Patents

Literature

33results about How to "Reduce depreciation costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combined fruit and vegetable dehydrating production by vacuum freeze, dry and hot air re-dry

InactiveCN1711854AReduce energy consumption and production cycleReduce dehydration processing costsFruit and vegetables preservationEngineeringAir drying

A process for preparing the dewatered fruit or vegetable by vacuum freeze drying and hot air drying includes such steps as providing raw fruit or vegetable, washing, peeling or removing kernel, slicing, scaling for deactivating enzyme, conditioning, freezing, freeze drying, hot air drying, and packing.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

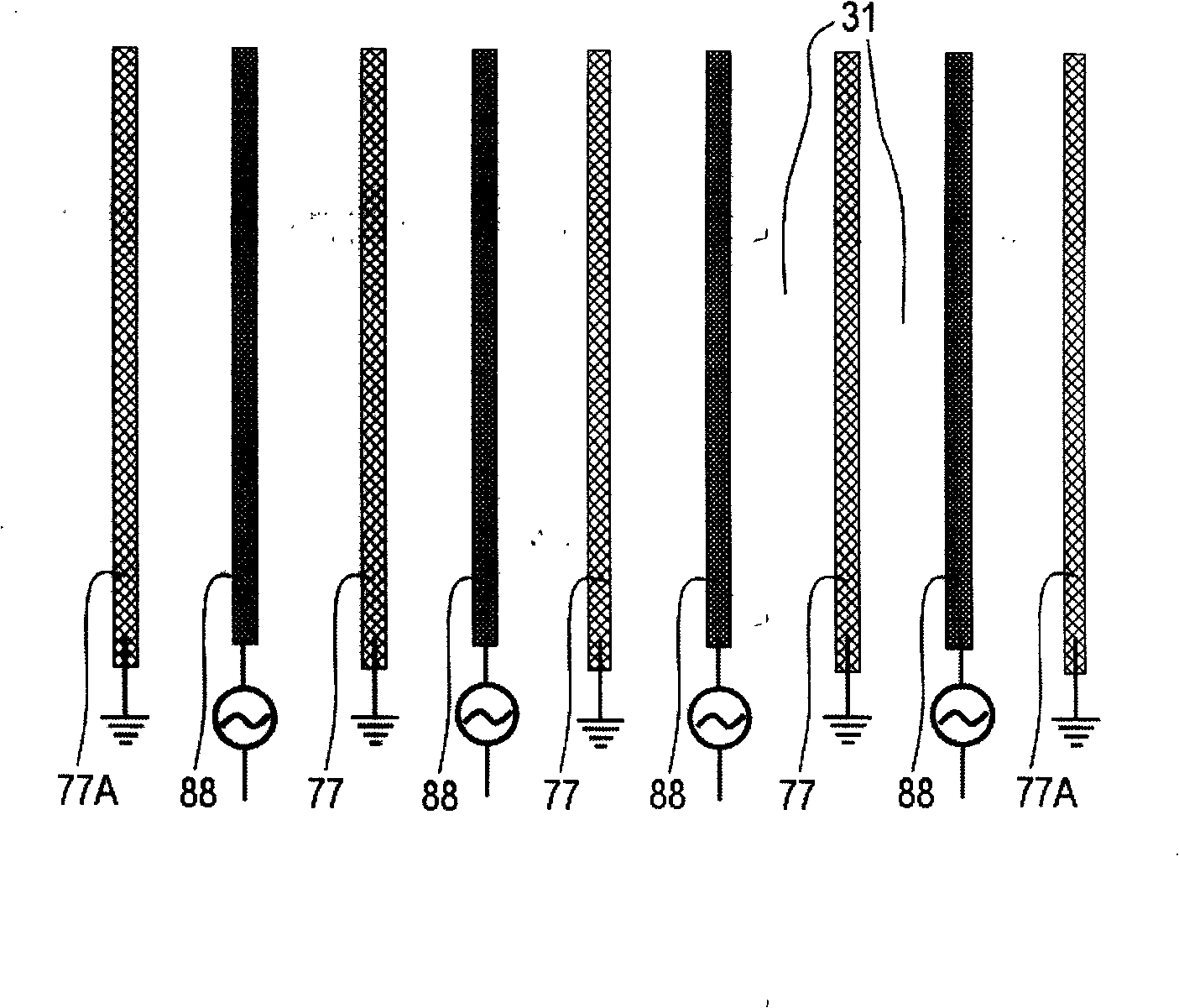

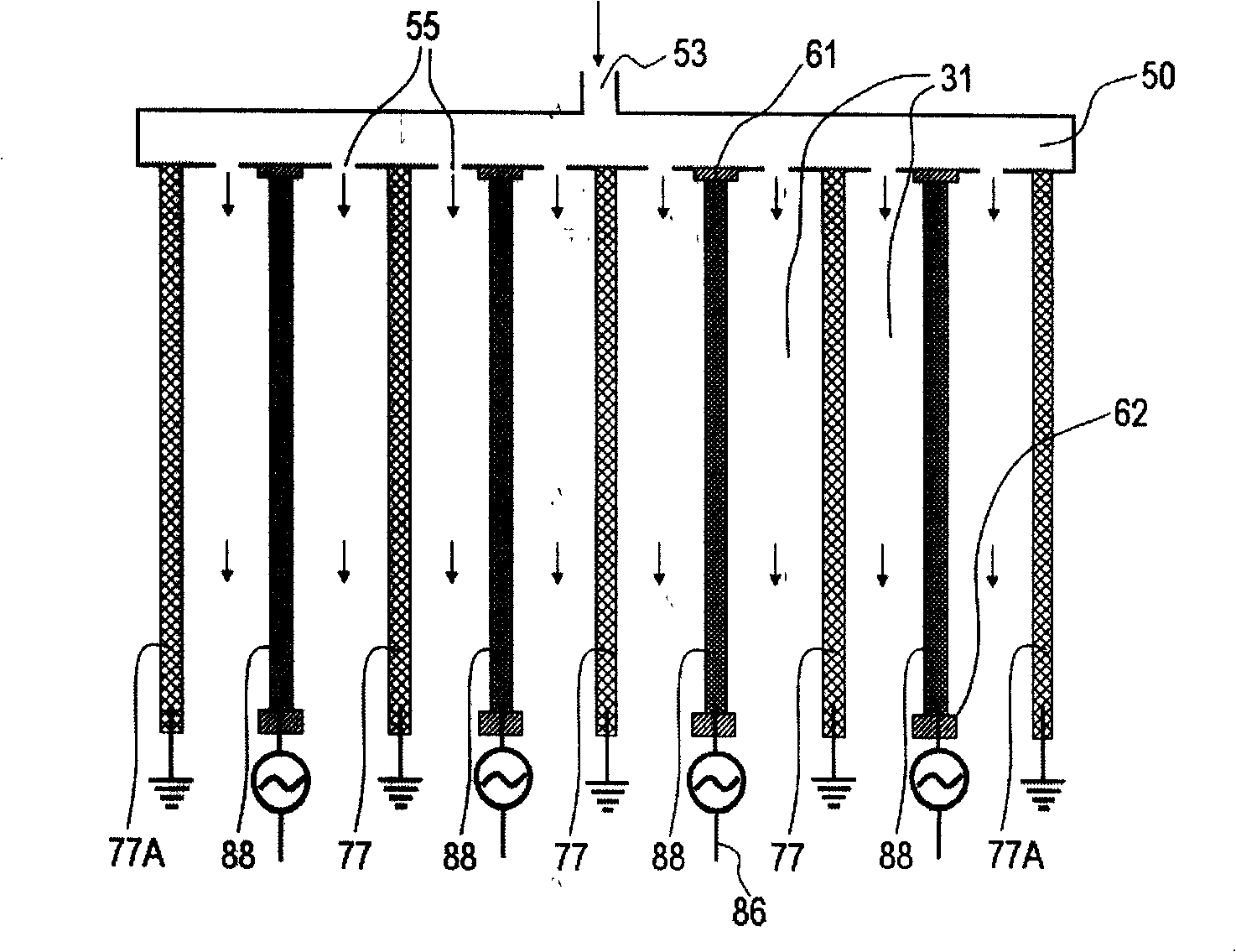

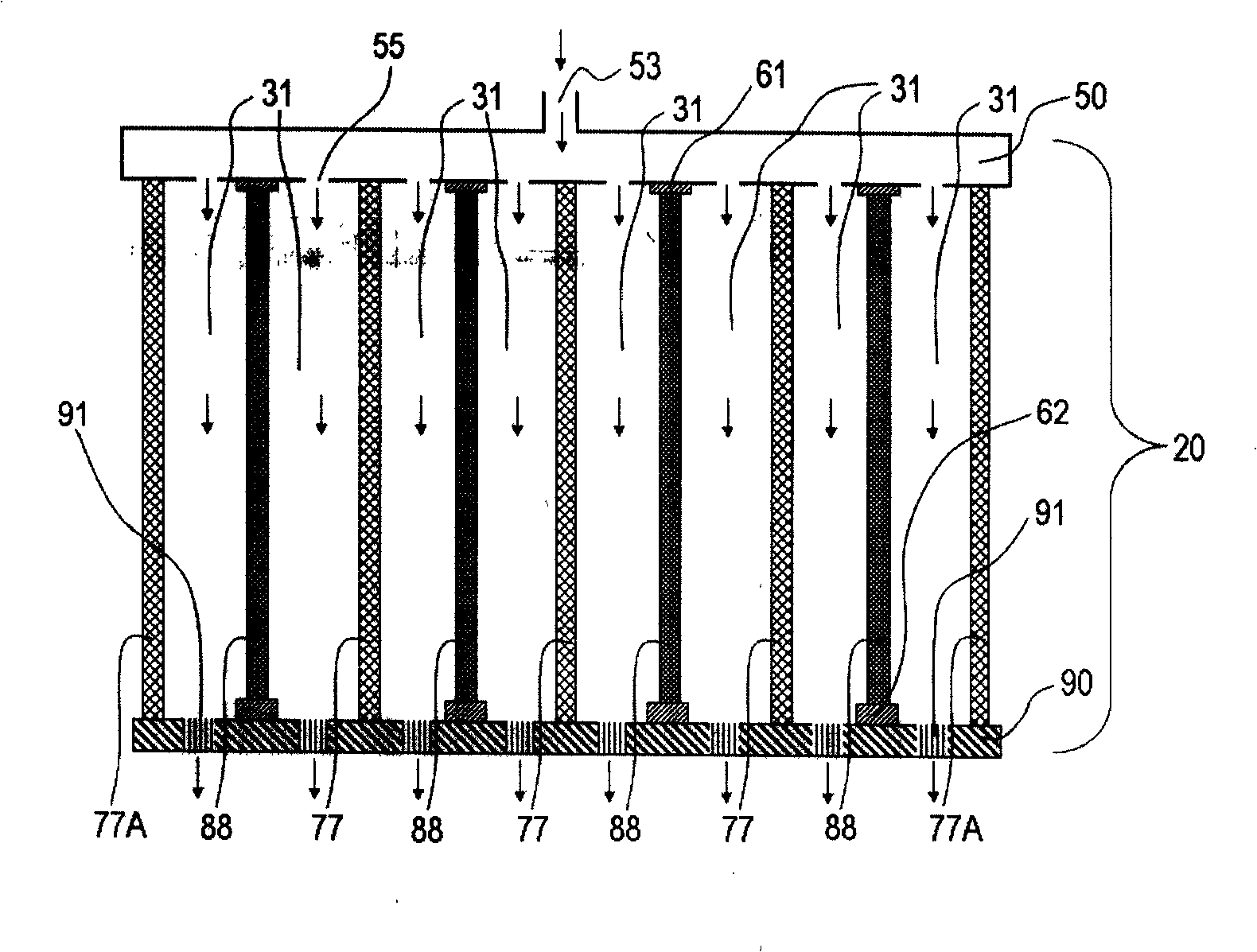

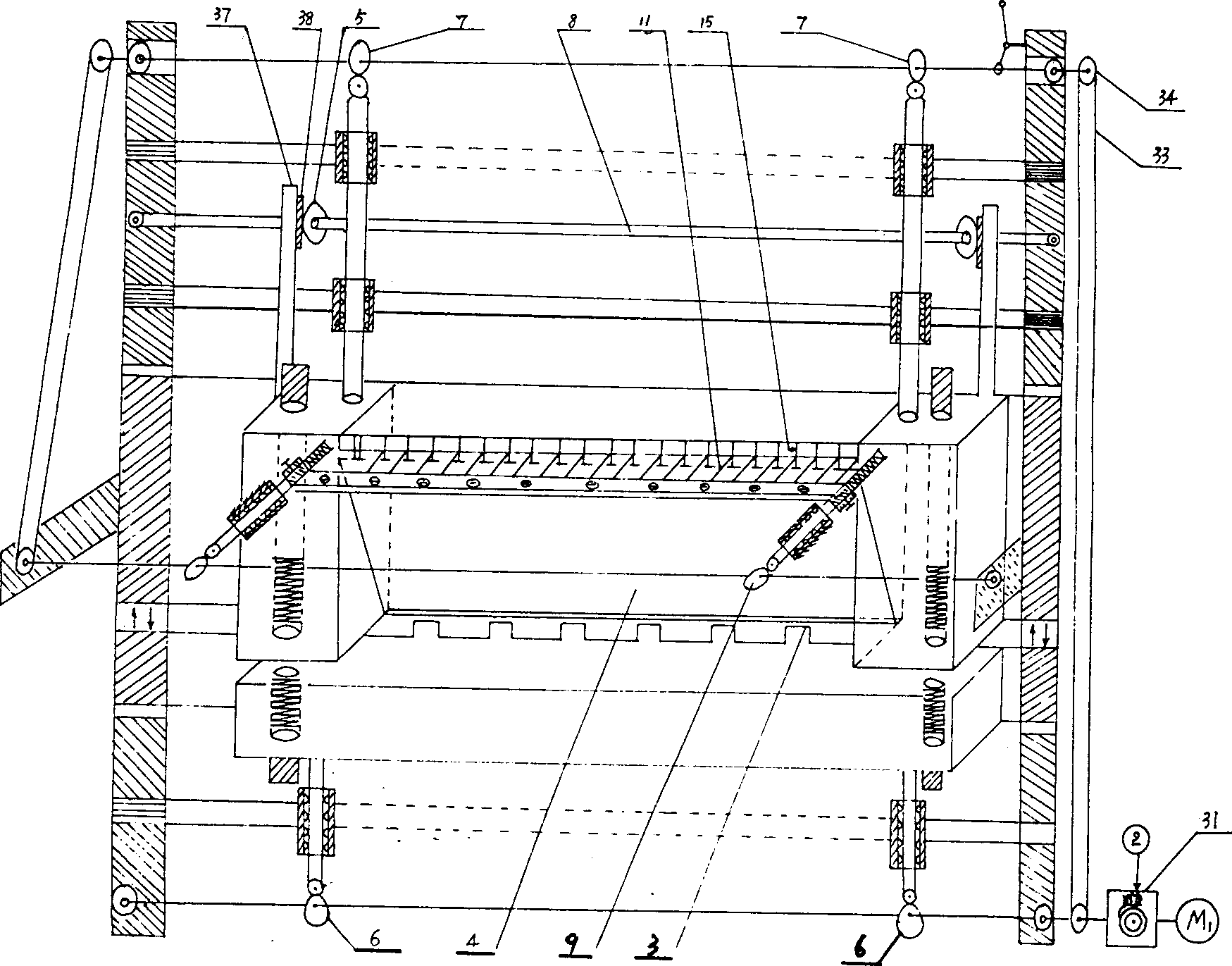

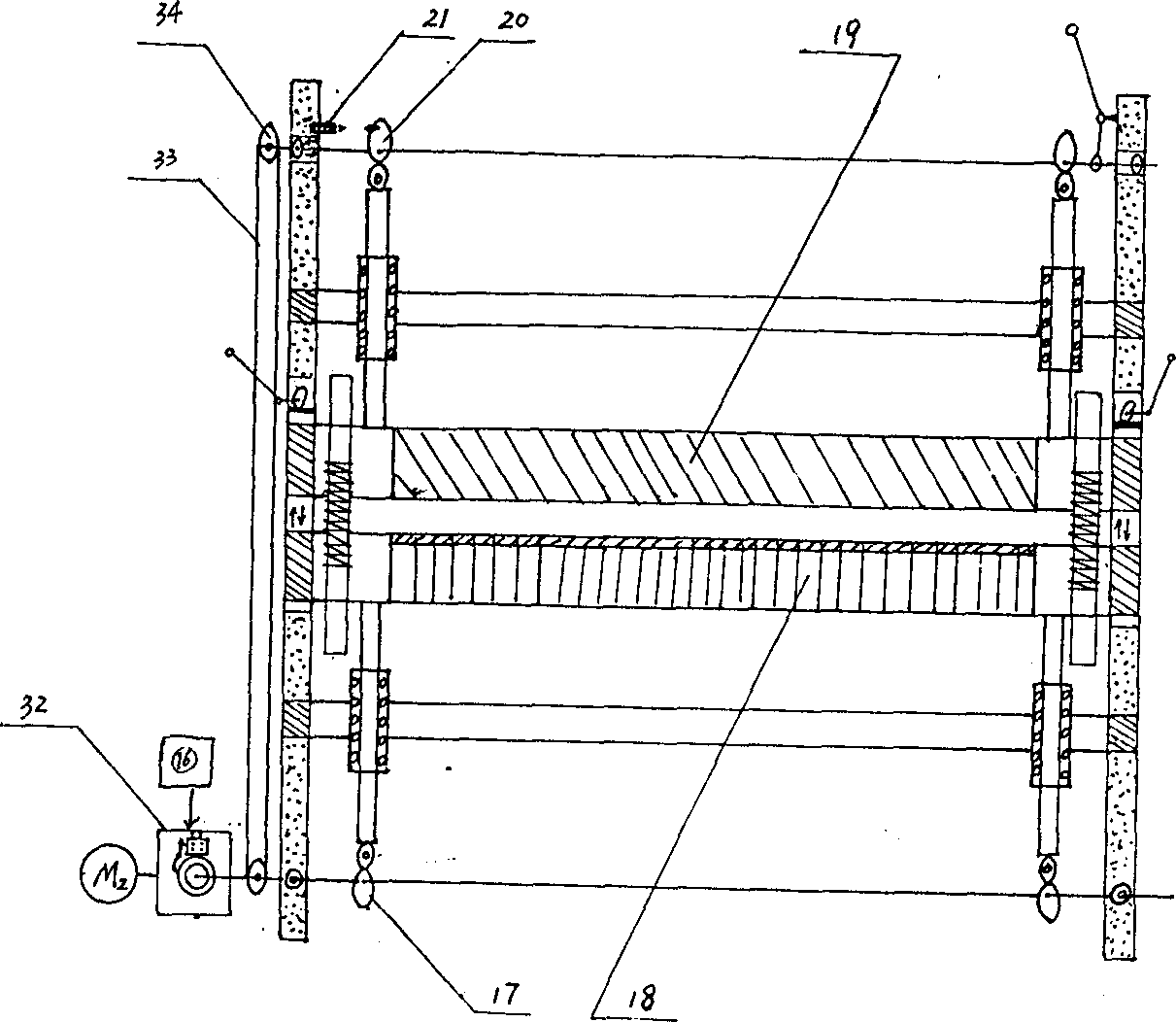

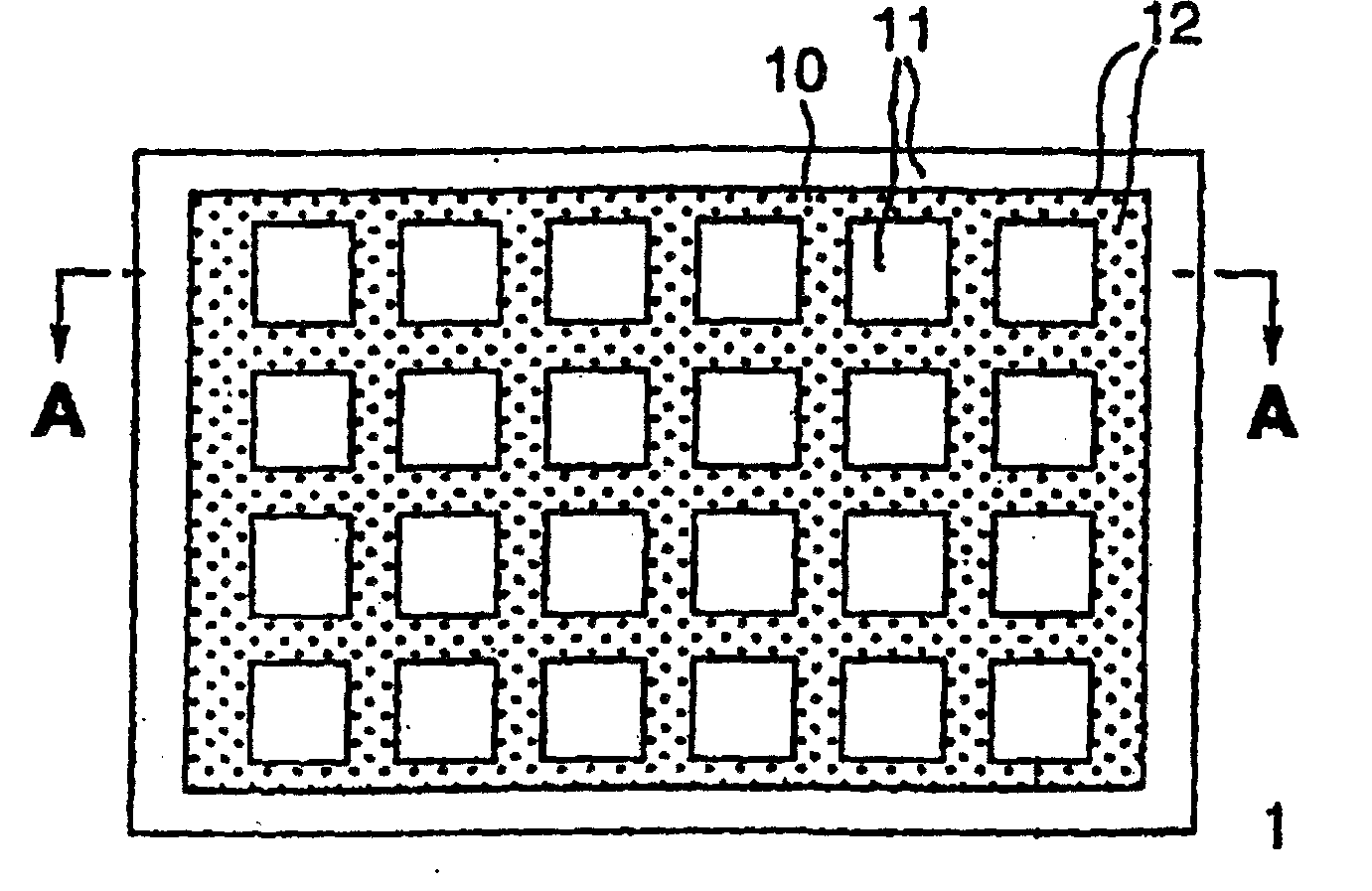

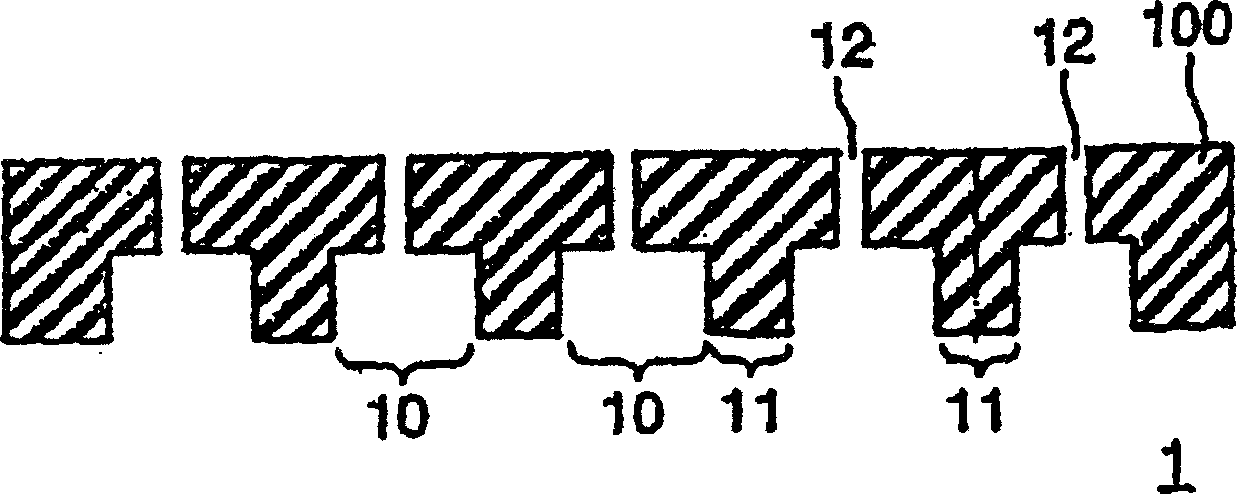

Plasma case for thin film production in enormous quantities

InactiveCN101245449AReduce pollutionIncrease productionChemical vapor deposition coatingPlasma techniqueHigh volume manufacturingVacuum chamber

The invention discloses a plasma enhanced chemical vapor deposition (PECVD) device and a method which are used for simultaneously coating films on a plurality of large-area base plates. A plurality of large-area base plates are arranged in rectangle plasma chambers comprising a plurality of parallel exciting electrodes and grounding electrodes at intervals and in staggered arrangement. A plurality of plasma regions are uniformly formed among all adjacent and opposite electrodes. The large-area electrode surfaces of all plasma chambers are used in a great quantity of the same, fixed and grouped film coatings of the PECVD system of a single vacuum chamber.

Owner:BEIJING XINGZHE MULTIMEDIA TECH

Process for preparing foam composite material of magnesium alloy-pearlite

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

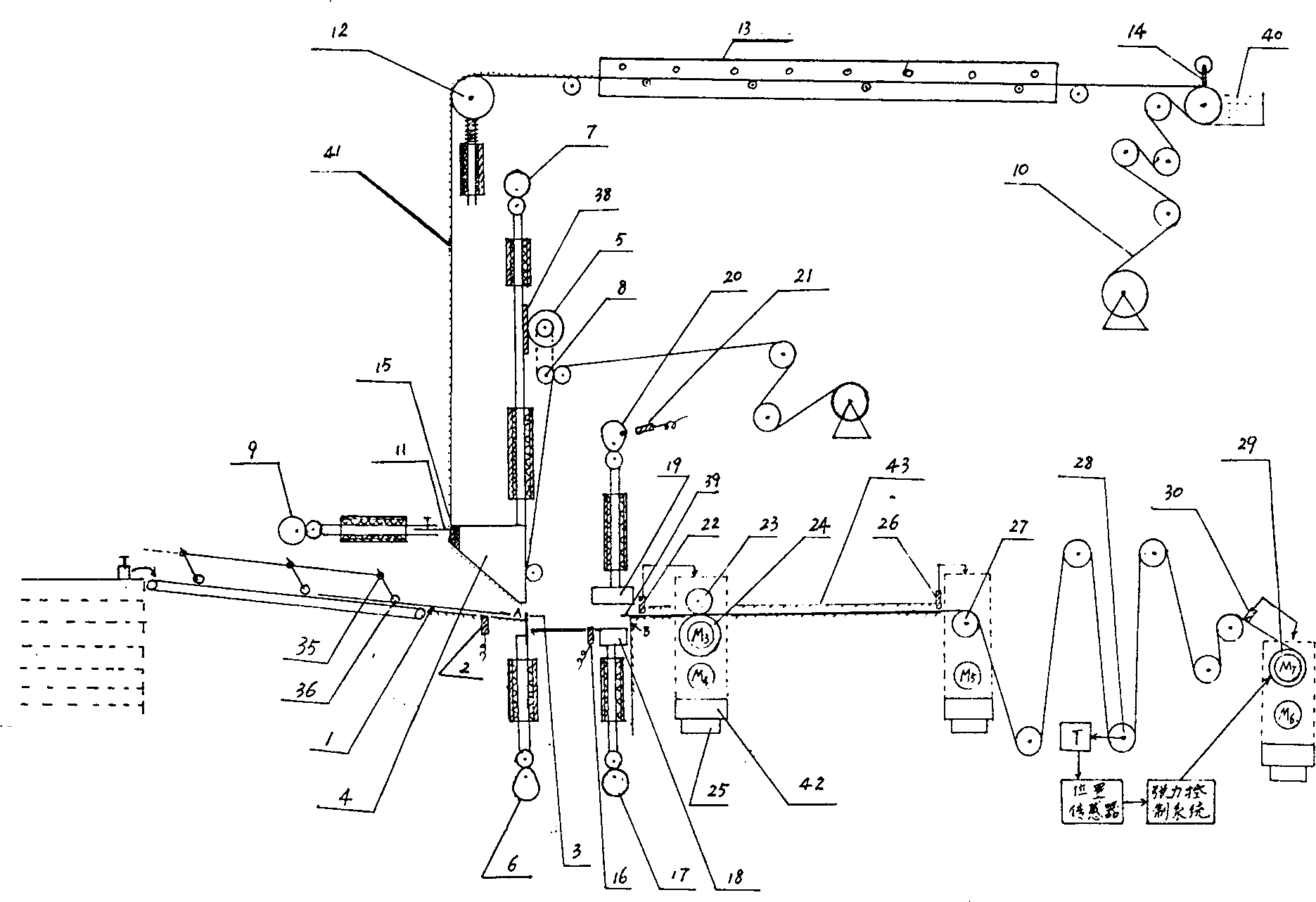

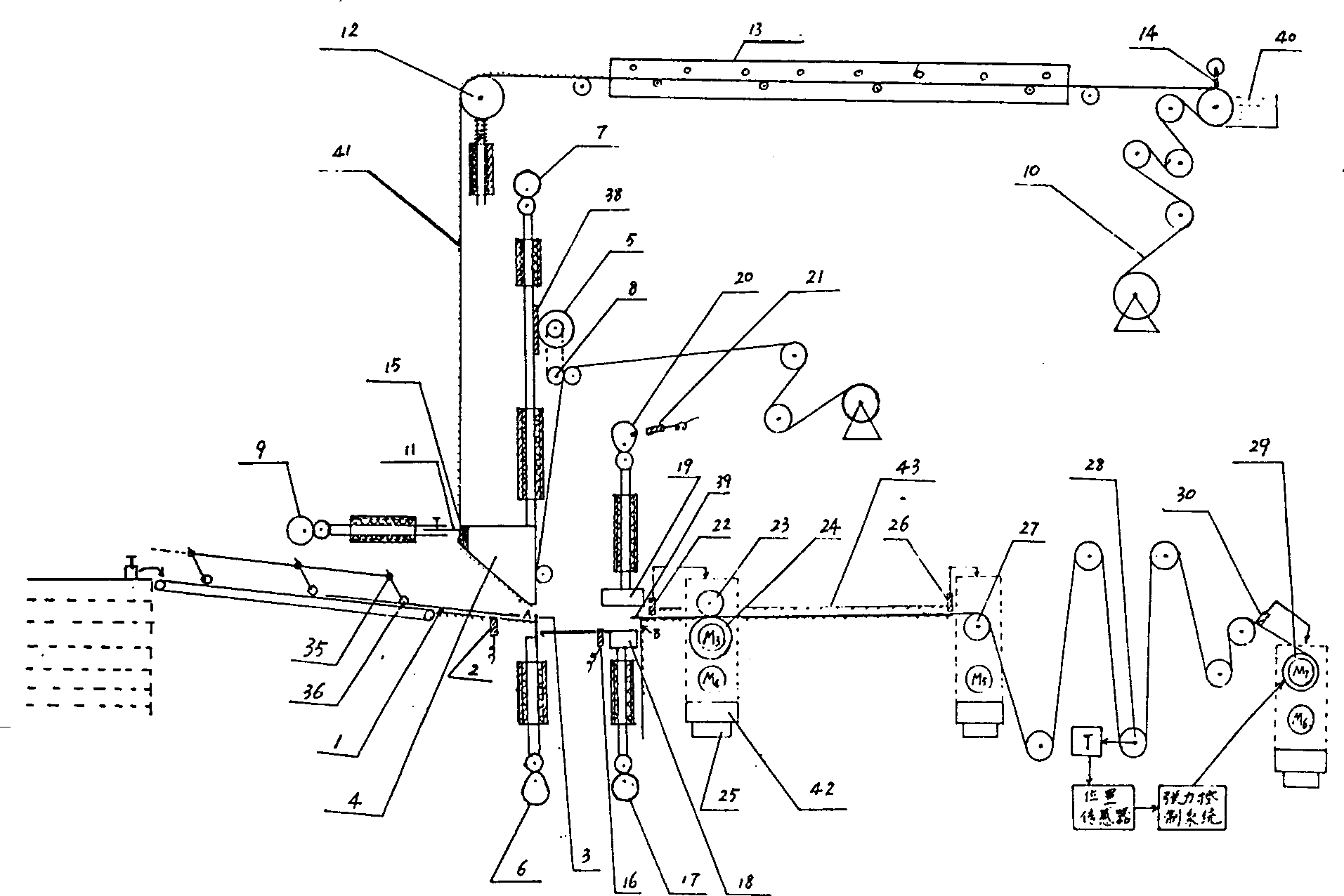

Production process of flat offset printing roll color-printing pressure-sensitive adhesive trade mark

The production process of plane sheet offset rolled colour-printed pressure-sensitive adhesive label includes the following steps: 1. face paper plane sheet PS plate printing; 2. edging; 3. automatically-adhering single-sheet printed face paper and coiling; 4. finely-coating pressure-sensitive adhesive and lamination; 5. cutting roll and die-cutting. The single-sheet printed face paper automatically adhering and coiling process includes the following steps: positioning face paper to the glue-applying place, at the same time transferring and pressing pressure-sensitive adhesive onto the face paper form parting paper; adhering head and tail of face paper, digital-control taking up by servo-motor, rectifying deviation, using position sensor and tension control system to regulate and control brake and constant tension rolling up.

Owner:高国明

Method for shortening processing time of microwave freezing drying of fruit or vegetable powder by utilizing dielectric core

InactiveCN1868321AShorten spin timeImprove qualityFood preservationFood preparationMicrowaveFreeze-drying

A dielectric core method for shortening the time taken by microwave freeze-drying of fruit-vegetable powder includes such steps as choosing raw materials, conventional pre-treating, slicing, beating, adding the high-dielectric-constant titanium oxide ceramic nano-particles, amino acid and sugar or salt to form dielectric cores, quick freezing, microwave vacuum freeze-drying, and pulverizing. It features less loss of nutrients.

Owner:JIANGNAN UNIV

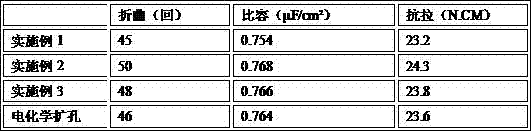

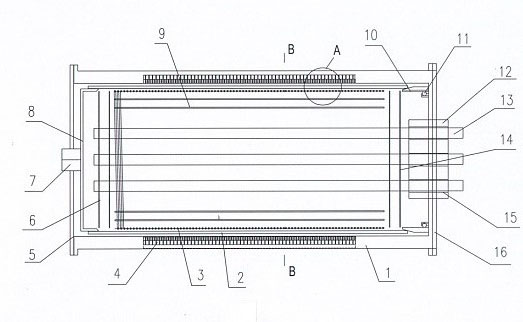

Novel etched foil chambering technology

InactiveCN107502948AExtended service lifeEasy to handleElectrolytic capacitorsMetal surface removal provisionCopperMaterials science

The invention relates to a novel etched foil chambering technology. The novel etched foil chambering technology comprises the following steps that (1) pretreatment is carried out; (2) first-stage etching hole forming is carried out; (3) medium treatment is carried out; (4) second-stage pure chemistry chambering etching is carried out; and (5) aftertreatment is carried out. The novel etched foil chambering technology is mainly used for solving the problem that in the existing chambering technology, electrocorrosion is adopted, and therefore the factors like high cost, large heat generating amount, short copper bar using service life and the like exist.

Owner:江苏国瑞科技有限公司

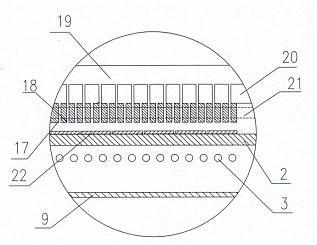

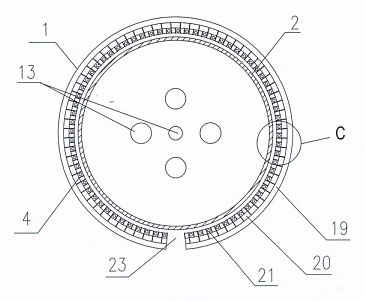

Barrel-shaped metal organic chemical vapor deposition reaction tube

ActiveCN102094185AReduce power consumptionReduce raw material consumptionChemical vapor deposition coatingEngineeringChemical vapor deposition

The invention discloses a barrel-shaped metal organic chemical vapor deposition reaction tube which comprises a barrel body. The barrel type metal organic chemical vapor deposition reaction tube is characterized in that the barrel body is in a barrel shape with an open left end and an open right end, and a graphite barrel, an electric stove wire barrel and a molybdenum sheet heat insulation barrel are sequentially sleeved in the barrel body. The left end and the right end of the electric stove wire barrel are respectively provided with a left heat insulation molybdenum sheet and a right heat insulation molybdenum sheet which are sleeved on an electrode stem. A multiple-layer spray tube is arranged in the barrel body and is composed of a liquid cooling tube, an ammonia spray tube and a metal organic source spray tube. An ammonia nozzle connected with the ammonia spray tube and a metal organic source nozzle connected with the metal organic source spray tube are arranged on the inner wall of the barrel body, and an exhaust port is arranged on the inner wall of the barrel body. The barrel type metal organic chemical vapor deposition reaction tube has the advantages that the throughput can be raised on a large scale, the product cost can be reduced, the production efficiency can be increased, the surface temperature uniformity of graphite is good, the product percent of pass is high, and the energy consumption is low. The productivity is 20 times as high as that of three kinds of popular MOVCD great machines at present.

Owner:南昌硅基半导体科技有限公司

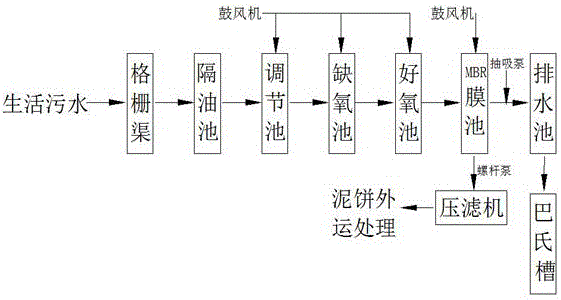

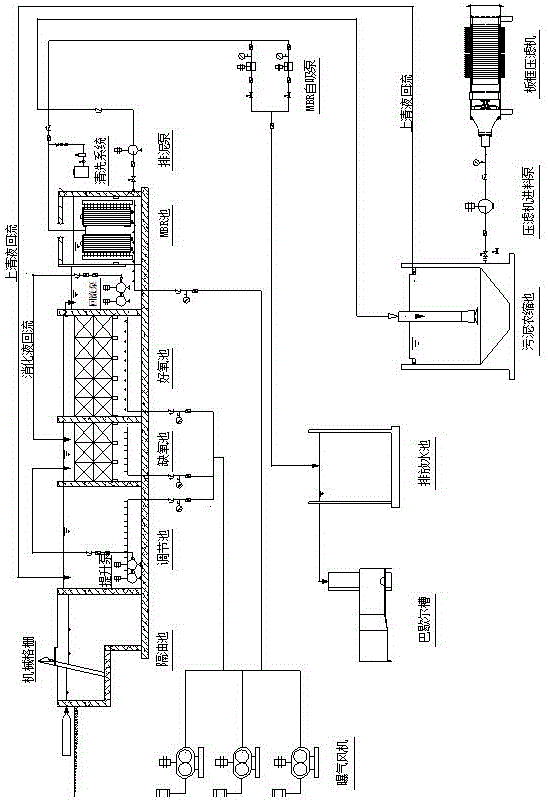

Method for treating domestic wastewater with porous multilayer hollow PTFE-MBR membrane

InactiveCN105923896AThe water is clear and transparentEfficient solid-liquid separationFatty/oily/floating substances removal devicesTreatment involving filtrationPollutantOil separation

The invention provides a method for treating domestic wastewater with a porous multilayer hollow PTFE-MBR membrane. The method comprises the steps that domestic wastewater is collected through a pipe network and then enters a wastewater treatment station, wherein gratings are arranged at the front end of the wastewater treatment station, and the gaps between the gratings is 5 mm; water out of the gratings automatically flows into an oil separation tank; water out of the oil separation tank enters a regulating tank; water out of the regulating tank is lifted to an anoxia tank through a submersible sewage pump, wherein the primary function of the anoxia tank is denitrification; water out of the anoxia tank automatically flows into an aerobic tank, wherein the aerobic tank performs the functions of making active sludge carry out aerobic respiration, further decomposing organic matter into inorganic matter and removing pollutants; water out of the aerobic tank automatically flows into a membrane bioreactor; water of the membrane bioreactor is sucked to a discharging tank through a self-priming pump and then discharged into a natural water body through a Parshall trough. According to the method, the occupied area is small, the technological process is short, the water quality of outlet water is stable, it is ensured that outlet water is clear and transparent, and high-quality produced water is obtained.

Owner:安徽洋森环保节能科技有限公司

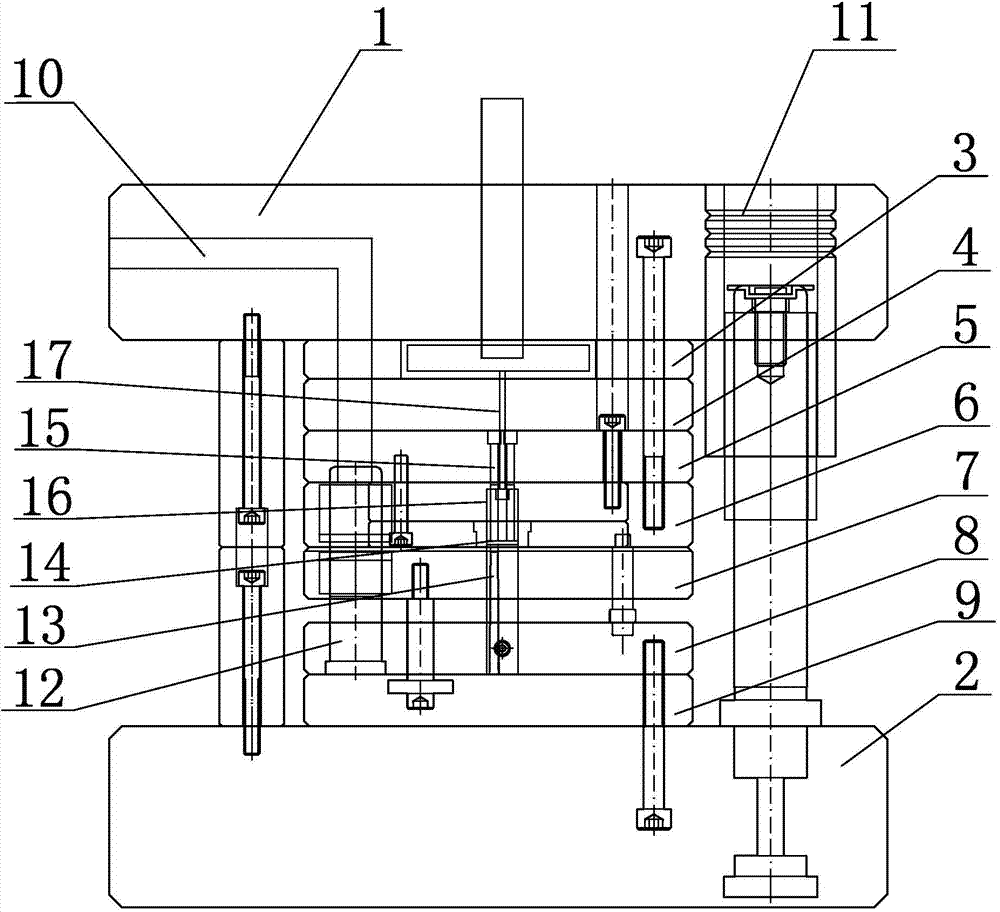

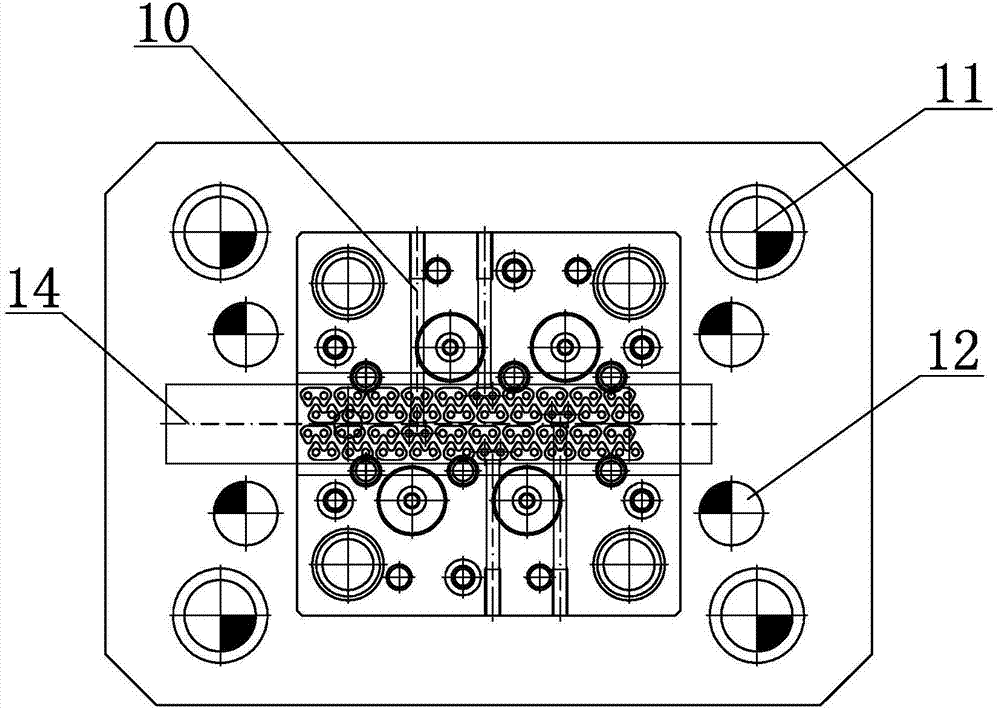

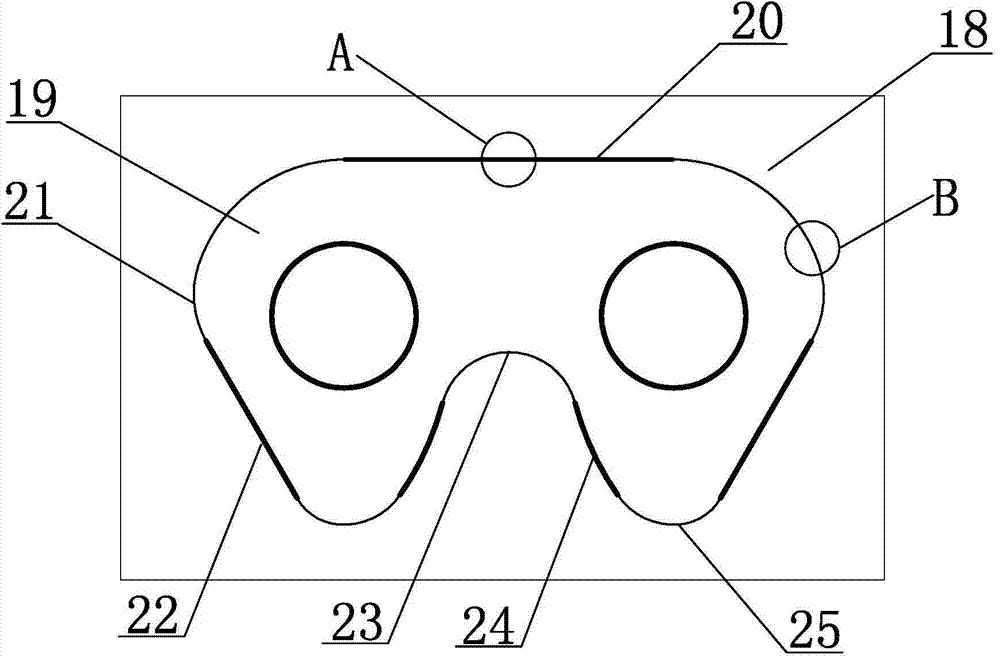

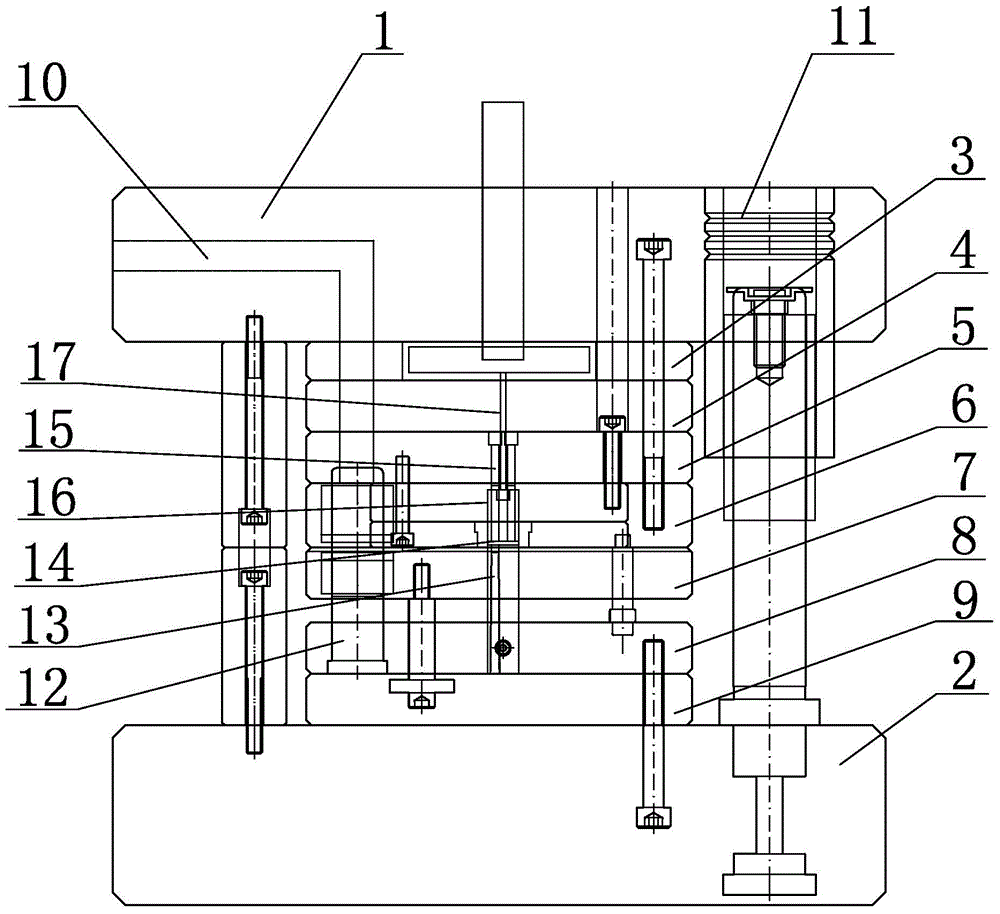

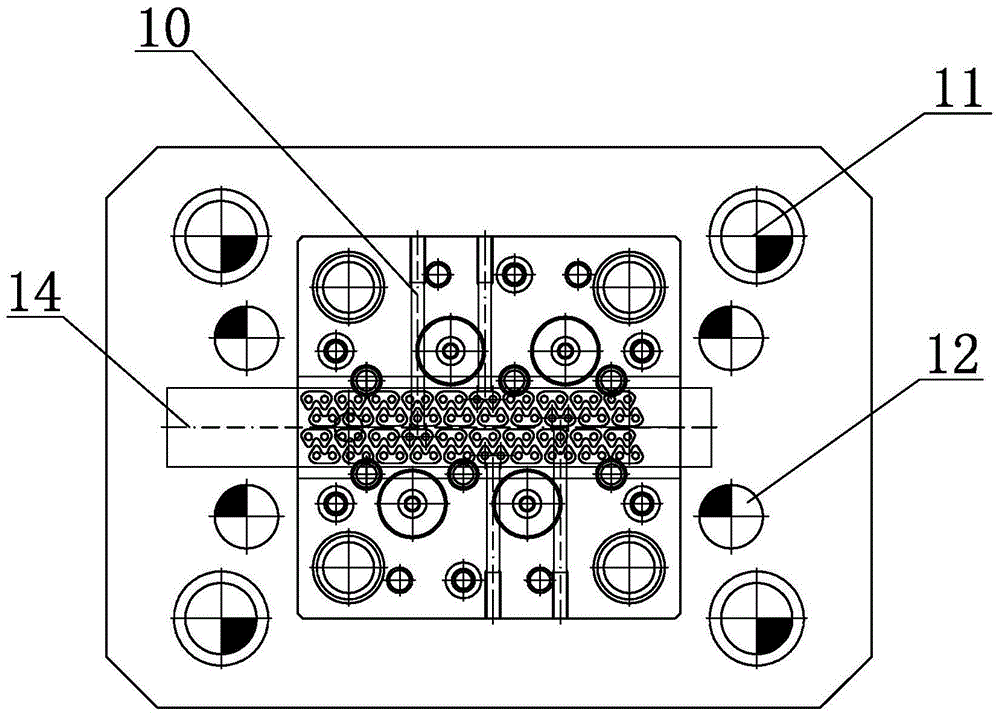

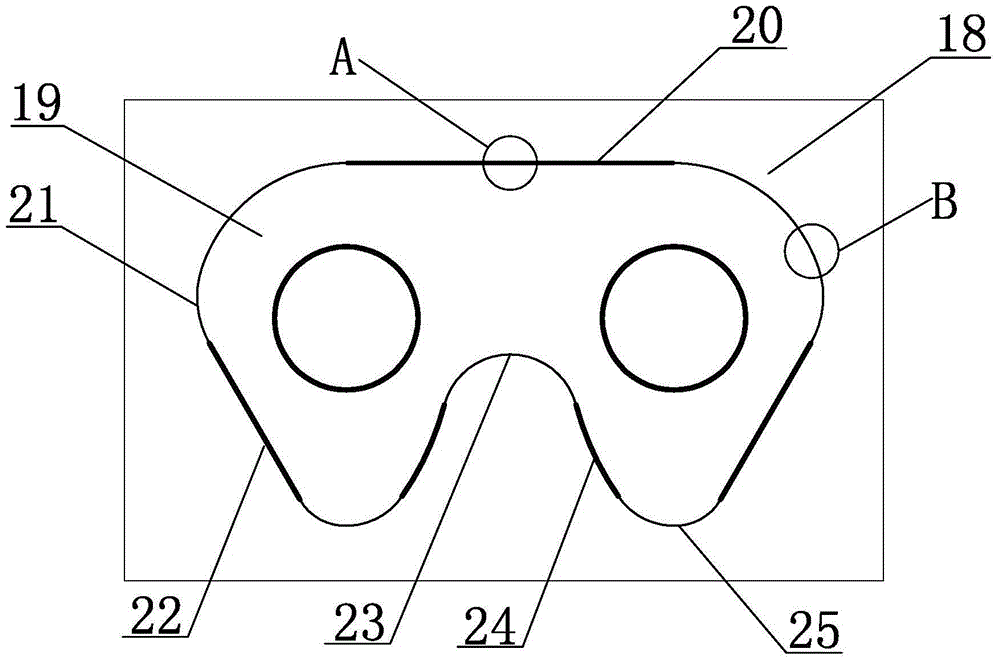

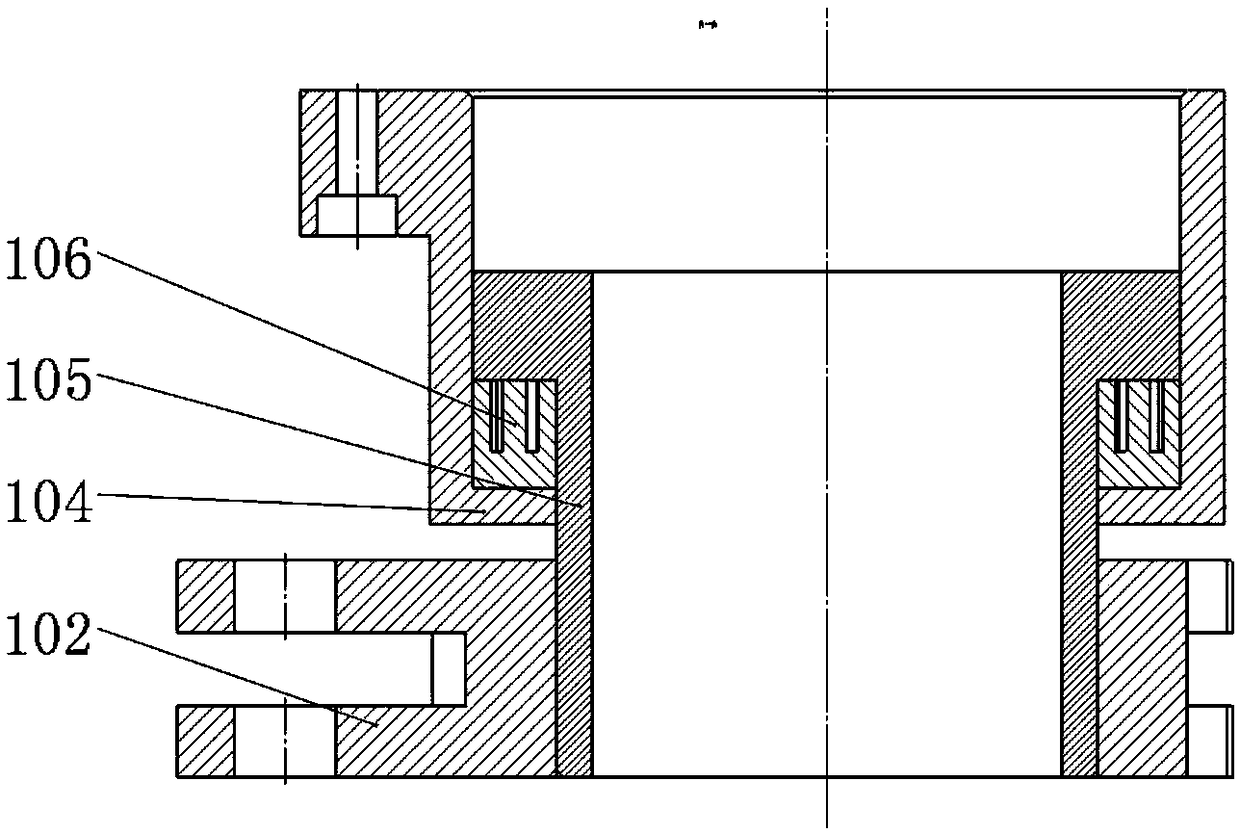

Method for manufacturing efficient silent chain plate long in service life

The invention relates to a method for manufacturing an efficient silent chain plate long in service life. The method includes the following steps of firstly, placing a steel plate to be machined in the middle of a die of a horizontal punching machine, wherein a silent chain multi-particle blanking smooth punching composite die is adopted as the die; secondly, making a front die holder and a rear die holder get close so that a female formwork and an outer stripper can be closed, making a protruding block enter a concave hole, punching the steel plate to form small steel pieces with die shapes, and using the small steel pieces in cooperation with parts with small gaps for conducting smooth punching; thirdly, conducting inner hole punching on the inner portions of the small steel pieces through punching nails to obtain a chain plate, and discharging waste out of the gap between the outer stripper and a rear clamping plate through discharge through holes, wherein the chain plate inner hole punching can be smooth due to the fact that the fit clearance between the punching nails and the through holes are small; fourthly, separating the female formwork from the outer stripper, embedding the chain plate in the concave hole, pushing the chain plate out of the concave hole through a piece ejecting block at the moment, and meanwhile conducting high-pressure flushing to blow down the chain plate when the front die holder and the rear die holder are separated. By means of the method, high-speed and large-batch production is achieved, and the raw material waste caused by progressive dies is avoided.

Owner:HANGZHOU DONGHUA CHAIN GRP

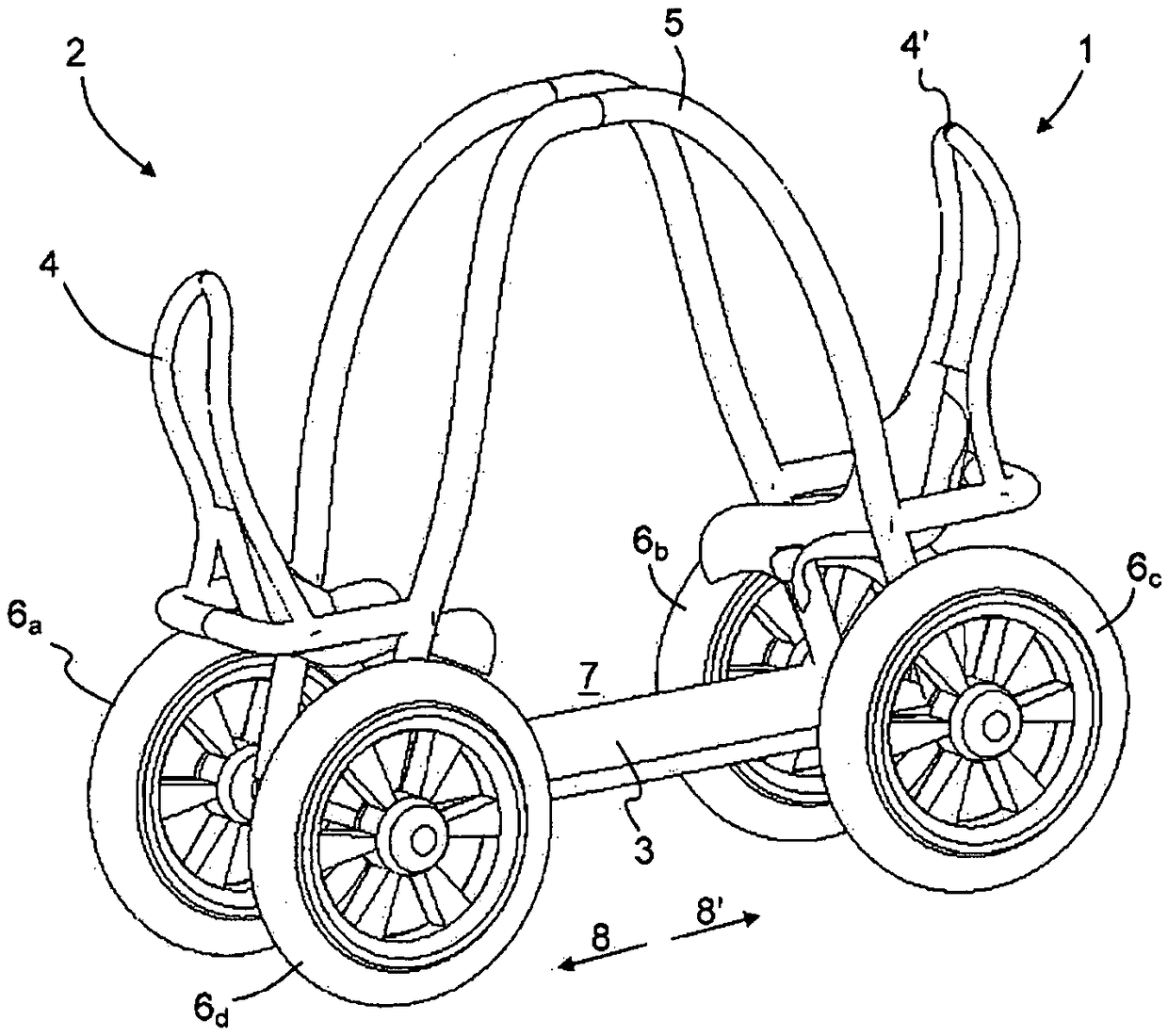

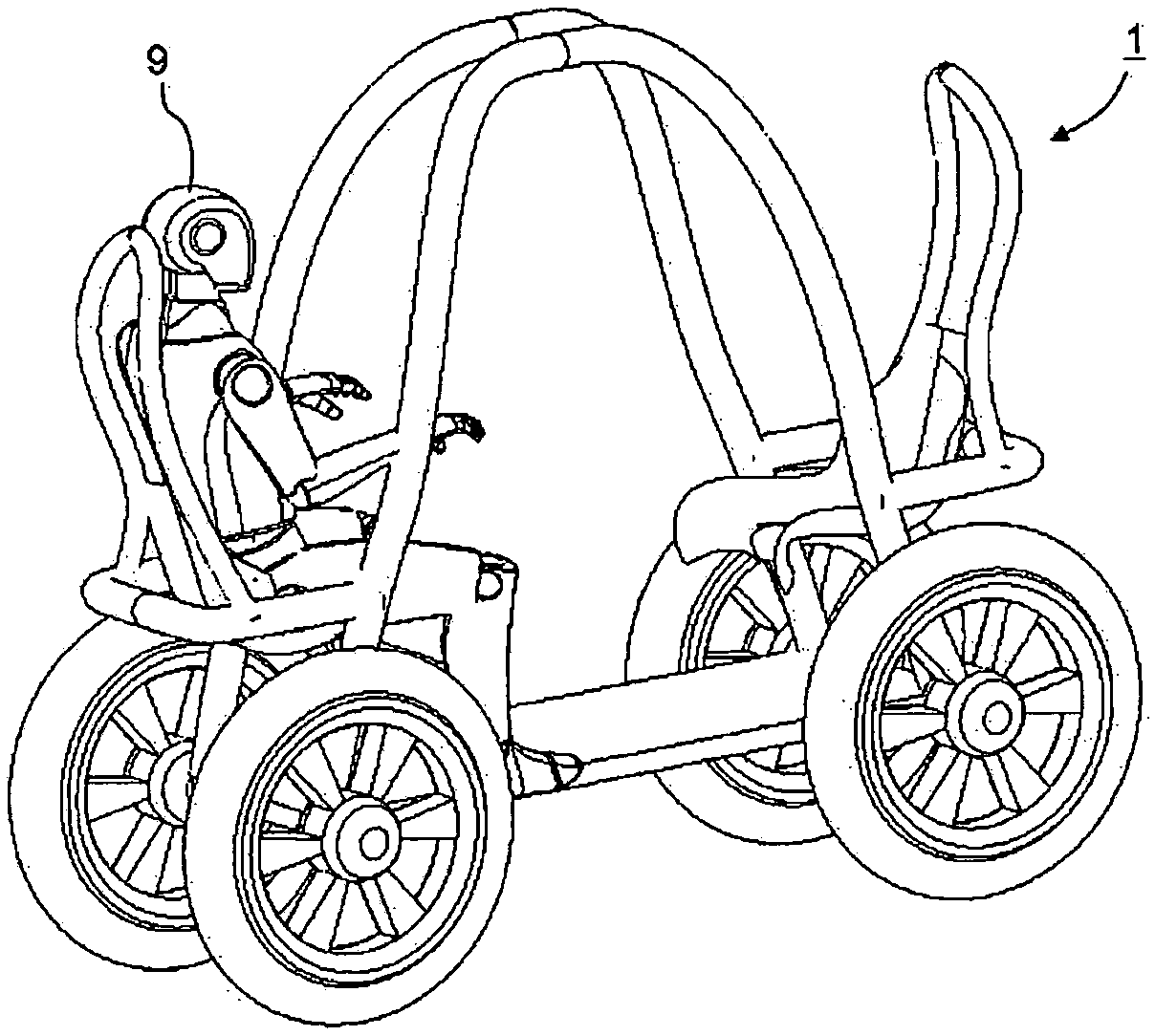

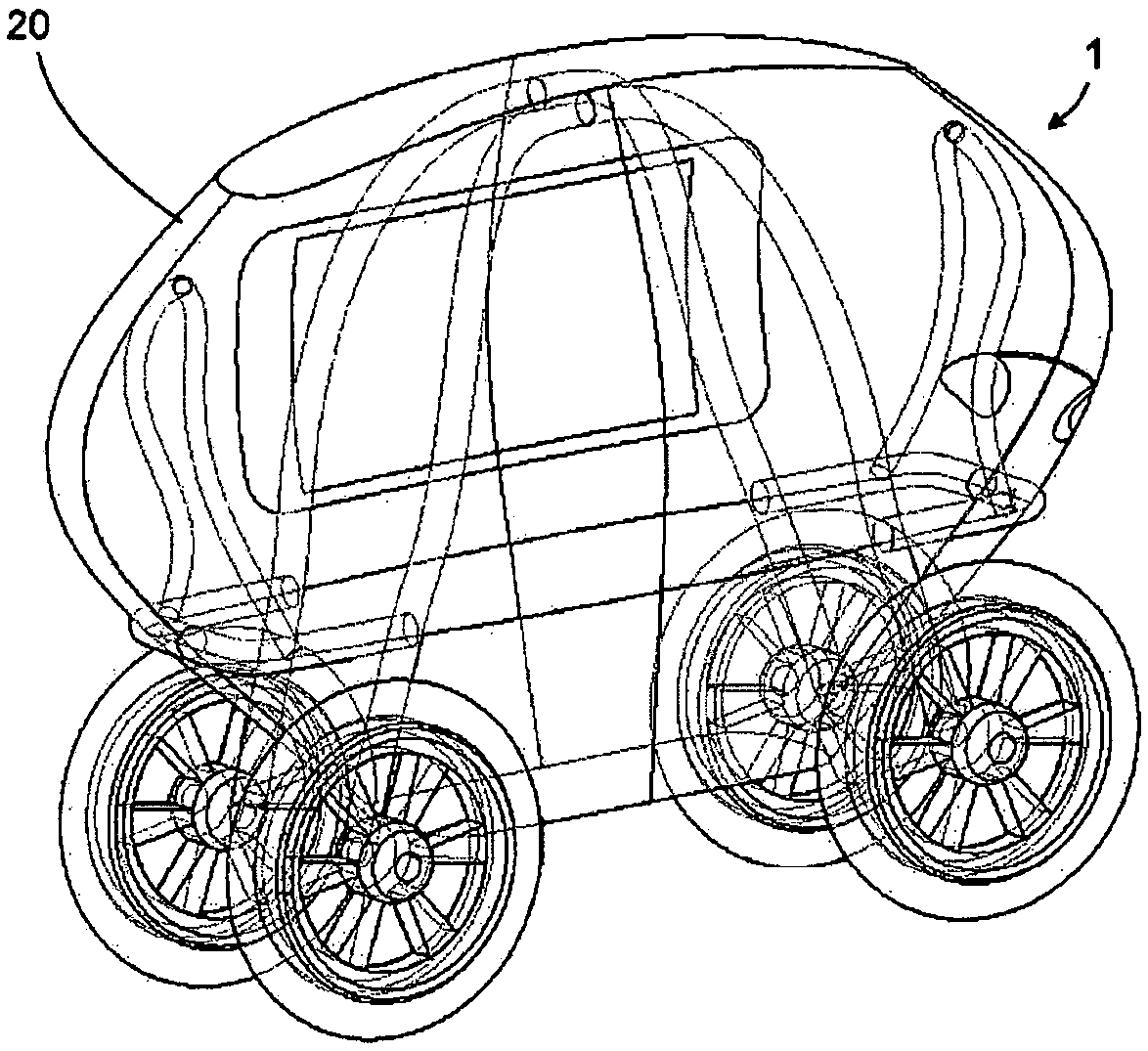

Traffic system, self-propelled vehicle, and traffic system control process

InactiveCN109478371AIncrease profitLow investment costAutonomous decision making processAnti-theft devicesVehicle dynamicsIn vehicle

The invention relates to a traffic system comprising a fleet of self-propelled vehicles for transporting passengers and / or packets within a defined region, a self-propelled vehicle for use within sucha traffic system, and a control process for a traffic system comprising a fleet of self-propelled vehicles. In order to create a traffic system that allows for cost-effective and individual mobilityof passengers and / or packets especially in urban traffic, according to the invention, a vehicle controller is provided that comprises an on-board unit assigned to the individual vehicle as well as a central computer connected to all of the vehicles in the fleet, the vehicle dynamics of an individual vehicle are controlled by the on-board unit, and the navigation and integration of an individual vehicle into traffic are controlled by both the on-board unit and the central computer.

Owner:INNOVATIVE DRAGON

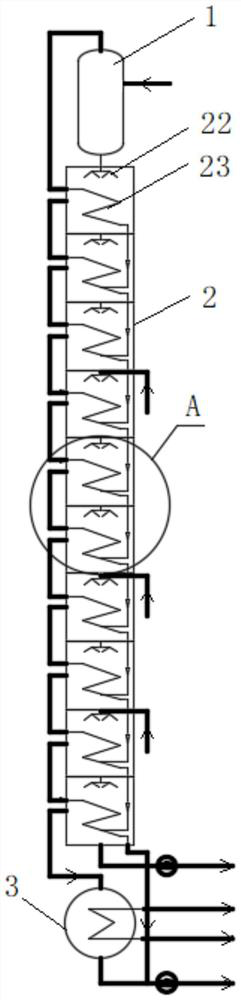

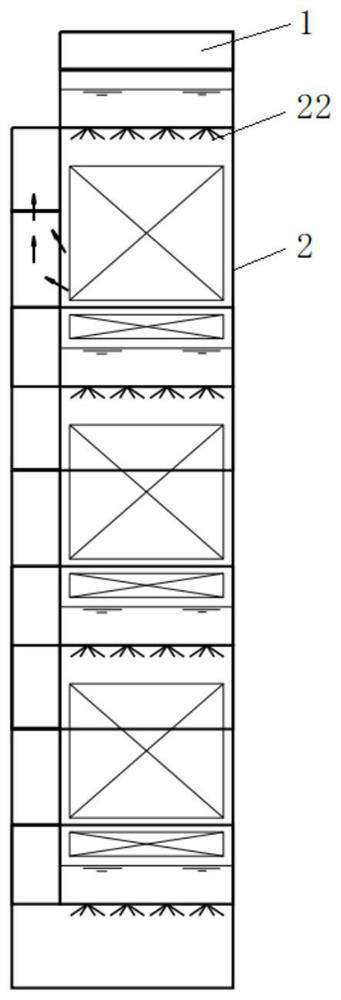

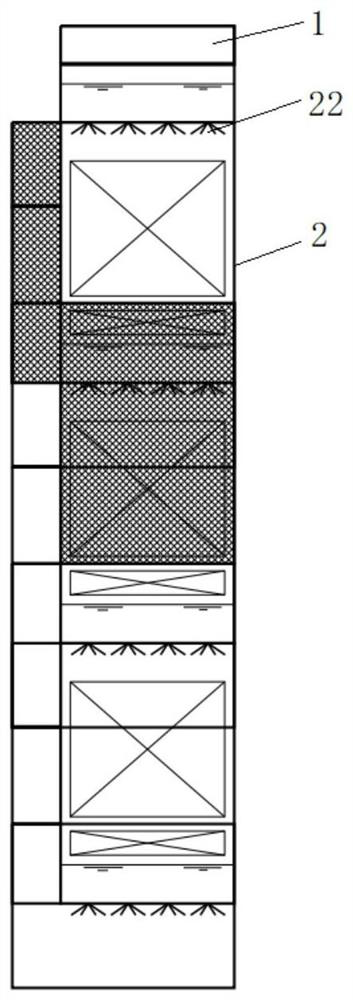

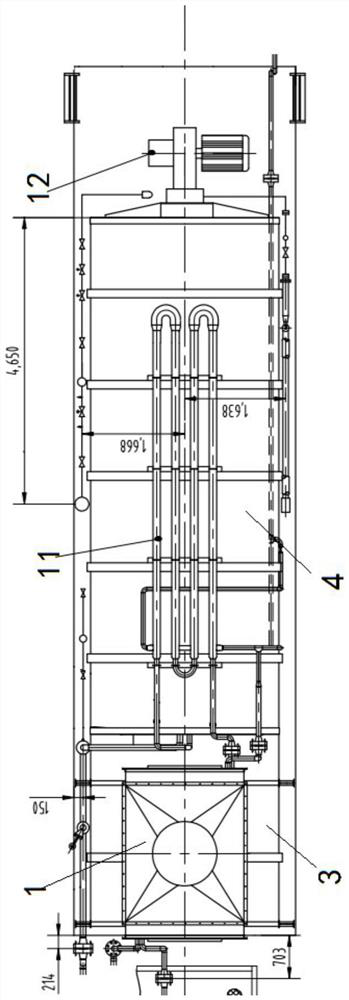

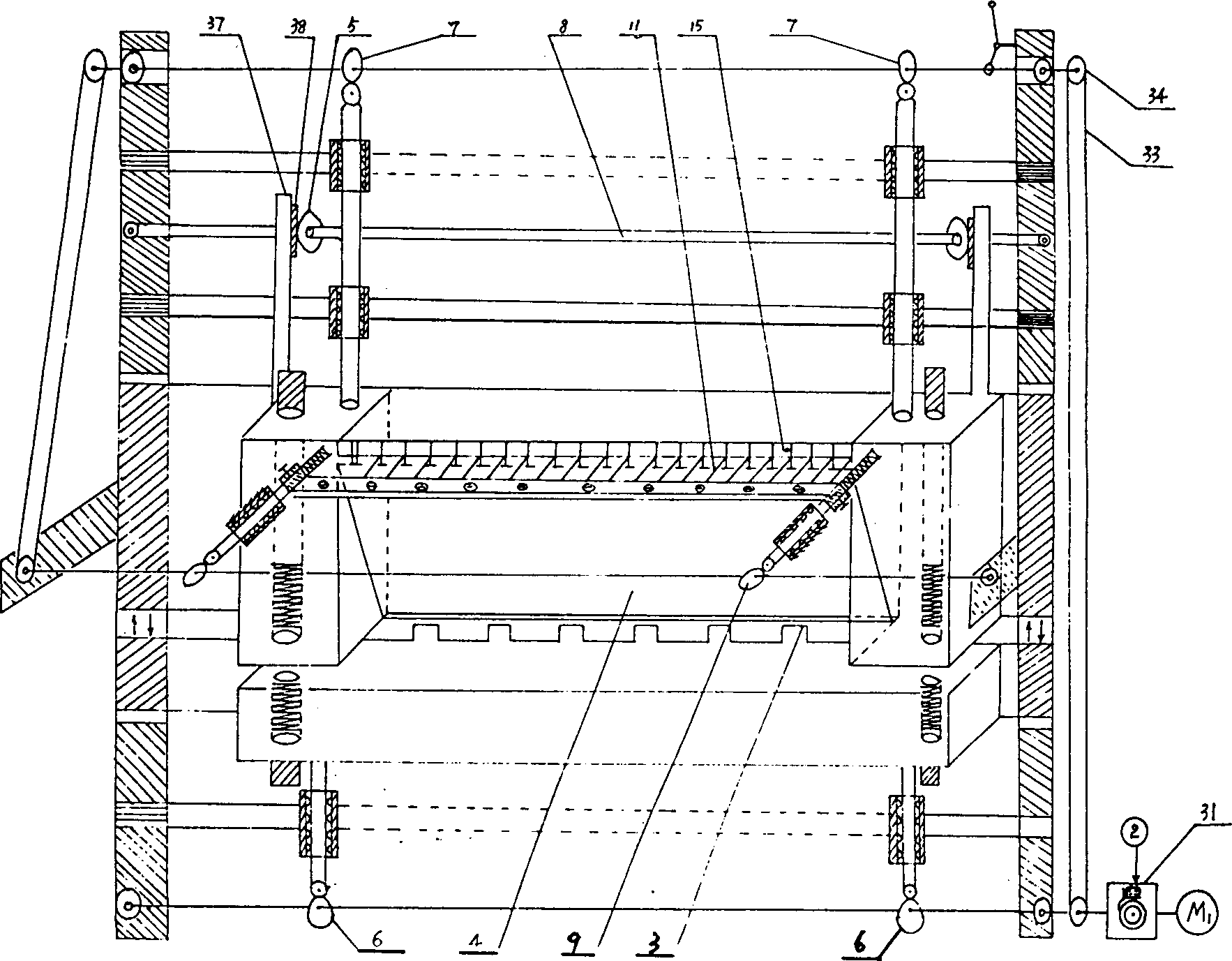

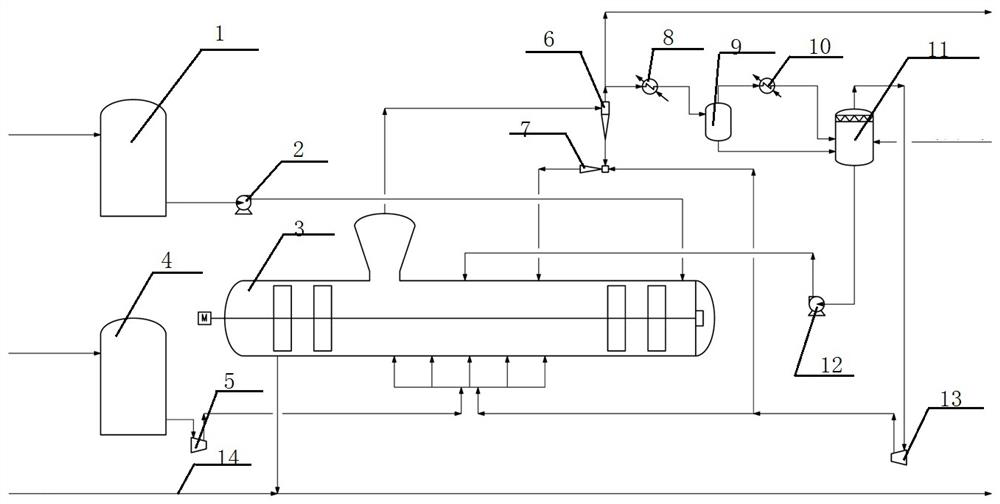

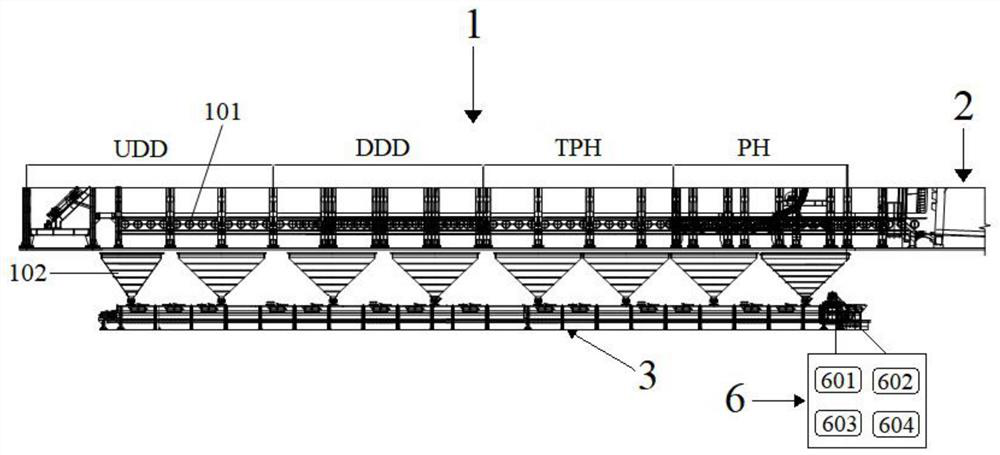

High-temperature sewage self-desalting multi-effect distillation equipment

PendingCN112960715AReduce depreciation costsLow costGeneral water supply conservationWater contaminantsDesalinationWater production

The invention provides high-temperature sewage self-desalting multi-effect distillation equipment which comprises a flash tank, a multi-effect evaporator and a condenser, and material water distribution devices and a heat exchange tube bundle are arranged in the multi-effect evaporator; the multi-effect evaporator is formed by connecting a plurality of evaporators in series, the plurality of evaporators are sequentially called as a first-effect evaporator, a second-effect evaporator, and the like till a last-effect evaporator from front to back, the flash tank is arranged at the upstream of the multi-effect evaporator, and one material water distribution device is arranged at the inner top of each evaporator; and steam generated by flash evaporation of high-temperature sewage in the flash tank is used as first-effect heating steam, residual sewage in the flash tank is used as material water, a heat source of the high-temperature sewage self-desalting multi-effect distillation equipment adopts high-temperature sewage discharge wastewater, a low-temperature steam heat source is obtained through low-temperature flash evaporation, heat of the sewage is utilized to the maximum extent, and therefore, the heat value of the maximum cost of desalting water production is basically zero.

Owner:高峰 +2

Energy-saving environment-friendly steel cord hot-dip coating copper-zinc alloy and thermal treatment production process thereof

The invention provides an energy-saving environment-friendly steel cord hot-dip coating copper-zinc alloy layer and a thermal treatment production process thereof in the process of steel cord production. The process comprises electrolytic degrading, washing, coating an assistant coating agent, drying, coating copper in hot-dip mode and austenitizing, coating zinc in hot-dip mode and isothermal treatment and diffusion annealing. The temperature for the process of coating the copper in hot-dip mode and austenitizing ranges from 1100 DEG C to 1140 DEG C, and the temperature for the process of coating the zinc in hot-dip mode and diffusion annealing ranges from 550 DEG C to 600 DEG C. After diffusion annealing, mass percentage of zinc in the copper-zinc alloy coating layer ranges from 30%-37%. The production process respectively utilizes the two procedures of coating the copper in hot-dip mode and austenitizing and coating the zinc in hot-dip mode and isothermal treatment to replace four procedures of austenitizing, copper coating, isothermal treatment and zinc coating, solves the problems of heavy metal iron sewage discharging, waste gas exhaust during austenitizing heating and lead and powder pollution during isothermal treatment in the existing production process, and has the advantages of being good in environment protection performance, high in production efficiency and low in production cost.

Owner:NANJING INST OF TECH

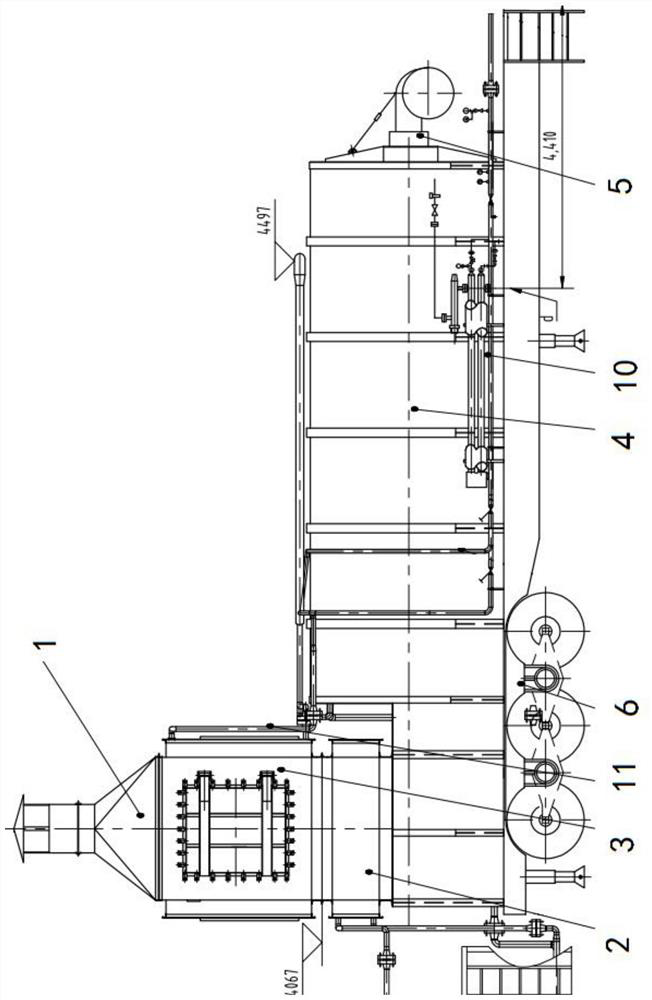

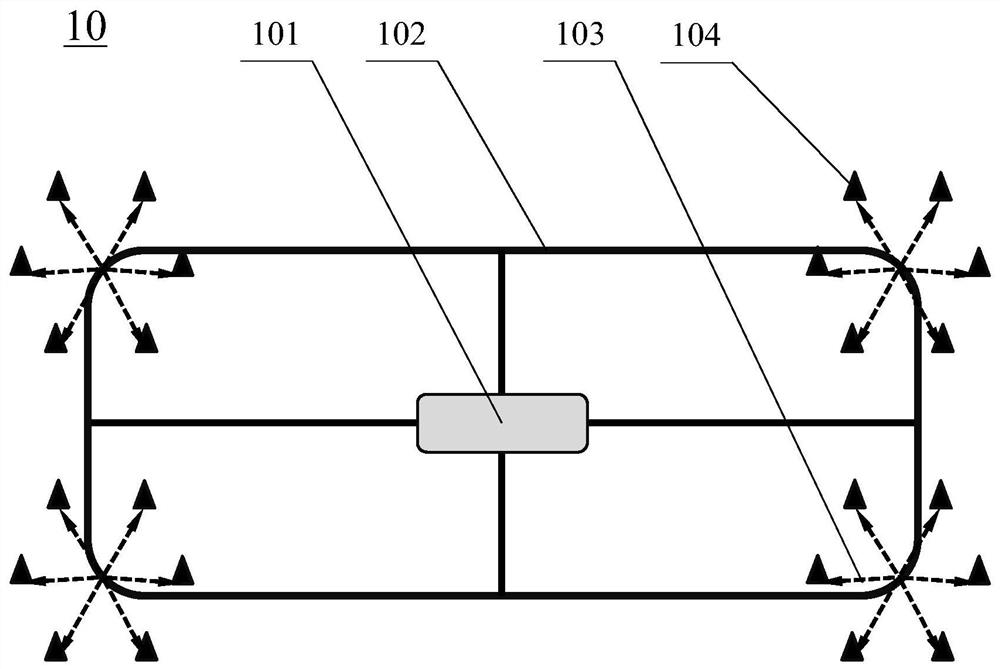

Water vapor heat exchange system and movable steam injection boiler and steam injection method thereof

PendingCN112944312AAvoid Low Temperature CorrosionGuaranteed steam injection effectFluid removalSteam superheatersFlue gasWater vapor

The invention provides a water vapor heat exchange system and a movable steam injection boiler and a steam injection method thereof. The water vapor heat exchange system comprises a water type heat exchanger located between a water pump and a boiler convection section, a flue gas heat exchanger located in the boiler convection section and a radiation section heat exchanger located in a boiler radiation section. The water type heat exchanger comprises a heat exchanger inner pipe and a heat exchanger outer pipe which exchange heat with each other and are used for water medium circulation, wherein the heat exchanger inner pipe, the flue gas heat exchanger, the heat exchanger outer pipe and the radiation section heat exchanger are sequentially communicated in the water medium circulation direction. After absorbing energy in the convection section, a water medium enters the water type heat exchanger to serve as a heat source for heating a water medium which does not enter the convection section, so that the temperature of the water medium is increased to exceed the dew point temperature, and low-temperature corrosion of flue gas to finned tubes is avoided, a flue gas outlet of the radiation section is communicated with an overheating section, a superheat section heat exchanger used for further heating and evaporating the water medium is arranged in the overheating section, wet saturated steam from the radiation section is continuously heated and evaporated through the superheat section heat exchanger, and the steam injection effect on an oil well is guaranteed.

Owner:KARAMAY SHENGLI PLATEAU MACHINERY CO LTD

Combined fruit and vegetable dehydrating production by vacuum freeze, dry and hot air re-dry

InactiveCN1275532CReduce energy consumptionShorten the production cycleFruits/vegetable preservation by dehydrationFreeze-dryingEngineering

A process for preparing the dewatered fruit or vegetable by vacuum freeze drying and hot air drying includes such steps as providing raw fruit or vegetable, washing, peeling or removing kernel, slicing, scaling for deactivating enzyme, conditioning, freezing, freeze drying, hot air drying, and packing.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

Method for shortening processing time of microwave freezing drying of fruit or vegetable powder by utilizing dielectric core

InactiveCN100396195CShorten spin timeImprove qualityFood preservationFood preparationMicrowaveFreeze-drying

A dielectric core method for shortening the time taken by microwave freeze-drying of fruit-vegetable powder includes such steps as choosing raw materials, conventional pre-treating, slicing, beating, adding the high-dielectric-constant titanium oxide ceramic nano-particles, amino acid and sugar or salt to form dielectric cores, quick freezing, microwave vacuum freeze-drying, and pulverizing. It features less loss of nutrients.

Owner:JIANGNAN UNIV

A method of manufacturing a silent chain chain plate

The invention relates to a method for manufacturing an efficient silent chain plate long in service life. The method includes the following steps of firstly, placing a steel plate to be machined in the middle of a die of a horizontal punching machine, wherein a silent chain multi-particle blanking smooth punching composite die is adopted as the die; secondly, making a front die holder and a rear die holder get close so that a female formwork and an outer stripper can be closed, making a protruding block enter a concave hole, punching the steel plate to form small steel pieces with die shapes, and using the small steel pieces in cooperation with parts with small gaps for conducting smooth punching; thirdly, conducting inner hole punching on the inner portions of the small steel pieces through punching nails to obtain a chain plate, and discharging waste out of the gap between the outer stripper and a rear clamping plate through discharge through holes, wherein the chain plate inner hole punching can be smooth due to the fact that the fit clearance between the punching nails and the through holes are small; fourthly, separating the female formwork from the outer stripper, embedding the chain plate in the concave hole, pushing the chain plate out of the concave hole through a piece ejecting block at the moment, and meanwhile conducting high-pressure flushing to blow down the chain plate when the front die holder and the rear die holder are separated. By means of the method, high-speed and large-batch production is achieved, and the raw material waste caused by progressive dies is avoided.

Owner:HANGZHOU DONGHUA CHAIN GRP

Schizochytrium limacinum fermentation medium

ActiveCN103740776AReduce depreciation costsPromote growthMicroorganism based processesFermentationInorganic saltsChloride

The invention relates to a schizochytrium limacinum fermentation medium. By improvement of a fermentation medium formula, the seawater crystal in the medium is replaced by other inorganic salts without chlorine, thereby not only avoiding chloride ion seriously corroding the fermentation equipment, and but also being in favour of DHA accumulation.

Owner:HUBEI XINHE BIOTECH

Production process of flat offset printing roll color-printing pressure-sensitive adhesive trade mark

The production process of plane sheet offset rolled colour-printed pressure-sensitive adhesive label includes the following steps: 1. face paper plane sheet PS plate printing; 2. edging; 3. automatically-adhering single-sheet printed face paper and coiling; 4. finely-coating pressure-sensitive adhesive and lamination; 5. cutting roll and die-cutting. The single-sheet printed face paper automatically adhering and coiling process includes the following steps: positioning face paper to the glue-applying place, at the same time transferring and pressing pressure-sensitive adhesive onto the face paper form parting paper; adhering head and tail of face paper, digital-control taking up by servo-motor, rectifying deviation, using position sensor and tension control system to regulate and control brake and constant tension rolling up.

Owner:高国明

Improved method for 5-tube area smelting furnace

InactiveCN110093518AExtended service lifeSafe and reliable production and operationIncreasing energy efficiencyMetallurgyImproved method

The embodiment of the invention discloses an improved method for a 5-tube area smelting furnace. The improved method comprises the following steps that (a) a furnace body is re-arranged according to the structural layout of the 5-tube area smelting furnace, and a plurality of furnace tubes are arranged in the furnace body; (2) electromagnetic induction coils are correspondingly sleeved on the furnace tube, and a plurality of electromagnetic induction coils are sequentially connected in series; and (c) a cooling water inlet pipe is correspondingly arranged at the front end part and the middle part of the plurality of electromagnetic induction coils which are sequentially connected in series, and a cooling water outlet pipe is arranged at the tail end part. According to the improved method,the water inlet pipe is correspondingly arranged at the front end and the middle part of the plurality of electromagnetic induction coils which are sequentially connected in series, the cooling requirements of the electromagnetic induction coils of the tube area smelting furnace are met, the production operation safety is guaranteed, the service life of the electromagnetic induction coils is prolonged, and the equipment cost is reduced.

Owner:YUNNAN CHIHONG INT GE CO LTD

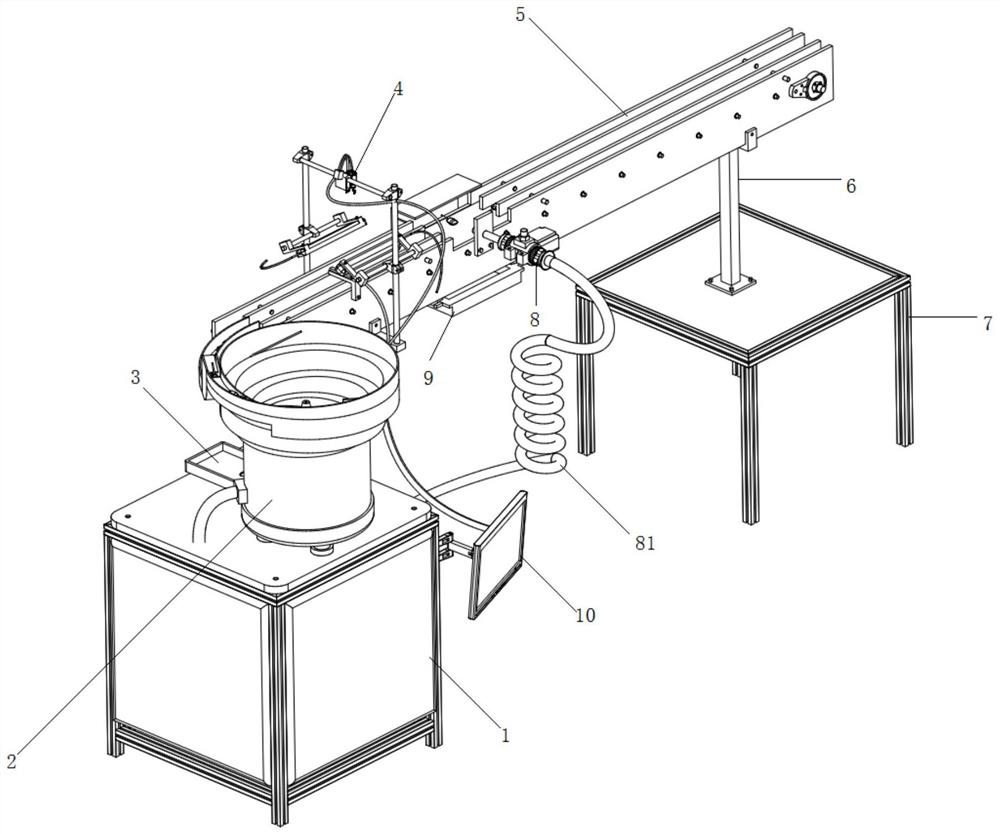

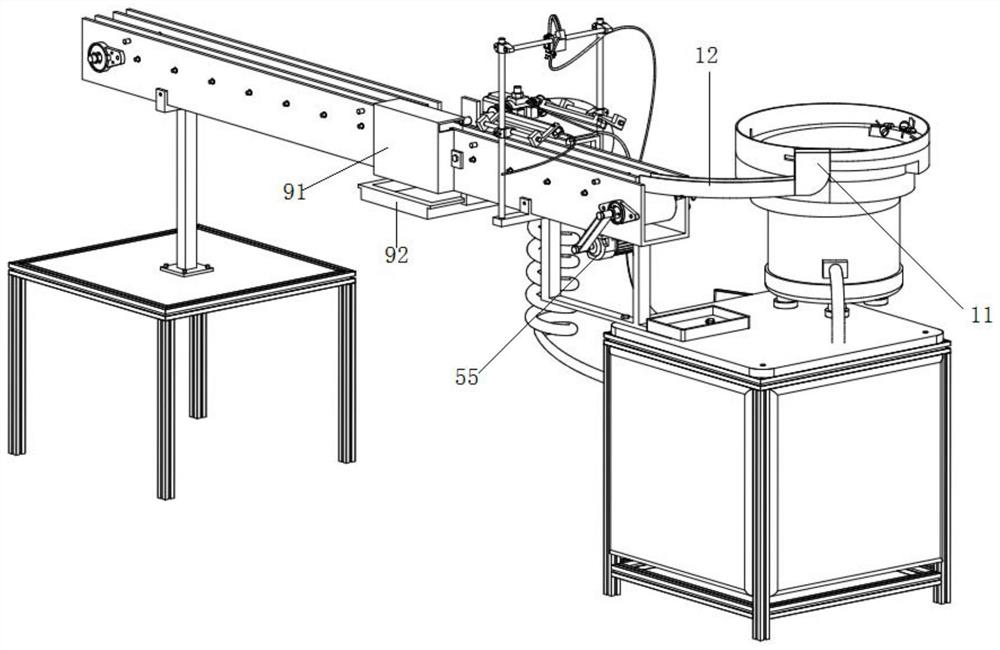

Candy quality detection method based on machine vision and feeding rejecting system

PendingCN114700273AReduce lossAccurate detectionImage enhancementImage analysisProcess engineeringDelivery system

The invention discloses a candy quality detection method based on machine vision and a feeding and rejecting system. The candy quality detection system is characterized by comprising an ordered discharging system, a visual detection and rejecting system and a feeding and conveying system, the feeding conveying system is connected to the rear end of the orderly discharging system, and the visual detecting and removing system is erected on the upper portion of the feeding conveying system and used for detecting the quality of candies and removing defective products. According to the device, orderly discharging of candy products and appearance quality detection and removal can be achieved, the problems of adhesion and different discharging directions in the candy production process are effectively solved, the quality inspection quality and efficiency of candies are improved, and the labor cost is saved.

Owner:广东猛犸象智能机器人制造有限公司

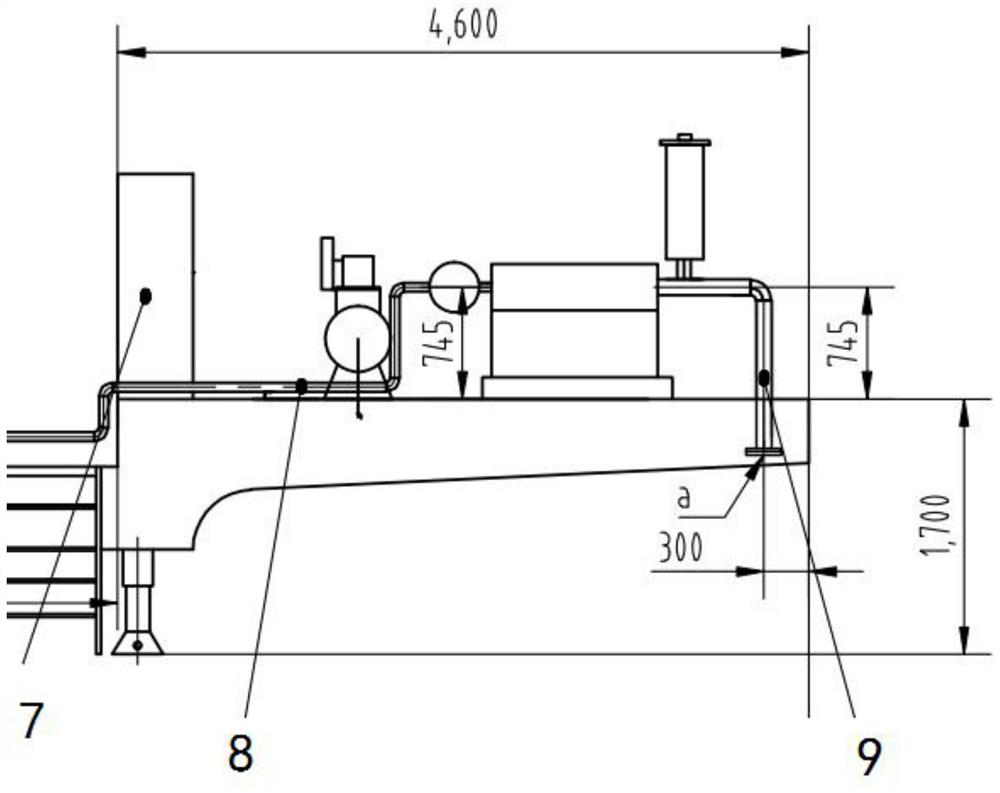

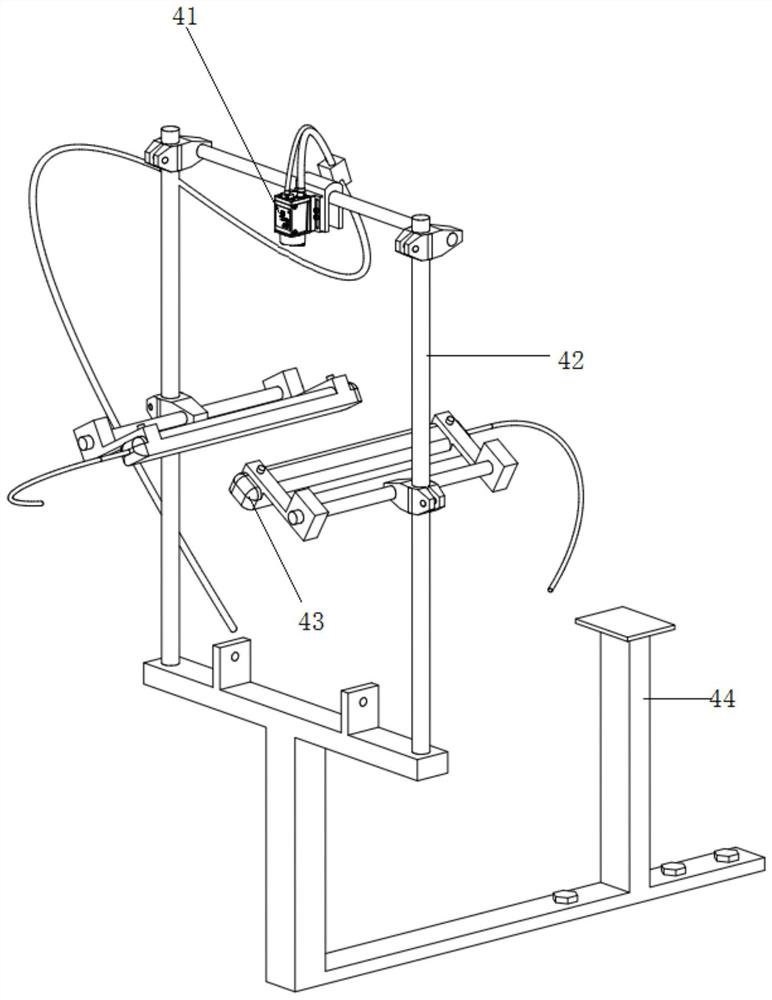

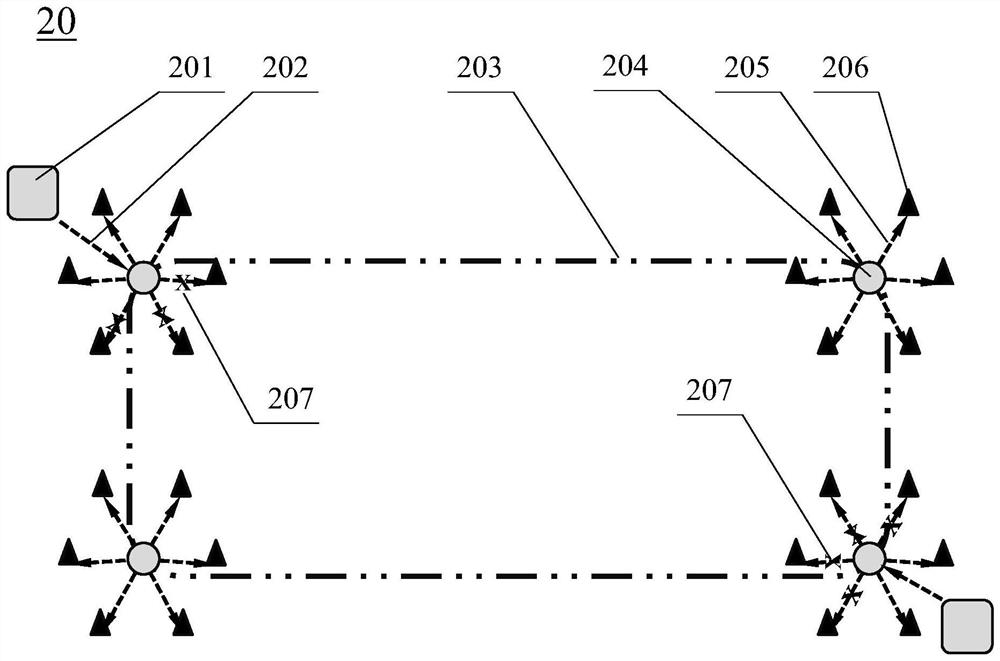

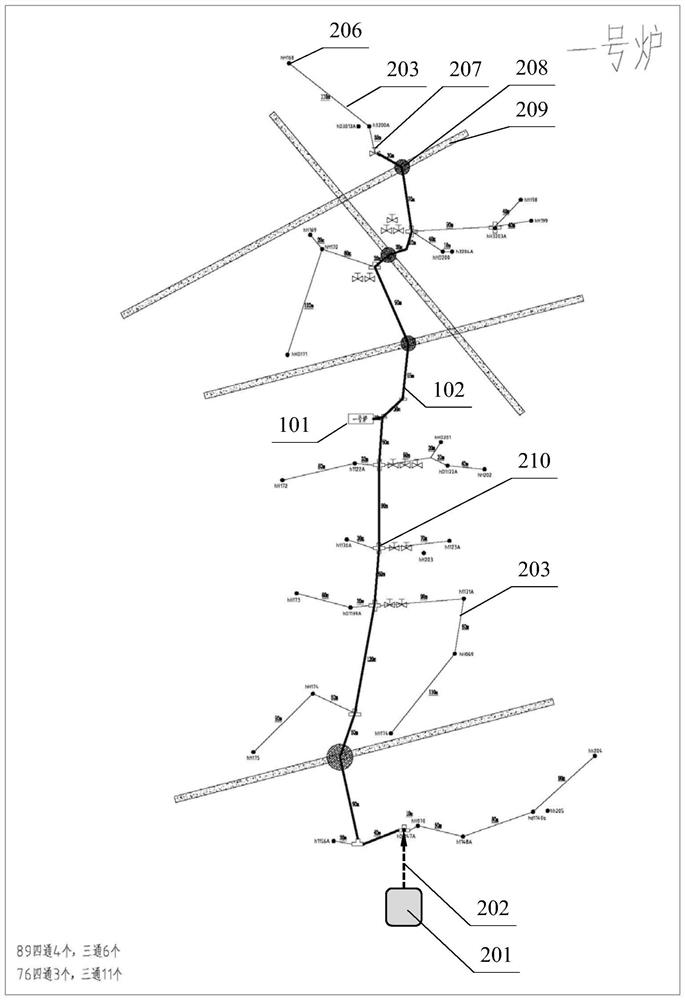

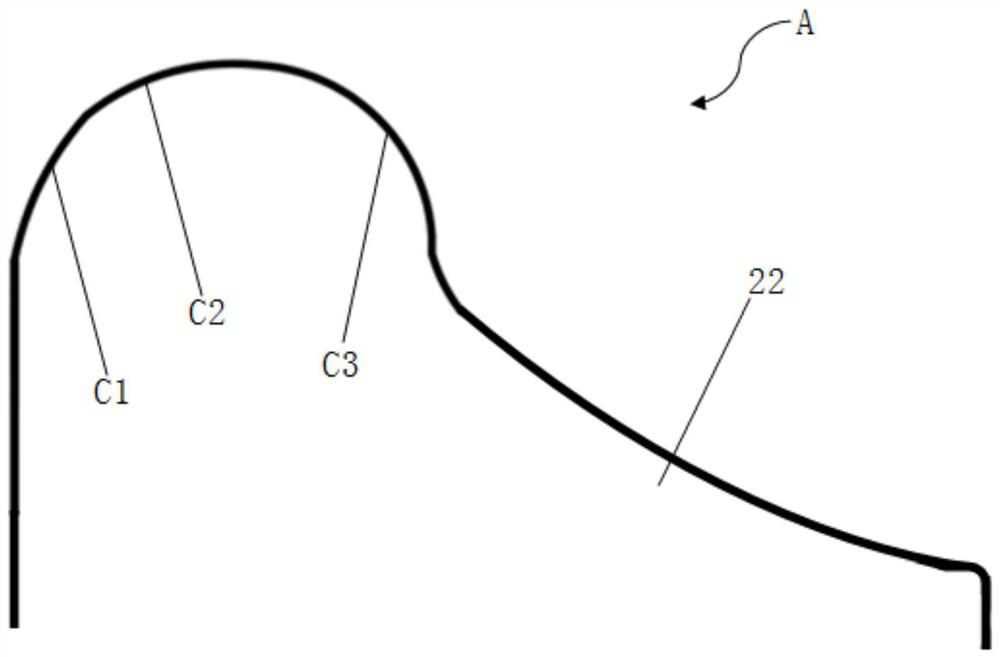

Discrete layout movable steam injection device and steam injection process thereof

PendingCN113236213AShorten the lengthShorten the overall lengthFluid removalSteam boilersThermodynamicsOil field

The invention discloses a discrete layout movable steam injection device and a steam injection process thereof. The discrete layout movable steam injection device are used for steam injection of a plurality of oil production wellheads distributed in each area of an oil field, and the multiple oil production wellheads communicate to an underground oil layer through a Christmas tree and an underground oil pipe. The discrete layout movable steam injection device comprises a movable boiler, a movable pipeline, a plurality of steam thin pipelines, a plurality of water, electricity and gas stations and water, electricity and gas thin pipelines, wherein one end of the movable pipeline can be quickly and detachably connected with the movable boiler; one end of each steam thin pipeline is connected with one oil production wellhead, and the other end of each steam thin pipeline can be quickly and detachably connected with the other end of the movable pipeline; the multiple water, electricity and gas stations are distributed in all areas of the oil field, and each water, electricity and gas station comprises a water interface, an electricity interface and a gas interface at fixed positions; the water, electricity and gas thin pipelines are arranged at all the water, electricity and gas stations, and the movable boiler is connected with water, electricity and gas interfaces at the fixed positions of the water, electricity and gas stations through the water, electricity and gas thin pipelines. Nearby steam injection can be achieved, the length of a steam injection pipeline is shortened, and heat loss is reduced.

Owner:KARAMAY SHENGLI PLATEAU MACHINERY CO LTD

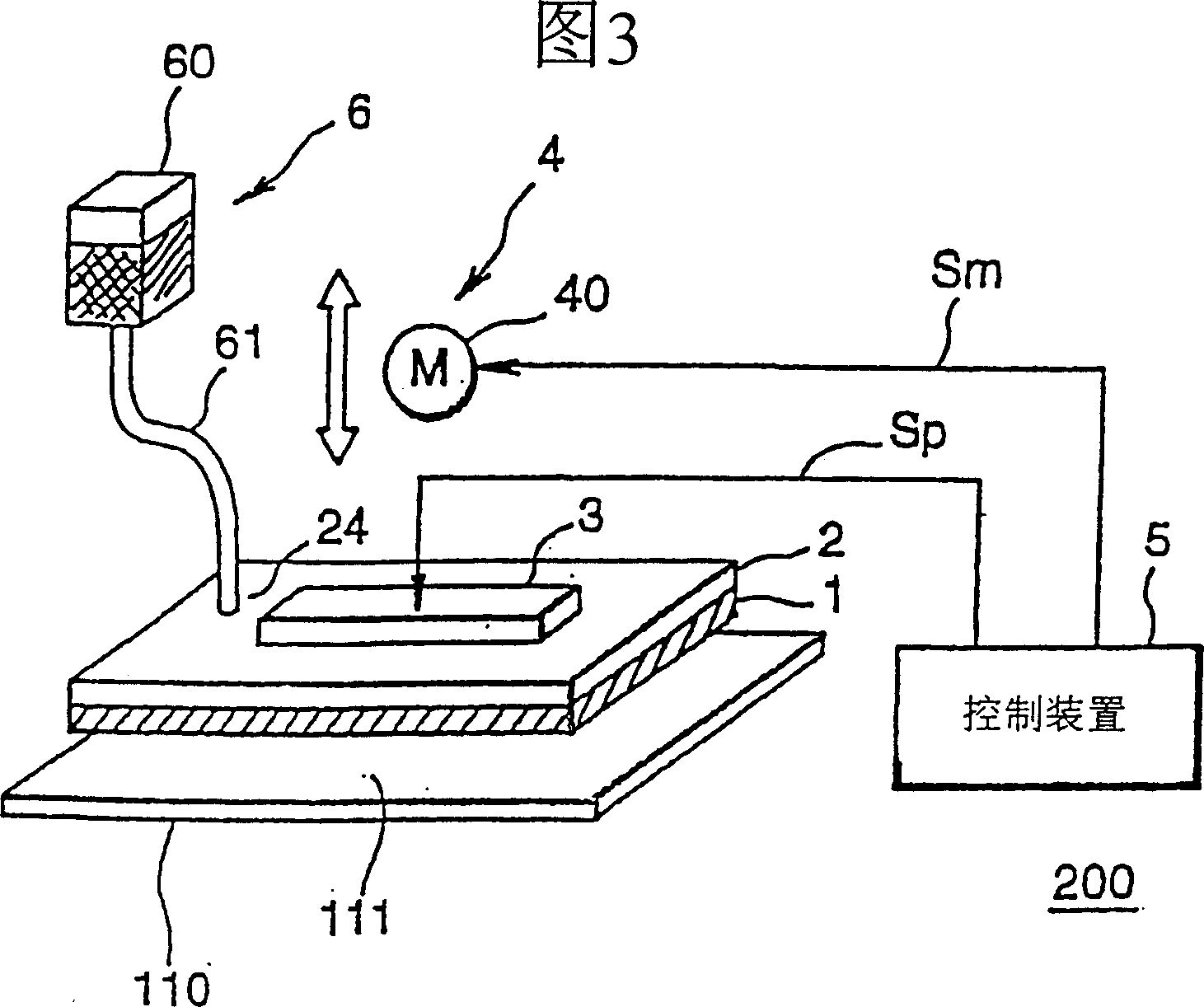

Picture composition method, device, template and method for making same

InactiveCN1161242CReduce processing costsLow costDecorative surface effectsSemiconductor/solid-state device manufacturingEngineeringSemiconductor

Owner:SEIKO EPSON CORP

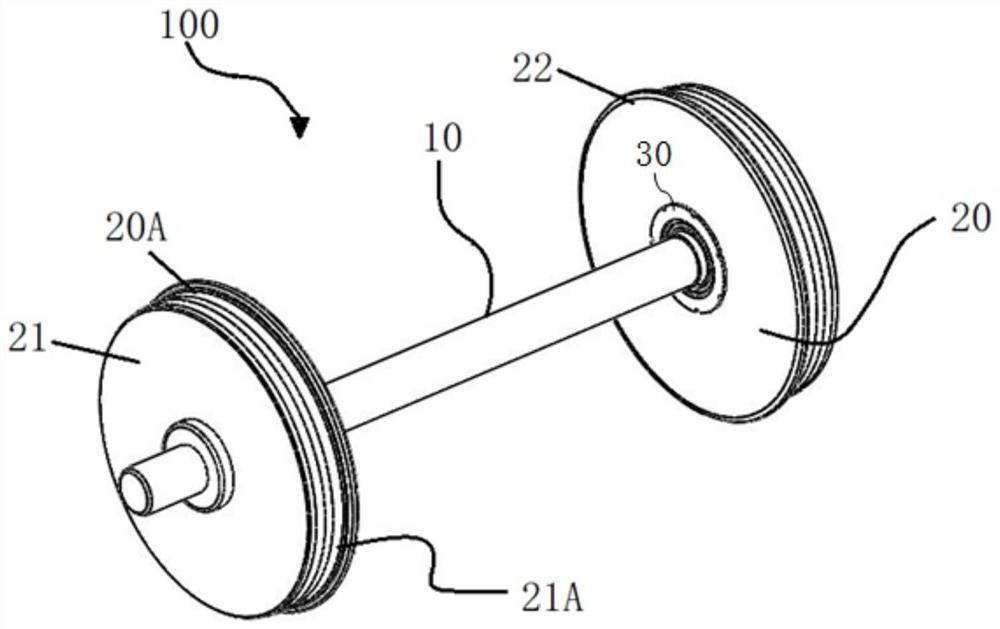

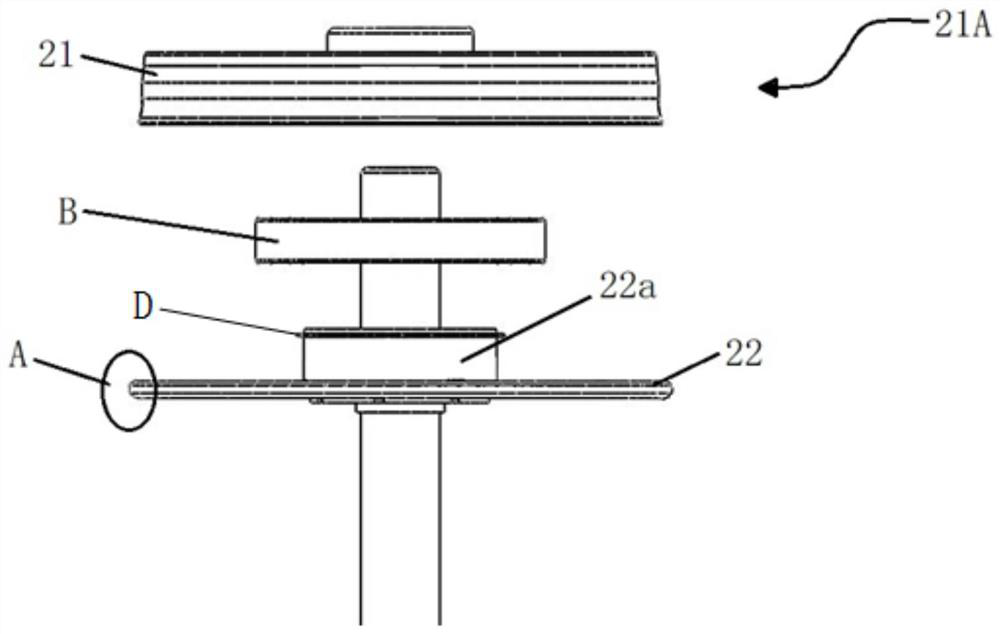

Low-abrasion wheel set and rail vehicle applied to multi-small-radius curve rail

PendingCN112721538AGood curve passing performanceReduce wearRail-engaging wheelsWheel-axle combinationsBridge engineeringCoupling

The invention belongs to the field of road and bridge engineering, and discloses a low-abrasion wheel set which can greatly reduce abrasion between a rail and a rim surface and greatly reduce depreciation cost of a rail vehicle wheel set and comprises a wheel set body, the wheel set body comprises wheels, and each wheel comprises a tread portion, a rim portion and a coupling bearing for connecting the tread portion and the rim portion together. When a curve passes, the tread portion and the rim surface can independently rotate in the curve passing process, so that rolling friction instead of sliding friction is generated between the rim surface and the side surface of the rail in the curve passing process. The invention further provides a rail vehicle applied to the multi-small-radius curve rail, and the service life of the rail vehicle can be greatly prolonged by using the low-abrasion wheel set.

Owner:SHANGHAI UNIV OF ENG SCI

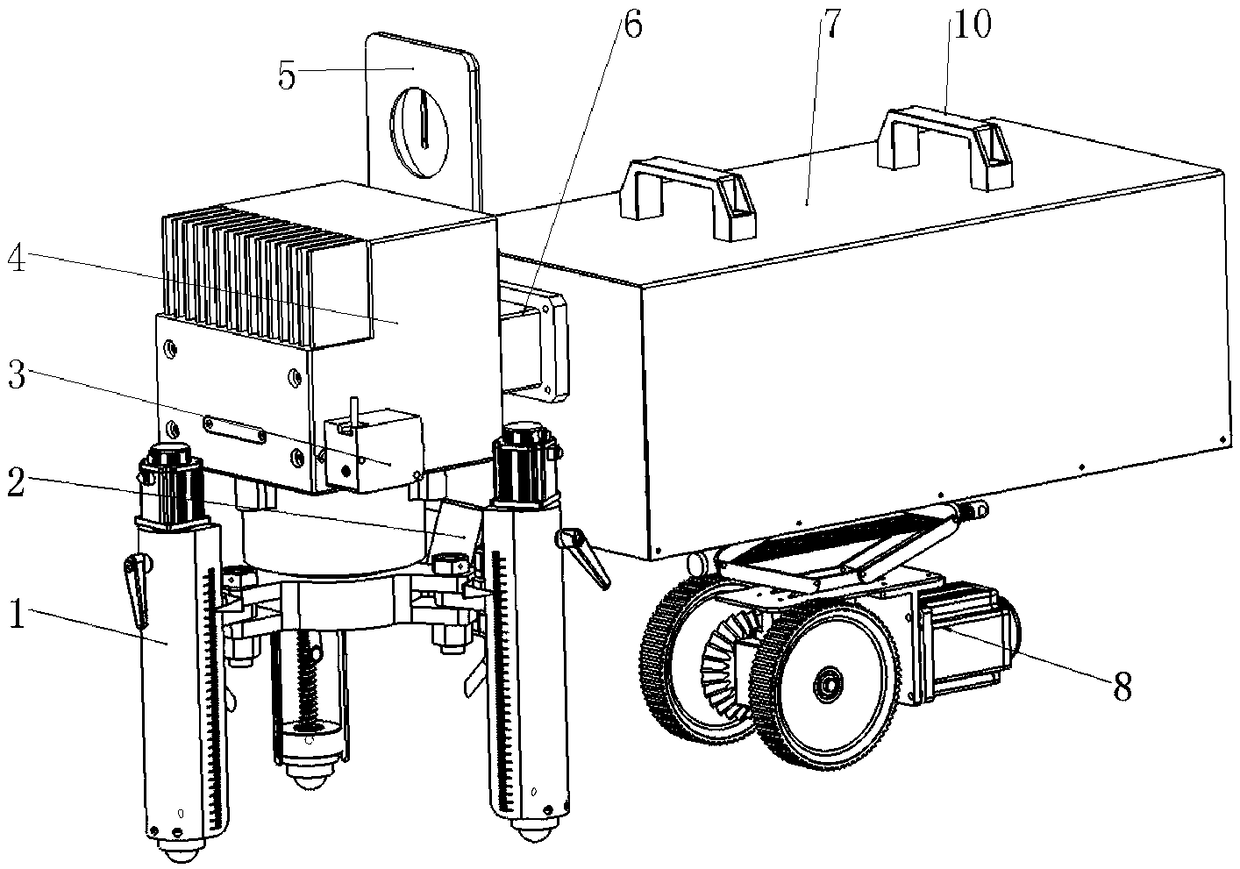

A handheld self-adaptive laser cleaning device with folded optical path

ActiveCN107433395BReduce depreciation costsExtended service lifeCleaning processes and apparatusLaser beam welding apparatusLaser rangingElectricity

The invention provides a folded light path type handheld self-adaption laser cleaning device. The device comprises a lifting focusing assembly, a laser distance measuring sensor, a galvanometer scanning system, a lifting guide electric drive assembly and a laser-folded path system. The galvanometer scanning system is used for focusing incident laser beams on the surface of a workpiece and making the laser beams do scanning motion on the surface of the workpiece according to a set track; the lifting focusing assembly is arranged under the emergence end of the laser beams of the galvanometer scanning system, the laser distance measuring sensor is installed on the lateral side of the galvanometer scanning system, a laser device id arranged in the laser-folded path system, and the output end of the laser-folded path system is fixedly connected with the emergence end of the laser beams of the galvanometer scanning system, so that the output laser beams of the laser-folded path system become the emergence laser beams of the galvanometer scanning system; the lifting guide electric drive assembly is arranged below the bottom of the laser-folded path system. In the folded light path type handheld self-adaption laser cleaning device, the laser device and a laser cleaning machining head are combined so that the cleaning machining precision, quality and efficiency can be effectively improved.

Owner:圣同智能机械设备(上海)有限公司

Method for quickly preparing non-puffing high-colloid freeze-dry sea products

InactiveCN101433228BGood value for moneyReduce energy consumptionMeat/fish preservation by freezing/coolingMeat/fish preservation by dryingMicrowaveFreeze-drying

The invention discloses a method for quickly preparing a non-expanding high-gelatin marine freeze-drying product, which relates to the production of dehydrated marine products and belongs to the technical field of the processing of marine products. The method comprises the following steps: a high-gelatin marine product raw material is selected, washed, removed with internal organs, cut (depend onthe actual situation), pre-boiled, quick-frozen, freeze-dried under vacuum, microwave-dried under vacuum, packaged and stored. The method adopts vacuum freeze-drying when the moisture content is highto dehydrate most of moisture in a sublimation drying section to form a fixed porous structure, thereby effectively retaining the characteristics of intact texture and quick rehydration of products, and preventing high-gelatin marine products from being easy to harden and crust during the dehydration; and the method subsequently adopts vacuum microwave drying, thereby greatly reducing energy consumption and production period, so as to reduce the cost. The method is suitable for the dehydration of all the high-gelatin marine products, and has more remarkable advantages over the treatment of certain marine products with high value.

Owner:JIANGNAN UNIV +1

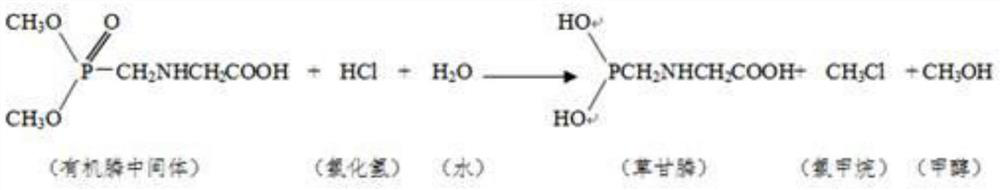

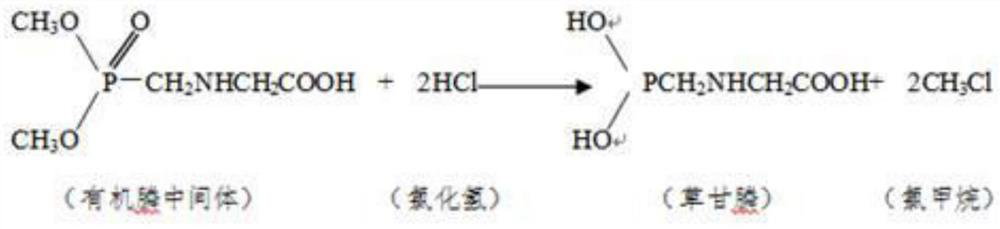

A heterogeneous continuous acid hydrolysis device and process for producing glyphosate by glycine method

ActiveCN110759944BTo avoidReduce pressure on environmental protectionGroup 5/15 element organic compoundsSeed crystalMethanol

Owner:HUBEI TAISHENG CHEM

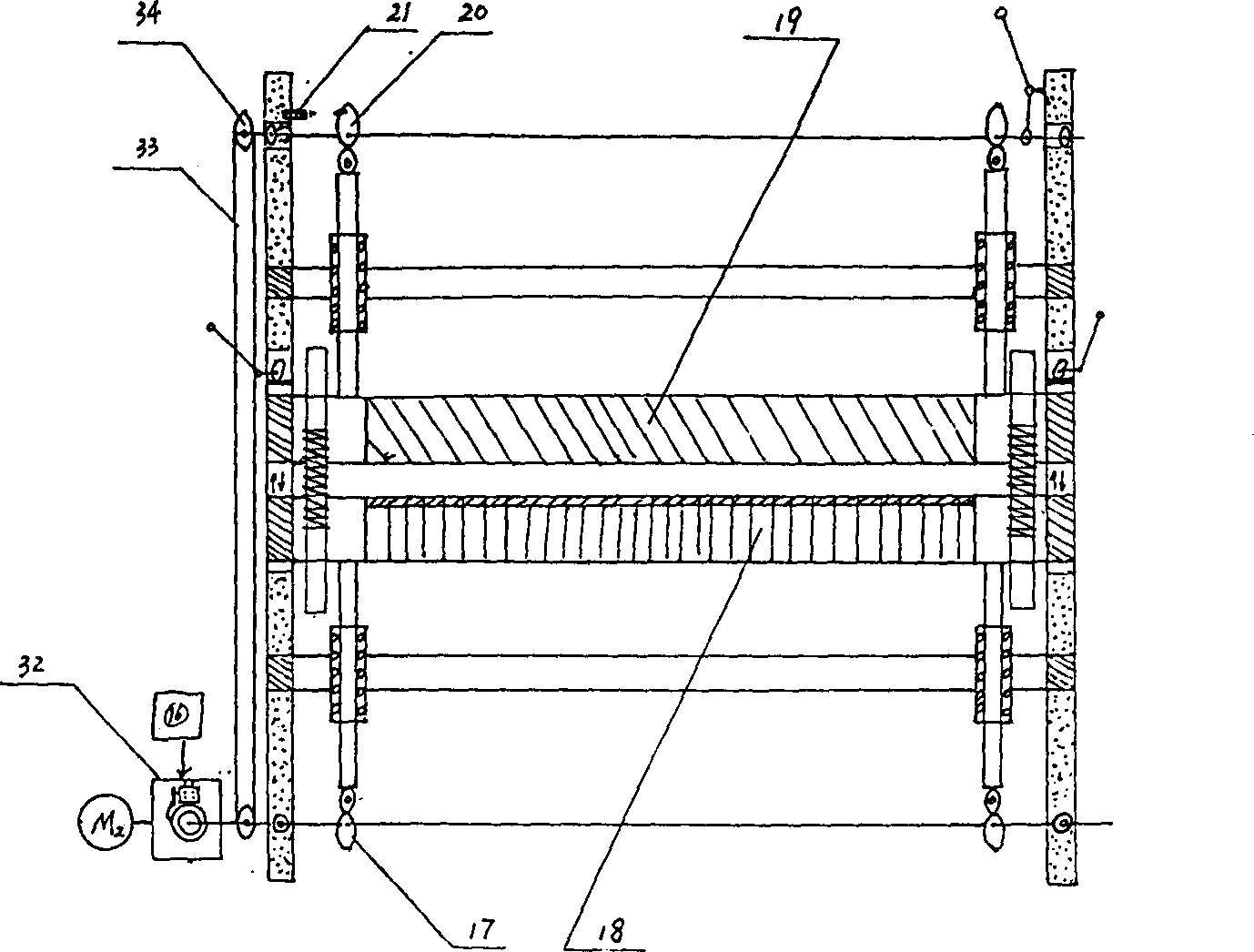

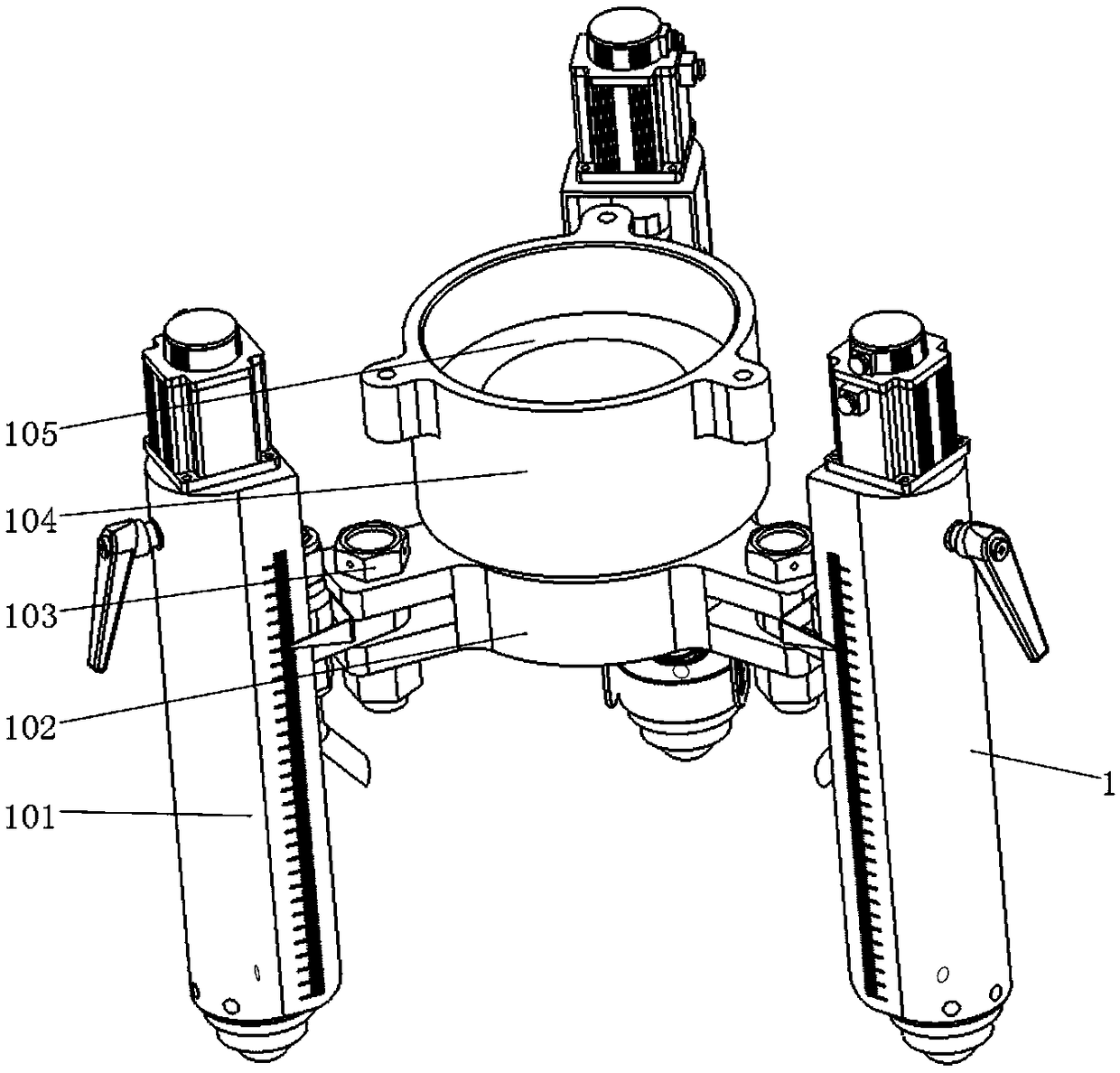

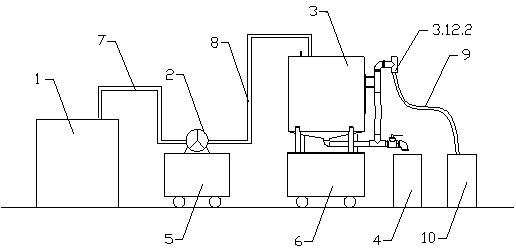

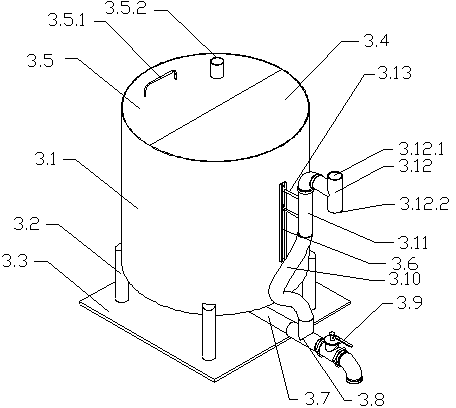

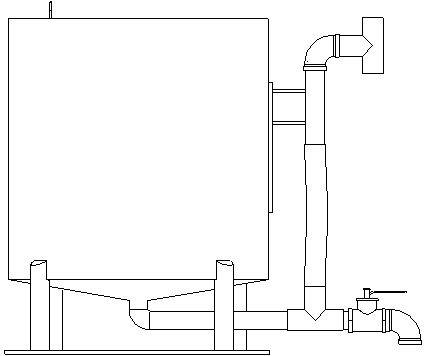

Quantitative mortar circulation system

InactiveCN103991142ALower purchase costReduce depreciation costsWorking accessoriesFine working devicesGeotechnical engineeringPipe

The invention relates to a quantitative mortar circulation system. The quantitative mortar circulation system is characterized by comprising a mortar stirring bucket (1), a membrane pump (2), a mortar circulation bucket (3) and a mortar tank (4), wherein the mortar circulation bucket (3) comprises a bucket body (3.1), the bottom of the bucket body (3.1) is connected with a discharging pipe (3.7), a guiding tee joint (3.8) and a valve (3.9) are arranged on the discharging pipe (3.7), the guiding tee joint (3.8) is connected with a hose (3.10), the top of the hose (3.10) is connected with a lifting pipe (3.11), the top of the lifting pipe (3.11) is connected with an overflow tee joint (3.12), the position of an overflow port (3.12.2) of the overflow tee joint (3.12) is connected to a material returning cylinder (10) through a material returning hose (9). The quantitative mortar circulation system has the advantages of being high in weighing accuracy and saving raw materials and labors.

Owner:HAREON SOLAR TECHNOLOGY CO LTD

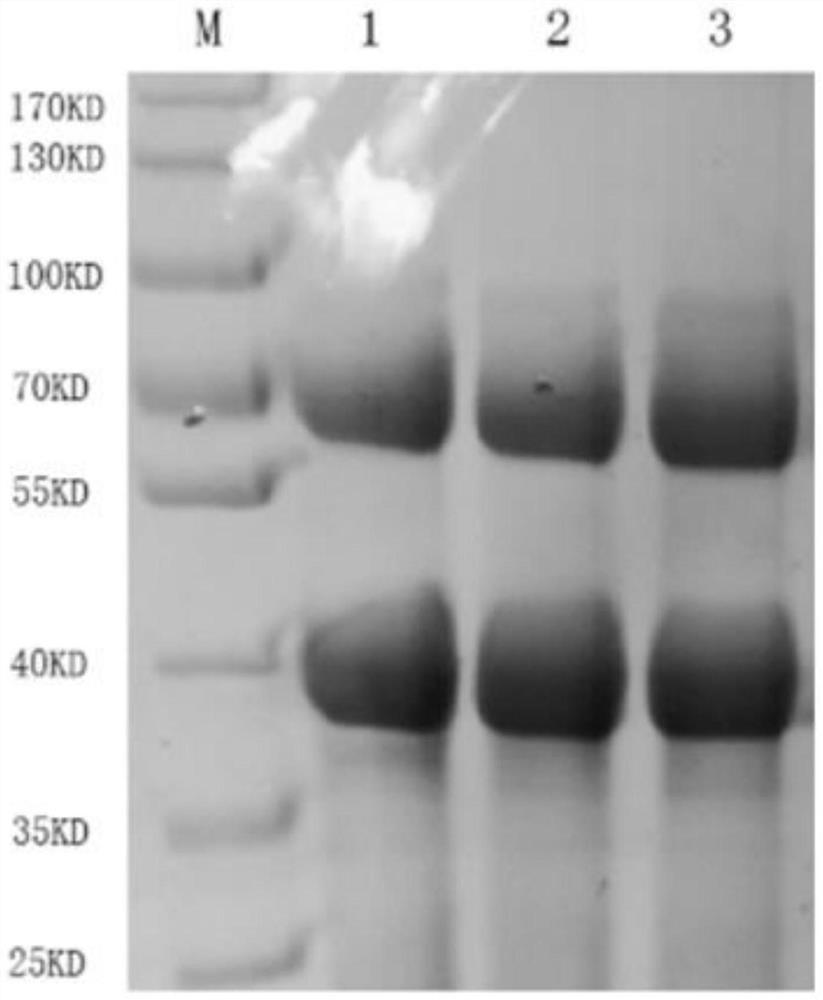

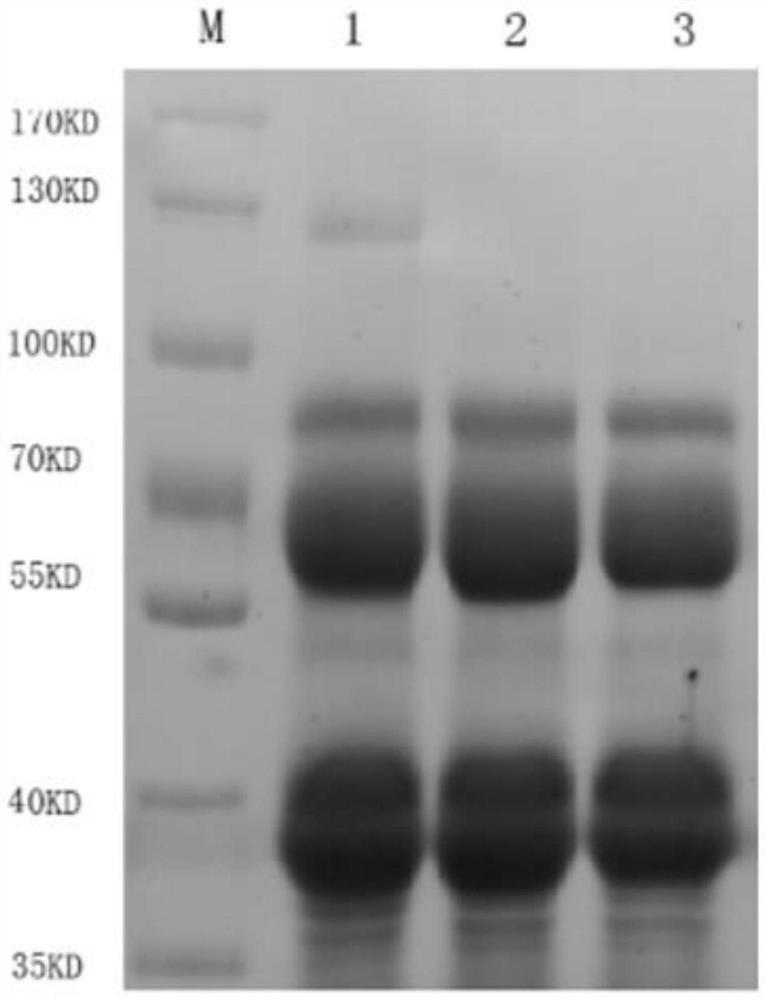

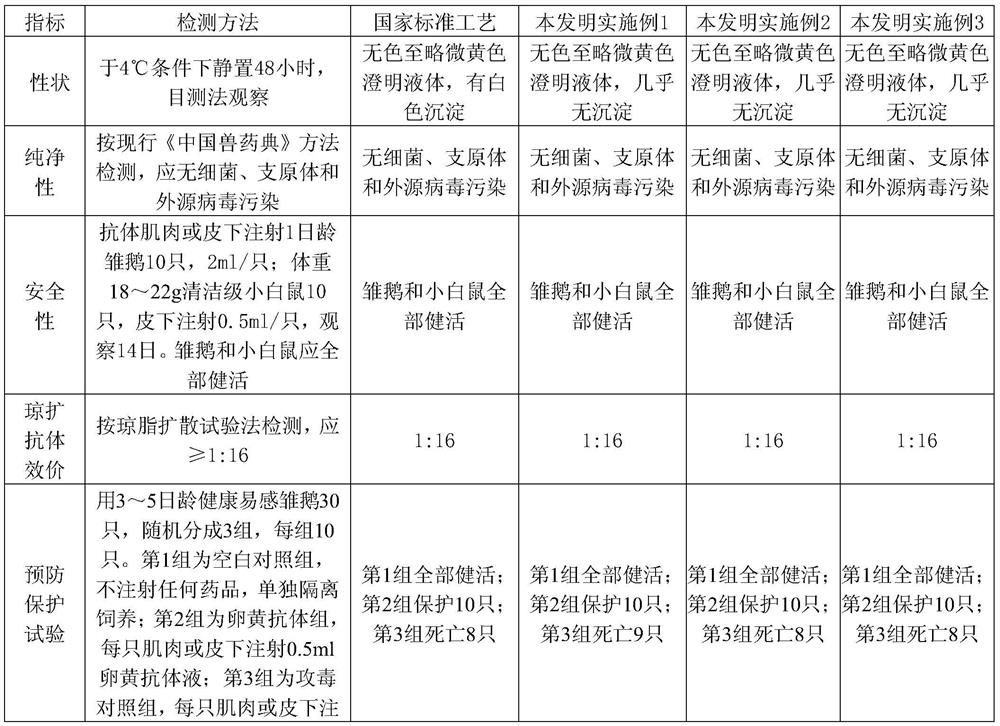

A large-scale extraction method of egg yolk antibody

ActiveCN108059674BShorten the production cycleReduce manufacturing costEgg immunoglobulinsYolkImmunity

The invention discloses a large-scale method for extracting egg yolk antibodies, which comprises the following steps: separating egg yolks after sterilizing high-free eggs; stirring the separated egg yolks into a paste, adding water for injection, and the volume ratio of egg yolks to injection water is 1 : 1.5‑1: 3; then adjust the pH value of the egg yolk liquid to 5.0‑5.2; then add octanoic acid solution with a concentration of 1.5‑3%, stir evenly and then stand still for 2‑3 hours to filter the egg yolk liquid, when 80% of the lower layer After the clear liquid is filtered, stir the remaining liquid evenly and continue to filter to collect the filtrate; then add an appropriate amount of water for injection to dilute the filtrate to obtain a clear liquid, then adjust the pH value of the clear liquid to 6.0-7.0, and then add Formaldehyde solution with a final concentration of 0.05%, the clear liquid is filtered again, the filtrate is collected for sub-packaging and then inspected. After passing the inspection, it is labeled and transferred to the finished product warehouse. The invention significantly shortens the production cycle of the egg yolk antibody, reduces the production cost, has higher product purity and prolongs the shelf life of the product.

Owner:CHONGQING SANJIE ZHONGXIN BIOLOGICAL ENG CO LTD

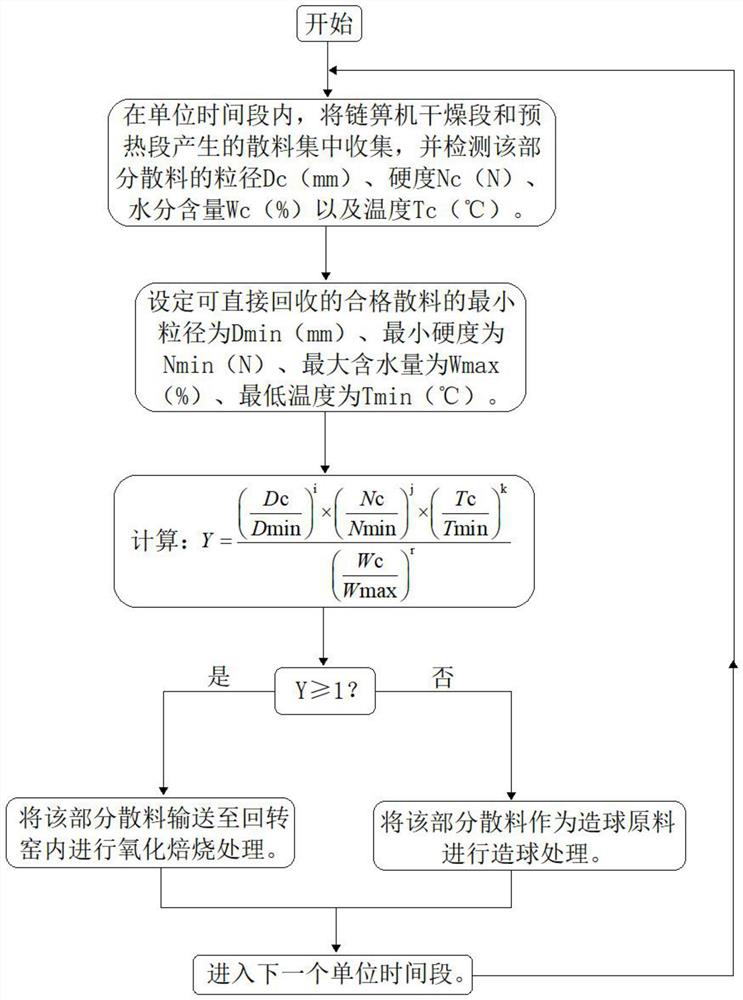

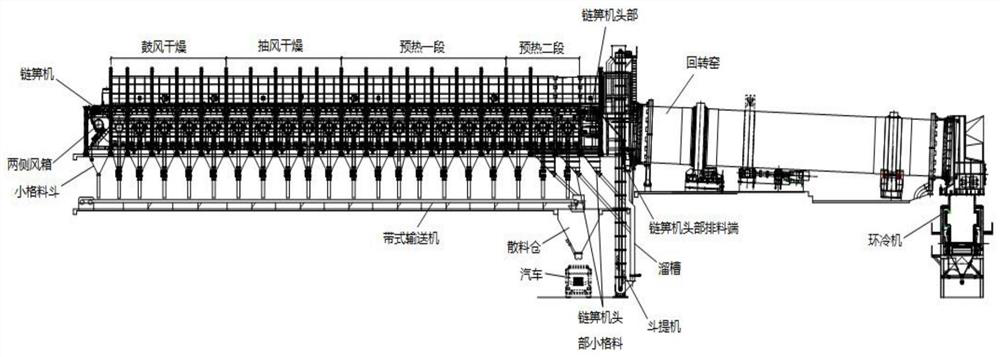

Pellet chain grate bulk material comprehensive treatment method and system

ActiveCN112853088AReduce storage costsReduce loss costRotary drum furnacesProcess efficiency improvementThermodynamicsProcess engineering

The invention discloses a pellet chain grate bulk material comprehensive treatment method and system. In a unit time period, bulk materials generated by a chain grate are collected and screened, the particle size, strength, temperature and water content of oversize coarse bulk materials are detected, then comprehensive performance index values of the bulk materials are obtained through calculation according to a bulk material sorting mathematical model, qualified bulk materials are screened out and directly recycled to a rotary kiln to be roasted, and unqualified oversize coarse-particle bulk materials and undersize fine-particle bulk materials are used as pelletizing raw and auxiliary materials to be directly pelletized. According to the method, the bulk materials in all sections of the chain grate are collected and treated in a centralized mode, recycling of the bulk materials in a pellet production system is realized, outward transport disposal is avoided, the outward transport cost, the stockpiling cost of a stockyard, the material loss cost and the mixed ore depreciation cost are lowered, meanwhile, the environment is improved, and the production efficiency is improved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Process for preparing foam composite material of magnesium alloy-pearlite

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com