Novel etched foil chambering technology

A technology of corroding foil and technology, which is applied in the field of new corroding foil hole reaming, can solve the problems of high cost, low service life of copper rods, large heat generation, etc., and achieve low equipment depreciation cost, low equipment maintenance cost, and low power generation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Please refer to figure 1 , soak the aluminum foil in the pretreatment solution for 55 seconds, clean it and put it in the primary corrosion mixture of 1% hydrochloric acid, 21% sulfuric acid and 1% aluminum ion at a temperature of 69°C, and apply a current density 0.45A / cm 2 Perform electrolytic corrosion with direct current for 50 seconds, clean it with pure water, put it in a bath solution containing 2% hydrochloric acid at a temperature of 70 ° C, and soak for 50 seconds; after that, clean it with pure water and put it in a bath solution with a temperature of 75 ° C and contain 4% sulfuric acid , 0.1% hydrochloric acid, 0.5ppm copper sulfate, 0.1ml / L phosphoric acid corrosion inhibitor and 1% aluminum ion solution, soak for 800s, then clean the foil sample and dry it.

Embodiment 2

[0036] Please refer to figure 2 , soak the aluminum foil in the pretreatment solution for 80 seconds, clean it and put it in a primary corrosion mixture of 3% hydrochloric acid, 26% sulfuric acid and 4% aluminum ions at a temperature of 70°C, and apply a current density 0.65A / cm 2 Perform electrolytic corrosion with direct current for 90 seconds, clean it with pure water, put it in a bath solution containing 2% hydrochloric acid at a temperature of 76°C, and soak for 75 seconds; after that, clean it with pure water and put it in a bath solution containing 5% sulfuric acid at a temperature of 78°C , 0.3% hydrochloric acid, 0.7ppm copper sulfate, 3ml / L phosphoric acid corrosion inhibitor and 4% aluminum ion solution, soaking time 1150S, then clean the foil sample and dry it.

Embodiment 3

[0038] Please refer to image 3 , soak the aluminum foil in the pretreatment solution for 100 seconds, clean it and put it in a primary corrosion mixture of 5% hydrochloric acid, 30% sulfuric acid and 7% aluminum ions at a temperature of 70°C, and apply a current density 0.80A / cm 2 Perform electrolytic corrosion with direct current for 120 seconds, clean it with pure water, put it in a bath solution containing 2% hydrochloric acid at a temperature of 82°C, and soak for 100 seconds; after that, clean it with pure water and put it in a bath solution with a temperature of 80°C containing 6% sulfuric acid , 0.5% hydrochloric acid, 1ppm copper sulfate, 5ml / L phosphoric acid corrosion inhibitor and 7% aluminum ion solution, soaking time 1300S, then clean the foil sample and dry it.

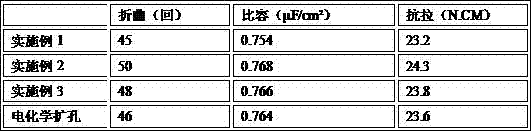

[0039] The following table 1 is the data related to embodiment 1, 2 and 3 and the existing electrochemical hole expansion comparison:

[0040]

[0041] It can be known from the above table 1 that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com