Blast furnace burden granularity video detection device and blast furnace burden granularity video detection method

A technology of video detection and blast furnace, which is applied in the direction of inspection equipment, etc., can solve the problems of low efficiency, inability to meet modern large-scale production, cumbersome and time-consuming problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

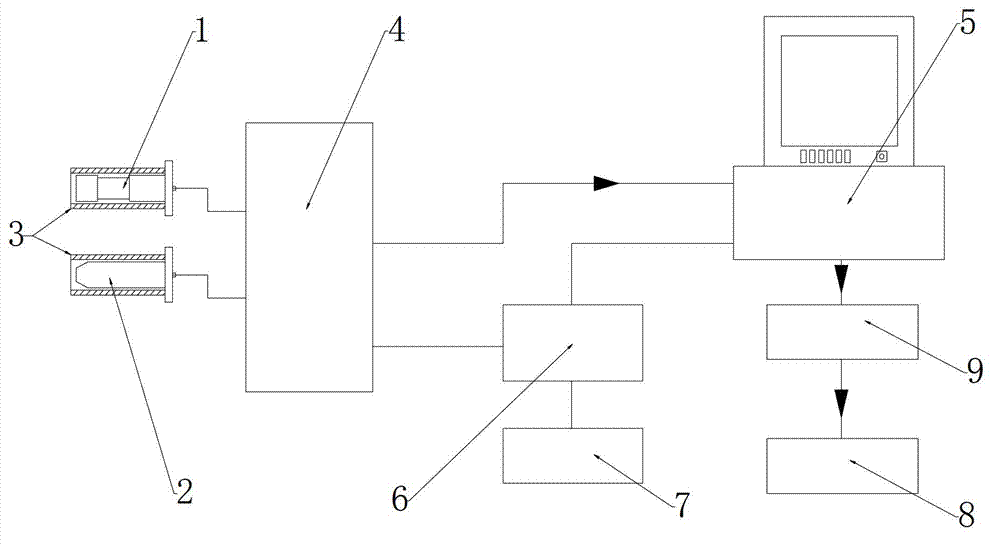

[0014] see Figure 1 to Figure 5 , the blast furnace charge particle size video detection device of the present invention includes: an imaging device 1 and an illuminating device 2 installed above the conveying belt conveyor of the blast furnace feeding system, a protective cover 3 providing protection for the imaging device 1 and the illuminating device 2, and a protective cover 3 for the imaging device 1 and the illuminating device 2 The lighting device 2 provides a field control box 4 with a stable power supply, a video image processing and display device 5 for analyzing and processing video images, and an indoor control box 6 for controlling the field control box 4 and the video image processing and display device 5, which is an indoor control box 6 provides a clean power supply 7 with a stable power supply, an audible and visual alarm device 8 and a signal converter 9 arranged between the video image processing and display device 5 and the audible and visual alarm device 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com