GaN-based light emitting diode and preparation method thereof

A light-emitting diode, gallium nitride-based technology, applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as electrodes, reduce production costs, reduce process steps, and avoid complex interface conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

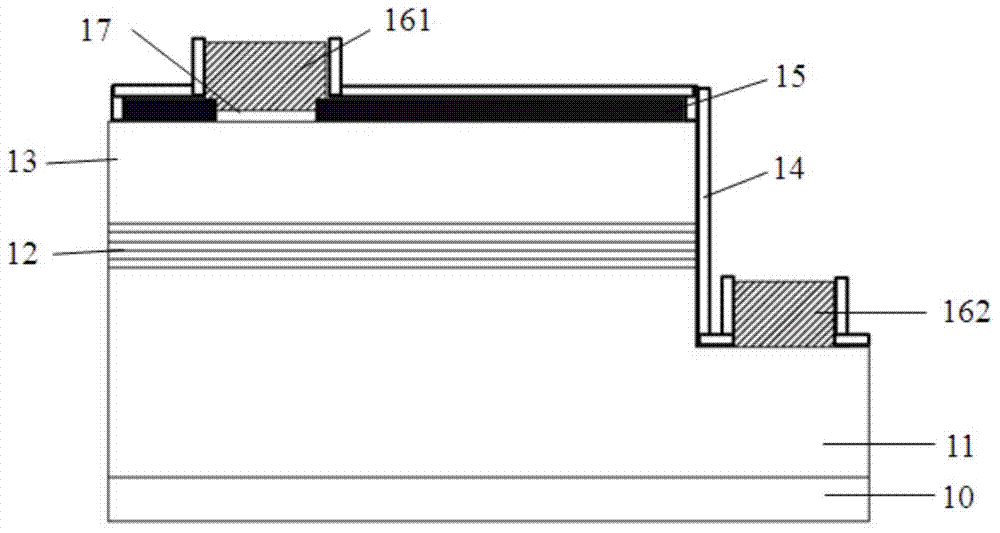

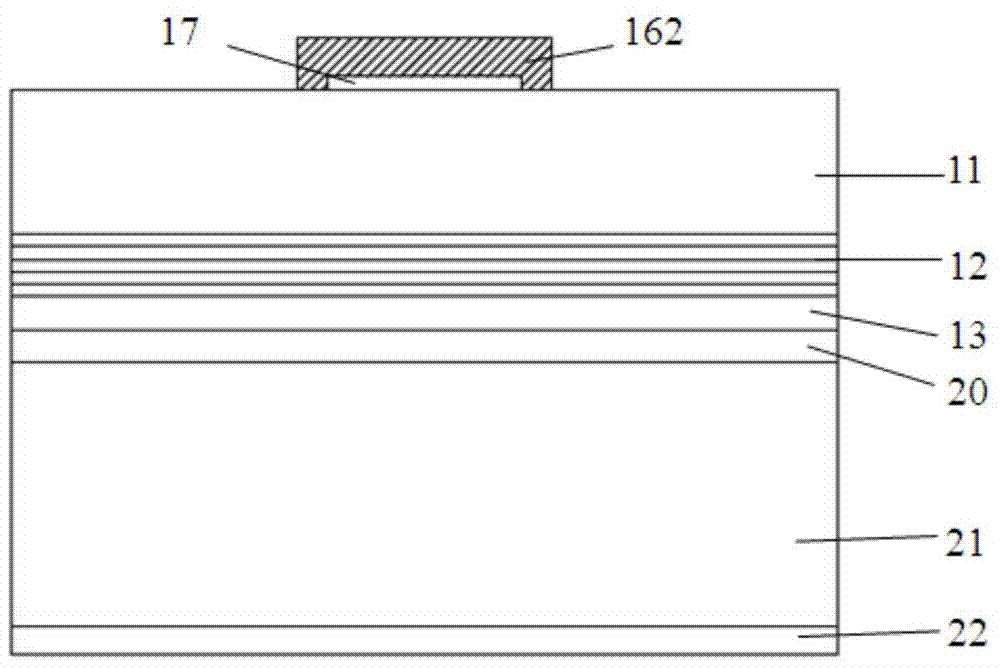

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] The preparation method of a gallium nitride-based light-emitting diode of the present invention uses photolithography and plasma dry etching technology to carry out surface treatment on the area under the P-type electrode of the LED chip, making it a high-resistance area to obtain a current blocking effect, so that The current flows through other low-resistance regions of the P-type gallium nitride layer, which reduces the loss of luminescence caused by the shading effect in this electrode region, indirectly improves the luminescence of other regions, and uses aluminum mirrors or silver mirrors as part of the metal structure of the P electrode , so as to achieve the purpose of high-efficiency light emission, the preparation method at least includes the following steps:

[0029] 1) Using MOCVD (Metal-organic Chemical Vapor Deposition, metal-organic compound chemi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com