Stabilizer for pasteurized yoghurt, pasteurized yoghurt and preparation method of pasteurized yoghurt

A pasteurizing acid and pasteurizing technology, which is applied in the directions of milk preparations, Streptococcus/Lactococcus, bacteria used in food preparation, etc. It is difficult to guarantee the quality and other problems, so as to achieve a good peptizing effect, reduce the precipitation of whey, and reduce the change of the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A stabilizer for pasteurized yogurt, prepared from the following raw materials in parts by weight: 30-40 parts of hydroxypropyl distarch phosphate, 15-25 parts of pectin, 4-7 parts of instant agar, and 10-15 parts of gelatin 20-30 parts of propylene glycol alginate and 10-20 parts of soybean polysaccharide. Wherein, the gel strength of the instant agar is 80-120 freezing force, and the gel strength of the gelatin is 100-140 freezing force.

[0023] The preparation method of above-mentioned pasteurized yogurt stabilizer specifically comprises the following steps:

[0024] (1) Weighing: Weigh the raw materials in the above parts by weight;

[0025] (2) Mixing: Mix the above-mentioned raw materials that have been weighed for 30-40 minutes, and mix well;

[0026] (3) Packaging: The mixed stabilizer is weighed and packaged according to the specification requirements to obtain the finished product.

Embodiment 2

[0028] A stabilizer for pasteurized yogurt, prepared from the following raw materials in parts by weight: 35 parts of hydroxypropyl distarch phosphate, 20 parts of pectin, 5.5 parts of instant agar, 12.5 parts of gelatin, and 25 parts of propylene glycol alginate , 15 parts of soybean polysaccharides. Wherein, the gel strength of the instant agar is 100 freezing strength, and the gel strength of the gelatin is 120 freezing strength.

[0029] The preparation method of above-mentioned pasteurized yogurt stabilizer specifically comprises the following steps:

[0030] (1) Weighing: Weigh the raw materials in the above parts by weight;

[0031] (2) Mixing: Mix the above-mentioned raw materials that have been weighed for 35 minutes, and mix well;

[0032] (3) Packaging: The mixed stabilizer is weighed and packaged according to the specification requirements to obtain the finished product.

Embodiment 3-24

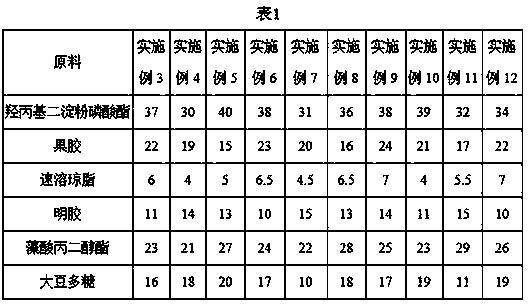

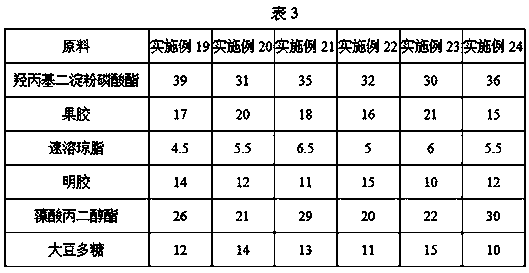

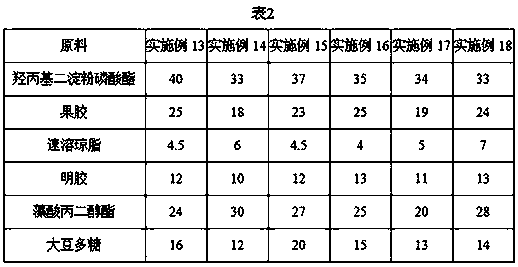

[0034] Examples 3-24 each provide a stabilizer for pasteurized yoghurt, its components and dosage are shown in Table 1-3, and its preparation method is the same as in Example 2.

[0035]

[0036]

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com