A chip using a microthermal generator

A generator and chip technology, which is applied to thermoelectric devices, circuits, and electrical components that only use the Peltier or Seebeck effect, can solve the problems of lack of thermoelectric power generation, complex chip arrangement structure, and complex circuit equipment structure. The comprehensive energy recovery rate, the realization of the overall cooling capacity, and the effect of convenient and accurate monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

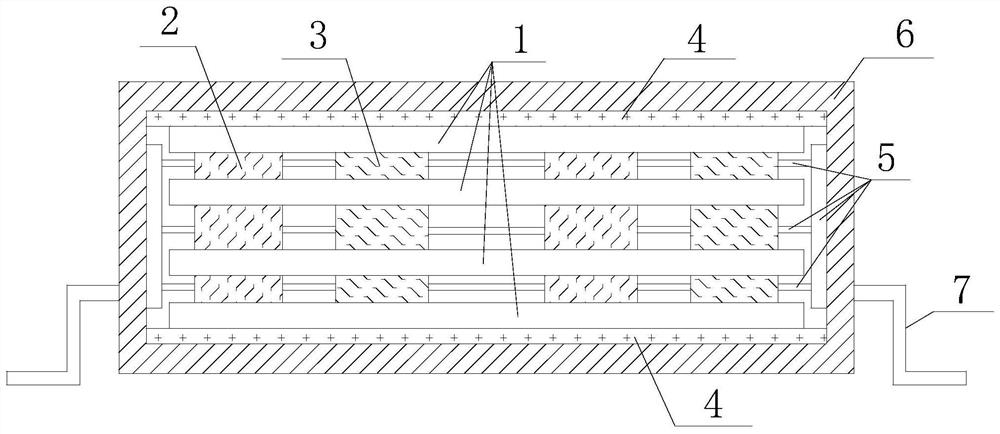

[0014] Such as figure 1 Described a kind of chip that adopts micro-hot spot generator, comprises operating chip 1, N-type semiconductor thin film 2, P-type semiconductor thin film 3, nano-carbon heat dissipation film 4, conductive metal foil sheet 5 and packaging case 6, wherein operating chip 1 At least three, and each operation chip 1 is coaxially distributed and evenly distributed from top to bottom. The semiconductor thin film 2 and the P-type semiconductor thin film 3 respectively abut against the upper and lower end faces of two adjacent operation chips 1, and the N-type semiconductor thin film 2 and the P-type semiconductor thin film 3 are spaced apart from each other, and are located in one of the same planes. The N-type semiconductor fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com