Quantitative mortar circulation system

A turnover system and mortar technology, applied in the direction of fine working devices, working accessories, stone processing equipment, etc., can solve the problems that affect the effective execution of the cutting process, product quality and cost impact, and it is difficult to accurately control the mortar, so as to save purchases cost, eliminate potential safety hazards, and save raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

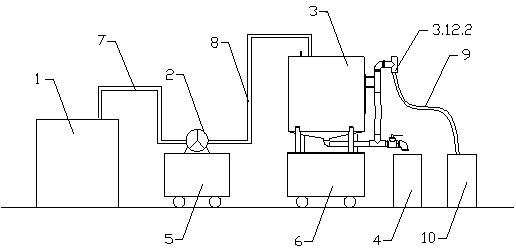

[0033] see Figure 1~Figure 5 , a kind of mortar quantitative turnover system that the present invention relates to, it comprises mortar mixing barrel 1, diaphragm pump 2, mortar turnover barrel 3 and mortar tank 4, and described diaphragm pump 2 is placed on a first moving trolley 5, and described mortar The turnover barrel 3 is placed on a second mobile trolley 6, the first pumping pipeline 7 is connected between the discharge port of the mortar mixing barrel 1 and the feed port of the diaphragm pump 2, and the discharge port of the diaphragm pump 2 is connected to the mortar turnover A second pumping pipeline 8 is connected between the feed ports of the barrels 3 , and the mortar tank 4 is located below the discharge port of the mortar turnover barrel 3 .

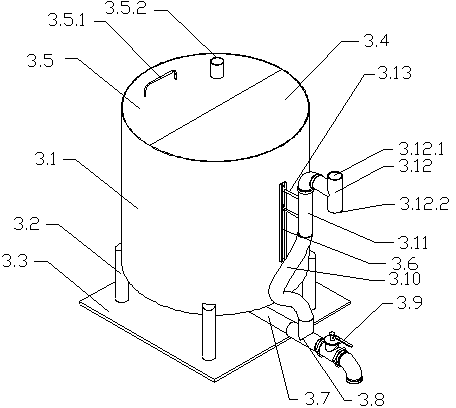

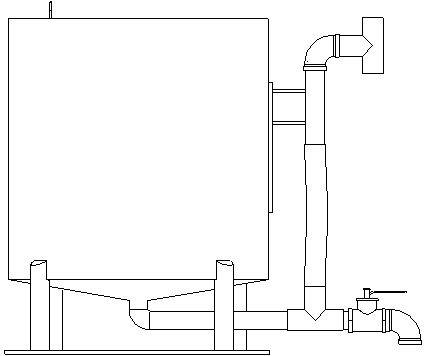

[0034] The mortar turnover barrel 3 includes a cylindrical barrel body 3.1, four support feet 3.2 are arranged on the bottom of the barrel body 3.1, and the four support feet 3.2 are fixed on a base plate 3.3, and the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com