Method for preparing fermented beverage using rice distiller's grains and fermented beverage

A technology for fermenting beverages and distiller's grains, which is applied in the field of beverage and food processing, can solve problems such as complex preparation processes, and achieve the effects of simple process flow, energy saving, and improvement of beneficial ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

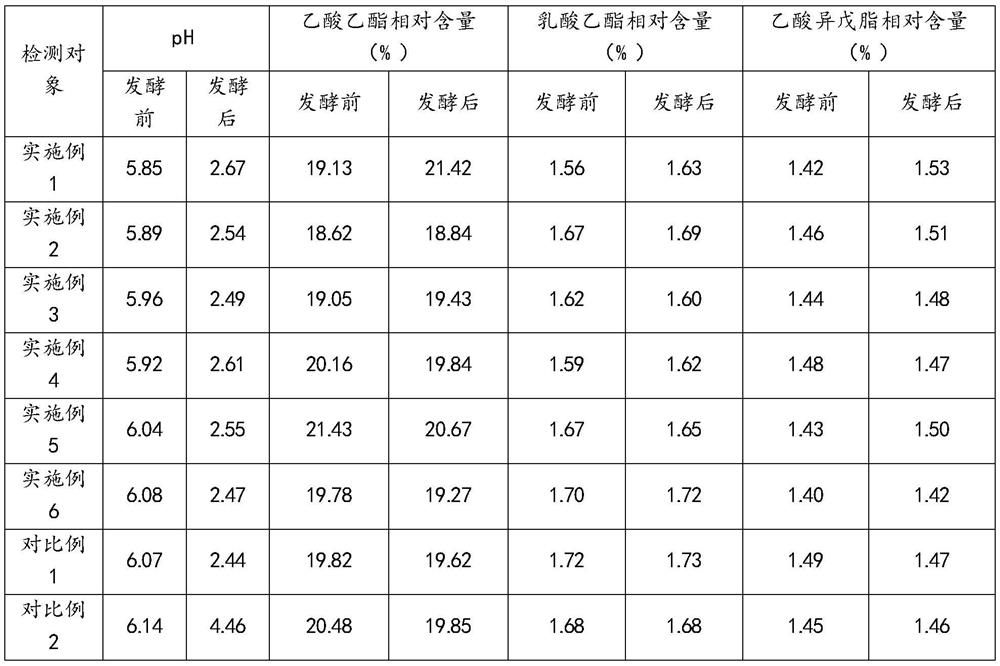

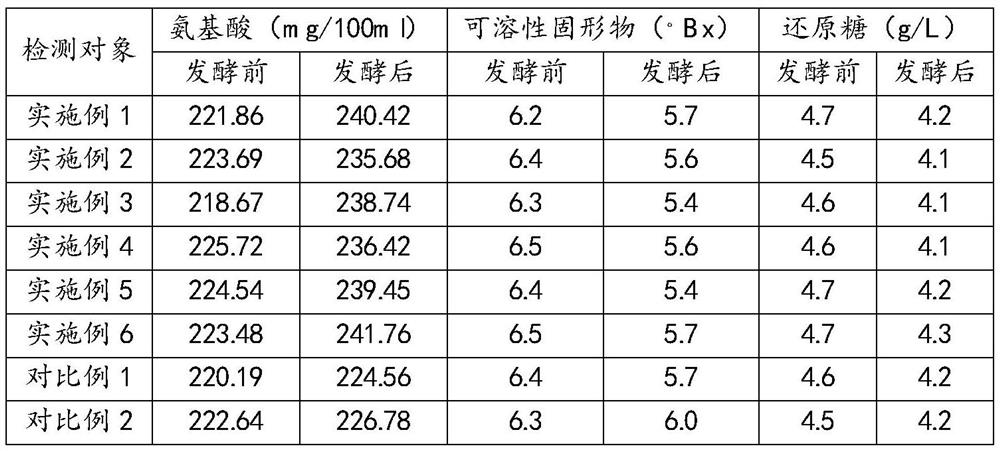

Examples

Embodiment 1

[0022] The method for preparing fermented beverages using rice distiller’s grains in this embodiment includes:

[0023] (1) Fill the fermenter with the distilled rice shochu liquor according to the filling factor of 50% by volume, and add 0.8% ethanol to the fermenter with the volume ratio of the rice distiller’s liquor. The volume ratio of vinasse is 4%, inoculated with acetic acid bacteria, at a temperature of 28℃, aeration rate of 0.4vvm, and tank pressure of 0.1Kg / cm 2 , Continuous stirring under the condition of rotation speed of 500r / min, culture for 20h.

[0024] (2) Inoculate lactic acid bacteria in a volume ratio of 2% of the rice distiller's glutinous liquid, stand for 3 hours at a temperature of 32° C., add sucrose with a volume ratio of 4% of the rice distiller's spent liquid to obtain a fermented beverage.

[0025] The acetic acid species in this example is Acetobacter pasteurii CICC20056.

[0026] The lactic acid bacteria species in this example is Lactobacillus acidophi...

Embodiment 2

[0028] The method for preparing fermented beverages using rice distiller’s grains in this embodiment includes:

[0029] (1) Fill the fermenter with the distilled rice shochu liquor according to the filling factor of 55% by volume, and add 1% ethanol in the fermenter with the volume ratio of 1% of the rice distiller’s liquor. The volume ratio of vinasse is 5%, inoculated with acetic acid bacteria, at a temperature of 29℃, aeration volume of 0.45vvm, and tank pressure of 0.11Kg / cm 2 , Stirring continuously at a speed of 550r / min, culture for 22h.

[0030] (2) Inoculate lactic acid bacteria at a volume ratio of 3% of the rice distiller’s glutinous liquid, culture it for 3.5h at a temperature of 33°C, add sucrose at a volume ratio of 5% of the rice distiller’s spent liquid, and mix well to obtain fermentation Drink.

[0031] The acetic acid species in this example is Acetobacter acetobacter CICC21684.

[0032] The lactic acid bacteria species in this example is Lactobacillus plantarum AT...

Embodiment 3

[0034] The method for preparing fermented beverages using rice distiller’s grains in this embodiment includes:

[0035] (1) Fill the fermenter with the distilled rice distiller’s lees according to the volume ratio of 60%, and add 1.2% ethanol in the fermenter with the volume ratio of the rice distiller’s lees. The volume ratio of vinasse is 6%, inoculated with acetic acid bacteria, at a temperature of 29℃, aeration volume of 0.48vvm, and tank pressure of 0.12Kg / cm 2 , Continuous stirring at a speed of 580r / min, culture for 24h.

[0036] (2) Inoculate the lactic acid bacteria in a volume ratio of 5% of the rice distiller's glutinous liquid, stand for 4 hours at a temperature of 34° C., and add sucrose with a volume ratio of 6% of the rice distiller's lees to obtain a fermented beverage.

[0037] Further, in this embodiment, step (2) also includes: clarification and filtration after 4 hours of standing culture.

[0038] The acetic acid strain in this example is Acetobacter CICC23563.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com