Manufacturing method for high-magnetic induction low-cost 250 MPa cold-rolled magnetic pole steel

A manufacturing method and low-cost technology, applied in metal rolling, manufacturing tools, metal rolling and other directions, can solve the problems of high manufacturing cost and further improvement of magnetic properties, achieve low production cost, be conducive to quality control, improve The effect of shape quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

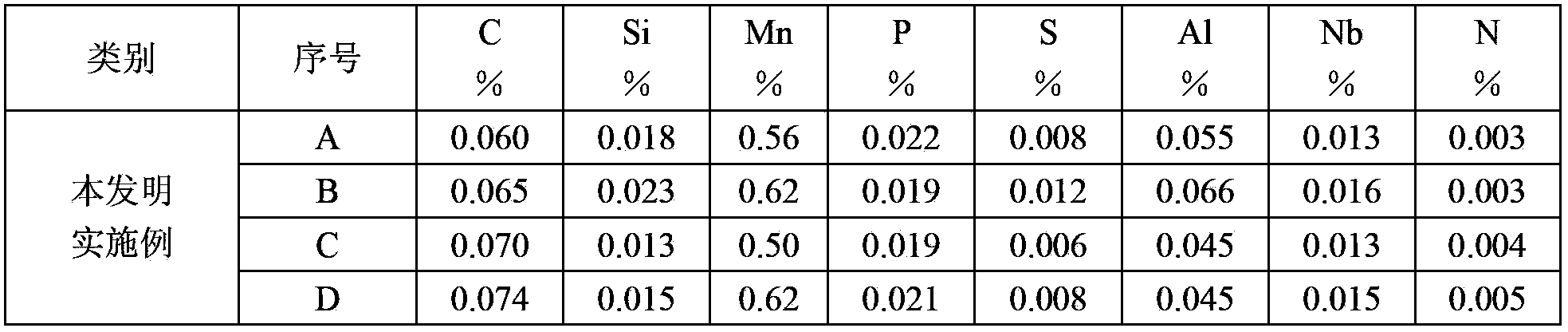

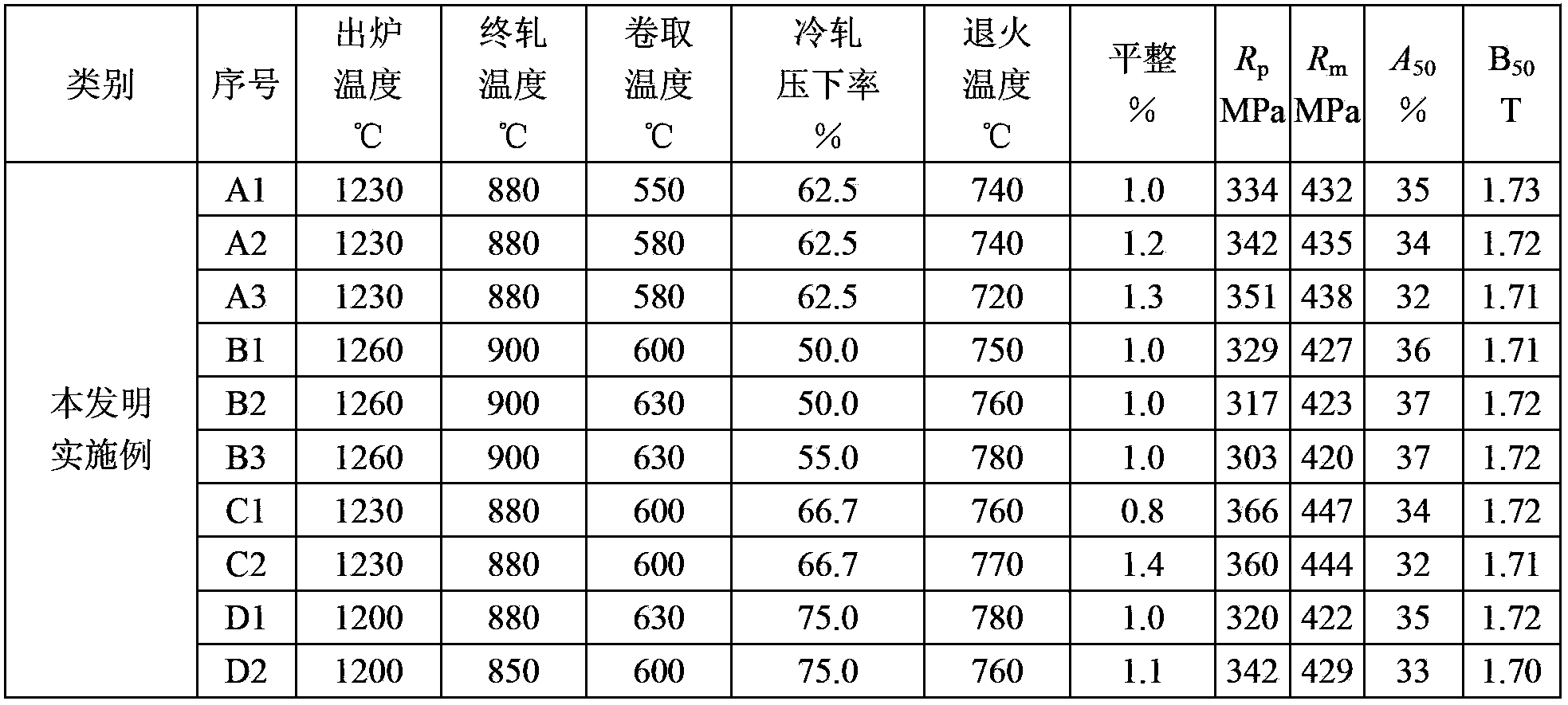

[0036] Embodiments A-D of the manufacturing method of 250MPa grade cold-rolled magnetic pole steel of the present invention, the specific steps are:

[0037] 1) The slab is heated, the heating temperature is 1200-1260°C, and the heat preservation is about 1 hour.

[0038] 2) Hot rolling steps: the final rolling temperature is 850-900°C; the deformation is rolled in 7 passes, and the steel billet is finally rolled from 30mm into a thin steel plate with a size of 2-4mm. After rolling, it is cooled to 550-630°C by water cooling Do coiling.

[0039] 3) Cool the hot-rolled steel coil to 60-80°C for pickling.

[0040] 4) The step of cold rolling: the cold rolling reduction rate is 50-75%, and the thin steel plate of 1-2mm specification is cold rolled.

[0041] 5) Carry out continuous annealing at a temperature of 720-780° C. in a continuous annealing furnace.

[0042] 6) Use 0.8-1.4% leveling elongation for leveling to make 250MPa grade cold-rolled magnetic pole steel.

[0043] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com