Method and device for measuring OCD (optical critical dimension)

A technology for measuring equipment and optical systems, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems that affect the repeatability and accuracy of industrial measurement, zero error cannot be realized, and it is difficult to consider the sensitivity difference of spectral signals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

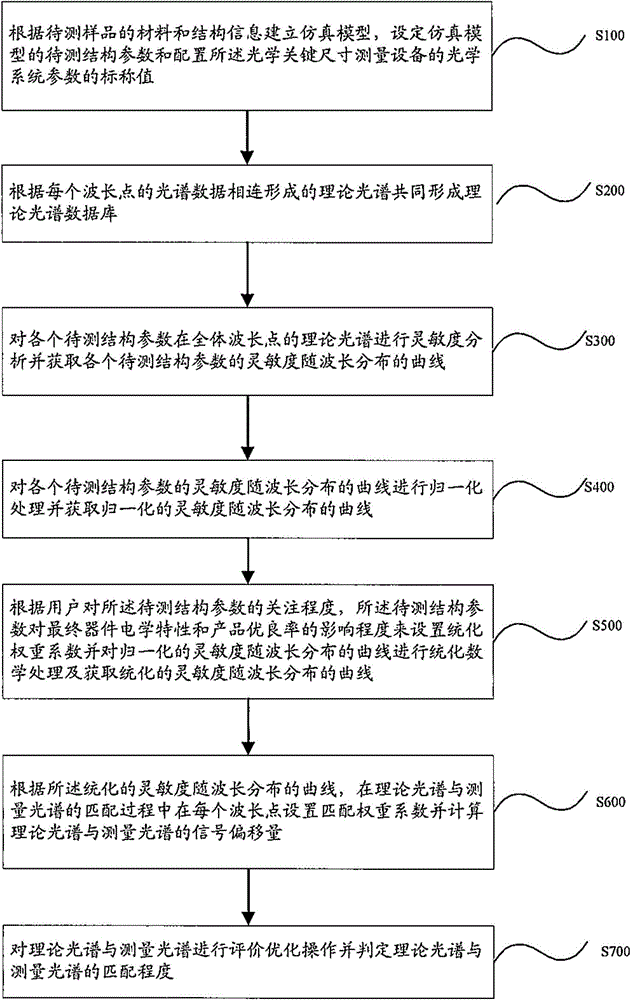

[0064] As required, specific embodiments of the present invention will be disclosed here. However, it should be understood that the embodiments disclosed herein are merely typical examples of the present invention, which can be embodied in various forms. Therefore, the specific details disclosed here are not considered to be restrictive, but merely serve as the basis for the claims and as a representative basis for teaching those skilled in the art to apply the present invention in any appropriate manner in practice. Including the use of various features disclosed here in combination with features that may not be clearly disclosed here.

[0065] In the following detailed description of the preferred embodiments, reference will be made to the attached drawings constituting a part of the present invention. The attached drawings illustrate specific embodiments capable of implementing the present invention by way of example. The illustrated embodiments are not intended to be exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com