Comprehensive soda ash producing process and product application thereof

A process and product technology, applied in the field of comprehensive soda production process and its product application, can solve the problems of low carbon dioxide purity, large environmental pollution, large energy consumption of synthetic ammonia plants, etc., and achieve the benefits of popularization and application, high quality, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

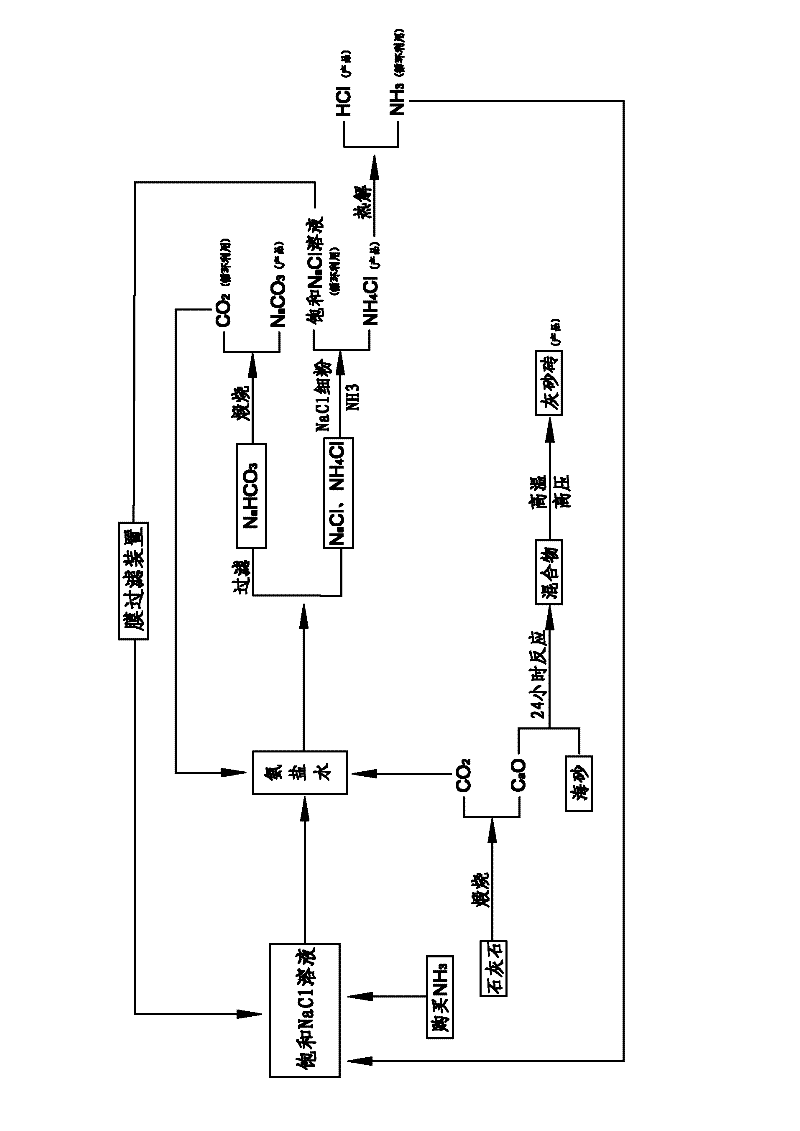

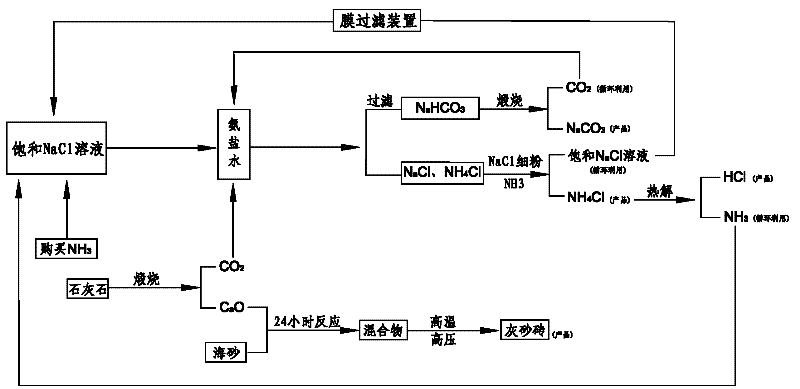

[0058] like figure 1 Shown, comprehensive soda making process of the present invention may further comprise the steps:

[0059] Step A, in the saturated sodium chloride (NaCl) solution, feed the purchased ammonia (NH 3 ) to produce ammonia brine;

[0060] Step B, calcined limestone (CaCO 3 ) to produce carbon dioxide (CO 2 ) and solid calcium oxide (CaO), will produce carbon dioxide (CO 2 ) into the above-mentioned ammonia brine to generate solid sodium bicarbonate (NaHCO 3 ), a mixture of sodium chloride (NaCl) solution and ammonium chloride (NH4Cl) solution;

[0061] Step C, the mixture in step B is filtered to obtain solid sodium bicarbonate (NaHCO 3 ), and ammonium chloride (NH 4 Cl) and sodium chloride (NaCl) mixed filtrate;

[0062] Step D, calcined solid sodium bicarbonate (NaHCO 3 ) to generate soda ash (Na 2 CO 3 ) products and carbon dioxide (CO 2 ), and then the generated carbon dioxide (CO 2 ) is recovered and introduced to ammonia brine for recycling;...

Embodiment 2

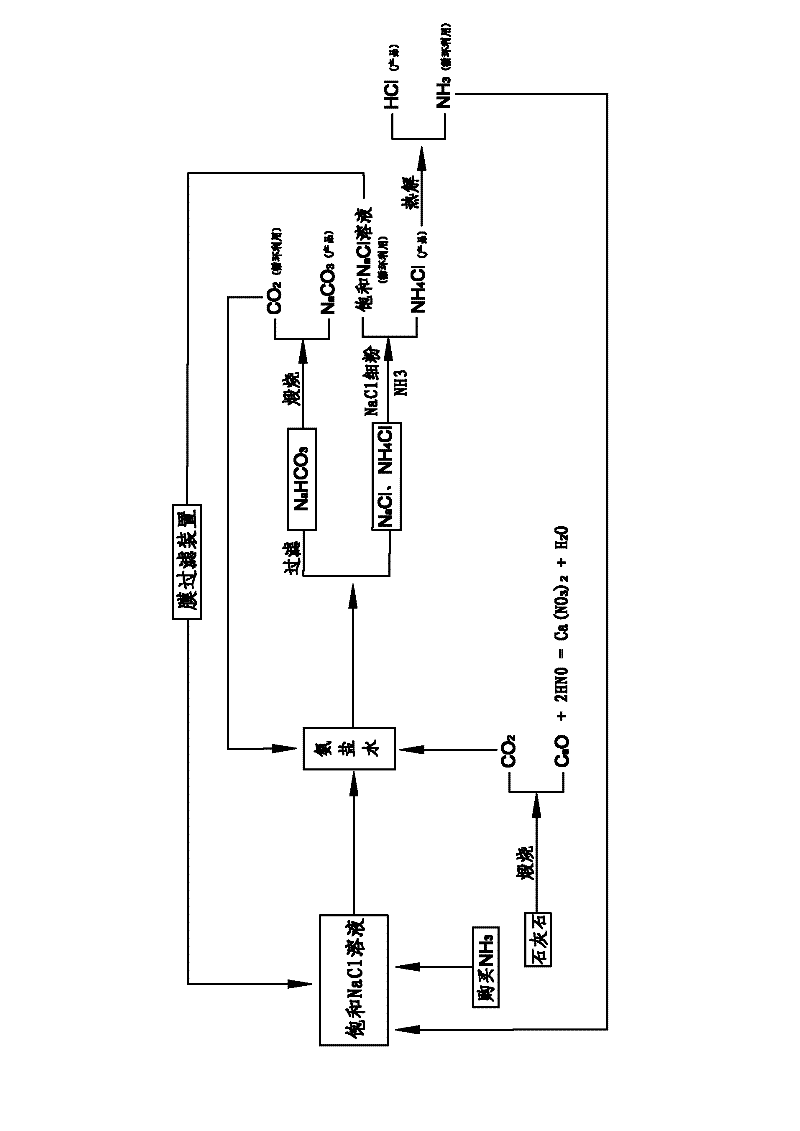

[0079] Such as figure 2 Shown, comprehensive soda making process of the present invention may further comprise the steps:

[0080] Step A, in the saturated sodium chloride (NaCl) solution, feed the purchased ammonia (NH 3 ) to produce ammonia brine;

[0081] Step B, calcined limestone (CaCO 3 ) to produce carbon dioxide (CO 2 ) and solid calcium oxide (CaO), will produce carbon dioxide (CO 2 ) into the above-mentioned ammonia brine to generate solid sodium bicarbonate (NaHCO 3 ), a mixture of sodium chloride (NaCl) solution and ammonium chloride (NH4Cl) solution;

[0082] Step C, the mixture in step B is filtered to obtain solid sodium bicarbonate (NaHCO 3 ), and ammonium chloride (NH 4 Cl) and sodium chloride (NaCl) mixed filtrate;

[0083] Step D, calcined solid sodium bicarbonate (NaHCO 3 ) to generate soda ash (Na 2 CO 3 ) products and carbon dioxide (CO 2 ), and then the generated carbon dioxide (CO 2 ) is recovered and introduced to ammonia brine for recycl...

Embodiment 3

[0095] Such as figure 1 Shown, comprehensive soda making process of the present invention may further comprise the steps:

[0096] Step A, in the saturated sodium chloride (NaCl) solution, feed the purchased ammonia (NH 3 ) to produce ammonia brine;

[0097] Step B, calcined limestone (CaCO 3 ) to produce carbon dioxide (CO 2 ) and solid calcium oxide (CaO), will produce carbon dioxide (CO 2 ) into the above-mentioned ammonia brine to generate solid sodium bicarbonate (NaHCO 3 ), a mixture of sodium chloride (NaCl) solution and ammonium chloride (NH4Cl) solution;

[0098] Step C, the mixture in step B is filtered to obtain solid sodium bicarbonate (NaHCO 3 ), and ammonium chloride (NH 4 Cl) and sodium chloride (NaCl) mixed filtrate;

[0099] Step D, calcined solid sodium bicarbonate (NaHCO 3 ) to generate soda ash (Na 2 CO 3 ) products and carbon dioxide (CO 2 ), and then the generated carbon dioxide (CO 2 ) is recovered and introduced to ammonia brine for recycli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com