Barrel-shaped metal organic chemical vapor deposition reaction tube

A metal organic chemistry and vapor deposition technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of increased equipment maintenance cost, difficult processing, low pass rate of nozzles, etc., to save equipment The effect of depreciation cost, reduction of raw material consumption, and reduction of product cost

Active Publication Date: 2011-06-15

南昌硅基半导体科技有限公司

View PDF5 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

These three kinds of MOVCD mainframes have the following disadvantages: 1. Since the heating source is in the form of a plane, the boundary of the thermal field is complicated. Although the furnace filaments of the electric furnace are controlled in different areas, it is difficult to obtain good temperature uniformity on the graphite surface (requiring plus or minus one degree ), which directly affects the qualified rate of the product; 2. Due to the turbulent flow between the nozzle and the graphite, ash will fall on the nozzle, which will also seriously affect the qualified rate of the product, and after each growth, it is necessary to It takes a long time to clean the nozzle, which seriously affects the production efficiency

3. The most deadly thing is that it is very difficult to enlarge the reaction tube, and it is even impossible to enlarge it. Naturally, it is impossible to increase the output and reduce the unit cost.

4. In terms of energy consumption of MOVCD equipment, because these three types of electric furnaces use single-sided radiation, half of the energy of the electric furnace is wasted, resulting in the power of the current electric furnace being as high as 70KW, which is too high. Affect the life of the electric furnace and increase the maintenance cost of the equipment

From the perspective of the equipment itself, since the nozzle is in the form of a plane and circular shape, it needs water cooling and two types of air holes. When the diameter is larger, it is already difficult to process, and the qualified rate of the nozzle is also low.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

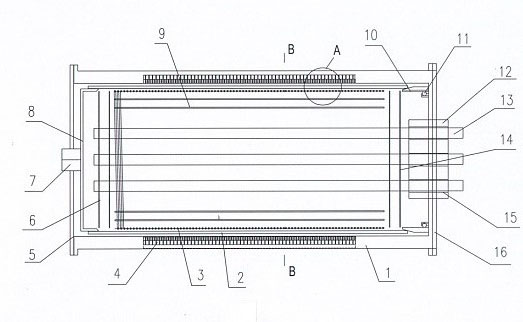

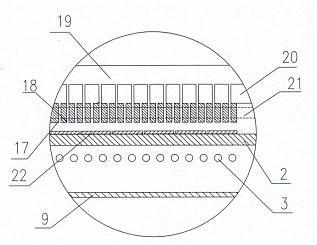

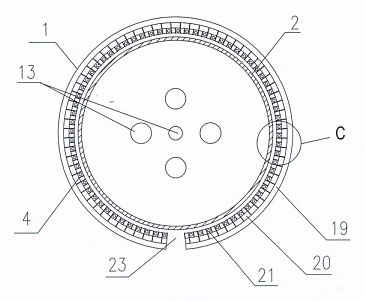

The invention discloses a barrel-shaped metal organic chemical vapor deposition reaction tube which comprises a barrel body. The barrel type metal organic chemical vapor deposition reaction tube is characterized in that the barrel body is in a barrel shape with an open left end and an open right end, and a graphite barrel, an electric stove wire barrel and a molybdenum sheet heat insulation barrel are sequentially sleeved in the barrel body. The left end and the right end of the electric stove wire barrel are respectively provided with a left heat insulation molybdenum sheet and a right heat insulation molybdenum sheet which are sleeved on an electrode stem. A multiple-layer spray tube is arranged in the barrel body and is composed of a liquid cooling tube, an ammonia spray tube and a metal organic source spray tube. An ammonia nozzle connected with the ammonia spray tube and a metal organic source nozzle connected with the metal organic source spray tube are arranged on the inner wall of the barrel body, and an exhaust port is arranged on the inner wall of the barrel body. The barrel type metal organic chemical vapor deposition reaction tube has the advantages that the throughput can be raised on a large scale, the product cost can be reduced, the production efficiency can be increased, the surface temperature uniformity of graphite is good, the product percent of pass is high, and the energy consumption is low. The productivity is 20 times as high as that of three kinds of popular MOVCD great machines at present.

Description

Barrel Type Metal Organic Chemical Vapor Deposition Reaction Tube technical field The invention relates to semiconductor material manufacturing equipment, in particular to a drum type metal organic chemical vapor deposition reaction tube. Background technique: At present, a large-scale energy-saving and emission-reduction campaign is emerging all over the world. Semiconductor lighting (ie, light-emitting diodes, LEDs) is one of the effective measures. However, to enter thousands of households in China, the cost must be greatly reduced. Through the efforts of the industry, other costs that can be reduced are also reduced. The depreciation of the equipment used in production and the low utilization rate of raw materials have become one of the main costs. At present, there are only three manufacturers of metal-organic chemical vapor deposition (MOCVD) equipment: AIXTRON in Germany, VEECO in the United States and Thomasswan Company in the United Kingdom (TS for short). At pre...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23C16/455C23C16/44

Inventor 方文卿江风益

Owner 南昌硅基半导体科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com