Flexible framework with slewing bearing for railway vehicle bogie

A technology for slewing bearings and rail vehicles, applied in the field of bogies, which can solve problems such as limited line adaptability and curve passing ability, inability to realize free torsion of both side beams, and inability to realize free torsion, so as to solve the problems of running stability and curve passing performance, excellent running stability and curve passability, and enhanced ability to adapt to road irregularities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

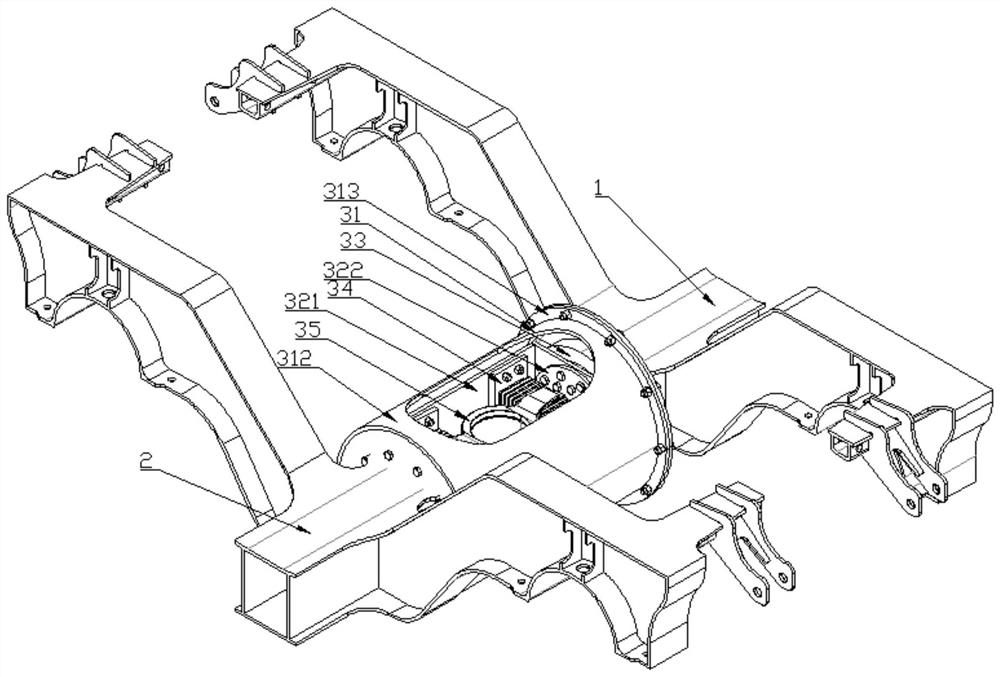

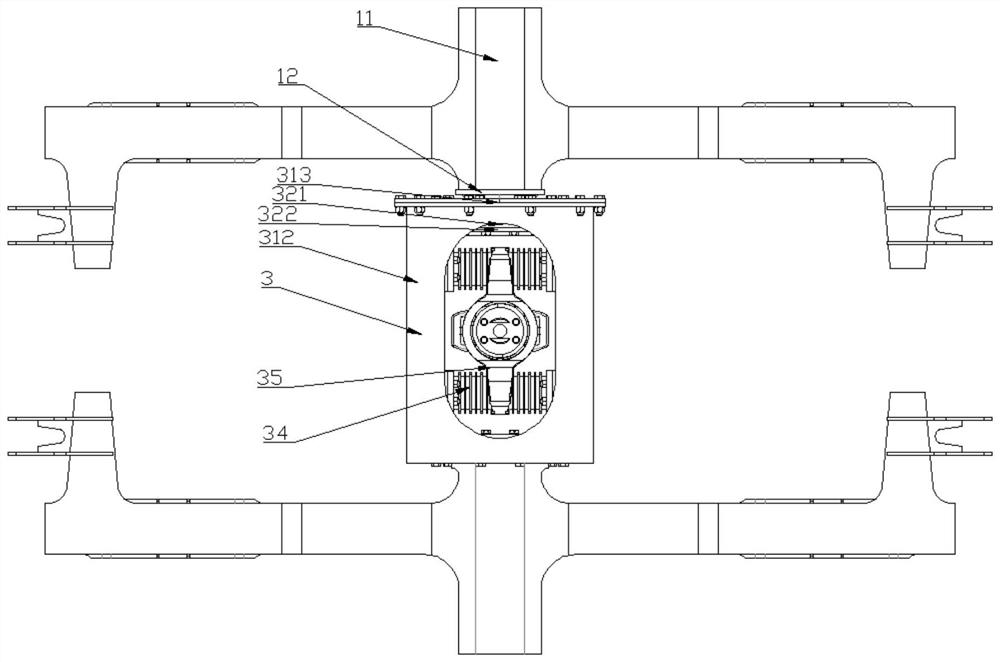

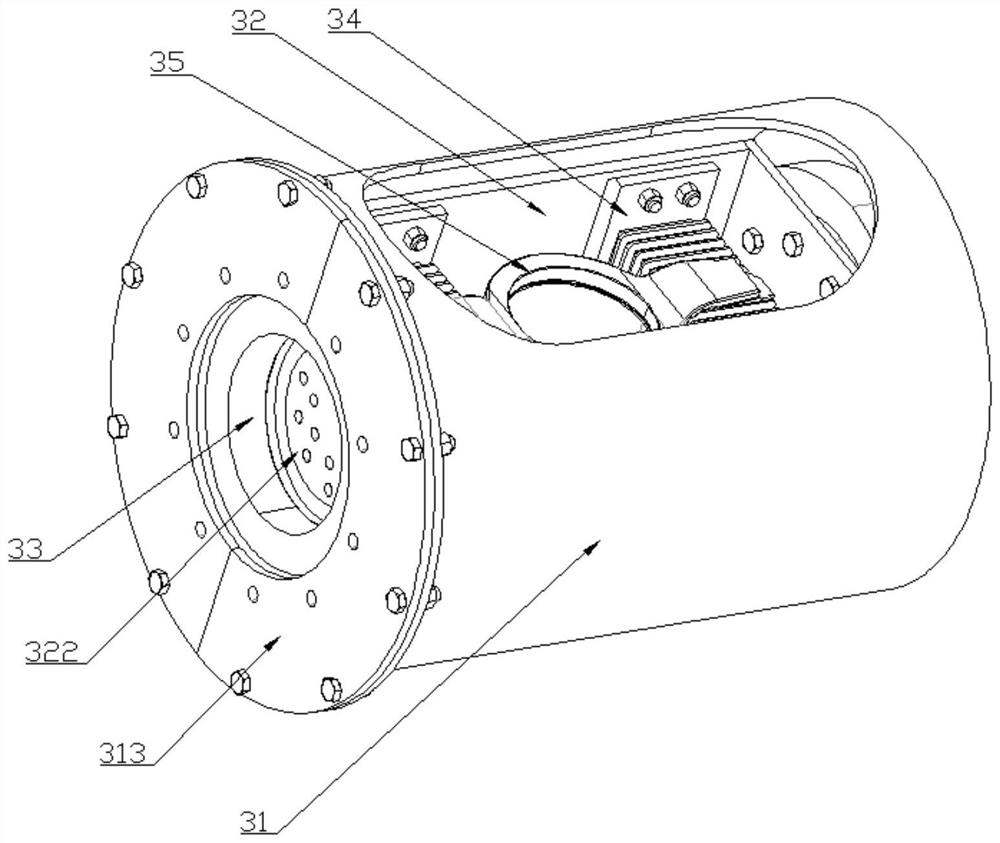

[0028] Such as Figure 1-8 As shown, the present invention provides a flexible frame for a railway vehicle bogie using a slewing bearing, comprising:

[0029] The flexible frame is an H-shaped frame, including two longitudinally arranged left beams 1, right side beams 2 and a set of horizontally arranged hinged beam devices 3, wherein: the two ends of the left side beam 1 and the right side beam 2 Connected to the wheel set through a series of suspension devices, a horizontally arranged hinged beam device 3 is connected between the left side beam 1 and the right side bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com