Technique control method for preventing CSP continuous casting machine from cast-on breakout

A technology of process control and continuous casting start-up, which is applied in the field of metallurgy, can solve the problems of poor applicability of thin slab start-up breakout prevention, improper control of start-up time of start-up casting, and increased production costs, so as to eliminate continuous casting start-up The occurrence of serious steel breakout accidents, the improvement of the overall process control level, and the effect of reducing the production cost of the enterprise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment prevents the process control method of CSP continuous casting machine from pouring and leaking steel, and its specific process steps are as follows:

[0027] 1) The chemical composition of the molten steel in the continuous casting tundish is as follows: low carbon steel series, C: 0.05%, N: 45ppm; the superheat of molten steel is controlled as follows: superheat △T: 15℃;

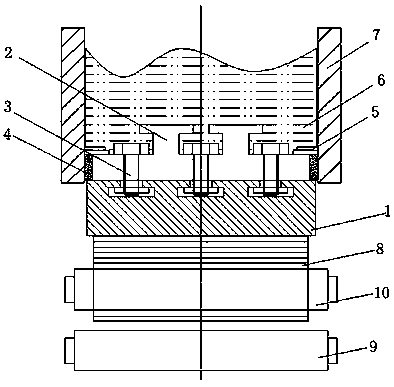

[0028] 2) Continuous casting opening dummy head sealing kit anti-seepage steel sealing operation: the thickness of dummy head 1 is 86mm. 10 Control the dummy bar 8, drive the dummy head 1 down to the lower opening of the crystallizer 7, and then use a shovel to block the asbestos fiber strip 4 to the gap between the whole periphery of the ferroalloy consumable part 2 and the copper plates on the four sides of the crystallizer 7, and finally use Two steel plates 5 with a width 2 mm smaller than the thickness of the dummy head 1 and a length of 60 mm cover the two ends of the ferroalloy...

Embodiment 2

[0033] This embodiment prevents the process control method of CSP continuous casting machine from pouring and leaking steel, and its specific process steps are as follows:

[0034] 1) The mass percentage of the chemical composition of molten steel in the continuous casting tundish is: medium carbon steel series: C: 0.17%, N: 40ppm;

[0035] 2) Continuous casting opening dummy head sealing kit anti-seepage steel sealing operation: the thickness of dummy head 1 is 86mm, before continuous casting starts, control dummy head 1 to rise to the upper mouth of crystallizer 7, and pass through the driving roller 10 Control the dummy bar 8 to drive the dummy head 1 down to the lower opening of the crystallizer 7, and then use a shovel to block the asbestos fiber strip 4 from the gap between the entire periphery of the ferroalloy consumable part 2 and the four copper plates of the crystallizer 7, and finally use Four steel plates 5 with a width 2.5 mm smaller than dummy head 1 and a lengt...

Embodiment 3

[0040] This embodiment prevents the process control method of CSP continuous casting machine from pouring and leaking steel, and its specific process steps are as follows:

[0041] 1) The chemical composition of the molten steel in the continuous casting tundish is as follows: low carbon steel series, C: 0.04%, N: 35ppm; the control of the superheat of the molten steel at the start of pouring is: superheat △T: 30℃;

[0042] 2) Continuous casting opening dummy head sealing kit anti-seepage steel sealing operation: the thickness of dummy head 1 is 86mm, before continuous casting starts, control dummy head 1 to rise to the upper mouth of crystallizer 7, and pass through the driving roller 10 Control the dummy bar 8 to drive the dummy head 1 down to the lower opening of the crystallizer 7, and then use a shovel to block the asbestos fiber strip 4 from the gap between the entire periphery of the ferroalloy consumable part 2 and the four copper plates of the crystallizer 7, and final...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com