A planet carrier structure with flexible floating and load sharing

A planet carrier, flexible technology, applied in transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems of not ensuring smooth operation, mitigating vibration, lack of flexibility, etc. Vibration and shock reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

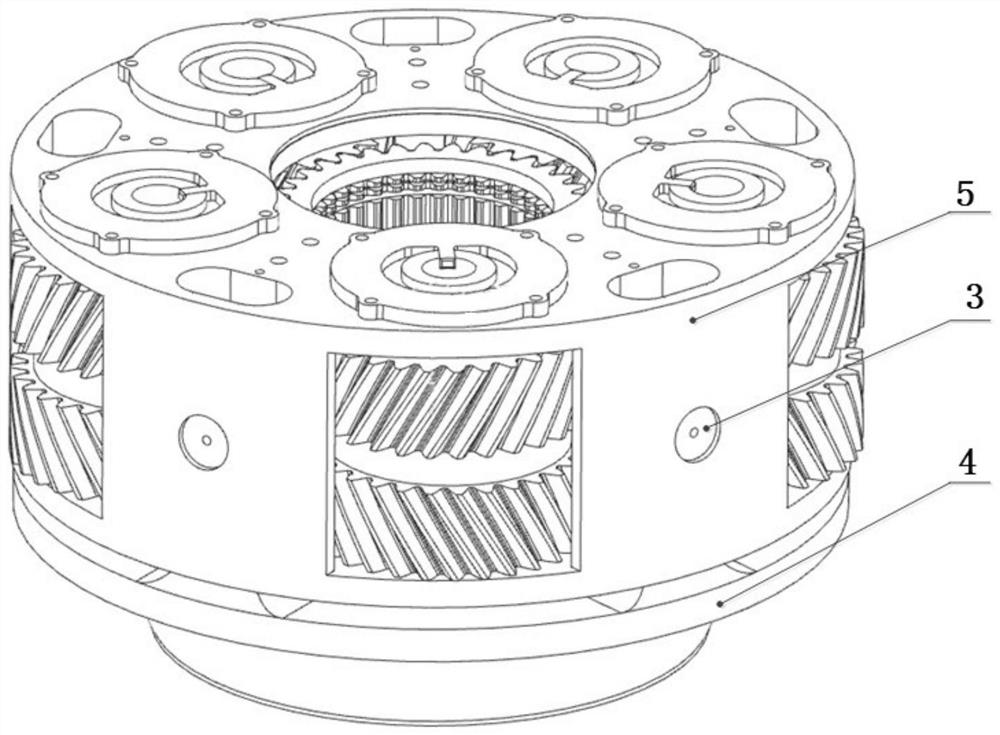

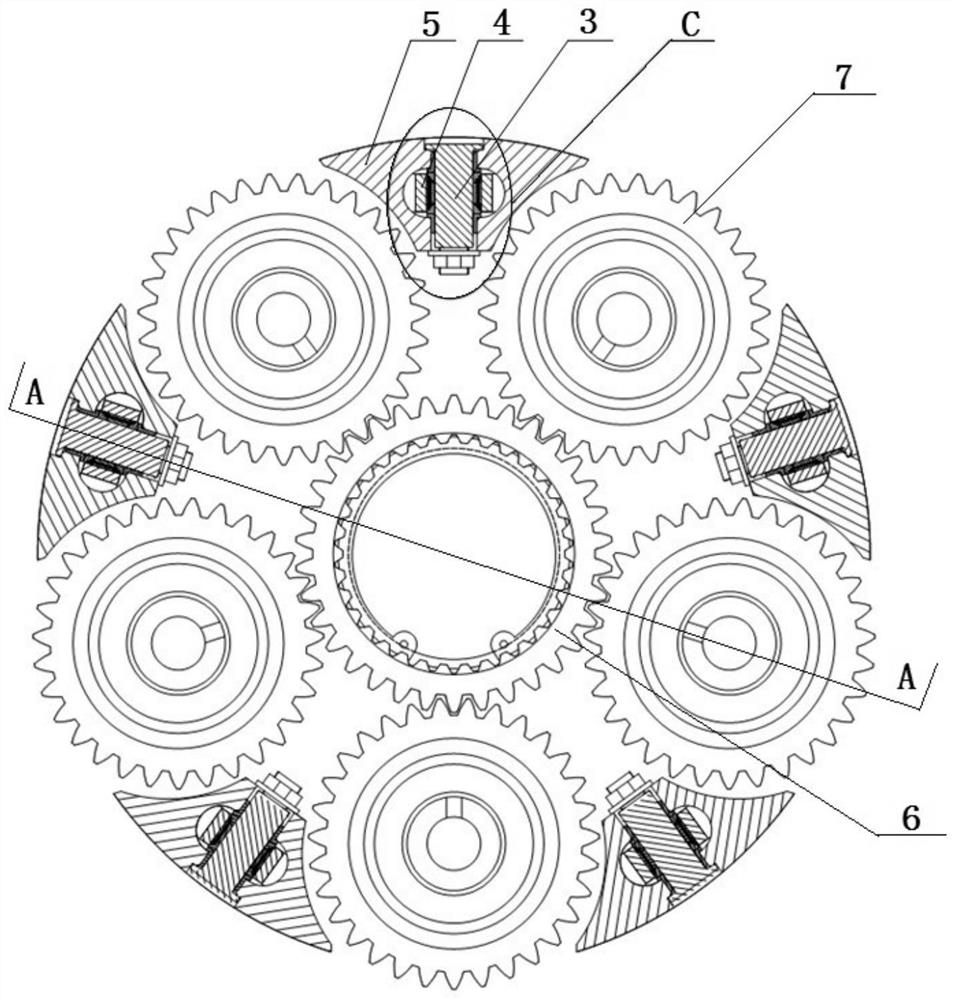

[0027] This embodiment discloses a planetary carrier structure with flexible floating and load balancing functions, including a flexible support 4 , connecting bolts 3 , a planetary carrier 5 , an inner ring gear 2 , a sun gear 6 and a planetary gear 7 .

[0028] The planet carrier 5 is a hollow cylindrical structure, and the inner ring gear 2 is sheathed on the outer surface of the planet carrier 5 . see Figure 4 , the inner ring gear 2 is cut along its cross section to form two parts, and when installed, the two parts are spliced by several bolts 201 to form the inner ring gear 2 .

[0029] see figure 1 Or 2, the inside of the planet carrier 5 is provided with a sun gear 6 and five evenly distributed planetary gears 7, and each planetary gear 7 meshes with the ring gear 2 and the sun gear 6 respectively. In this embodiment, the sun gear 6 is a herringbone gear. In practical applications, other types of gears are also suitable for the device of the present invention.

...

Embodiment 2

[0042] This embodiment discloses a planetary carrier structure with flexible floating and load balancing functions, including a flexible support 4 , connecting bolts 3 , a planetary carrier 5 , an inner ring gear 2 , a sun gear 6 and a planetary gear 7 .

[0043] The planet carrier 5 is a hollow cylindrical structure, and the inner ring gear 2 is sheathed on the outer surface of the planet carrier 5 .

[0044] see figure 1 Or 2, the inside of the planet carrier 5 is provided with a sun gear 6 and five evenly distributed planetary gears 7, and each planetary gear 7 meshes with the ring gear 2 and the sun gear 6 respectively. In this embodiment, the sun gear 6 is a spur gear. In practical applications, other types of gears are also suitable for the device of the present invention.

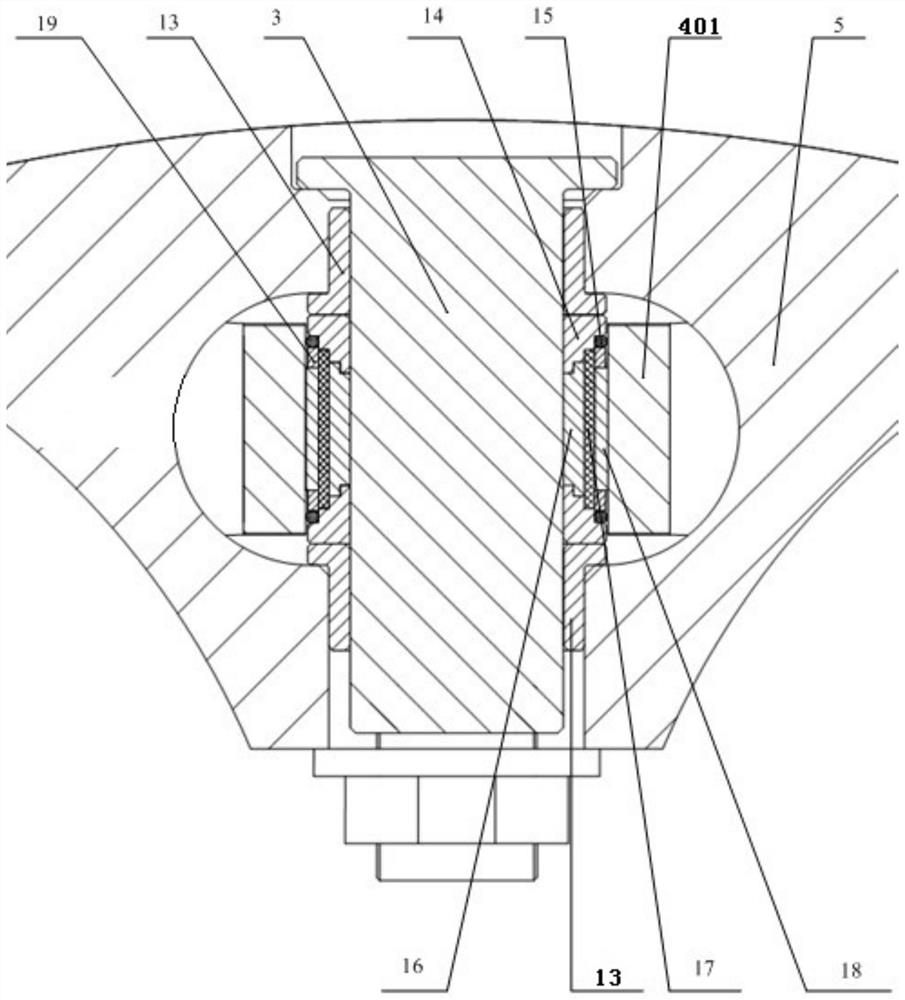

[0045] see Figure 4 Each of the planet wheels 7 is assembled on the planet carrier by a planet wheel shaft 9 and a sliding bearing 11, the sliding bearing 11 is sleeved on the planet wheel shaft 9...

Embodiment 3

[0056] The main structure of this embodiment is the same as that of Embodiment 2, further, refer to Figure 4 , the flexible bracket 4 includes a bracket bottom plate 402 and an annular thin wall 403, the bracket bottom plate 402 is provided with an annular thin wall 403 on the surface facing the planet carrier 5, and the ring edge of the annular thin wall 403 away from the bracket bottom plate 402 is connected with five Strut 401 . The support bottom plate 402 is fixed on the box body on the plate surface facing away from the planetary carrier 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com