Discrete layout movable steam injection device and steam injection process thereof

A mobile, discrete technology, used in steam generation, steam boilers, steam boiler accessories, etc., can solve problems such as high equipment maintenance and depreciation costs, hindering the implementation of refined management, and inaccurate oil-gas ratio data. Network investment and post-maintenance loss, promotion of well condition grading management, and accurate oil-gas ratio data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0035] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

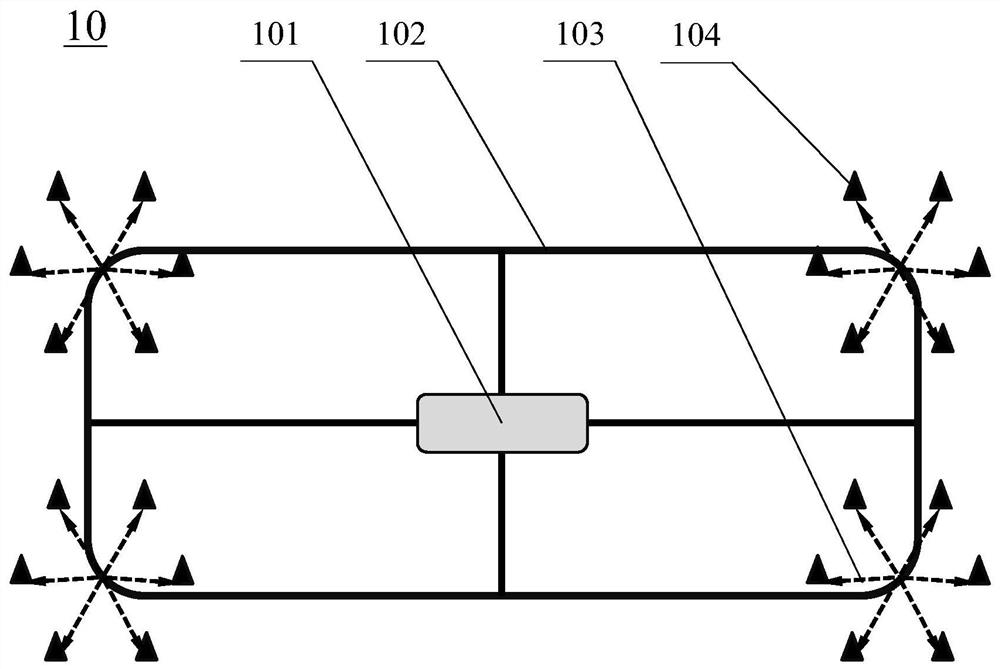

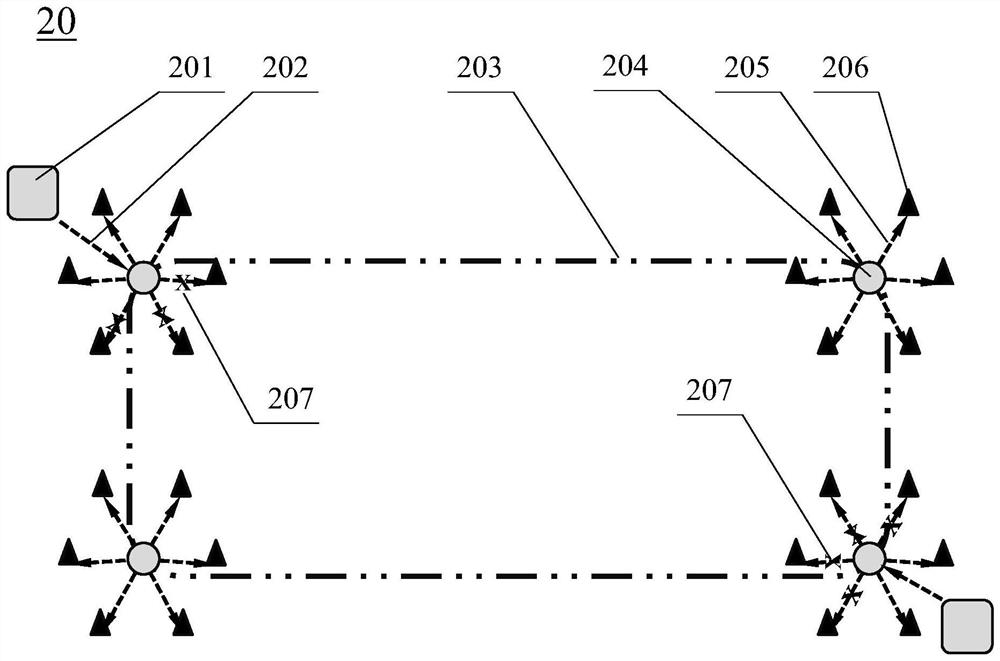

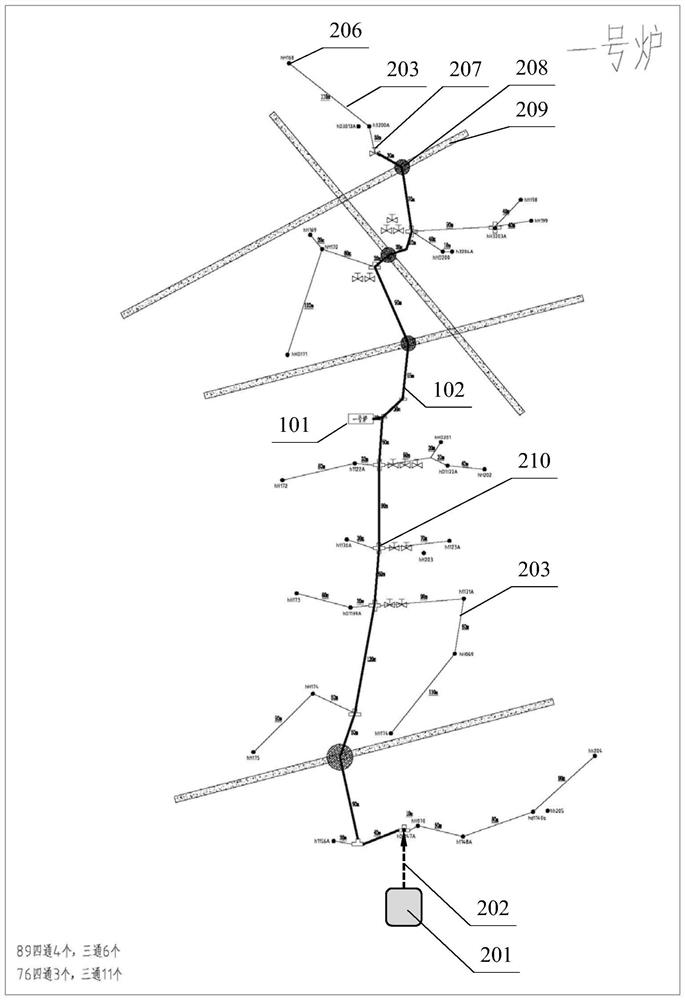

[0036] Such as Figure 2 to Figure 3As shown, a discrete layout movable steam injection device 20 according to a preferred embodiment of the present invention is used for steam injection of multiple oil production wellheads 206 distributed in each area of the oil field, and multiple oil production wellheads 206 pass through The Christmas tree and the downhole tubing are connected to the underground oil layer, and the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com