Preparation method for silicon germanium (SiGe) monitoring chip and monitoring method adopting chip

A technology of monitor sheet and grating graphics, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as high cost of measuring equipment, unsuitable for production, and inability to characterize, so as to improve process control ability and reduce Monitoring costs, effects of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

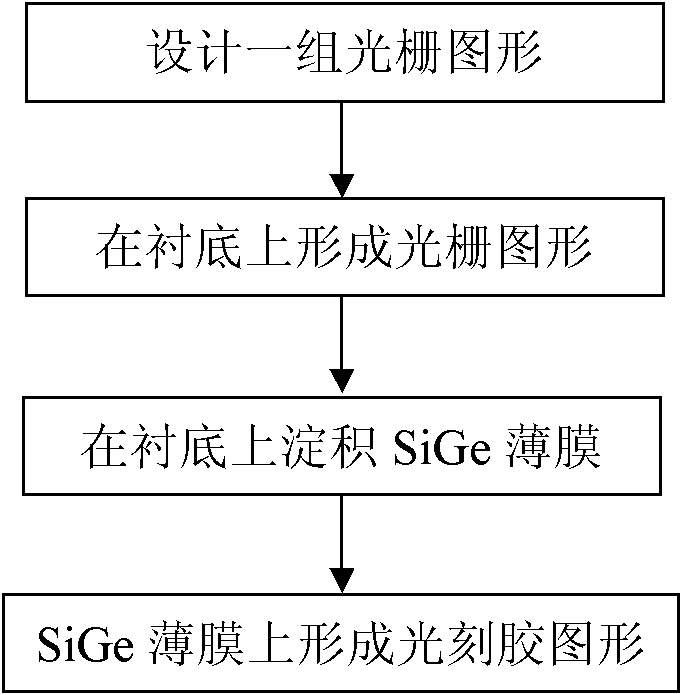

[0026] The preparation method of SiGe monitoring sheet of the present invention, this SiGe monitoring sheet is used for monitoring the content of SiGe thin film, comprises the steps (see figure 1 ):

[0027] 1) At least one set of grating graphics is designed; the lithography graphics can be regularly arranged line graphics, or regularly arranged box-like dot matrix graphics. The spatial period of the grating pattern is 0.1-100 microns, preferably 1-20 microns.

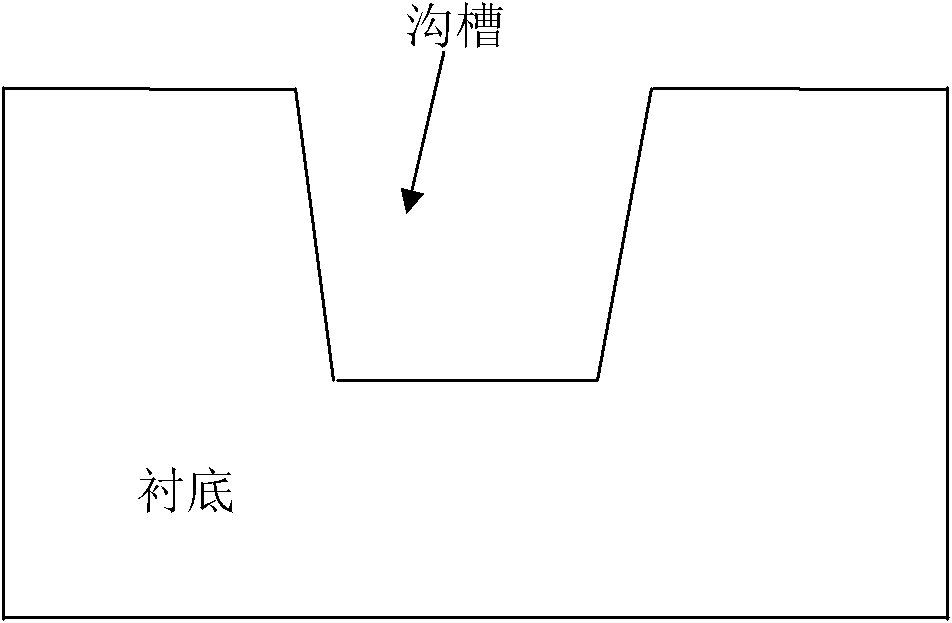

[0028] 2) Define the grating pattern in step 1 on the substrate (which can be a silicon substrate), and etch the substrate to form a grating pattern with a step difference (see image 3 ); that is, to form a grating pattern composed of a plurality of regularly arranged grooves.

[0029] 3) Depositing a SiGe film with a specific content on the substrate to form a SiGe film grating pattern;

[0030] 4) adopt photolithography process, keep photoresist in the middle of groove bottom in described SiGe film grating patte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com