A heterogeneous continuous acid hydrolysis device and process for producing glyphosate by glycine method

A technology of glyphosate and glycine, applied in chemical instruments and methods, compounds of group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problem of increased material consumption and energy consumption in the production process, increased waste water volume, and dissolution loss Increase and other issues, to achieve the effect of improving market competitiveness, reducing production costs, and reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

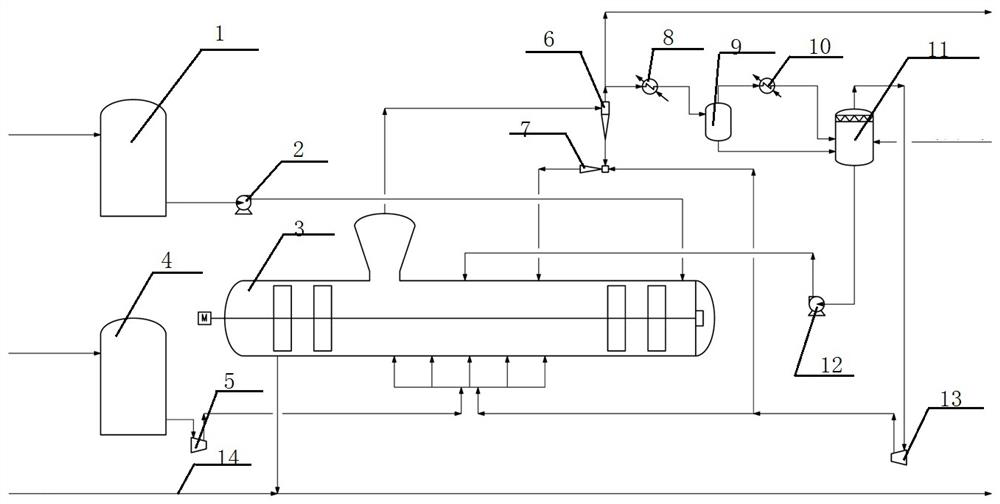

[0056] A heterogeneous continuous acidolysis device for producing glyphosate by the glycine method, the synthetic liquid buffer tank 1 is connected to the acid hydrolysis reactor 3 through the synthetic liquid feed pump 2, the hydrogen chloride gas tank 4 is connected to the acid hydrolysis reactor through the hydrogen chloride intake compressor 5 Solution reactor 3 is connected;

[0057] Acidolysis reactor 3 is connected with circulation cyclone wind separator 6, and circulation cyclone wind separator 6 is connected with primary circulation condenser 8, and primary circulation condenser 8 is connected with primary circulation tank 9, and primary circulation tank 9 is connected with secondary circulation tank 9. The primary circulating condenser 10 is connected, the secondary circulating condenser 10 is connected with the secondary circulating tank 11, and the secondary circulating tank 11 is connected with the acidolysis reactor 3 through the circulating gas cabinet compressor...

Embodiment 2

[0064]The heterogeneous continuous acidolysis process is adopted in the acidolysis process of the glyphosate powder production plant with a production capacity of 5,000 tons per year. The diameter of the acidolysis reactor is 1 meter, the length of the horizontal straight section is 10 meters, and the vertical settling section The cone angle is 26°, the diameter of the lower circular platform is 0.6 meters, and the height of the vertical settlement section is 2.5 meters. Fill the acidolysis reactor with 9.5 tons of glyphosate powder (purity not less than 95%, average particle size 50 microns). The stirring of the reactor was started, and the stirring speed was controlled at 25 rpm.

[0065] Turn on the circulating gas compressor, a part of the gas phase mixture coming out of the acidolysis reactor is returned to the acidolysis reactor through the cyclone separation of the solid phase, the gas phase is condensed in two stages and the liquid phase enters the secondary circulatio...

Embodiment 3

[0070] The heterogeneous continuous acidolysis process is adopted in the acidolysis process of the glyphosate powder production plant with a production capacity of 10,000 tons per year. The acidolysis reactor has a diameter of 1.2 meters and a horizontal straight edge length of 12 meters. Vertical sedimentation The cone angle of the section is 24°, the diameter of the lower circular platform is 0.75 meters, and the height of the vertical settlement section is 2.8 meters. Fill the acidolysis reactor with 16.5 tons of glyphosate powder (purity not less than 95%, average particle size 100 microns). The stirring of the reactor was started, and the stirring speed was controlled at 22rpm.

[0071] Turn on the circulating gas compressor, a part of the gas phase mixture coming out of the acidolysis reactor is returned to the acidolysis reactor through the cyclone separation of the solid phase, the gas phase is condensed in two stages and the liquid phase enters the secondary circulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com