Plasma case for thin film production in enormous quantities

A plasma box and plasma technology, applied in plasma, gaseous chemical plating, metal material coating process, etc., can solve problems such as complex design, and achieve the effects of reducing equipment costs, low production and maintenance costs, and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

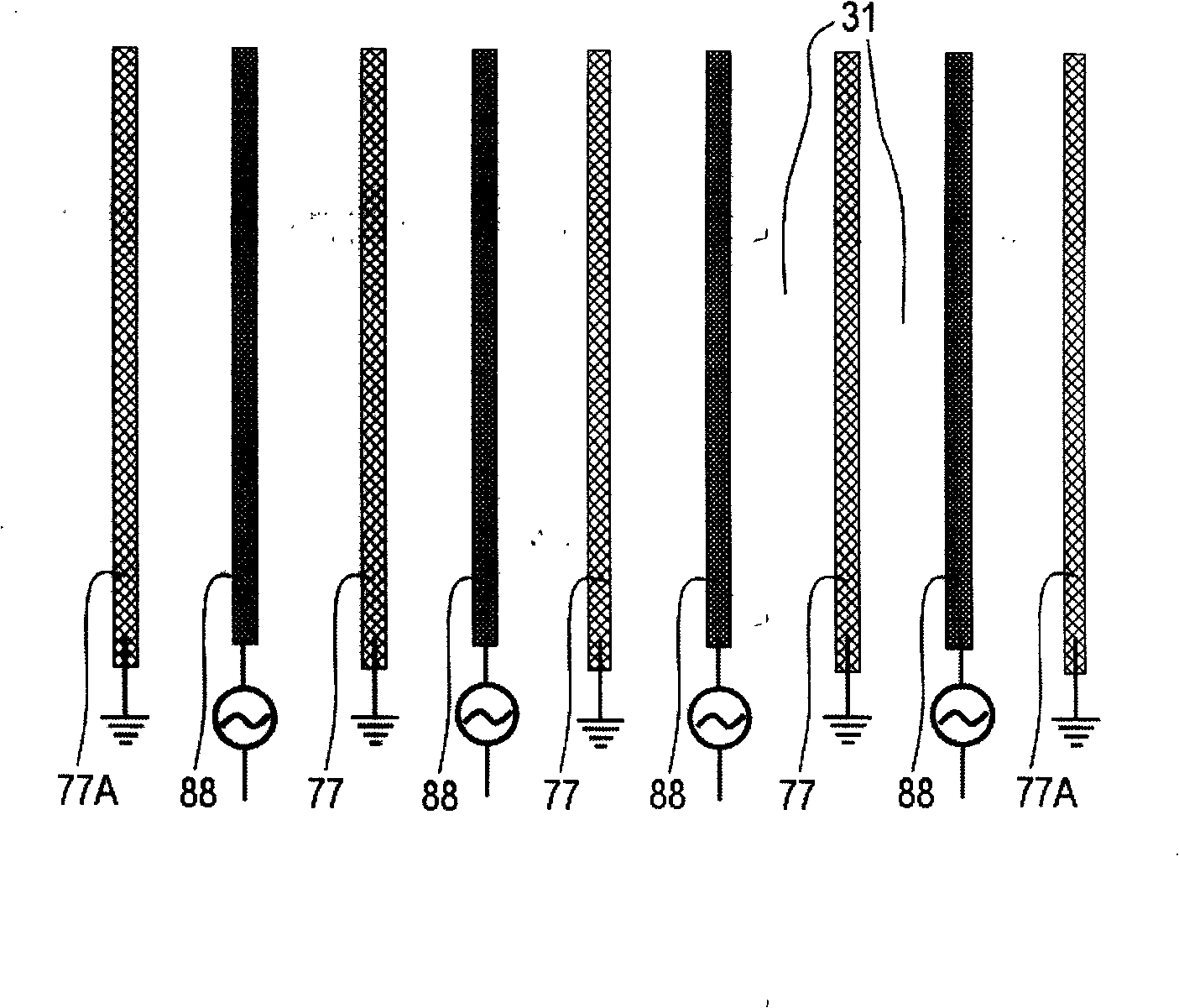

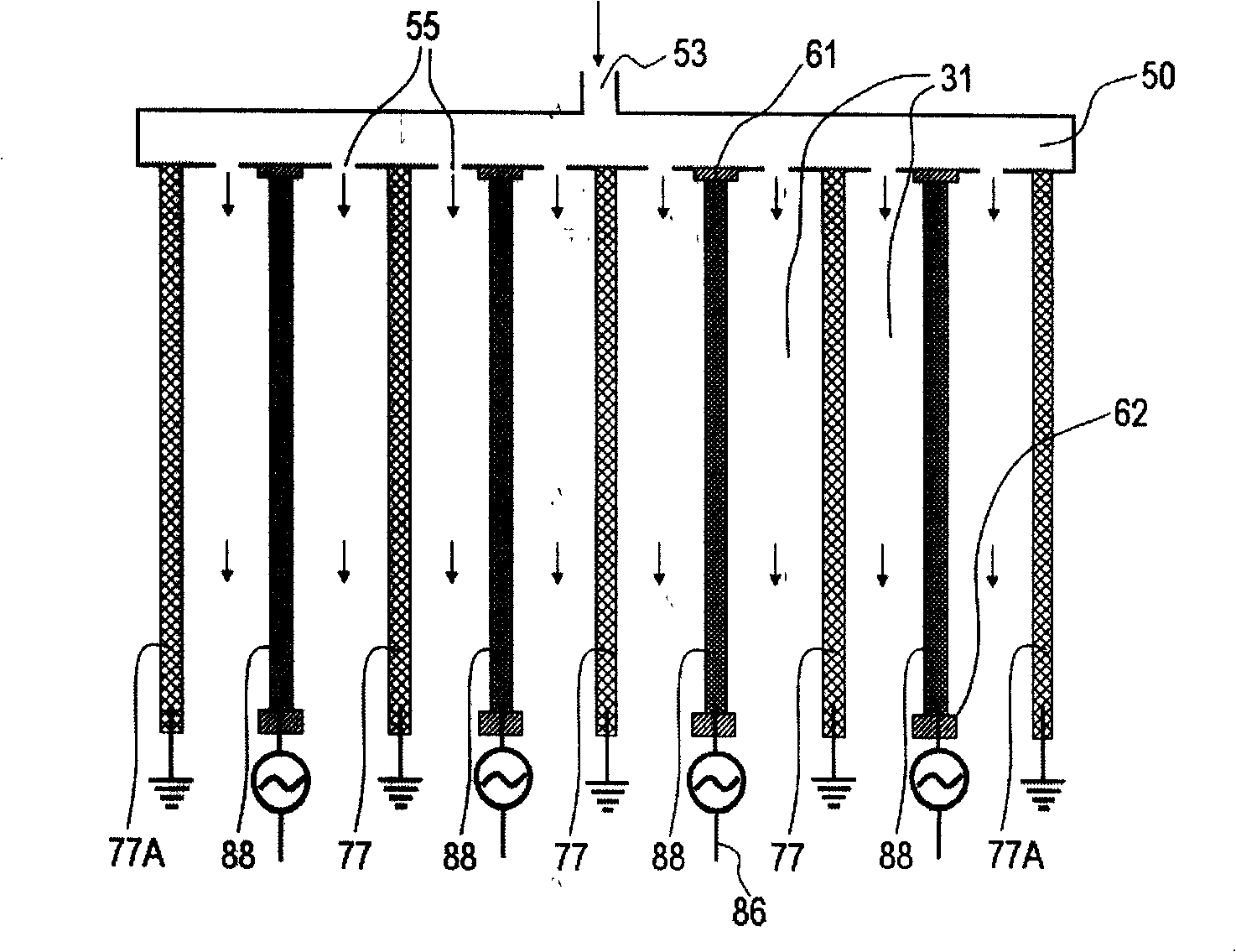

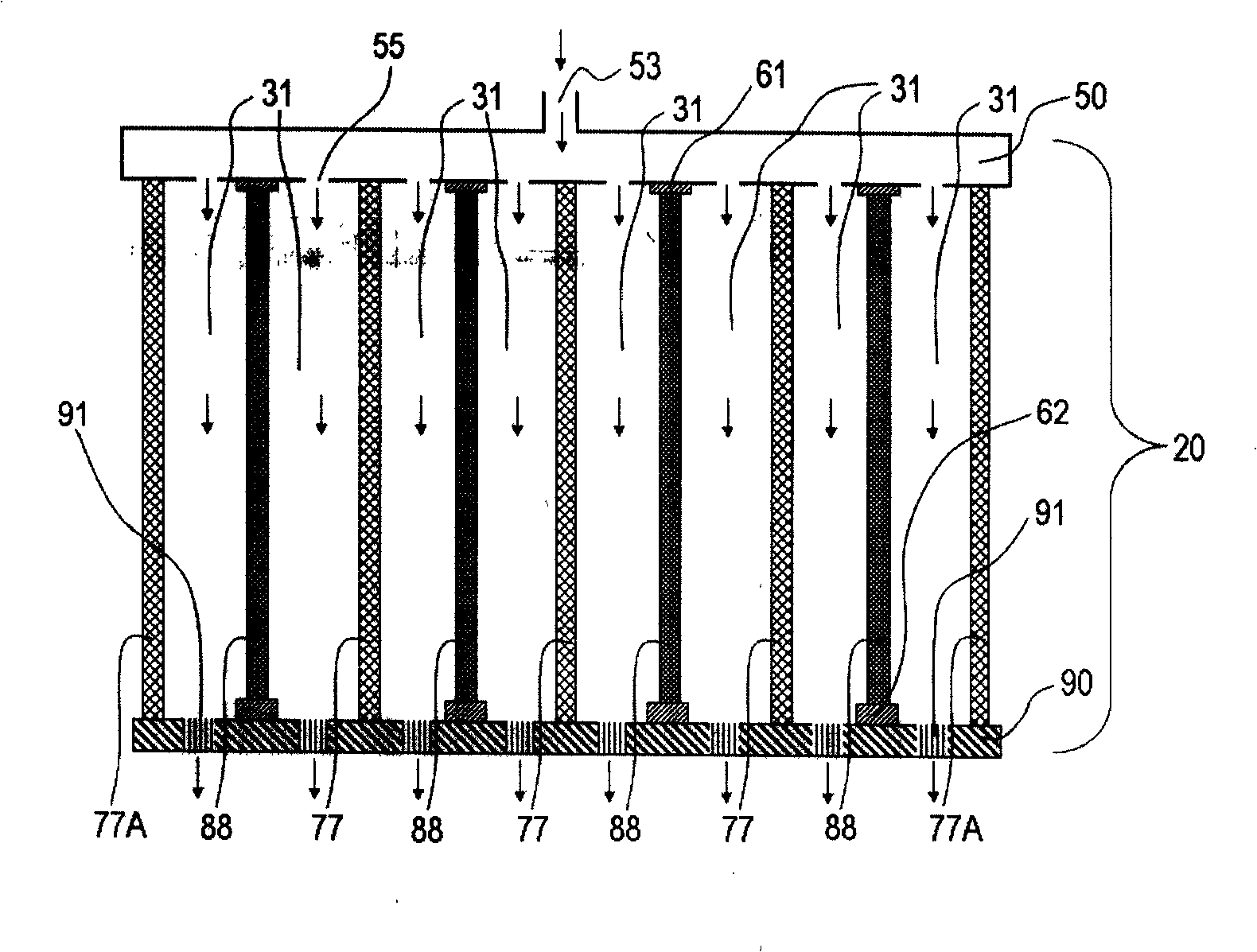

[0032] Figure 1 to Figure 7 The structure and operation of the plasma chamber 20 is shown.

[0033] Such as figure 1 As shown, a plurality of flat rectangular metal plates 77, 77A and 88 are placed in parallel with the same spacing distance. These metal plates are preferably perpendicular to the ground to facilitate flexible loading and unloading of the substrates and to reduce particulates falling on the substrates. The distance value between electrodes is in the range of 0.6-5 cm. Each electrode plate has two flat surfaces parallel to each other. That is, all electrodes 77, 77A and 88 have a uniform plate thickness. The ground electrode plates 77 all have the same size of not less than 0.6 square meters (6000 square centimeters). The outermost two ground electrodes 77A are used to form image 3 The two side walls of the plasma box 20 are shown. All the excitation electrodes 88 have the same size, which can be similar to the size of the ground electrode 77, but prefe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com