Low-abrasion wheel set and rail vehicle applied to multi-small-radius curve rail

A low-wear, wheel-set technology, applied in the field of rail vehicles, can solve the problems of wheel flange wear, reduced curve passing capacity, increased depreciation costs of rail vehicle wheelsets, and various damages to rails, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following embodiments will specifically explain the low-wear wheelset of the present invention and the rail vehicle applied to multiple small-radius curved tracks in conjunction with the accompanying drawings. It is to be noted that the descriptions of these embodiments are used to help understanding of the present invention, but are not intended to limit the present invention.

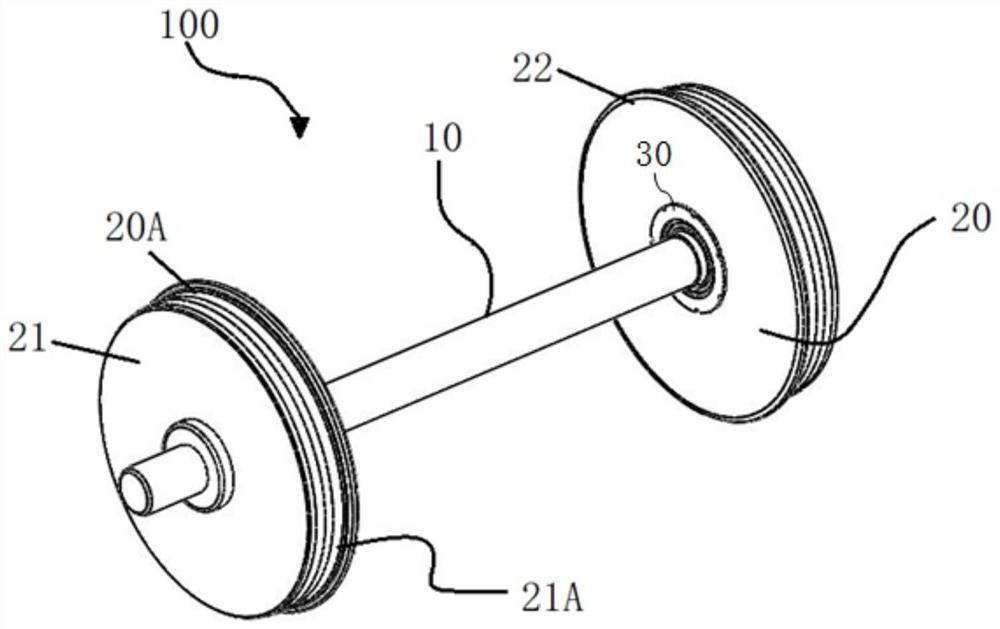

[0026] Such as figure 1 As shown, the low-wear wheel set 100 in this embodiment includes a wheel axle 10 , a wheel set 20 and an oil stop unit 30 .

[0027] The wheel set 20 includes wheels 21A respectively arranged at both ends of the wheel axle 10 . In this embodiment, the wheels 21A are fixed at both ends of the wheel axle 10 through shoulder structures on the wheel axle 10 .

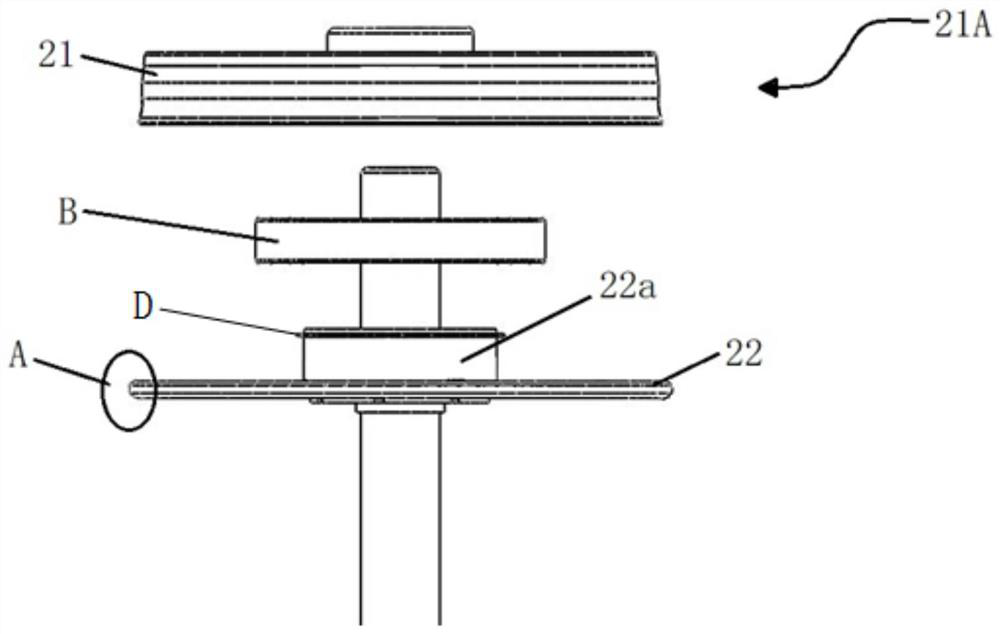

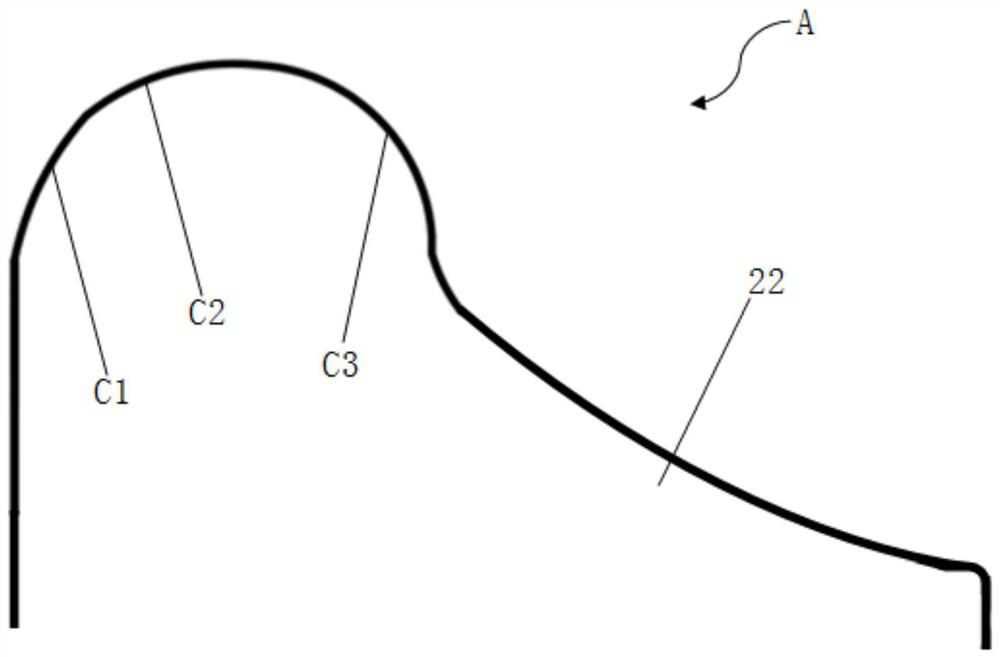

[0028] Such as figure 2 As shown, the wheel 21A includes a tread portion 21, a ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com