Neck type coupler

A coupler and coupler body technology, which is used in railway car body parts, railway couplings, transportation and packaging, etc., can solve the problem of high center of gravity height of empty vehicles and heavy vehicles, large wear of hook pin holes and hook tail pins, etc. Poor wear resistance and other problems, to achieve great economic and social benefits, reduce maintenance workload, and improve the effect of dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

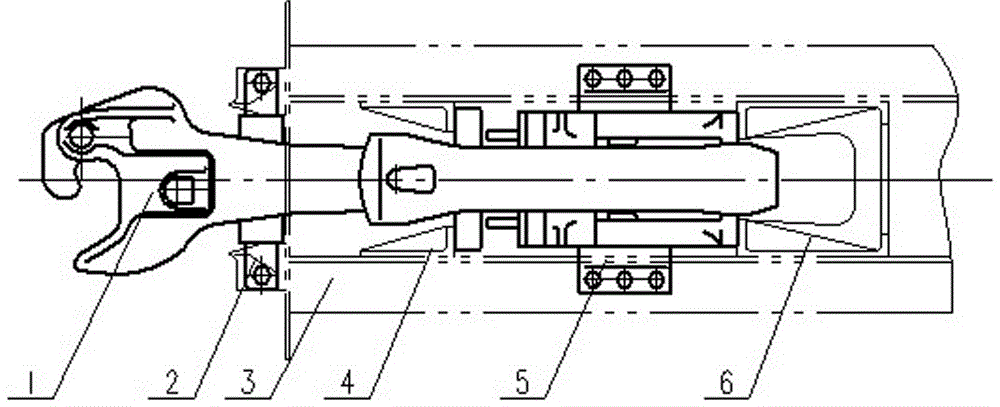

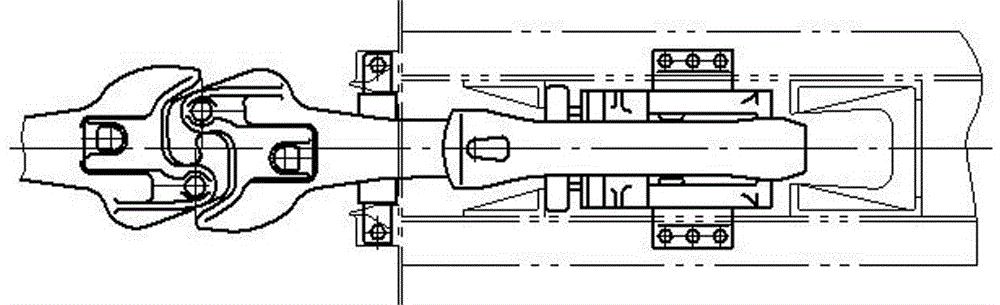

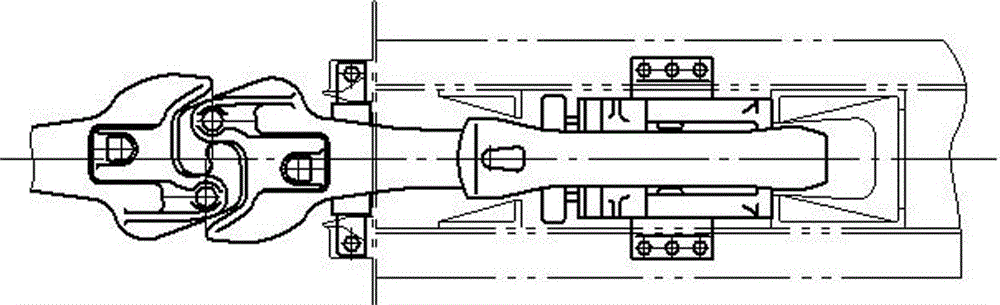

[0037] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0038] a. Raise the coupler head so that the horizontal centerline of the coupler head is higher than the horizontal centerline of the coupler body, and reduce the distance between the floor surface of the railway freight car or the container bearing surface and the rail surface on the basis of satisfying the coupling height (880mm for empty car) Height and center of gravity height of empty and heavy vehicles. At the same time, when the vehicle is subjected to a strong impact and the compression of the buffer is large, the hook body of the coupler is prevented from being stuck by the contact with the top of the impact seat of the coupler, so that the shoulder of the coupler is first in contact with the impact seat. The elevation angle of the raised part of the coupler body is set to 12~16°, preferably 16°, the distance from the starting point of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com