Breakout warning method

A technology of breakout and alarm information, which is applied in the field of iron and steel metallurgical continuous casting, can solve problems such as late alarm, unsuitable for high casting speed production requirements, and long alarm judgment period of the breakout prediction system, so as to achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

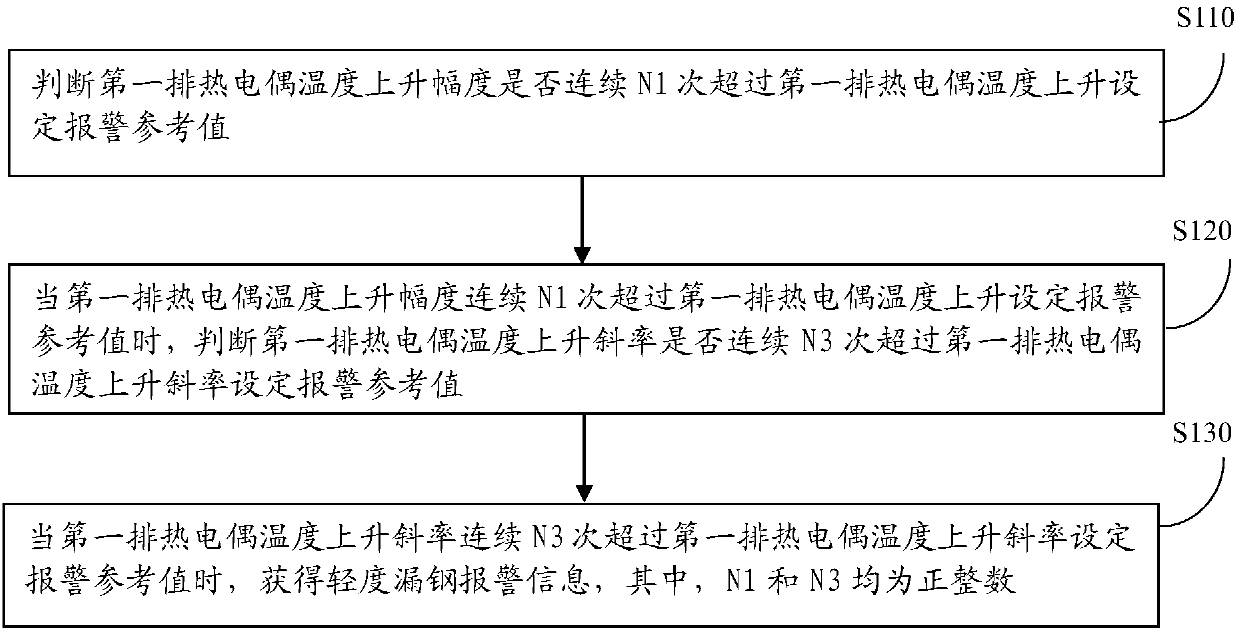

[0028] An early warning method for steel breakout is provided in the embodiment of the present invention, please refer to figure 1 , the method is applicable to a large slab continuous casting machine, wherein the large slab continuous casting machine includes a crystallizer, and a first row of thermocouples and a second row of thermocouples are arranged on the copper plate of the crystallizer, wherein the first A row of thermocouples has a first distance from the upper mouth of the crystallizer; a second row of thermocouples has a second distance from the upper mouth of the crystallizer, wherein the first distance is smaller than the second distance, wherein the The methods described include:

[0029] Step 110: Determine whether the temperature rise of the first row of thermocouples exceeds the set alarm reference value for N1 consecutive times of temperature rise of the first row of thermocouples.

[0030] Step 120: When the temperature rise of the first row of thermocouple...

Embodiment 2

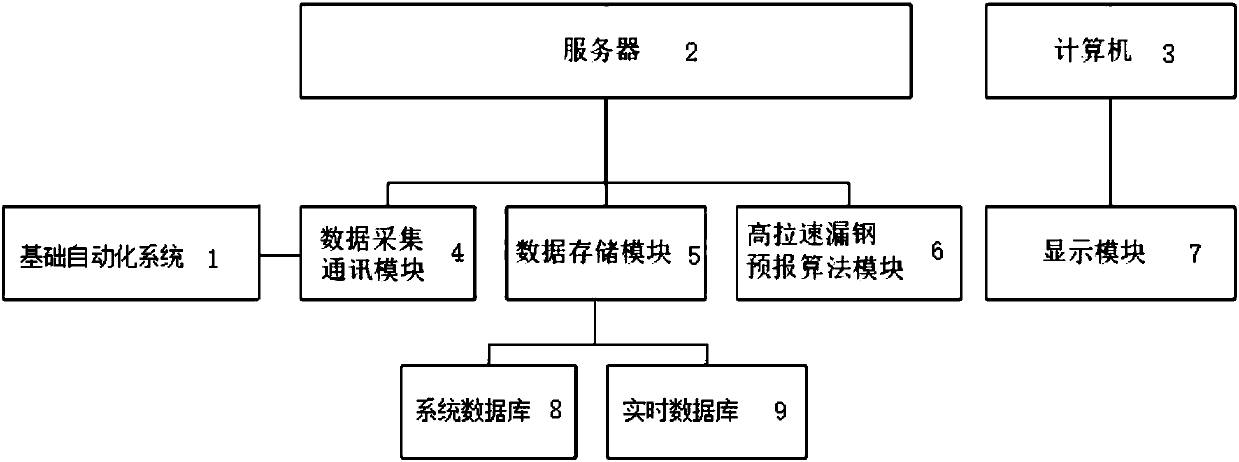

[0061] Based on the same inventive concept as that of a steel breakout early warning method in the foregoing embodiments, the present invention also provides a steel breakout early warning device, such as figure 2 shown, including:

[0062] Data acquisition communication module 4, described data acquisition communication module 4 completes the data uploading and downloading of data storage module and basic automatic control system 1 through Ethernet;

[0063] Data storage module 5, described data storage module 5 comprises system database 8 and real-time database 9; Wherein, described system database 8 stores thermocouple equipment parameter, drawing speed setting parameter, collection frequency setting parameter, steel type definition, steel Corresponding vertical propagation breakout prediction parameters, steel type corresponding horizontal propagation breakout prediction parameters; the real-time database 9 stores the temperature of the first row of thermocouples and the ...

Embodiment 3

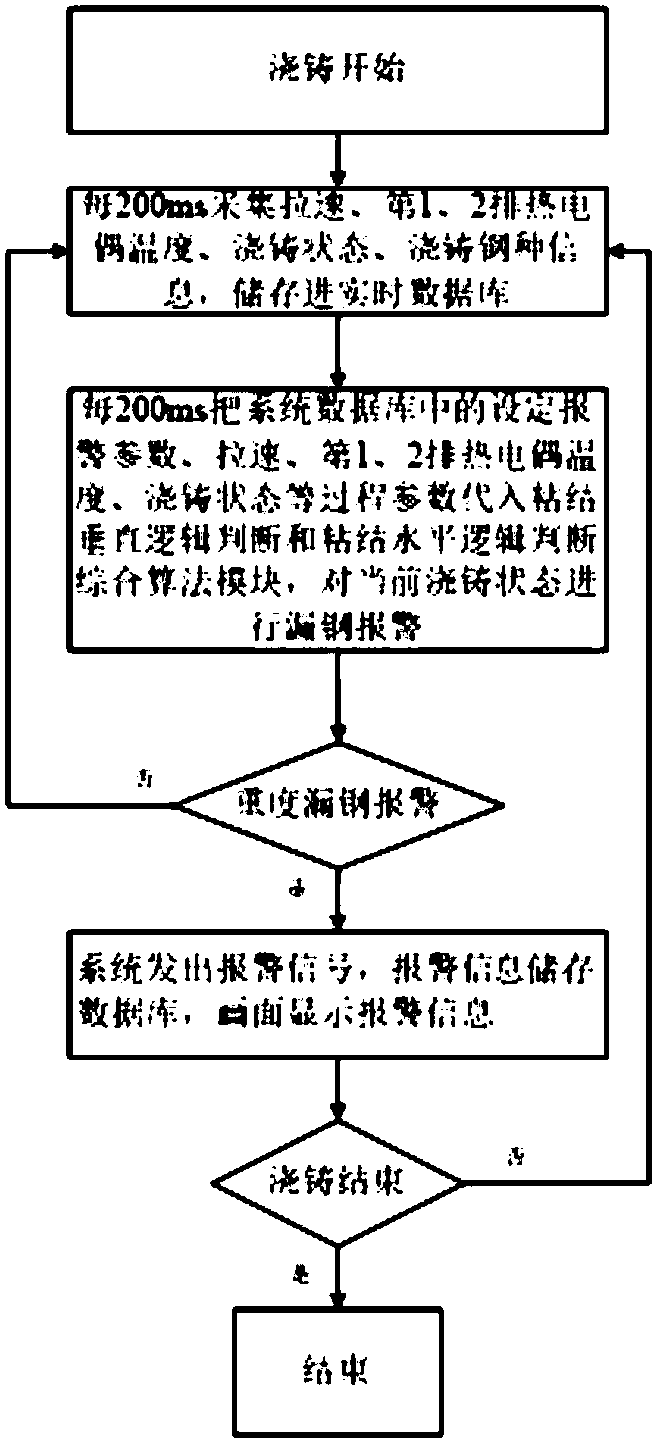

[0070] image 3 It is a kind of steel breakout early warning method in the embodiment of the present invention, and described method comprises:

[0071]A domestic steel mill provided a double-strand high-efficiency large slab continuous casting machine. The length of the mold is 900mm. Six rows of thermocouples are embedded in the copper plate of the mold. There are 108 thermocouples installed in 6 rows and 9 columns on the wide surface of the outer arc and inner arc respectively. For thermocouples, 24 thermocouples in 6 rows and 2 columns are installed on the left and right narrow sides, 132 thermocouples in total. The thermocouple row spacing is 111mm and the column spacing is 185mm. The installation position of the first row of thermocouples on the copper plate is 172.5mm away from the copper plate opening of the crystallizer, and about 72.5mm away from the meniscus during normal production.

[0072] The set logical judgment counting values are as follows: N1=3, N2=1, N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com