Three-phase separator comprising a skimming disc and solid discharge orifices

A separator and peeling disc technology, applied in the field of separators, can solve the problems of small mobility of the separation zone and cannot move the separation zone, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

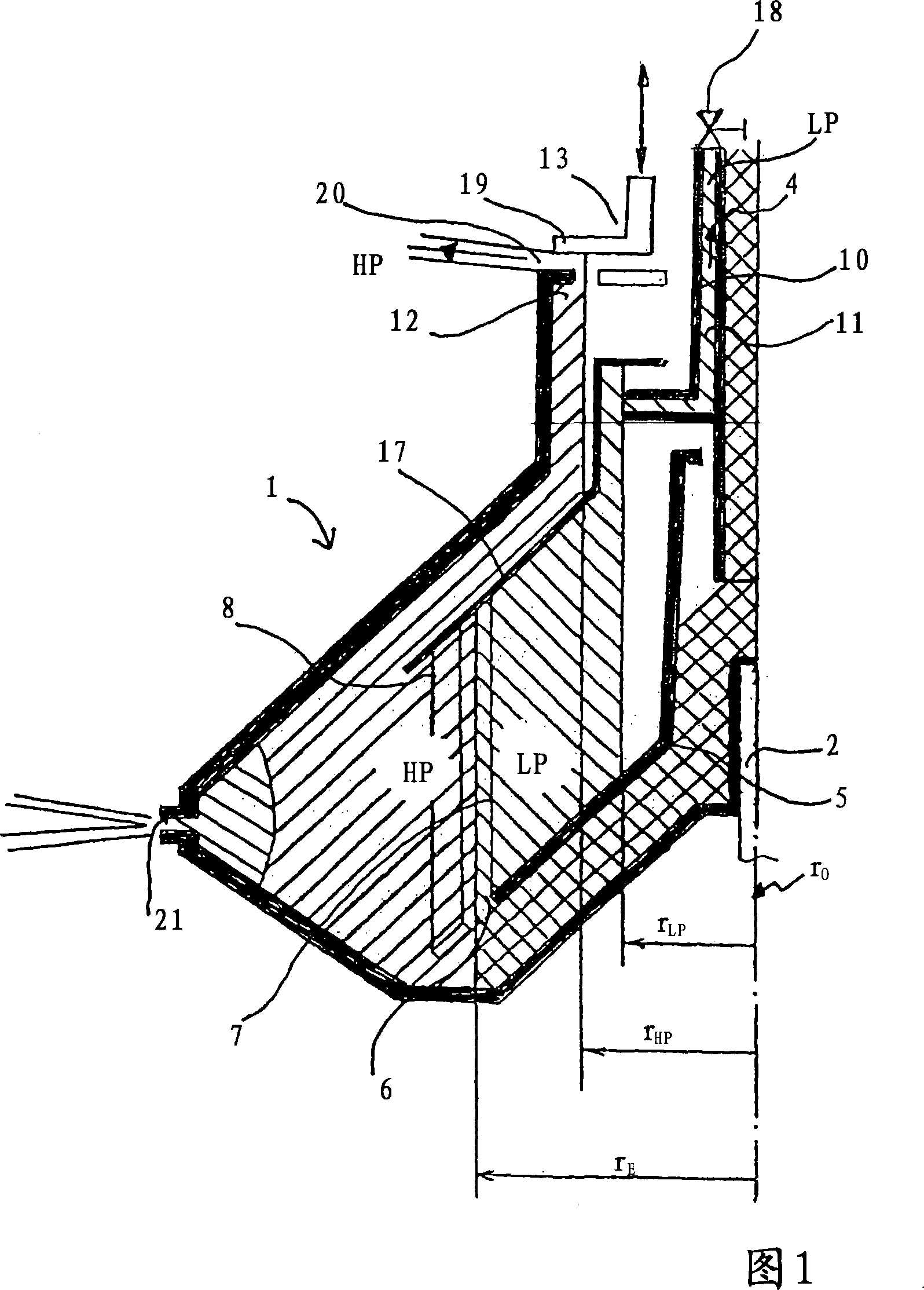

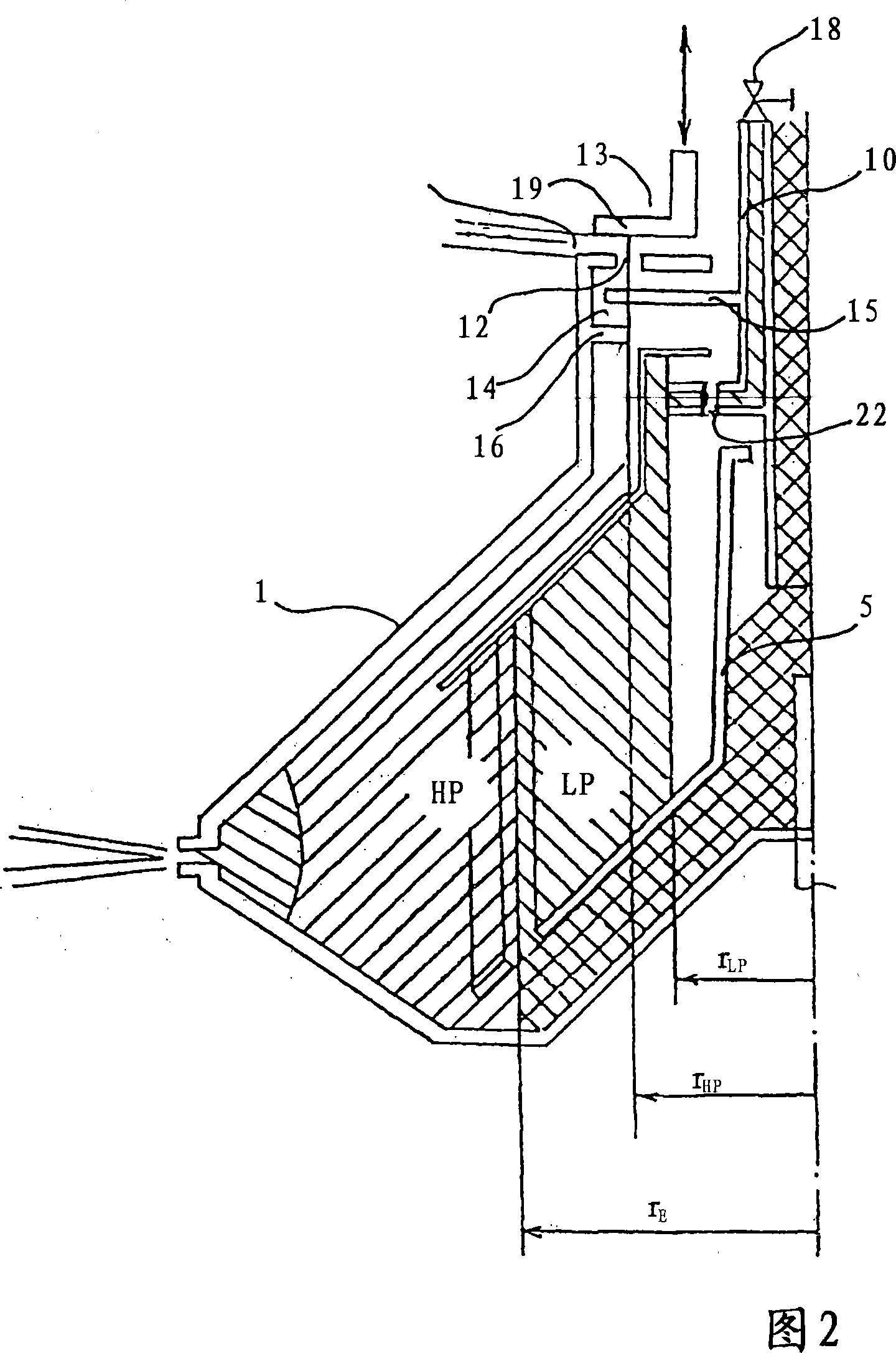

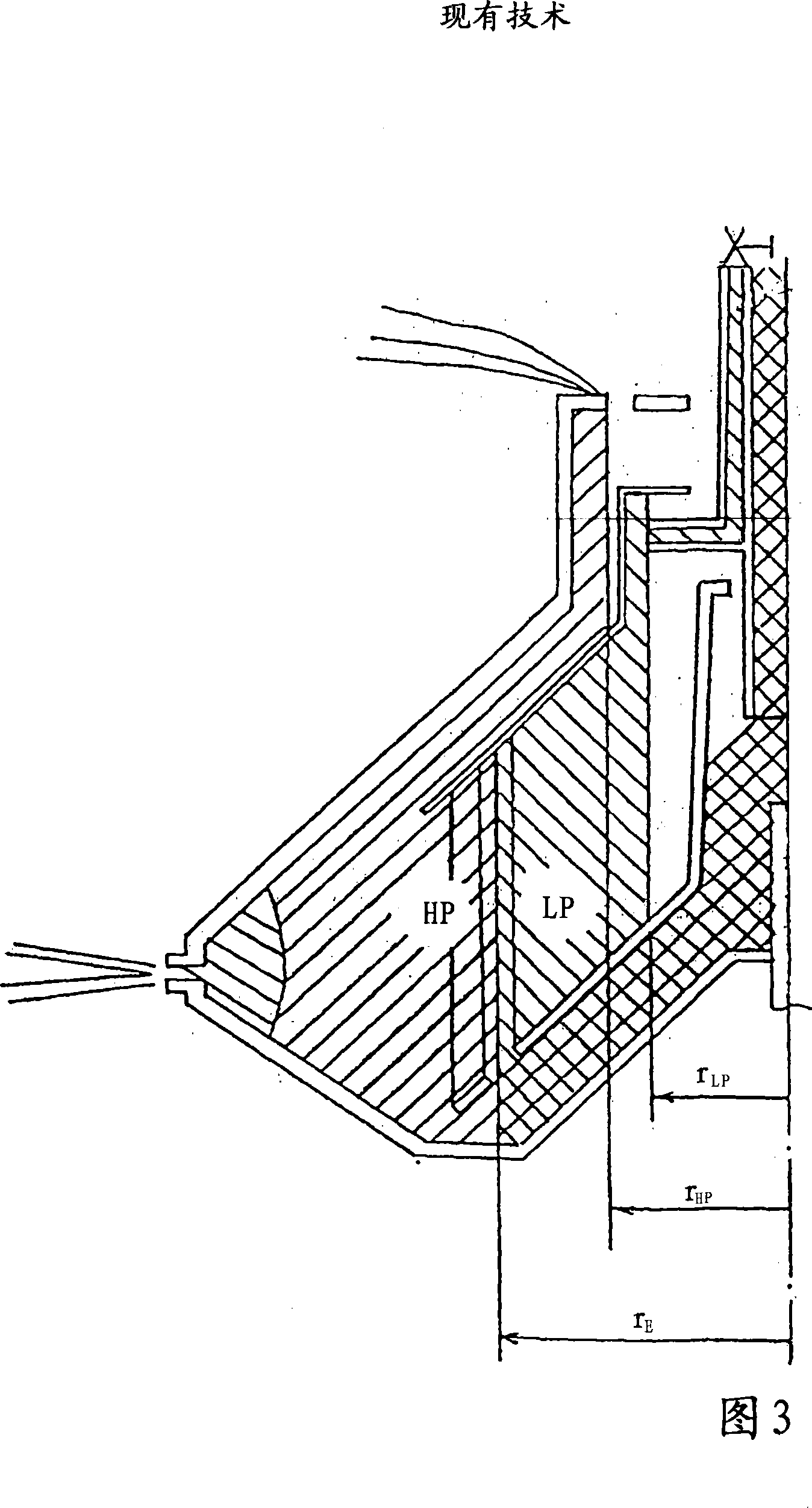

[0026] Figures 1 to 3 show separator drums 1, respectively, which have a radius r 0 has a vertically oriented axis of rotation.

[0027] The separator drums 1 are each mounted on a rotary spindle 2 , which is driven, for example in the form of FIG. 4 , directly or via a belt (not shown here) or in another way (for example, a transmission). The rotary spindle 2 can be formed conically in its upper peripheral region.

[0028] The rotating spindle 2 is pivotally mounted on one side of the drum—here below the drum—by at least one or more roller bearings 3 and thus describes a new centrifuge differently from a screw discharge decanter centrifuge in terms of residual imbalance during operation. axis, which describes an axis around a vertical line r 0 The precession motion (see Figure 4, where the inclination angle α is shown).

[0029] In addition to this type of construction, constructions are also known in which a lower drum is "suspended" as if on the upper rotating shaft. He...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com