Inner axle box bogie adopting novel flexible framework and permanent magnet direct drive motor

A permanent magnet direct drive, bogie technology, applied in the field of bogies, can solve the problems of large wheel-rail action force, long journal center distance, high traction energy consumption, and achieve strong twisting ability, small turning angle, and load-equalizing performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

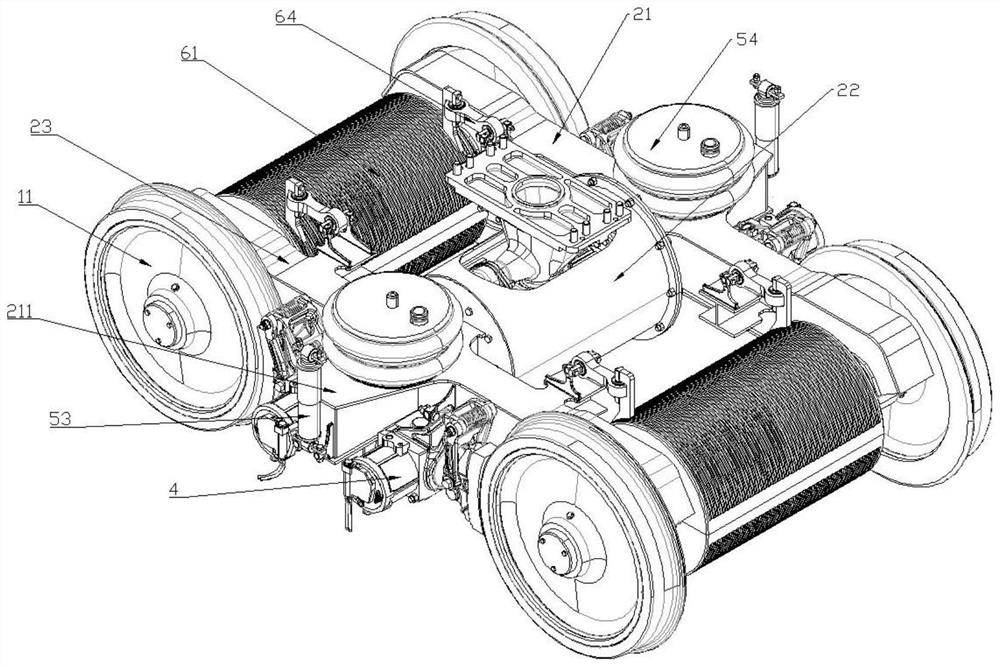

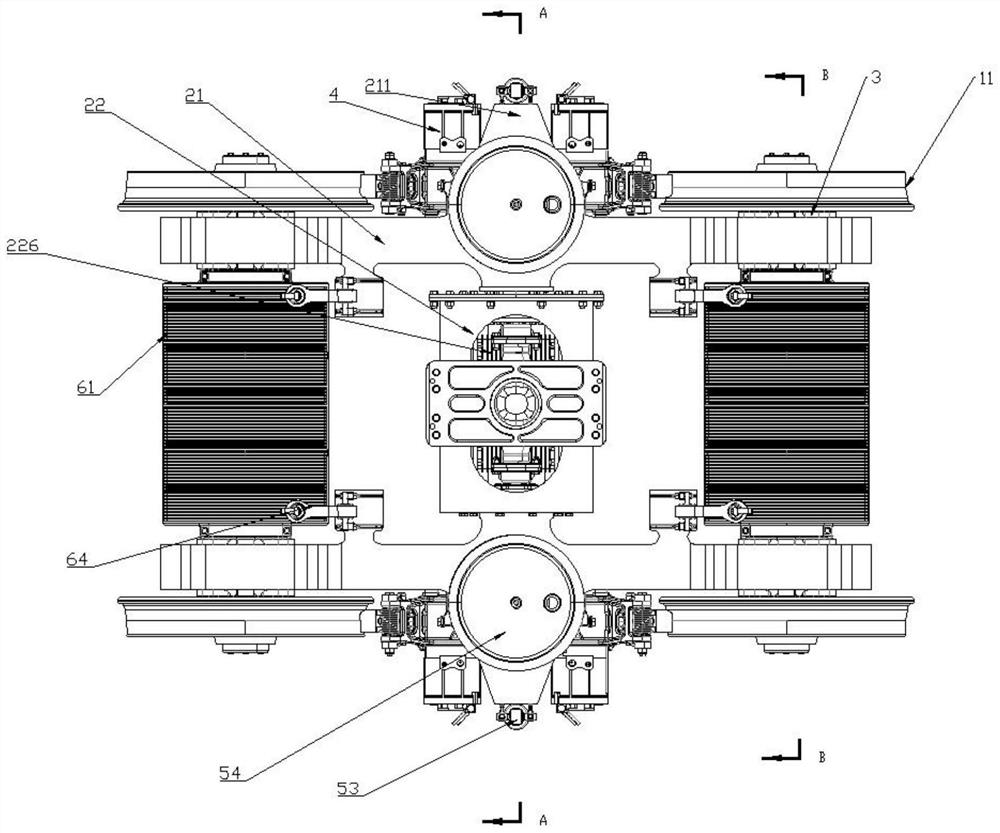

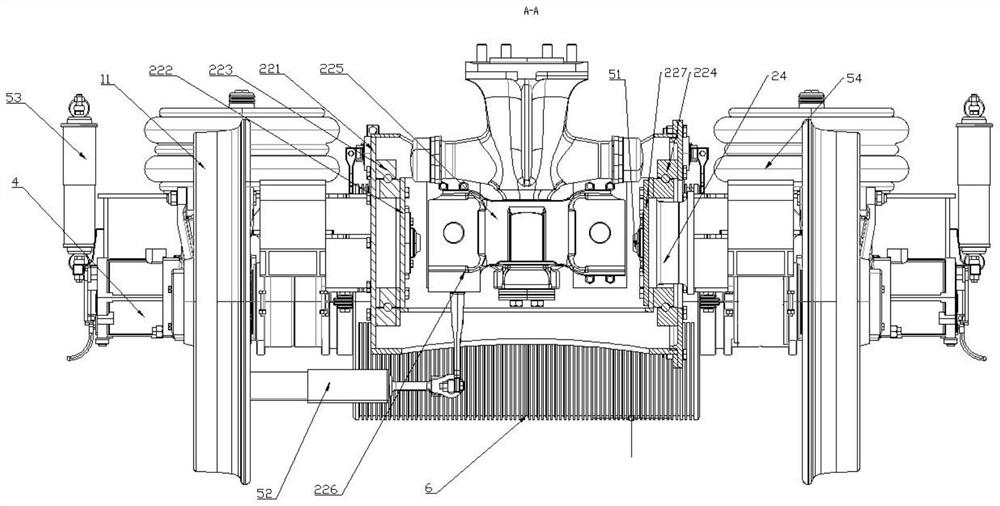

[0034] like Figure 1-8 As shown, the present invention provides an inner axle box bogie adopting a novel flexible frame and a permanent magnet direct drive motor, comprising:

[0035] Wheel sets 1, each wheel set 1 includes two wheels 11 and an axle 12;

[0036]Frame 2 is an H-shaped overall frame, including two longitudinally arranged left beams 21, right side beams 23 and a set of horizontally arranged hinged beam devices 22, wherein: the hinged beam devices 22 are hinged by the outer hinged beam 221 and the inner hinged beam. The beam 222, the left slewing bearing 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com