Method for forming grid medium layer and estimating its electrical parameter

A gate dielectric layer and electrical parameter technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as the inability to evaluate the electrical parameters of the gate dielectric layer online, and achieve improved electrical stability and Reliability, cost savings, and the effect of reducing R&D cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

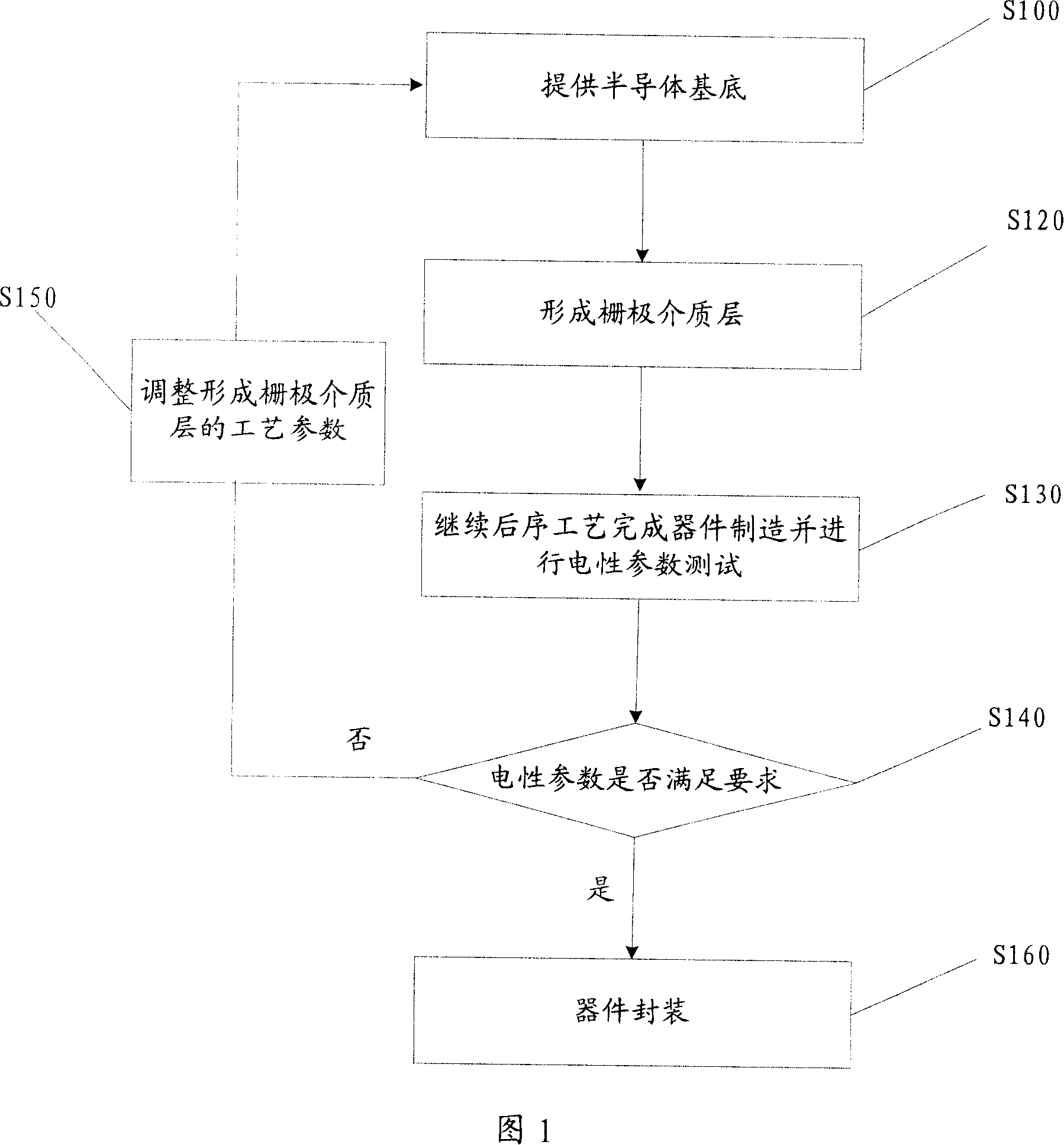

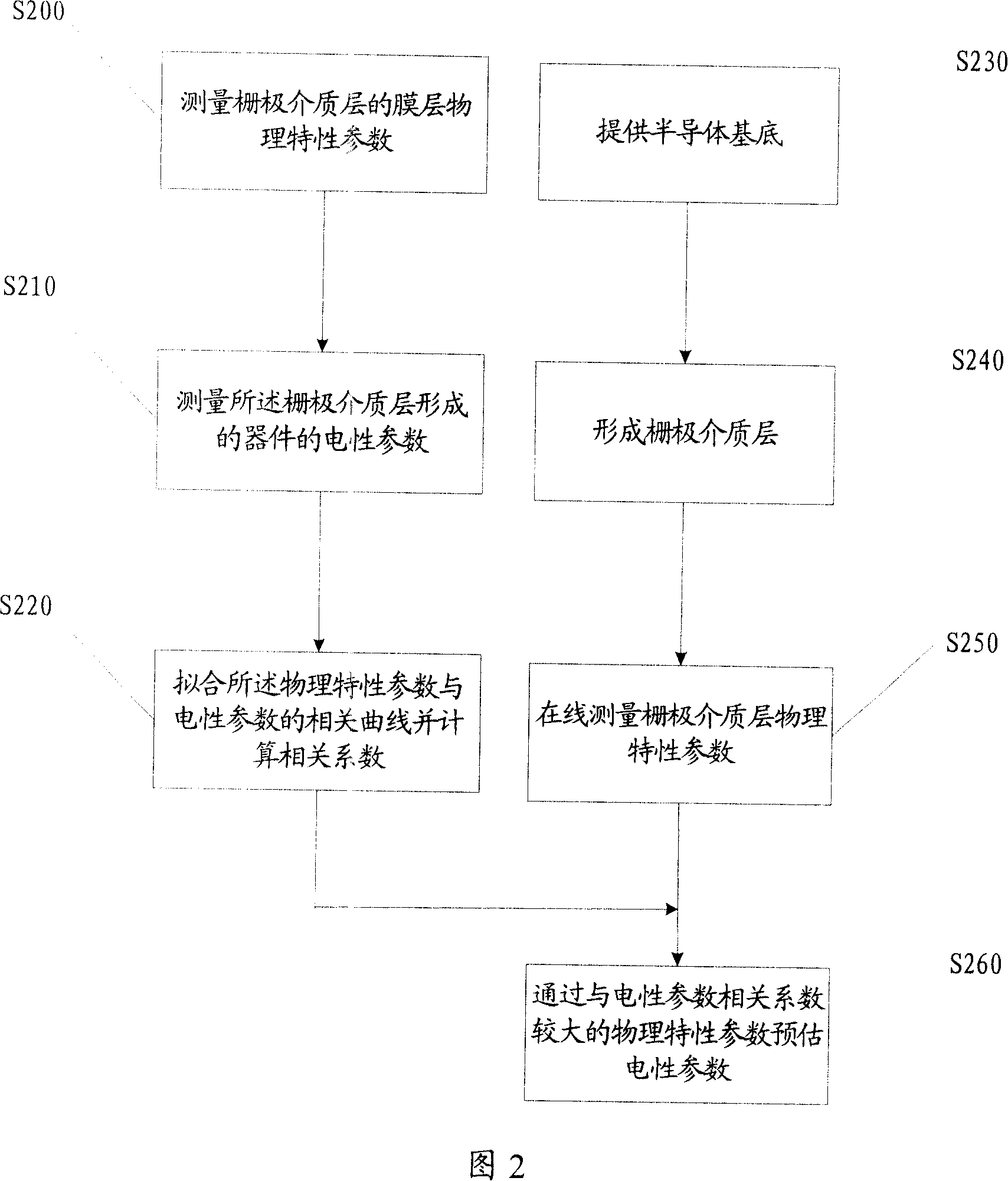

[0022] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

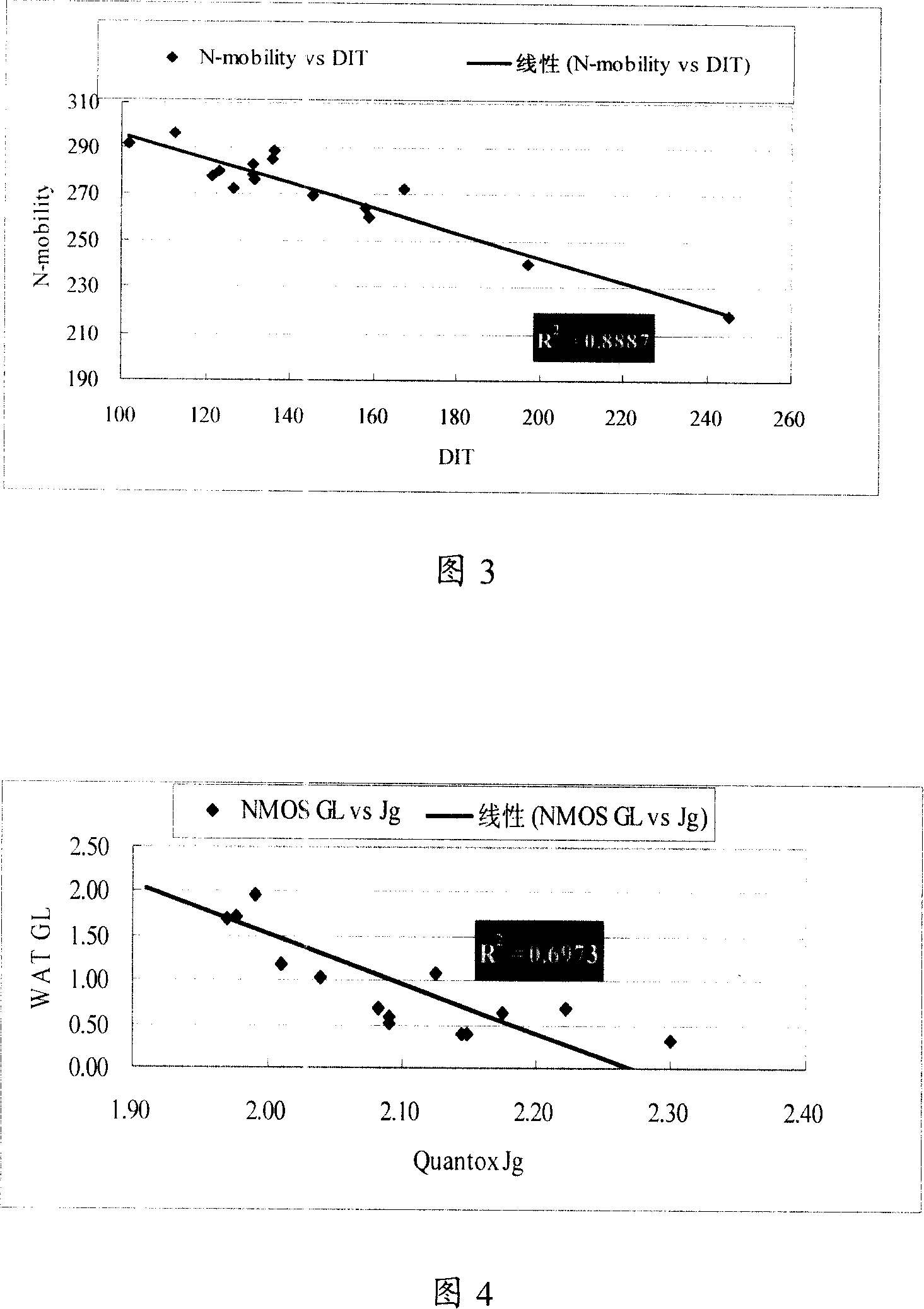

[0023] The gate dielectric layer plays a very important role as an insulating layer between the gate and the conductive channel of the substrate. The physical characteristic parameters of the gate dielectric layer will affect the formed device leakage current, turn-on voltage, carrier migration performance, and response speed The isoelectric parameter is also referred to as the electrical parameter of the gate dielectric layer in the present invention. Especially with the development of semiconductor technology to the technical node of 90nm and below, the thickness of the gate dielectric layer has been reduced to 5nm or even smaller. Controlling process parameters to form a high-quality gate dielectric layer is a problem that process pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com