A method of manufacturing a silent chain chain plate

A manufacturing method and technology of silent chain, applied in the direction of manufacturing tools, metal chains, metal processing equipment, etc., can solve the problems of reducing the service life of molds, investing a lot, increasing the production cost of silent chains, etc., so as to avoid waste of raw materials and reduce depreciation costs. , the effect of shortening the maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

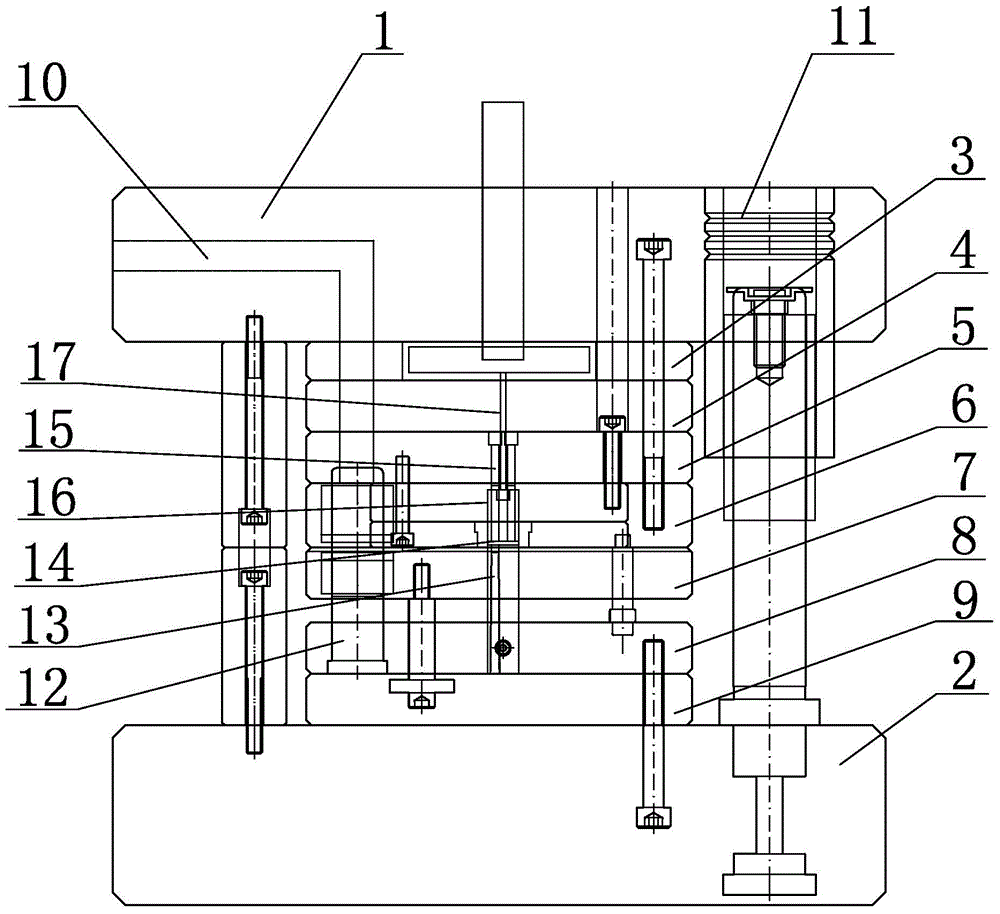

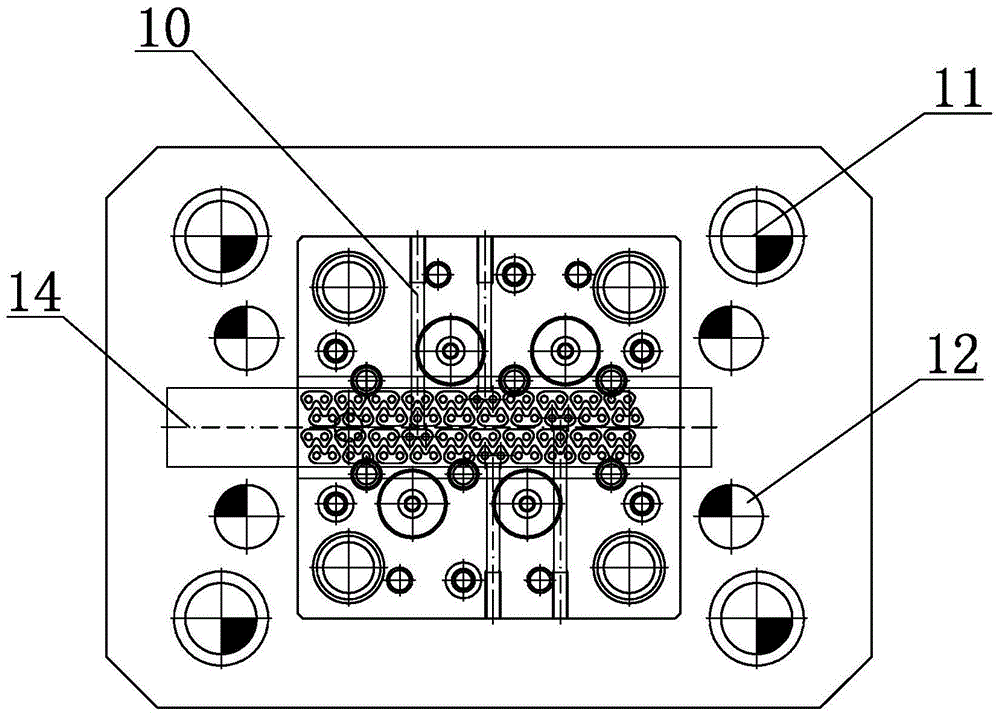

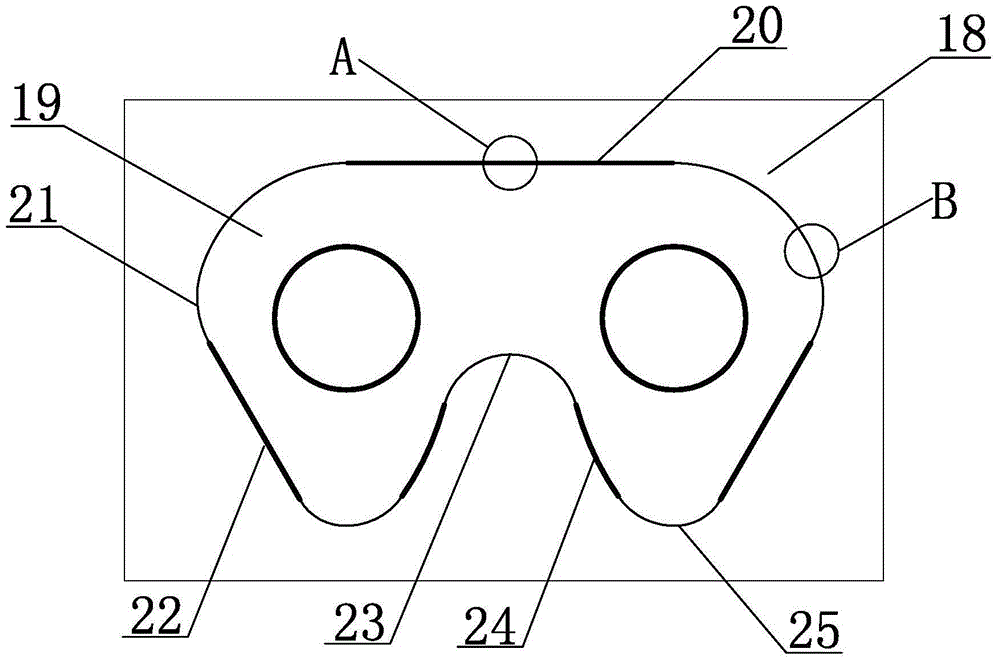

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 A method for manufacturing a high-efficiency and long-life silent chain chain plate shown includes the following steps:

[0024] a) Put the steel plate 14 to be processed in the middle of the mold of the horizontal punching machine. The mold adopts a silent chain multiple blanking and bright blanking composite mold. The mold includes a front mold base 1, a rear mold base 2, a front lining plate 3, a front Backing plate 4, front splint 5, mother template 6, outer stripping plate 7, rear splint 8 and rear backing plate 9, the front mold base 1 and the rear mold base 2 are connected by rolling guide pillars 11, and the front lining The plate 3, the front backing plate 4, the front splint 5 and the mother template 6 are fixed on the rear end surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com