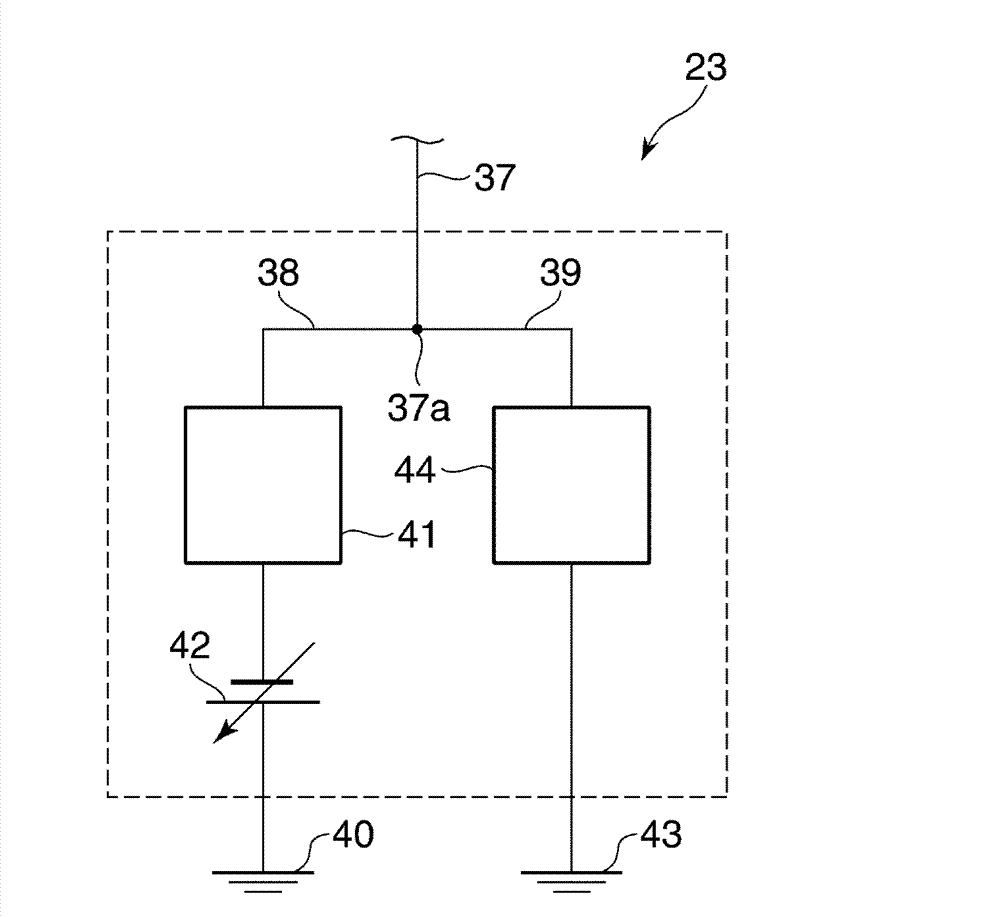

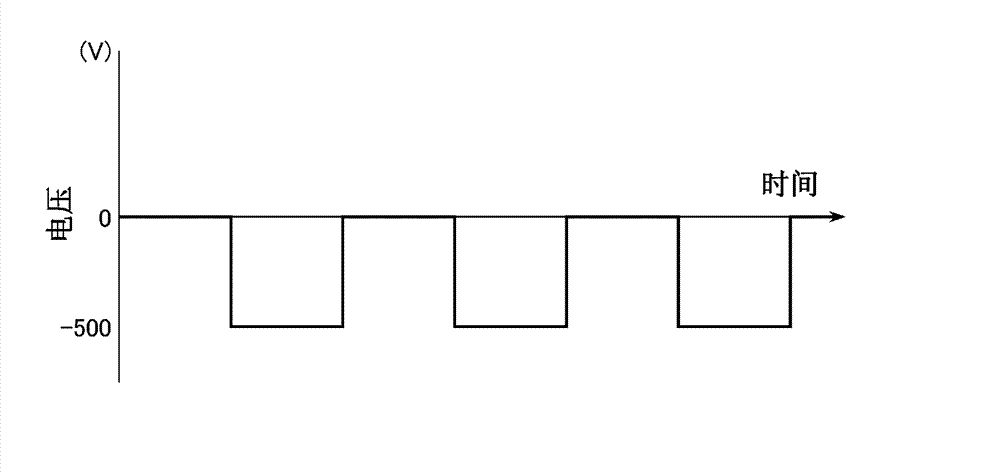

Substrate processing method

ActiveCN102737942AReduced strengthImprove process controlElectric discharge tubesSemiconductor/solid-state device manufacturingHigh frequency powerEngineering

Owner:TOKYO ELECTRON LTD

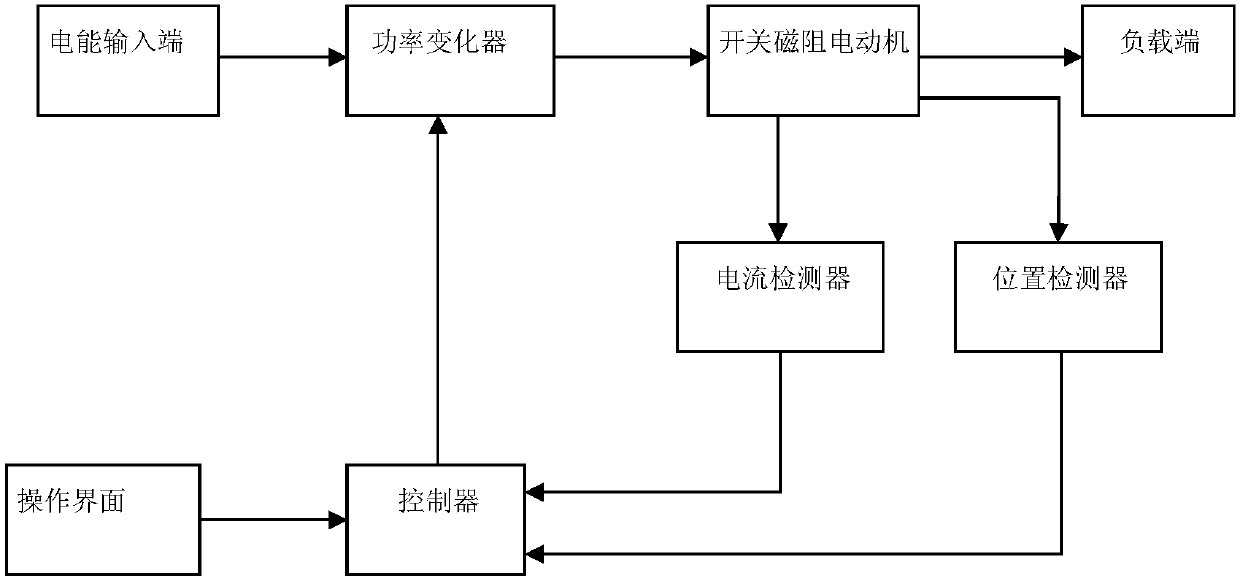

Switched reluctance motor control system used for oil pumping of oil field

InactiveCN107565858AImprove informatizationIncrease the level of automationAC motor controlElectronic commutatorsControl systemEngineering

The invention involves the field of oilfield equipment application technology, and a kind of oil field oil pumping magnetic resistance motor control system is released.The system includes switching magnetic motors, power converters connected to the switch magnetic motor motor, the load terminal connected to the switch magnetic resistance motor, and the controller used to control the power converter;The connection between the controller is used to detect the position detector of the oil volume position and the current detector used to detect the current size.The advantage of the present invention is to improve the informationization, automation level, and the control level of the oil pumping process, thereby achieving energy saving and consumption reduction and improving production efficiency.

Owner:王慧玲

Standard sample for aluminium electrolyte analysis

InactiveCN1546998AImprove process controlAccurate and reliable control dataMaterial analysis using radiation diffractionAluminum fluorideControl data

The invention refers to a kind of media in process of manufacturing aluminum electrolyzation, especially refers to a kind of standard sample in industrial aluminum electrolyzation analysis. The technology project of the invention is: the industrial aluminum electrolyzation analysis sample uses low molecular ratio industrial cryolite as base, adds in sodium fluoride, aluminum fluoride, calcium fluoride, magnesium fluoride, lithium fluoride, aluminum oxide; the cryolite 80%, aluminum fluoride 6-12%, aluminum oxide 3-5%; the additives calcium fluoride, magnesium fluoride, lithium fluoride 5-7%. The analysis is simple and convenient, low cost, quick, provides accurate and reliable control data for aluminum electrolyzation effectively, and upgrades the aluminum electrolyzation process level.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

A Salvage Repair Method for Thin Gauge Flat Roll Defects

The invention belongs to the technical field of ferrous metallurgy rolling, and particularly relates to a remedying and repairing method for a flaw of a thin-specification flat roll. The method specifically comprises the following steps that a, the inner diameter of the flat roll is measured; b, the direction of the flat roll is adjusted; c, the inner diameter of the flat roll is subjected to external force correction; d, the flat roll is manually coiled to a coiling block of an uncoiler, and coiling is finished; and e, production control parameters of the flat roll are input. The remedying and repairing method solves the problems that due to thin-specification steel roll rolling abnormality, in the horizontal stacking and cooling process, the inner diameter of an inner ring of a flat roll formed in the manner that an inner ring of a steel roll collapses is irregular, the flat roll cannot get on a unit to be remedied or sold externally, and consequently the product can only be judged to return to a furnace, and the technology control level of a flat roll splitting unit is improved. The technology control technique is widely applied, delivery of externally entrusted products on schedule is ensured, the production cost is reduced, and the operation current situation that according to a conventional flat roll treatment operation manner, a large amount of labor / a large number of material resources are consumed, time is long, and serious safety hidden danger exists is avoided.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

Preparation method for silicon germanium (SiGe) monitoring chip and monitoring method adopting chip

ActiveCN102456539BAccurate and convenient monitoringImprove sex-to-noise ratioSemiconductor/solid-state device detailsSolid-state devicesGratingLattice mismatch

The invention discloses a preparation method for a silicon germanium (SiGe) monitoring chip. The preparation method comprises the following steps of: 1) at least designing a group of raster graphics; 2) defining the raster graphics designed by the step 1) on a substrate, and etching the substrate to form a raster graphics consisting of a plurality of regularly arranged trenches; 3) depositing a SiGe thin film with specific content on the substrate to form the SiGe thin film with the raster graphics; and 4) preserving a photoresist on middle parts at the bottoms of the trenches of the raster graphics of the SiGe thin film to form a photoresist raster graphics. The SiGe monitoring chip prepared by the method is highly sensitive to optical characteristic changes caused by lattice mismatching in pre-bake, and the changes of a pre-bake process can be accurately and conveniently monitored. The invention also discloses a monitoring method for the SiGe thin film.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Manufacturing method for high-magnetic induction low-cost 250 MPa cold-rolled magnetic pole steel

ActiveCN102650016BFully exert the strengthening effectImprove shape qualityRoll mill control devicesMetal rolling arrangementsReduction rateHeating time

The invention discloses a manufacturing method for high-magnetic induction low-cost 250 MPa cold-rolled magnetic pole steel. The manufacturing method comprises the steps as follows: heating a plate blank to be 1200-1260 DEG C and insulating; hotly rolling, wherein the final rolling temperature is 850-900 DEG C, the coiling temperature is 550-630 DEG C and a jet water cooling way is adopted as a cooling way; cooling to be 60-80 DEG C for acid washing, wherein an air cooling way is adopted as the cooling way; coldly rolling, wherein the cold rolling reduction rate is 50-75%; continuously annealing, wherein the temperature of an uniform heating section is 720-780 DEG C and the uniform heating time is 60-200 s; and flattening by a flattening elongation rate of 0.8-1.4% to prepare the 250 MPa cold-rolled magnetic pole steel. The produced magnetic pole steel has lower yield strength ReL of more than 250 MPa and magnetic induction strength B50 of more than 1.70 T, and is suitable for manufacturing a magnetic pole iron core of a rotor body of a large water-wheel generator.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com