A medium-speed maglev traction frame system

A maglev, medium-speed technology, applied in electric traction, transportation and packaging, power management, etc., can solve the problems of performance can not meet the requirements, equipment installation size restrictions, lower voltage of traction linear motor terminals, etc., to meet the requirements of counterweight and installation. Size requirements, simple electrical wiring, and the effect of taking into account the particularity of the car body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to facilitate those skilled in the art to understand the technical content of the present invention, the content of the present invention will be further explained below in conjunction with the accompanying drawings.

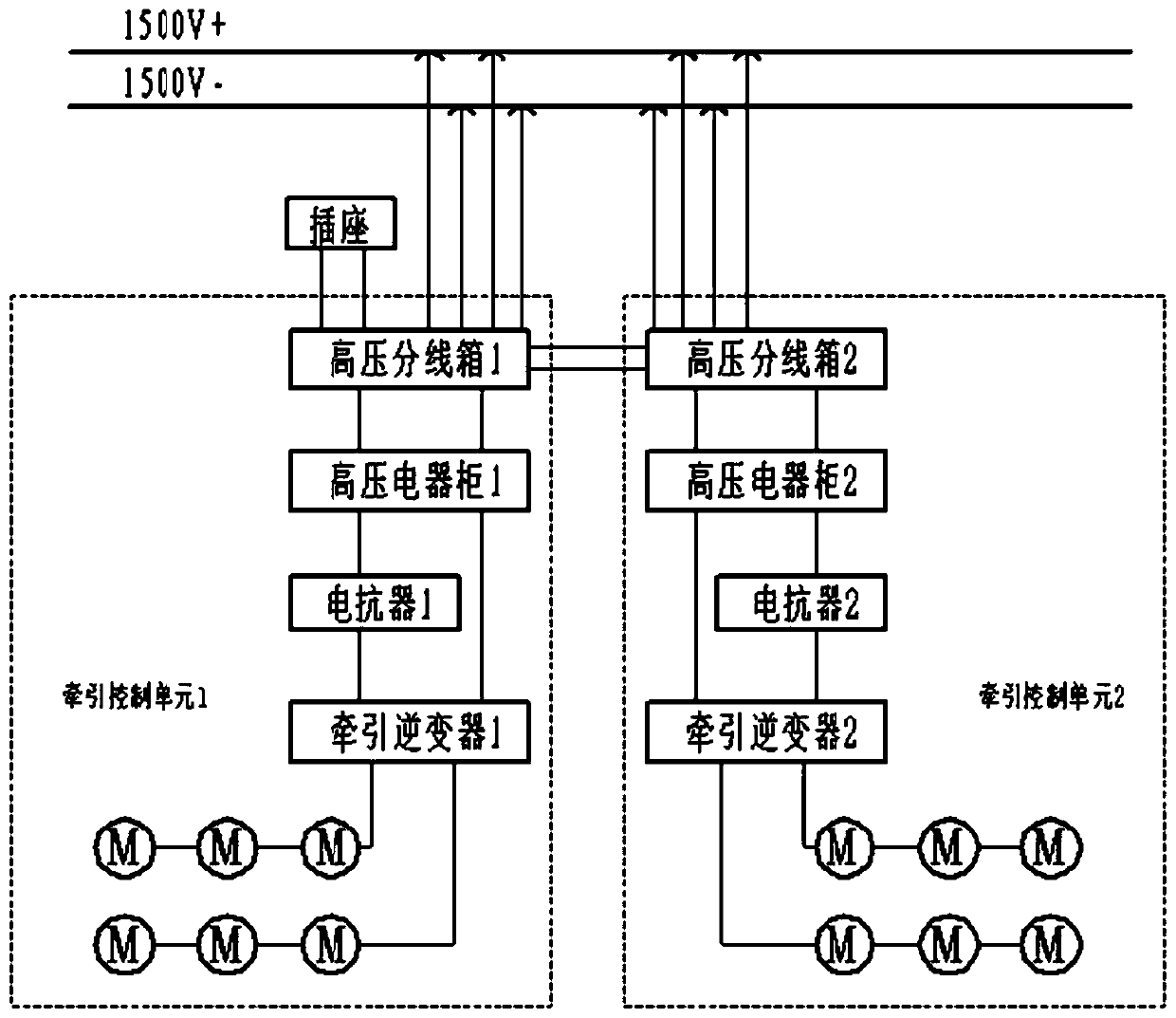

[0017] Such as figure 1 As shown, a medium-speed maglev traction frame system of the present invention is equipped with 6 suspension frames in a single carriage, and a linear motor is arranged on the left and right sides of each suspension frame. The 12 linear motors are divided into two parts by the middle of the carriage. , the 6 linear motors corresponding to the three suspension frames of each part are regarded as a linear motor unit, and are classified into a control unit, and the 6 linear motors in each control unit are wired in three series and two parallels; thus the single linear motor of the present invention A carriage consists of two control units

[0018] In the present invention, a single compartment is equipped with 6 suspension f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com